lock OPEL ANTARA 2017.5 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: ANTARA, Model: OPEL ANTARA 2017.5Pages: 225, PDF Size: 6.2 MB

Page 136 of 225

134Driving and operatingFilling station9Danger

Follow the operating and safety

instructions of the filling station

when refilling AdBlue.

1. Switch off engine and remove key

from ignition switch.

2. Disengage the cover using a suitable screwdriver and remove.

3. Unscrew protective capanticlockwise from the filler neck.

4. Fully insert the pump nozzle intothe filler neck and switch it on.

5. When refilling is complete, mount the protective cap and turn

clockwise until it engages.

6. Replace the cover by inserting the

right side first.

AdBlue canister Note

Only use the designated AdBlue

canisters for refilling, to prevent a

topping-up of too much AdBlue.

Additionally, the fumes in the tank

are captured in the canister and do

not emerge.

Note

Since AdBlue has a limited

durability, check the date of expiry

before refilling.

1. Switch off engine and remove key

from ignition switch.

2. Disengage the cover using a suitable screwdriver and remove.

3. Unscrew protective cap anticlockwise from the filler neck.

Page 137 of 225

Driving and operating135

4. Attach the adapter (located inglovebox) to the filler neck.

5. Open AdBlue canister.

6. Mount one end of the hose on the

canister and screw the other end

on the filler neck adapter.

7. Lift the canister until it is empty. 8. Unscrew the hose from the filler neck adapter.

9. Remove the adapter and return to

its container in the glovebox.

10. Mount the protective cap and turn

clockwise until it engages.

11. Replace the cover.

Note

Dispose of AdBlue canister and

hose according to environmental requirements.

Note

If an AdBlue refill is not detected,

drive continuously for 10 minutes,

keeping vehicle speed above

20 km/h.

If the AdBlue refill is detected

successfully, AdBlue level warnings

will disappear.

If the AdBlue refill is not detected

some time after running the engine,

seek the assistance of a workshop.

Note

If less than 10 litres of AdBlue have

been refilled during the last 2 years,

the remaining fluid should be

exchanged since AdBlue has a

limited durability. Seek the

assistance of a workshop.

Disregard could lead to damage to

the selective catalytic reduction

system.

Filler cap

Only use genuine filler caps. AdBlue

tank has a special filler cap.Fault

If the system detects an operating

fault, control indicator Y illuminates

together with a warning chime. Seek

the assistance of a workshop

immediately.

A corresponding message may

appear in the Driver Information

Centre 3 91.

Page 138 of 225

136Driving and operatingAutomatic transmission

The automatic transmission permits

automatic gearshifting (automatic

mode) or manual gearshifting

(manual mode).

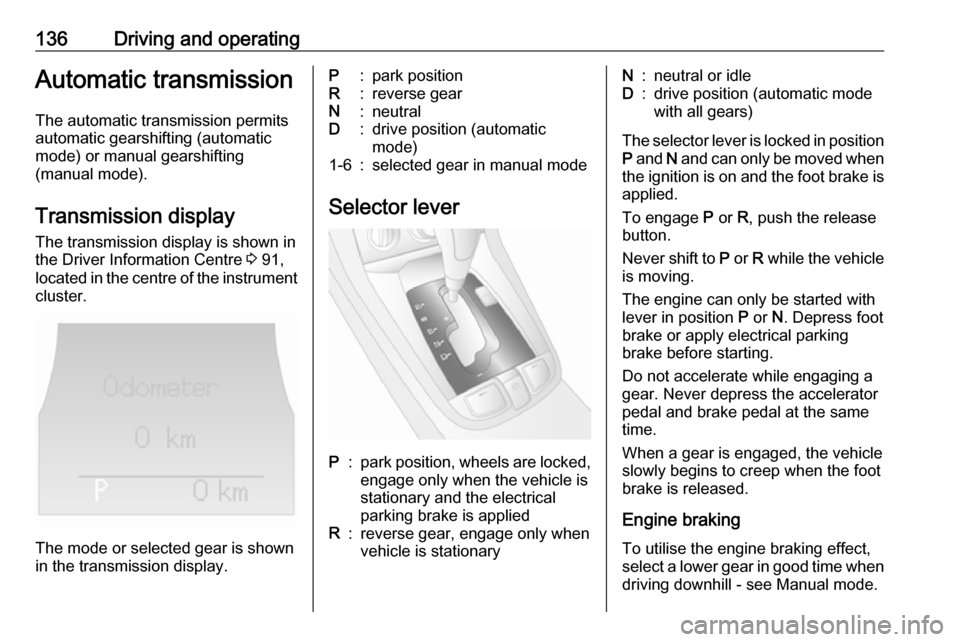

Transmission display

The transmission display is shown in

the Driver Information Centre 3 91,

located in the centre of the instrument

cluster.

The mode or selected gear is shown

in the transmission display.

P:park positionR:reverse gearN:neutralD:drive position (automatic

mode)1-6:selected gear in manual mode

Selector lever

P:park position, wheels are locked, engage only when the vehicle is

stationary and the electrical

parking brake is appliedR:reverse gear, engage only when

vehicle is stationaryN:neutral or idleD:drive position (automatic mode

with all gears)

The selector lever is locked in position

P and N and can only be moved when

the ignition is on and the foot brake is applied.

To engage P or R, push the release

button.

Never shift to P or R while the vehicle

is moving.

The engine can only be started with

lever in position P or N. Depress foot

brake or apply electrical parking

brake before starting.

Do not accelerate while engaging a

gear. Never depress the accelerator

pedal and brake pedal at the same

time.

When a gear is engaged, the vehicle

slowly begins to creep when the foot

brake is released.

Engine braking To utilise the engine braking effect,

select a lower gear in good time when

driving downhill - see Manual mode.

Page 141 of 225

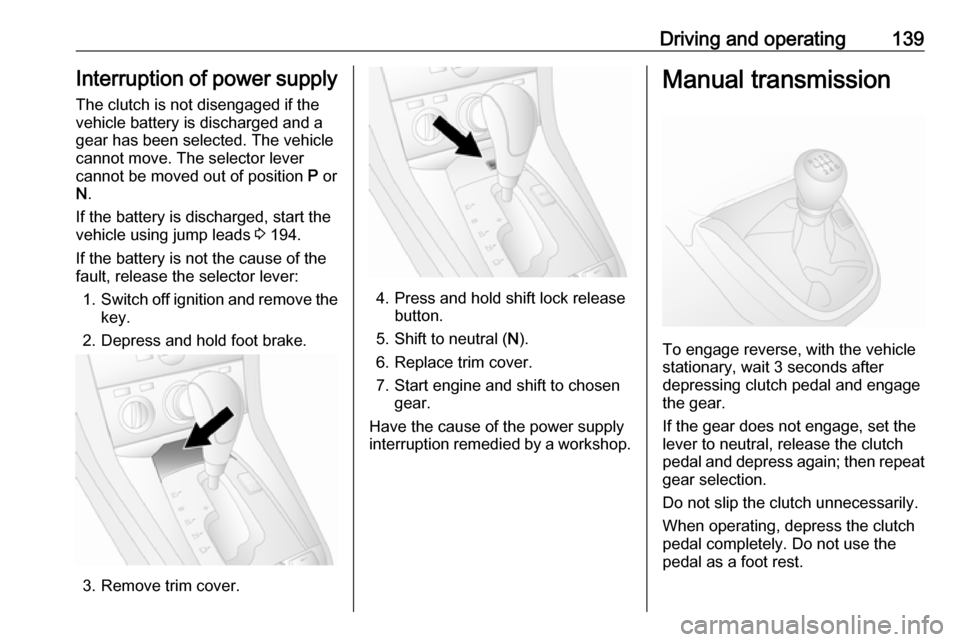

Driving and operating139Interruption of power supplyThe clutch is not disengaged if the

vehicle battery is discharged and a

gear has been selected. The vehicle

cannot move. The selector lever

cannot be moved out of position P or

N .

If the battery is discharged, start the

vehicle using jump leads 3 194.

If the battery is not the cause of the

fault, release the selector lever:

1. Switch off ignition and remove the

key.

2. Depress and hold foot brake.

3. Remove trim cover.

4. Press and hold shift lock release button.

5. Shift to neutral ( N).

6. Replace trim cover.

7. Start engine and shift to chosen gear.

Have the cause of the power supply

interruption remedied by a workshop.

Manual transmission

To engage reverse, with the vehicle

stationary, wait 3 seconds after

depressing clutch pedal and engage

the gear.

If the gear does not engage, set the

lever to neutral, release the clutch

pedal and depress again; then repeat

gear selection.

Do not slip the clutch unnecessarily.

When operating, depress the clutch

pedal completely. Do not use the

pedal as a foot rest.

Page 144 of 225

142Driving and operatingEnsure the radiator core and the areabetween the radiator and intercooler/

oil cooler (where installed) is cleaned, to maintain proper cooling air flow.Check the radiator and cooler cores

for blockage (sand, silt etc.).

Check the tyre treads.

Clean and check the mechanical

parts of the vehicle, particularly the

following areas:

● Driveshafts, including sealing bellows

● Front brake calipers, pads and discs

● Front suspension

● Clutch fork sealing bellows

● Rear brake calipers, pads and discs

● Rear suspension

● Fuel tank and underguard

● Breathers, axles and fuel tank

● Load sensing valve

● Transfer box and underguard

● Engine oil pan and underguardObserve the following: ● Do not spray high-pressure water

directly at the vehicle seals

● The wheels must be removed to clean all mud and stones from the

brake calipers and to check

brake pad wear

● The areas on the upper side of the underguards must be clearedof stones, to prevent damage to

the engine oil pan and the fuel

tankBrakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek

the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 85.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.

Page 145 of 225

Driving and operating143ABS starts to regulate brake pressure

as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off, the system performs a self-test which may be audible.

Control indicator u 3 85.

Fault9 Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS

are no longer available. During

hard braking, the vehicle can nolonger be steered and may

swerve.

You can continue driving, provided

you drive with care and anticipation.

Have the cause of the fault remedied

by a workshop.

Parking brake

Electrical parking brake

Applying when vehicle is stationary

Pull switch m, the electrical parking

brake operates automatically with

adequate force. For maximum force,

e.g. parking with a trailer or on

inclines, pull switch m twice.

The electrical parking brake can

always be activated, even if the

ignition is off.

Do not operate electrical parking

brake system too often without

engine running as this will discharge

the battery.

Before leaving the vehicle, check the

electrical parking brake status.

Control indicator m 3 85.

Releasing

Switch on ignition. Keep foot brake

depressed and then push switch m.

If the foot brake is not depressed

when attempting to release electrical

parking brake, a warning chime will

sound and control indicator -

illuminates in the instrument cluster

3 90.

Page 146 of 225

144Driving and operatingDrive away function

With the engine running, selecting a

forward gear (manual transmission)

or engaging D (automatic

transmission) and then depressing

the accelerator pedal automatically

releases the electrical parking brake.

This is not possible when the switch

m is pulled at the same time.

This function also helps driving away

on inclines.

Aggressive drive away may reduce

life time of wear parts.

Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, a warning

chime will sound and the electrical

parking brake system will decelerate

the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Fault

Failure mode of electrical parking

brake is indicated by control indicator

j 3 85.In the event of a fault, to apply

electrical parking brake: pull and hold the switch m for a few seconds. If

control indicator m illuminates,

electrical parking brake has been applied successfully.

To release electrical parking brake:

push and hold the switch m for a few

seconds. If control indicator m

extinguishes, electrical parking brake

has been released successfully.

If control indicator m flashes:

electrical parking brake is not fully applied or released. When m is

continuously flashing, with ignition

switched on depress brake pedal,

release electrical parking brake and

retry applying.

If m continues to flash, do not drive

the vehicle. If necessary, place

wedge blocks or equivalent in front of and behind wheels to prevent vehicle movement. Seek the assistance of a

workshop to have the cause of the

fault remedied.Brake assist

If the brake pedal is depressed

quickly and forcefully, maximum

brake force is automatically applied

(full braking).

Maintain steady pressure on the brake pedal for as long as full braking

is required. Maximum brake force is

automatically reduced when the

brake pedal is released.

Hill start assist The system helps prevent unintendedmovement when driving away on

inclines.

When releasing the foot brake after

stopping on an incline, the brakes

remain on for a further 2 seconds. The

brakes release automatically as soon as the vehicle begins to accelerate.

Page 153 of 225

Driving and operating151Fuel filler flap is located at left rear

side of vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked 3 22.

Release the fuel filler flap by pushing

the flap.

To unlock fuel filler cap: turn it

anticlockwise. If hissing occurs, wait

until it stops before completely

unscrewing the cap.

The fuel filler cap can be retained in

the holder on the inside of the fuel

filler flap.

When refuelling, fully insert the pump nozzle and switch it on.

After automatic cut-off, the tank can

be topped up by operating the pump

nozzle a maximum of two more times.Caution

Wipe off any overflowing fuel

immediately.

After refuelling, replace the fuel filler

cap and turn it clockwise until you

hear several clicks. Ensure the cap is

screwed in completely, otherwise

control indicator Z may illuminate in

the instrument cluster 3 84.

Close fuel filler flap.

Fuel filler cap

Only a genuine fuel filler cap provides full functionality. Diesel-engined

vehicles have special fuel filler caps.

Fuel consumption - CO 2-

Emissions

The fuel consumption (combined) of

the model Opel Antara is within a range of 10.9 to 6.3 l/100 km.

The CO 2 emission (combined) is

within a range of 255 to 167 g/km.

For the values specific for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

General information

The official fuel consumption and

specific CO 2 emission figures quoted

relate to the EU base model with

standard equipment.

Fuel consumption data and CO 2

emission data are determined

according to regulation R (EC) No.

715/2007 (in the latest applicable

version), taking into consideration the

vehicle weight in running order, as

specified by the regulation.

The figures are provided only for the

purpose of comparison between

different vehicle variants and must

not be taken as a guarantee for the

actual fuel consumption of a

particular vehicle. Additional

equipment may result in slightly

higher results than the stated

Page 156 of 225

154Driving and operatingTowing equipment with

detachable coupling ball bar

The coupling ball bar is kept in a bag,

fastened with a strap and is stowed

below the floor cover in the load

compartment.

Fitting the coupling ball bar

Remove sealing plug from the hole for

the coupling ball bar and stow it in the load compartment.

Confirm that the colour marking on

the lever is red.

Inserting the coupling ball bar

Insert the coupling ball bar into the

coupling housing and push firmly

downwards until the coupling ball bar

audibly engages. If it does not

engage, repeat fitting procedure.

Do not swing the coupling ball bar to

the left or right, or upwards and

downwards, to avoid disrupting

correct fitting.

Lock coupling ball bar by turning the

supplied key in the lock cylinder of the coupling ball bar. Remove key.

Page 157 of 225

Driving and operating155Check that the coupling ball bar is

correctly attached:

● Green marking must be visible on

lever.

● Coupling ball bar must be seated

firmly in coupling housing.

Coupling ball bar must be locked and key must be removed.9 Warning

Towing a trailer is permitted only

when the coupling ball bar is fitted correctly. If the coupling ball bar

cannot be properly attached, seek the assistance of a workshop.

Eye for break-away stopping cable

In the case of trailers with brakes,

attach the break-away stopping cable

to the eye - not to the coupling ball

bar.

Dismounting the coupling ball bar

Unlock coupling ball bar and remove

key. Push lever to the left, towards the

coupling ball bar and turn it

downwards. Pull coupling ball bar out of coupling housing.

Remove any rust or dirt from area

around the coupling housing and

coupling ball bar connection before

inserting sealing plug in the hole.

Place the coupling ball bar in the bag supplied, fasten it with the strap and

stow it below the floor cover in the

load compartment.

Do not use steam-jet cleaners or

other high-pressure cleaners to clean

the coupling ball bar.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 145.