OPEL CALIBRA 1988 Service Repair Manual

Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 121 of 525

Glovebox assembly

Removal

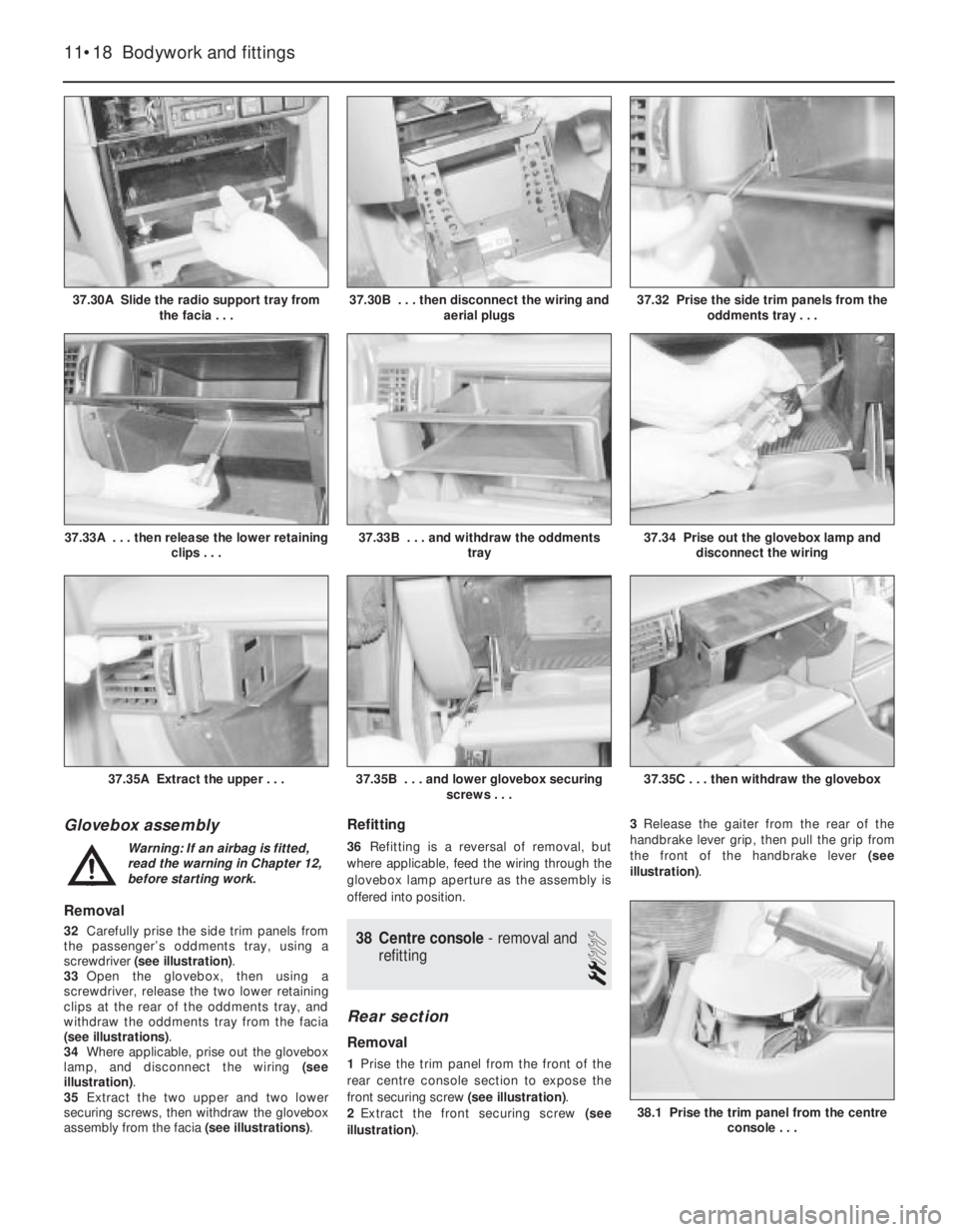

32Carefully prise the side trim panels from

the passenger’s oddments tray, using a

screwdriver (see illustration).

33Open the glovebox, then using a

screwdriver, release the two lower retaining

clips at the rear of the oddments tray, and

withdraw the oddments tray from the facia

(see illustrations).

34Where applicable, prise out the glovebox

lamp, and disconnect the wiring (see

illustration).

35Extract the two upper and two lower

securing screws, then withdraw the glovebox

assembly from the facia (see illustrations).

Refitting

36Refitting is a reversal of removal, but

where applicable, feed the wiring through the

glovebox lamp aperture as the assembly is

offered into position.

38Centre console - removal and

refitting

2

Rear section

Removal

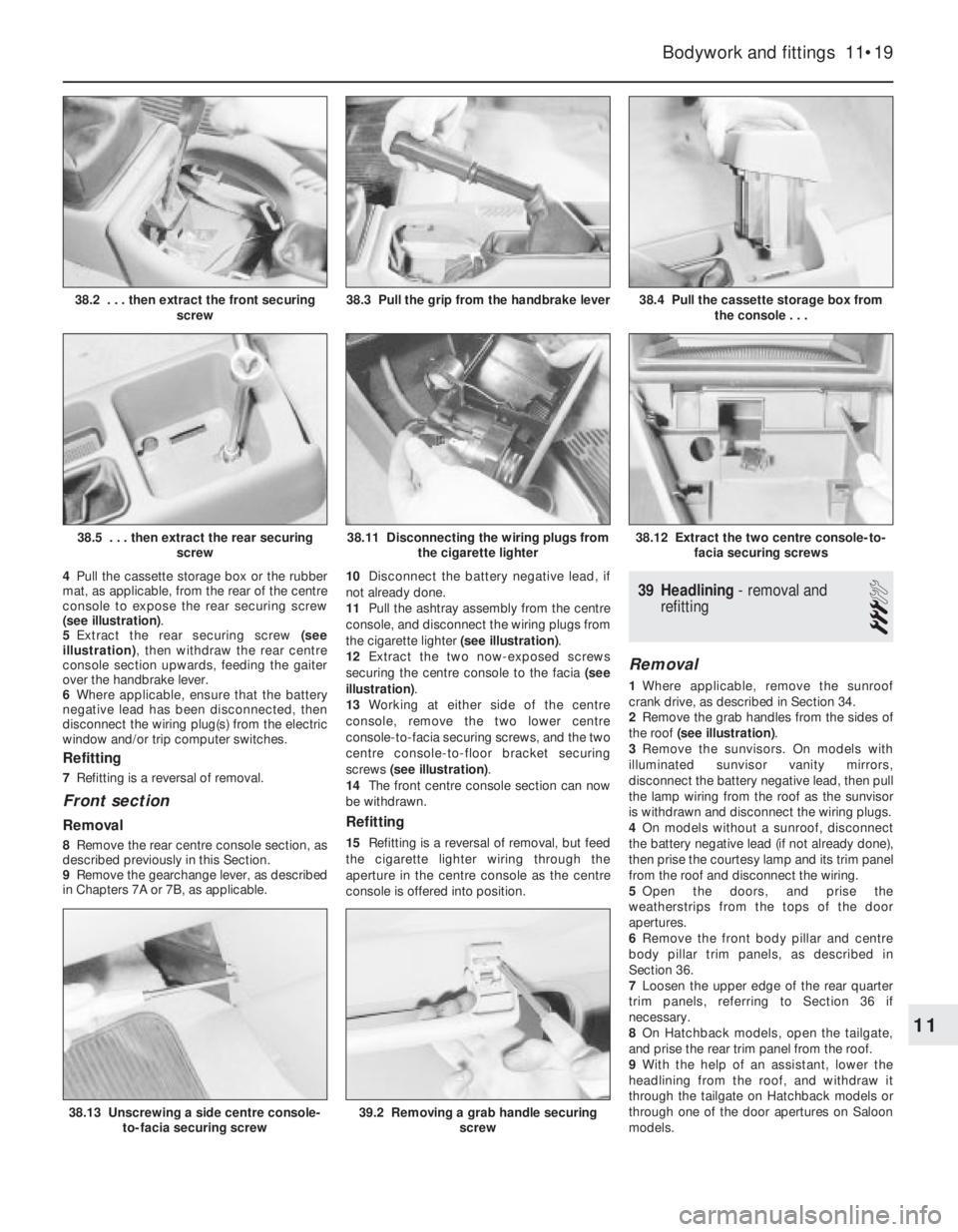

1Prise the trim panel from the front of the

rear centre console section to expose the

front securing screw (see illustration).

2Extract the front securing screw (see

illustration).3Release the gaiter from the rear of the

handbrake lever grip, then pull the grip from

the front of the handbrake lever (see

illustration).

11•18Bodywork and fittings

37.30A Slide the radio support tray from

the facia . . .37.32 Prise the side trim panels from the

oddments tray . . .

37.35C . . . then withdraw the glovebox37.35B . . . and lower glovebox securing

screws . . .37.35A Extract the upper . . .

37.34 Prise out the glovebox lamp and

disconnect the wiring37.33B . . . and withdraw the oddments

tray37.33A . . . then release the lower retaining

clips . . .

37.30B . . . then disconnect the wiring and

aerial plugs

38.1 Prise the trim panel from the centre

console . . .

Warning: If an airbag is fitted,

read the warning in Chapter 12,

before starting work.

Page 122 of 525

4Pull the cassette storage box or the rubber

mat, as applicable, from the rear of the centre

console to expose the rear securing screw

(see illustration).

5Extract the rear securing screw (see

illustration), then withdraw the rear centre

console section upwards, feeding the gaiter

over the handbrake lever.

6Where applicable, ensure that the battery

negative lead has been disconnected, then

disconnect the wiring plug(s) from the electric

window and/or trip computer switches.

Refitting

7Refitting is a reversal of removal.

Front section

Removal

8Remove the rear centre console section, as

described previously in this Section.

9Remove the gearchange lever, as described

in Chapters 7A or 7B, as applicable. 10Disconnect the battery negative lead, if

not already done.

11Pull the ashtray assembly from the centre

console, and disconnect the wiring plugs from

the cigarette lighter (see illustration).

12Extract the two now-exposed screws

securing the centre console to the facia (see

illustration).

13Working at either side of the centre

console, remove the two lower centre

console-to-facia securing screws, and the two

centre console-to-floor bracket securing

screws (see illustration).

14The front centre console section can now

be withdrawn.

Refitting

15Refitting is a reversal of removal, but feed

the cigarette lighter wiring through the

aperture in the centre console as the centre

console is offered into position.

39Headlining -removal and

refitting

3

Removal

1Where applicable, remove the sunroof

crank drive, as described in Section 34.

2Remove the grab handles from the sides of

the roof (see illustration).

3Remove the sunvisors. On models with

illuminated sunvisor vanity mirrors,

disconnect the battery negative lead, then pull

the lamp wiring from the roof as the sunvisor

is withdrawn and disconnect the wiring plugs.

4On models without a sunroof, disconnect

the battery negative lead (if not already done),

then prise the courtesy lamp and its trim panel

from the roof and disconnect the wiring.

5Open the doors, and prise the

weatherstrips from the tops of the door

apertures.

6Remove the front body pillar and centre

body pillar trim panels, as described in

Section 36.

7Loosen the upper edge of the rear quarter

trim panels, referring to Section 36 if

necessary.

8On Hatchback models, open the tailgate,

and prise the rear trim panel from the roof.

9With the help of an assistant, lower the

headlining from the roof, and withdraw it

through the tailgate on Hatchback models or

through one of the door apertures on Saloon

models.

Bodywork and fittings 11•19

38.4 Pull the cassette storage box from

the console . . .

38.12 Extract the two centre console-to-

facia securing screws38.11 Disconnecting the wiring plugs from

the cigarette lighter

38.3 Pull the grip from the handbrake lever38.2 . . . then extract the front securing

screw

11

38.5 . . . then extract the rear securing

screw

38.13 Unscrewing a side centre console-

to-facia securing screw39.2 Removing a grab handle securing

screw

Page 123 of 525

Refitting

10Refitting is a reversal of removal, but

where applicable, refit the sunroof crank drive,

as described in Section 34.

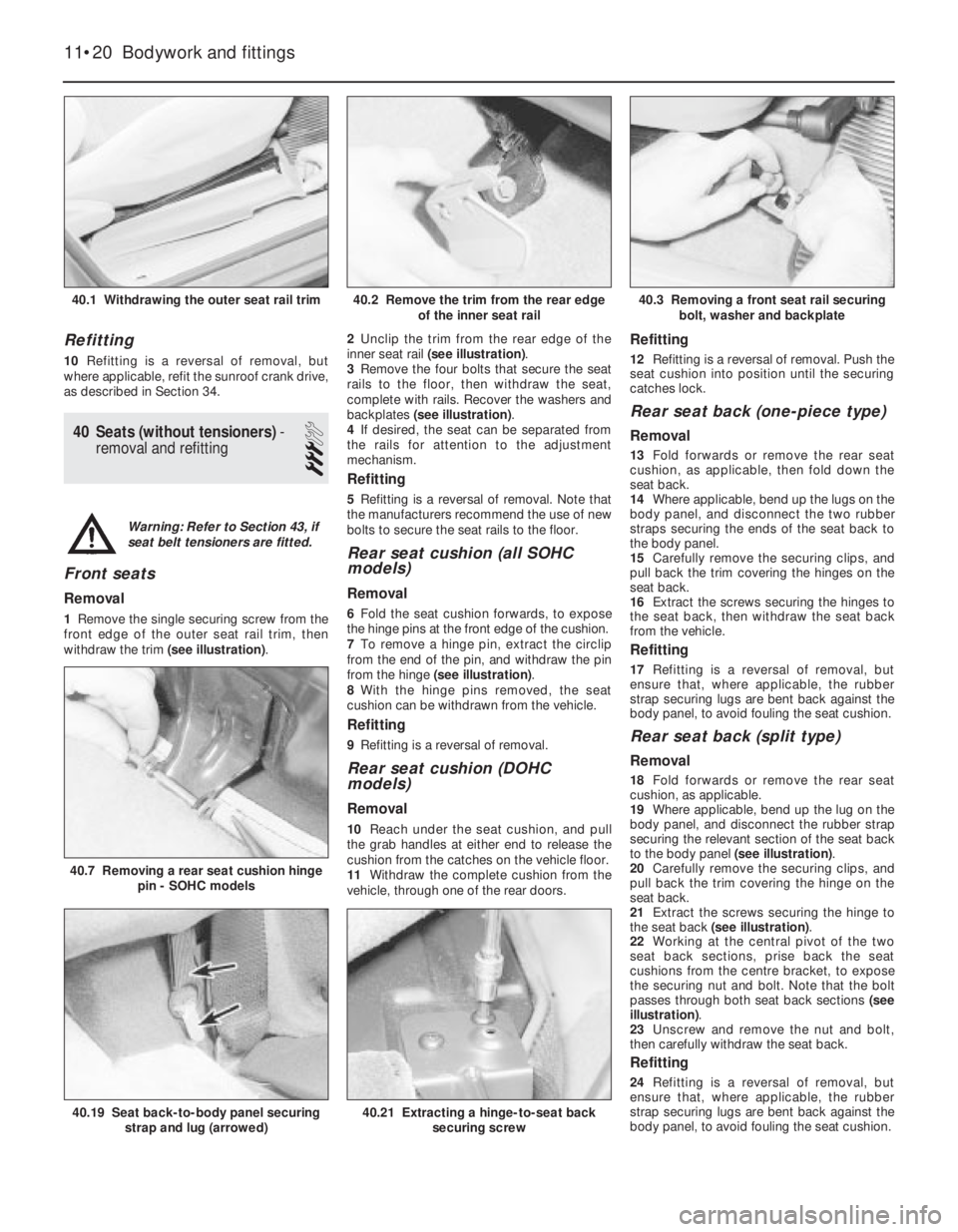

40Seats (without tensioners) -

removal and refitting

3

Front seats

Removal

1Remove the single securing screw from the

front edge of the outer seat rail trim, then

withdraw the trim (see illustration).2Unclip the trim from the rear edge of the

inner seat rail (see illustration).

3Remove the four bolts that secure the seat

rails to the floor, then withdraw the seat,

complete with rails. Recover the washers and

backplates (see illustration).

4If desired, the seat can be separated from

the rails for attention to the adjustment

mechanism.

Refitting

5Refitting is a reversal of removal. Note that

the manufacturers recommend the use of new

bolts to secure the seat rails to the floor.

Rear seat cushion (all SOHC

models)

Removal

6Fold the seat cushion forwards, to expose

the hinge pins at the front edge of the cushion.

7To remove a hinge pin, extract the circlip

from the end of the pin, and withdraw the pin

from the hinge (see illustration).

8With the hinge pins removed, the seat

cushion can be withdrawn from the vehicle.

Refitting

9Refitting is a reversal of removal.

Rear seat cushion (DOHC

models)

Removal

10Reach under the seat cushion, and pull

the grab handles at either end to release the

cushion from the catches on the vehicle floor.

11Withdraw the complete cushion from the

vehicle, through one of the rear doors.

Refitting

12Refitting is a reversal of removal. Push the

seat cushion into position until the securing

catches lock.

Rear seat back (one-piece type)

Removal

13Fold forwards or remove the rear seat

cushion, as applicable, then fold down the

seat back.

14Where applicable, bend up the lugs on the

body panel, and disconnect the two rubber

straps securing the ends of the seat back to

the body panel.

15Carefully remove the securing clips, and

pull back the trim covering the hinges on the

seat back.

16Extract the screws securing the hinges to

the seat back, then withdraw the seat back

from the vehicle.

Refitting

17Refitting is a reversal of removal, but

ensure that, where applicable, the rubber

strap securing lugs are bent back against the

body panel, to avoid fouling the seat cushion.

Rear seat back (split type)

Removal

18Fold forwards or remove the rear seat

cushion, as applicable.

19Where applicable, bend up the lug on the

body panel, and disconnect the rubber strap

securing the relevant section of the seat back

to the body panel (see illustration).

20Carefully remove the securing clips, and

pull back the trim covering the hinge on the

seat back.

21Extract the screws securing the hinge to

the seat back (see illustration).

22Working at the central pivot of the two

seat back sections, prise back the seat

cushions from the centre bracket, to expose

the securing nut and bolt. Note that the bolt

passes through both seat back sections (see

illustration).

23Unscrew and remove the nut and bolt,

then carefully withdraw the seat back.

Refitting

24Refitting is a reversal of removal, but

ensure that, where applicable, the rubber

strap securing lugs are bent back against the

body panel, to avoid fouling the seat cushion.

11•20Bodywork and fittings

40.1 Withdrawing the outer seat rail trim40.3 Removing a front seat rail securing

bolt, washer and backplate

40.7 Removing a rear seat cushion hinge

pin - SOHC models

40.21 Extracting a hinge-to-seat back

securing screw40.19 Seat back-to-body panel securing

strap and lug (arrowed)

40.2 Remove the trim from the rear edge

of the inner seat rail

Warning: Refer to Section 43, if

seat belt tensioners are fitted.

Page 124 of 525

41Seat belts - removal and

refitting

3

Note: For details on mechanical seat belt

tensioners, refer to Section 42.

Front seat belt

Removal

1Open both front and rear doors, and prise

the weatherstrips from the edge of the centre

body pillar.

2Prise off the pillar lower trim panel to

expose the inertia reel unit.

3Unscrew the securing bolt, and tilt the

inertia reel unit from the body pillar (see

illustration).

4Prise off the trim and unbolt the seat belt

upper mounting from the body pillar. Recover

the spacer.

5Similarly, unbolt the seat belt lower

mounting, then withdraw the seat belt

assembly from the vehicle.

6If desired, the seat belt stalk can be

unbolted from the seat frame, and the upper

mounting height adjuster (where applicable)

can be unbolted from the body pillar (Torx

bolts), after prising off the pillar upper trim

panel.

Refitting

7Refitting is a reversal of removal, but note

that, when refitting the height adjuster, the

arrows should be uppermost, pointingtowards the vehicle roof. Ensure that the belt

is fitted untwisted.

Rear seat belt

Removal

8Fold the rear seat cushion forwards, or

remove it, as applicable, for access to the

seat belt lower mountings. Prise up the carpet

to expose the mounting bolts, and unscrew

the relevant bolt(s) from the floor (see

illustrations).

9Prise off the trim, and unbolt the seat belt

upper mounting from the body pillar. Recover

the spacer (see illustration).

10Open the relevant rear door, and pull back

the weatherstrip from the rear of the door

aperture.

11On Hatchback models, remove the

screws securing the upper rear quarter trim

panel to the body. Note that all the screws are

of the Torx type, and when working on the

right-hand side, it will be necessary to open

the first-aid kit/warning triangle cover flap in

the luggage compartment for access to some

of the screws. Withdraw the trim panel

carefully, taking care not to damage

surrounding panels.

12Detach the front edge of the lower rear

quarter trim panel from the body. The panel is

secured by clips on Saloon models, and by

screws on Hatchback models.

13Pull the lower rear quarter trim panel away

from the body sufficiently to gain access to

the seat belt inertia reel unit (see illustration).14Unscrew the securing bolt, and lift the

inertia reel unit from the body panel, then

withdraw the seat belt assembly from the

vehicle.

15If desired, the upper seat belt mounting

height adjuster can be unbolted from the body

pillar (Torx bolts), after removing the upper

rear quarter trim panel (see illustration).

Refitting

16Refitting is a reversal of removal, but note

that, when refitting the height adjuster (where

applicable), the arrows should be uppermost,

pointing towards the vehicle roof. Ensure that

the belt is fitted untwisted.

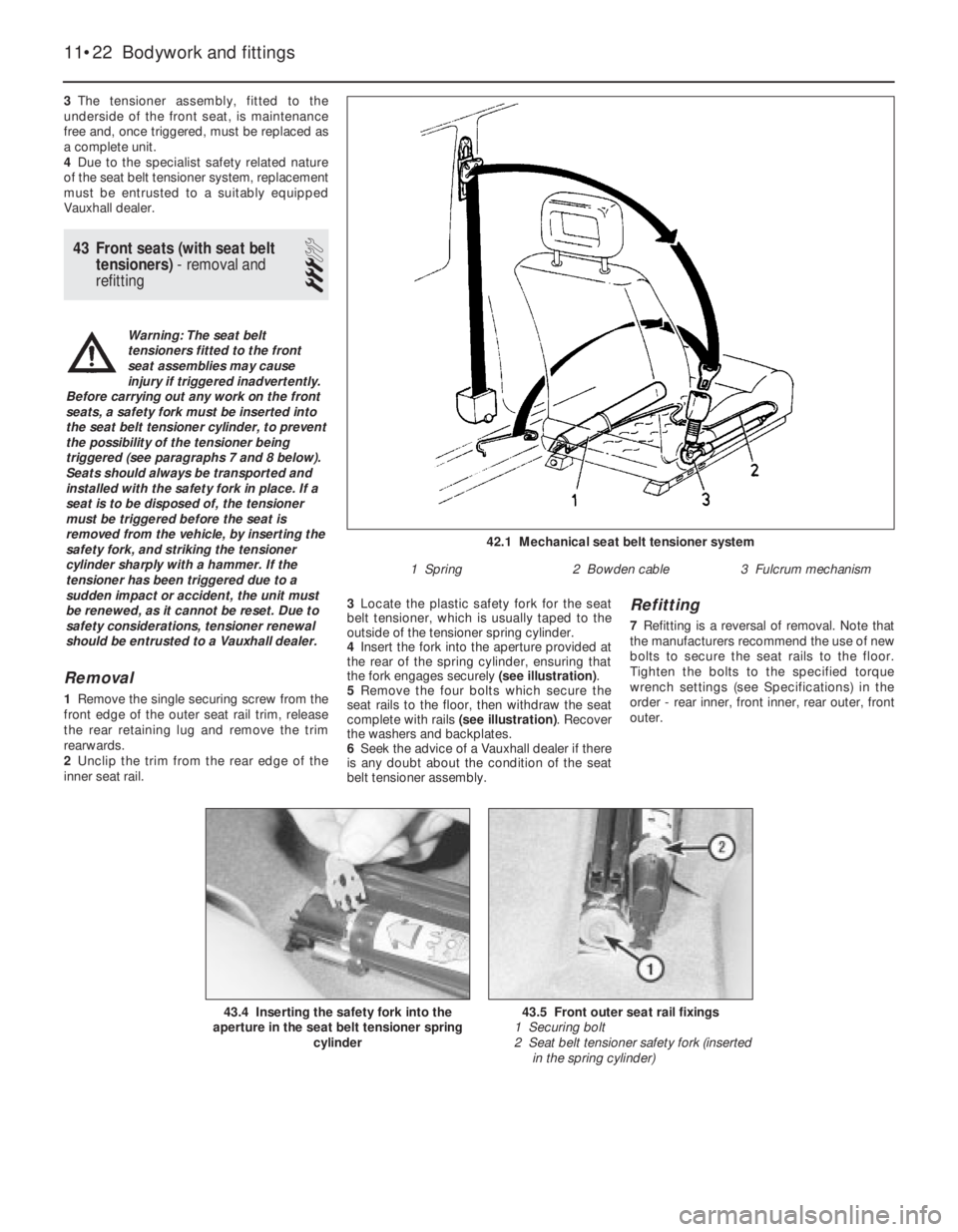

42Seat belt tensioners - general

5

1All 1993-onwards Cavalier models are

equipped with mechanical front seat belt

tensioners which automatically tighten the

front seat belts in the event of a head-on

collision. The mechanically operated device

ensures that the seat belt remains close to the

body, thus preventing the wearer from sliding

out, under the belt, during impact (see

illustration).

2The tensioner system consists of a powerful

preloaded spring, contained in a cylinder,

which is released in the event of severe

impact. The spring pulls back the seat belt by

means of a bowden cable and fulcrum

mechanism attached to the belt stalk,

mounted on the seat frame.

Bodywork and fittings 11•21

41.8 Rear seat belt lower side mounting -

Hatchback model

41.15 Upper rear quarter trim panel

removed, to expose upper seat belt

mounting height adjuster41.13 Rear seat belt inertia reel unit

location - Hatchback model41.9 Removing a rear seat belt upper

mounting from the body pillar - Hatchback

model

41.3 Unscrewing a front seat belt inertia

reel securing bolt40.22 Rear seat cushion pulled back to

expose seat back hinge nut and bolt - split

type rear seat back

11

Page 125 of 525

3The tensioner assembly, fitted to the

underside of the front seat, is maintenance

free and, once triggered, must be replaced as

a complete unit.

4Due to the specialist safety related nature

of the seat belt tensioner system, replacement

must be entrusted to a suitably equipped

Vauxhall dealer.

43Front seats (with seat belt

tensioners) -removal and

refitting

3

Removal

1Remove the single securing screw from the

front edge of the outer seat rail trim, release

the rear retaining lug and remove the trim

rearwards.

2Unclip the trim from the rear edge of the

inner seat rail.3Locate the plastic safety fork for the seat

belt tensioner, which is usually taped to the

outside of the tensioner spring cylinder.

4Insert the fork into the aperture provided at

the rear of the spring cylinder, ensuring that

the fork engages securely (see illustration).

5Remove the four bolts which secure the

seat rails to the floor, then withdraw the seat

complete with rails (see illustration). Recover

the washers and backplates.

6Seek the advice of a Vauxhall dealer if there

is any doubt about the condition of the seat

belt tensioner assembly.

Refitting

7Refitting is a reversal of removal. Note that

the manufacturers recommend the use of new

bolts to secure the seat rails to the floor.

Tighten the bolts to the specified torque

wrench settings (see Specifications) in the

order - rear inner, front inner, rear outer, front

outer.

11•22Bodywork and fittings

42.1 Mechanical seat belt tensioner system

1 Spring2 Bowden cable3 Fulcrum mechanism

43.5 Front outer seat rail fixings

1 Securing bolt

2 Seat belt tensioner safety fork (inserted

in the spring cylinder)43.4 Inserting the safety fork into the

aperture in the seat belt tensioner spring

cylinder

Warning: The seat belt

tensioners fitted to the front

seat assemblies may cause

injury if triggered inadvertently.

Before carrying out any work on the front

seats, a safety fork must be inserted into

the seat belt tensioner cylinder, to prevent

the possibility of the tensioner being

triggered (see paragraphs 7 and 8 below).

Seats should always be transported and

installed with the safety fork in place. If a

seat is to be disposed of, the tensioner

must be triggered before the seat is

removed from the vehicle, by inserting the

safety fork, and striking the tensioner

cylinder sharply with a hammer. If the

tensioner has been triggered due to a

sudden impact or accident, the unit must

be renewed, as it cannot be reset. Due to

safety considerations, tensioner renewal

should be entrusted to a Vauxhall dealer.

Page 126 of 525

4C

Torque wrench settingsNm lbf ft

AIR non-return valve to pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 22

AIR pipe support bracket to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

AIR pipe to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

AIR pipe to support bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

AIR pump bracket to protective shield . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

AIR pump to wheel arch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

AIR pump to insulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

AIR valves to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Carbon canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

EGR valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Heat shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 22

Chapter 4 Part C:

Fuel and exhaust systems - exhaust and emissions

AIR cut-off valve - removal, testing and refitting . . . . . . . . . . . . . . . . .7

AIR pipe and non-return valve - removal and refitting . . . . . . . . . . . . .9

AIR pump assembly (Simtec system) - removal and refitting . . . . . . . .6

AIR switchover valve - removal and refitting . . . . . . . . . . . . . . . . . . . .8

Carbon canister - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .11

Catalytic converter - description, general and precautions . . . . . . . .10

EGR module (X 16 SZ models) - removal and refitting . . . . . . . . . . . . .5EGR valve (Multec system models) - testing, removal and refitting . . .3

EGR valve (Simtec system) - testing, removal and refitting . . . . . . . . .4

Emissions control systems - general . . . . . . . . . . . . . . . . . . . . . . . . . .1

Exhaust gas recirculation (EGR) system - general . . . . . . . . . . . . . . . .2

Exhaust manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . .13

Exhaust system - checking, removal and refitting . . . . . . . . . . . . . . .14

Oxygen sensor (catalytic converter models) - removal and refitting .12

4C•1

Specifications Contents

1 Emissions control systems -

general

General

Multec system

1An evaporative emissions control system is

fitted to minimise the escape into the

atmosphere of unburned hydrocarbons.

2The fuel tank filler cap is sealed and a

charcoal canister is mounted under the

right-hand front wing to collect the petrol

vapours generated in the tank when the

vehicle is parked. It stores them until they can

be purged from the canister into the inlet tract

to be burned by the engine during normal

combustion. The canister’s control valve (on

the top of the canister) is opened by a vacuum

pipe from the front of the throttle body on C16

NZ, C16 NZ2 and C18 NZ engines. On X16 SZ

it’s opened by an electronically activated

purge valve, mounted on the camshaft

housing.

Motronic system

3The system is as described in Chapter 4B,

except that the charcoal canister is purged

under the control of the fuel injection/ignition

system module through the fuel tank vent

valve. To ensure that the engine runs correctly

when it is cold and/or idling, and to protect

the catalytic converter from the effects of an

over-rich mixture, the valve is not opened by

the module until the engine is under partial or

full load. The valve solenoid is then modulated

on and off to allow the stored vapour to pass

into the inlet tract.

4Canister removal and refitting is as

described in Section 11.

5On C20 NE engines, the vent valve is

mounted above the injectors for cylinders 2

and 4. To remove it, disconnect the battery

negative lead and the valve wiring plug, then

disconnect the two vent hoses having made

note of their connections. Either remove the

valve from its mounting bracket, or unbolt the

bracket, as required.

6On C20 XE engines, the vent valve is

mounted on the left-hand end of the engine,underneath the end of the fuel injector wiring

harness housing (see illustration). Removal

and refitting is as described in the previous

paragraph.

Simtec system

7For information refer to “General

description”, in Chapter 4B. Note that “AIR”,

is an abbreviation for the secondary Air

Injection Reactor system used on this model.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1.6 Disconnecting the fuel tank vent valve

wiring

Page 127 of 525

2Exhaust gas recirculation

(EGR) system - general

The system reintroduces small amounts of

exhaust gas into the combustion cycle to

reduce the generation of oxides of nitrogen

(NOx).

On C16 NZ, C16 NZ2 and C18 NZ engines,

the volume of exhaust gas reintroduced is

governed by manifold vacuum, through the

EGR valve mounted on the inlet manifold.

When the valve is opened small amounts of

exhaust gas are allowed to enter the inlet

tract, passing through ports in the cylinder

head.

On X16 SZ engines the EGR valve is

operated by an EGR module, mounted on the

left-hand side of the engine compartment

behind the battery. This module amplifies

signals received from the fuel system ECU

and operates the EGR valve electronically

providing precise control of exhaust gas

recirculation under all engine conditions.

3EGR valve (Multec system

models) - testing, removal and

refitting

2

Testing

1On C16 NZ, C16 NZ2 and C18 NZ engines,

it is recommended that the system is checked

annually, by checking the movement of the

valve’s diaphragm carrier plate as follows.

Note that the carrier plate is visible only

through the apertures in the underside of the

valve, so a battery-operated torch and small

mirror may be useful. On X16 SZ engines,

Vauxhall test equipment is necessary to check

the EGR system.

2With the engine fully warmed up to normal

operating temperature and idling, briefly open

and close the throttle. The carrier plate should

move upwards as the manifold vacuum

changes. When the engine is idling smoothly

again, press the carrier plate upwards (do this

very carefully, so that the plate is not distorted or

the diaphragm damaged). The idle speed should

drop significantly (approximately 100 rpm).

3If the valve does not respond as described,

it must be cleaned.

Removal

4Pull off the hose from the valve, then unbolt

the valve and remove it (see illustrations).

Clean away all carbon using a wire brush and

a pointed tool, but take care not to damage

the valve seat. Renew the valve gasket to

prevent induction leaks.

Refitting

5Refit the valve and reconnect the hose,

then recheck the system’s performance; if

there is no improvement, the valve must be

renewed.

4EGR valve (Simtec system) -

testing, removal and refitting

3

Note: A new gasket will be required when

refitting the valve.

Removal

1Disconnect the battery negative lead.

2Remove wiring harness and vacuum hose.

3Mark position of the valve, to ensure

correct relocation.

4Undo the 3 bolts, and remove the valve

from the dual spark ignition coil’s coolant

flange.

Refitting

5Clean the sealing surfaces of the valve and

flange.

6Refit the valve with a new gasket and line

up the marks made before removal (see

illustration).

5EGR module (X16 SZ

models) - removal and

refitting

2

Removal

1Disconnect the knock module from its

bracket (refer to Chapter 4B, if necessary),

and place to one side.

2Remove wiring plug from module. Remove

module from bracket.

Refitting

3Refitting is a reversal of removal.

6AIR pump assembly (Simtec

system) - removal and refitting

3

Removal

1Chock the rear wheels, jack up the front of

the vehicle and support it on axle stands

placed under the body side members (see

“Jacking and Vehicle Support”)

2Remove the left hand front wheel and inner

wheel arch lining.

3Loosen the hose clamp and remove the air

duct hose from the pump.

4Disconnect the battery negative lead.

5Undo the securing nuts and remove the

pump assembly from its location. Disconnect

the wiring plug.

6Remove the wiring plug from the pump’s

bracket.

7Mark the position of the pump on it’s

bracket before separating.

8Remove the fixing bolts and disconnect the

pump from it’s insulator.

9The insulator can also be checked by

removing the 3 nuts, securing the protective

shield. Before removing, mark the shield and

insulator. Replace if necessary.

10Check the pump’s air cleaner for damage.

Refitting

11Refitting is a reversal of removal. Ensure

correct alignment of the components.

7AIR cut-off valve - removal,

testing and refitting

3

Removal

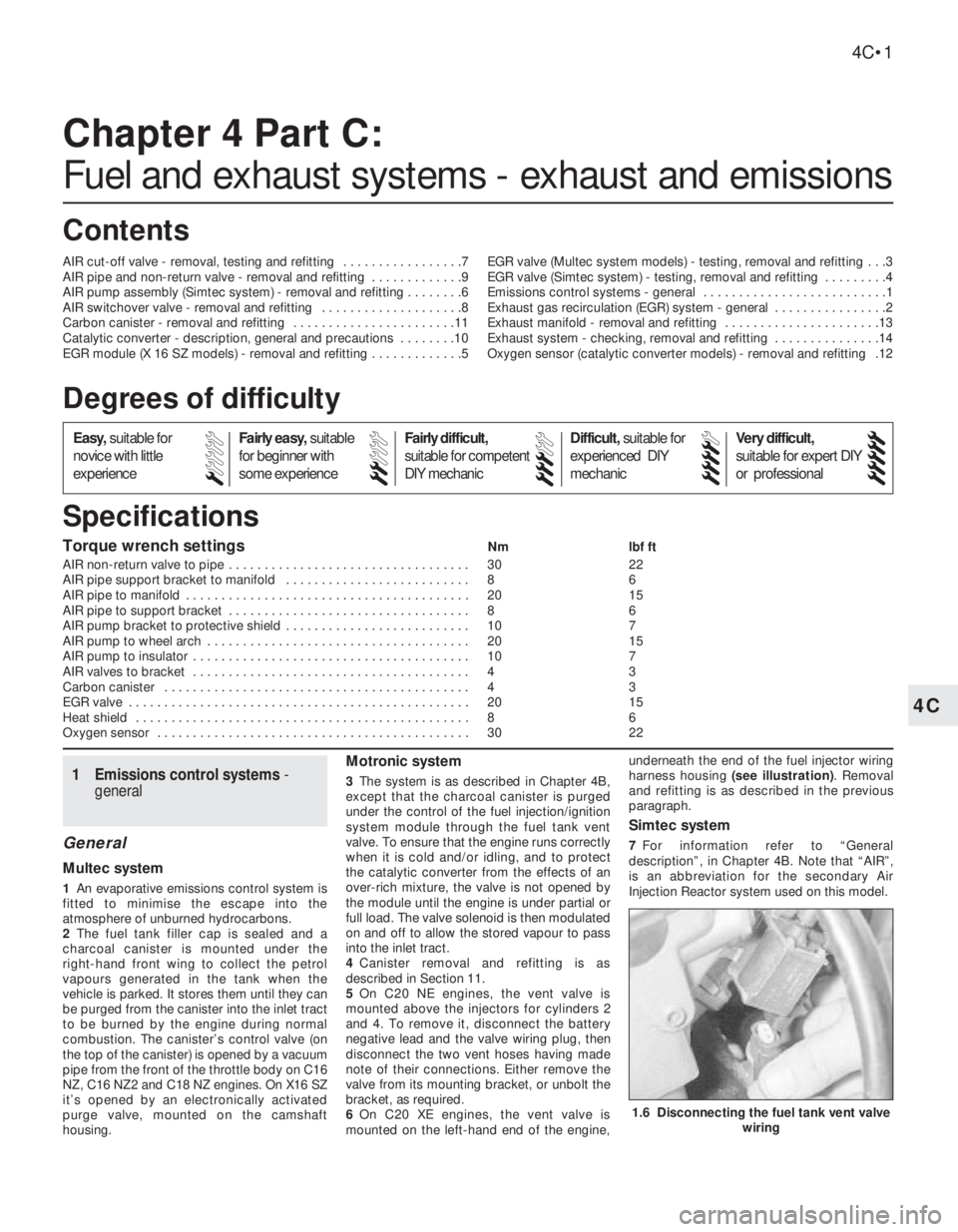

1Before removal, mark on the cut-off valve,

the direction of flow towards the non-return

valve (see illustration).

2Disconnect and remove the air duct and

vacuum hoses.

3Undo the switchover valve’s bolts and

move to one side.

4C•2Fuel and exhaust systems - exhaust and emissions

3.4 Disconnecting the vacuum hose from

the exhaust gas recirculation valve

4.6 EGR valve

1 Valve 2 Gasket

3.4B Withdrawing the exhaust gas

recirculation valve

Page 128 of 525

4The cut-off valve can now be removed from

the bracket.

Testing

5To test the cut-off valve a vacuum hand

pump with gauge will be required. If available,

connect to the cut-off valve and ensure that

air through-flow aperture is fully open.

Refitting

6Refitting is a reversal of removal. Ensure

valve is fitted in the correct direction.

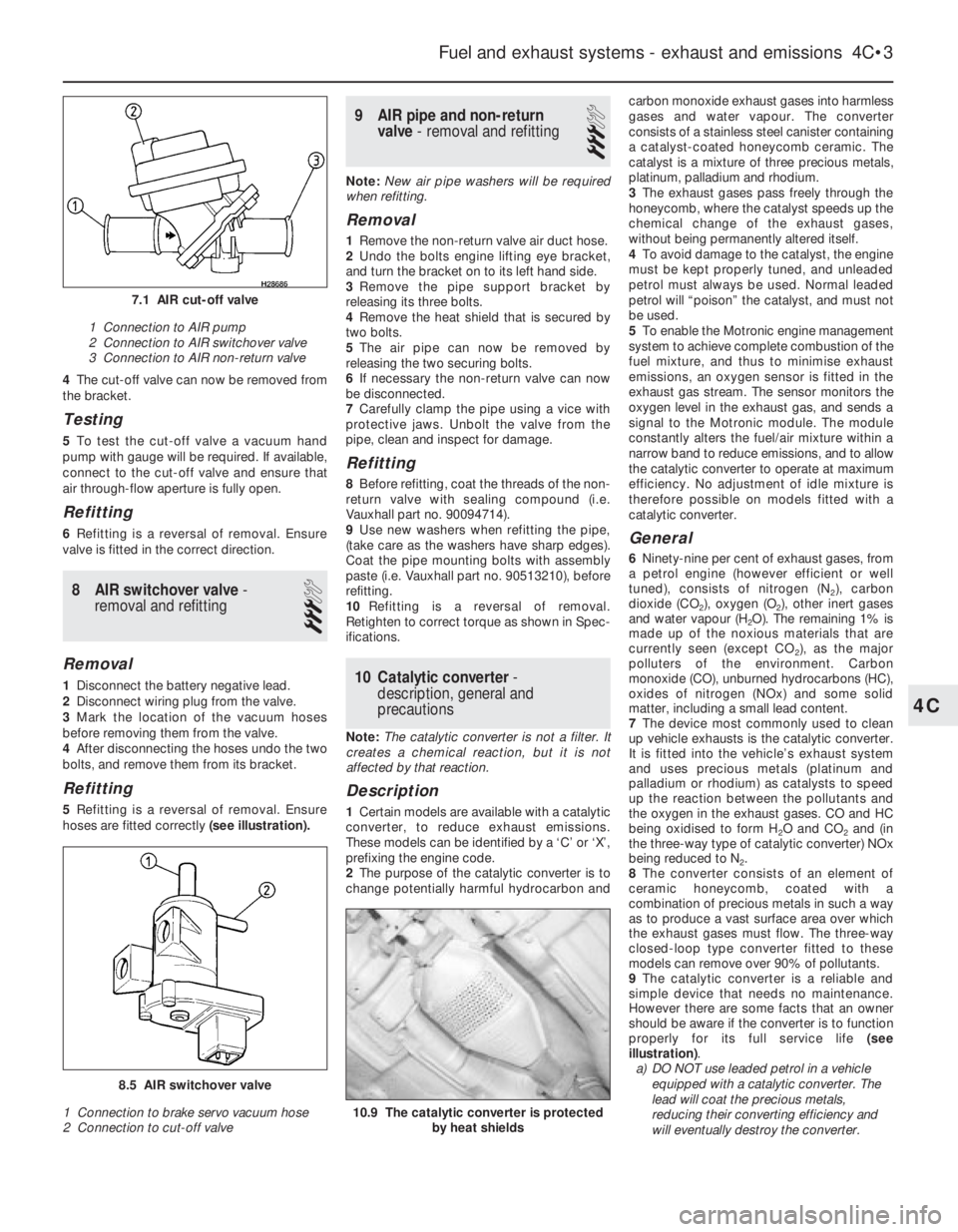

8AIR switchover valve -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect wiring plug from the valve.

3Mark the location of the vacuum hoses

before removing them from the valve.

4After disconnecting the hoses undo the two

bolts, and remove them from its bracket.

Refitting

5Refitting is a reversal of removal. Ensure

hoses are fitted correctly (see illustration).

9AIR pipe and non-return

valve - removal and refitting

3

Note:New air pipe washers will be required

when refitting.

Removal

1Remove the non-return valve air duct hose.

2Undo the bolts engine lifting eye bracket,

and turn the bracket on to its left hand side.

3Remove the pipe support bracket by

releasing its three bolts.

4Remove the heat shield that is secured by

two bolts.

5The air pipe can now be removed by

releasing the two securing bolts.

6If necessary the non-return valve can now

be disconnected.

7Carefully clamp the pipe using a vice with

protective jaws. Unbolt the valve from the

pipe, clean and inspect for damage.

Refitting

8Before refitting, coat the threads of the non-

return valve with sealing compound (i.e.

Vauxhall part no. 90094714).

9Use new washers when refitting the pipe,

(take care as the washers have sharp edges).

Coat the pipe mounting bolts with assembly

paste (i.e. Vauxhall part no. 90513210), before

refitting.

10Refitting is a reversal of removal.

Retighten to correct torque as shown in Spec-

ifications.

10Catalytic converter -

description, general and

precautions

Note: The catalytic converter is not a filter. It

creates a chemical reaction, but it is not

affected by that reaction.

Description

1Certain models are available with a catalytic

converter, to reduce exhaust emissions.

These models can be identified by a ‘C’ or ‘X’,

prefixing the engine code.

2The purpose of the catalytic converter is to

change potentially harmful hydrocarbon andcarbon monoxide exhaust gases into harmless

gases and water vapour. The converter

consists of a stainless steel canister containing

a catalyst-coated honeycomb ceramic. The

catalyst is a mixture of three precious metals,

platinum, palladium and rhodium.

3The exhaust gases pass freely through the

honeycomb, where the catalyst speeds up the

chemical change of the exhaust gases,

without being permanently altered itself.

4To avoid damage to the catalyst, the engine

must be kept properly tuned, and unleaded

petrol must always be used. Normal leaded

petrol will “poison” the catalyst, and must not

be used.

5To enable the Motronic engine management

system to achieve complete combustion of the

fuel mixture, and thus to minimise exhaust

emissions, an oxygen sensor is fitted in the

exhaust gas stream. The sensor monitors the

oxygen level in the exhaust gas, and sends a

signal to the Motronic module. The module

constantly alters the fuel/air mixture within a

narrow band to reduce emissions, and to allow

the catalytic converter to operate at maximum

efficiency. No adjustment of idle mixture is

therefore possible on models fitted with a

catalytic converter.

General

6Ninety-nine per cent of exhaust gases, from

a petrol engine (however efficient or well

tuned), consists of nitrogen (N

2), carbon

dioxide (CO

2), oxygen (O2), other inert gases

and water vapour (H

2O). The remaining 1% is

made up of the noxious materials that are

currently seen (except CO

2), as the major

polluters of the environment. Carbon

monoxide (CO), unburned hydrocarbons (HC),

oxides of nitrogen (NOx) and some solid

matter, including a small lead content.

7The device most commonly used to clean

up vehicle exhausts is the catalytic converter.

It is fitted into the vehicle’s exhaust system

and uses precious metals (platinum and

palladium or rhodium) as catalysts to speed

up the reaction between the pollutants and

the oxygen in the exhaust gases. CO and HC

being oxidised to form H

2O and CO2and (in

the three-way type of catalytic converter) NOx

being reduced to N

2.

8The converter consists of an element of

ceramic honeycomb, coated with a

combination of precious metals in such a way

as to produce a vast surface area over which

the exhaust gases must flow. The three-way

closed-loop type converter fitted to these

models can remove over 90% of pollutants.

9The catalytic converter is a reliable and

simple device that needs no maintenance.

However there are some facts that an owner

should be aware if the converter is to function

properly for its full service life (see

illustration).

a)DO NOT use leaded petrol in a vehicle

equipped with a catalytic converter. The

lead will coat the precious metals,

reducing their converting efficiency and

will eventually destroy the converter.

Fuel and exhaust systems - exhaust and emissions 4C•3

10.9 The catalytic converter is protected

by heat shields

8.5 AIR switchover valve

1 Connection to brake servo vacuum hose

2 Connection to cut-off valve

7.1 AIR cut-off valve

1 Connection to AIR pump

2 Connection to AIR switchover valve

3 Connection to AIR non-return valve

4C

Page 129 of 525

b)Always keep the ignition and fuel systems

well maintained according to the

manufacturers schedule (see “Routine

maintenance” and the relevant Chapter).

In particular, ensure that the air cleaner

filter element, the fuel filter and the spark

plugs are renewed at the correct intervals.

If the inlet air/fuel mixture is allowed to

become too rich due to neglect, the

unburned surplus will enter and burn in

the catalytic converter, overheating the

element and eventually destroying the

converter.

c)If the engine develops a misfire, do not

drive the vehicle at all (or at least as little

as possible) until the fault is cured. The

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

d)The engine control indicator (the outline

of an engine with a lightning symbol

superimposed), will light when the ignition

is switched on and the engine is started,

then it will go out. While it may light briefly

while the engine is running, it should go

out again immediately and stays unlit. If it

lights and stays on while the engine is

running, seek the advice of a Vauxhall

dealer as soon as possible. A fault has

occurred in the fuel injection/ignition

system that, apart from increasing fuel

consumption and impairing the engine’s

performance, may damage the catalytic

converter.

e)DO NOT push or tow-start the vehicle.

This will soak the catalytic converter in

unburned fuel causing it to overheat when

the engine does start see (b) above.

f)DO NOT switch off the ignition at high

engine speeds. If the ignition is switched

off at anything above idle speed,

unburned fuel will enter the (very hot)

catalytic converter, with the possible risk

of its igniting on the element and

damaging the converter.

g)DO NOT use fuel or engine oil additives.

These may contain substances harmful to

the catalytic converter.

h)DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke. The unburned

carbon deposits will clog the converter

passages and reduce its efficiency; in

severe cases the element will overheat.

i)Remember that the catalytic converter

operates at very high temperatures hence

the heat shields on the vehicle’s under-

body and the casing will become hot

enough to ignite combustible materials

that brush against it. DO NOT, therefore,

park the vehicle in dry undergrowth, over

long grass or over piles of dead leaves.

j)Remember that the catalytic converter is

FRAGlLE. Do not strike it with tools during

servicing work. Take great care when

working on the exhaust system. Ensure

that the converter is well clear of any

jacks or other lifting gear used to raise thevehicle. Do not drive the vehicle over

rough ground, road humps, etc., in such a

way as to ground the exhaust system.

k)In some cases, particularly when the

vehicle is new and/or is used for

stop/start driving, a sulphurous smell (like

that of rotten eggs) may be noticed from

the exhaust. This is common to many

catalytic converter-equipped vehicles and

seems to be due to the small amount of

sulphur found in some petrol’s reacting

with hydrogen in the exhaust to produce

hydrogen sulphide (CS) gas. While this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the

vehicle has covered a few thousand miles

the problem should disappear. In the

meanwhile a change of driving style or of

the brand of petrol may effect a solution.

l)The catalytic converter, used on a

well-maintained and well-driven vehicle,

should last for between 50 000 and 100

000 miles. From this point on, careful

checks should be made at all specified

service intervals of the CO level to ensure

that the converter is still operating

efficiently. If the converter is no longer

effective it must be renewed.

11Carbon canister - removal

and refitting

3

Removal

1Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members

(see “Jacking and Vehicle Support”).

2Remove the front right hand wheel and

wheel arch liner.

3Note the hose and pipe connections to the

canister, or label them, to ensure that they are

reconnected to their original unions, then

disconnect them (see illustration). Unscrew

the two nuts securing the canister mounting

bracket to the vehicle body.

Refitting

4Refitting is a reversal of removal, however

ensure correct fitment of hose and pipes.

12Oxygen sensor (catalytic

converter models) - removal

and refitting

3

Note: This sensor is also known as a Lambda

sensor.

Removal

1Disconnect the battery negative lead.

2Disconnect the oxygen sensor wiring plug,

which is located behind the coolant expansion

tank.

3Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members.

4On DOHC models, remove the engine

undershield, as described in Chapter 11.

5On models fitted with Multec injection

system, the sensor is screwed into the

exhaust manifold. Trace the wiring from the

sensor itself to the connector (either clipped

to the radiator cooling fan shroud or behind

the coolant expansion tank). Release it from

any clips or ties; disconnect the wiring before

unscrewing the sensor.

6On other models, unscrew the oxygen

sensor from the front section of the exhaust

system (see illustration). It is advisable to

wear gloves, as the exhaust system will be

extremely hot.

7Withdraw the oxygen sensor and its wiring,

taking care not to burn the wiring on the

exhaust system. If the sensor is to be re-used,

take care that the sealing ring is not lost, and

that the sensor is not dropped.

Refitting

8If a new sensor is being fitted, it will be

supplied with the threads coated in a special

grease to prevent it seizing in the exhaust

system.

9If the original sensor is being refitted,

ensure that the screw thread is clean. Coat

the thread with a lithium based copper grease

(i.e. Vauxhall Part No. 90295397).

10Refitting is a reversal of removal. Check

the exhaust system for leakage when the

engine is re-started.

4C•4Fuel and exhaust systems - exhaust and emissions

12.6 Oxygen sensor location in front

section of exhaust system - DOHC models

11.3 Charcoal canister

A Vent to atmosphere

B Vapour feed hose from filler pipe

C Vapour exhaust hose to inlet tract

D Control valve vacuum pipe from

throttle body

Page 130 of 525

13Exhaust manifold - removal

and refitting

3

Note:New manifold-to-cylinder head, and

manifold-to-downpipe, gaskets must be used

on refitting. Exhaust manifolds on DOHC

models are of tubular design, which form part

of the front section of the exhaust.

Removal

1Disconnect the battery negative lead.

2Disconnect the HT leads from the spark

plugs, if necessary labelling them to ensure

refitting to the correct cylinders.

3Loosen the clamp screw and disconnect

the air cleaner hot air tube from the shroud on

the manifold, if fitted. Remove the securing

screws and withdraw the hot air shroud from

the manifold.

4Working under the manifold, unscrew and

remove the four bolts securing the exhaust

downpipe to the manifold.

5If fitted, disconnect the oxygen sensor

wiring

6Separate the downpipe from the manifold,

and support with wire or string. Do not allow

the front section of the exhaust system to hang

under its own weight. Recover the gasket.

7Unscrew the securing nuts, and withdraw

the manifold from the cylinder head (see

illustration). Recover the gasket.

8It is possible that some of the manifold

studs may be unscrewed from the cylinder

head when the manifold securing nuts are

unscrewed. In this event, the studs should be

screwed back into the cylinder head once the

manifold has been removed, using two

manifold nuts locked together.

Refitting

9Refit the manifold using a new gasket, and

tighten the securing nuts to the specified

torque.

10Reconnect the exhaust downpipe to the

manifold, using a new gasket and tighten the

securing bolts to the specified torque.

11Further refitting is a reversal of removal.

14Exhaust system - checking,

removal and refitting

2

Note: All relevant gaskets and/or sealing rings

should be renewed on refitting

Checking

1Periodically, the exhaust system should be

checked for signs of leaks or damage. Also

inspect the exhaust system rubber

mountings, and renew if necessary.

2Small holes or cracks can be repaired using

proprietary exhaust repair products, but

where more serious corrosion or damage is

evident, renewal will be necessary.

Removal

3The original factory-fitted exhaust system

consists of four separate sections, all of which

can be renewed individually.

4On models fitted with a catalytic converter,

an oxygen sensor is fitted to the front section

of the exhaust. The catalytic converter is fitted

in place of the front expansion box in the

conventional exhaust system. The

manufacturers do not specify any renewal

intervals for the catalytic converter.

5Before renewing an individual section of the

exhaust system, it is wise to inspect the

remaining sections. If corrosion or damage is

evident on more than one section of the

system, it may prove more economical to

renew the entire system.

6Individual sections of the exhaust system

can be removed as follows.

Front section - SOHC models

7On models with a catalytic converter,

disconnect the battery negative lead, and

disconnect the oxygen sensor wiring plug,

which is located behind the coolant expansion

tank.

8Raise the vehicle, and support securely on

axle stands placed under the body side

members (see “Jacking and Vehicle

Support”).

9Unscrew the two securing bolts, and

disconnect the exhaust front section from the

front expansion box or catalytic converter (as

applicable) at the flexible joint. Recover the

sealing ring and the springs (see illustration).10Unbolt the exhaust front section from the

bracket on the cylinder block (see

illustration).

11Unscrew and remove the four bolts

securing the downpipe to the exhaust

manifold, and withdraw the exhaust front

section (see illustration). Recover the

downpipe-to-manifold gasket.

Refitting

12Refitting is a reversal of removal, but use a

new gasket when reconnecting the downpipe

to the manifold, and a new sealing ring when

connecting the flexible joint. Tighten all fixings

to the specified torque.

Front section - DOHC models

Removal

13Proceed as described in paragraphs 7

and 8.

14Remove the engine undershield, as

described in Chapter 11.

15Proceed as described in paragraphs 9

and 10.

16Working in the engine compartment,

remove the bolts securing the exhaust

manifold heat shield to the cylinder head.

17Unscrew the two lower exhaust manifold

securing nuts that also secure the heat shield

brackets, and withdraw the heat shield (see

illustration).

18Unscrew the remaining manifold securing

nuts, then withdraw the manifold/exhaust

front section from the vehicle. Recover the

manifold gasket.

Fuel and exhaust systems - exhaust and emissions 4C•5

14.10 Exhaust front section support

bracket - SOHC models

14.11 Unscrewing a downpipe-to-exhaust

manifold bolt - SOHC models

14.9 Exhaust front section flexible joint -

SOHC models13.7 Unscrewing an exhaust manifold

securing nut - SOHC models

4C