ECU OPEL CALIBRA 1988 Service Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 27 of 525

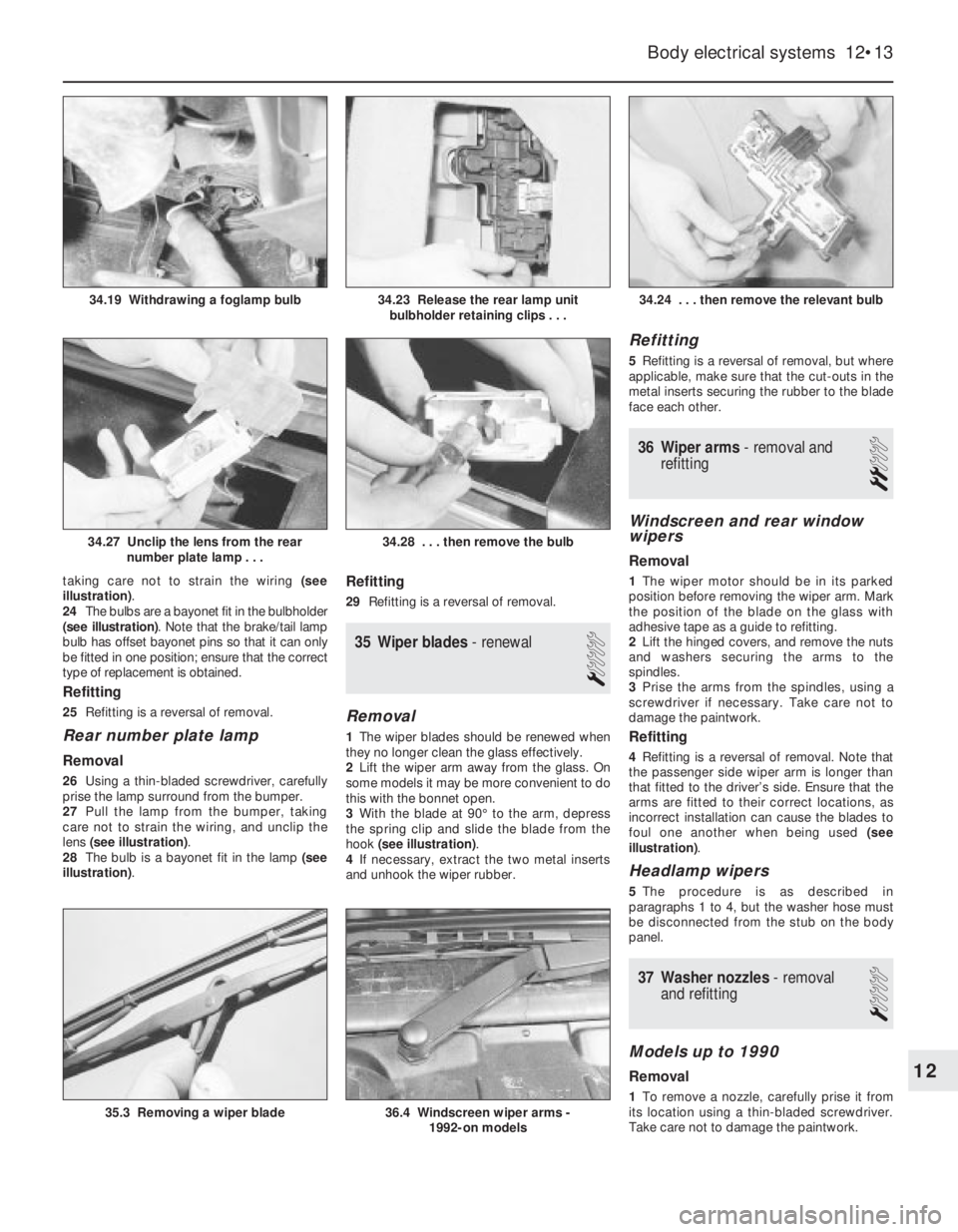

taking care not to strain the wiring (see

illustration).

24The bulbs are a bayonet fit in the bulbholder

(see illustration). Note that the brake/tail lamp

bulb has offset bayonet pins so that it can only

be fitted in one position; ensure that the correct

type of replacement is obtained.

Refitting

25Refitting is a reversal of removal.

Rear number plate lamp

Removal

26Using a thin-bladed screwdriver, carefully

prise the lamp surround from the bumper.

27Pull the lamp from the bumper, taking

care not to strain the wiring, and unclip the

lens (see illustration).

28The bulb is a bayonet fit in the lamp (see

illustration).

Refitting

29Refitting is a reversal of removal.

35Wiper blades -renewal

1

Removal

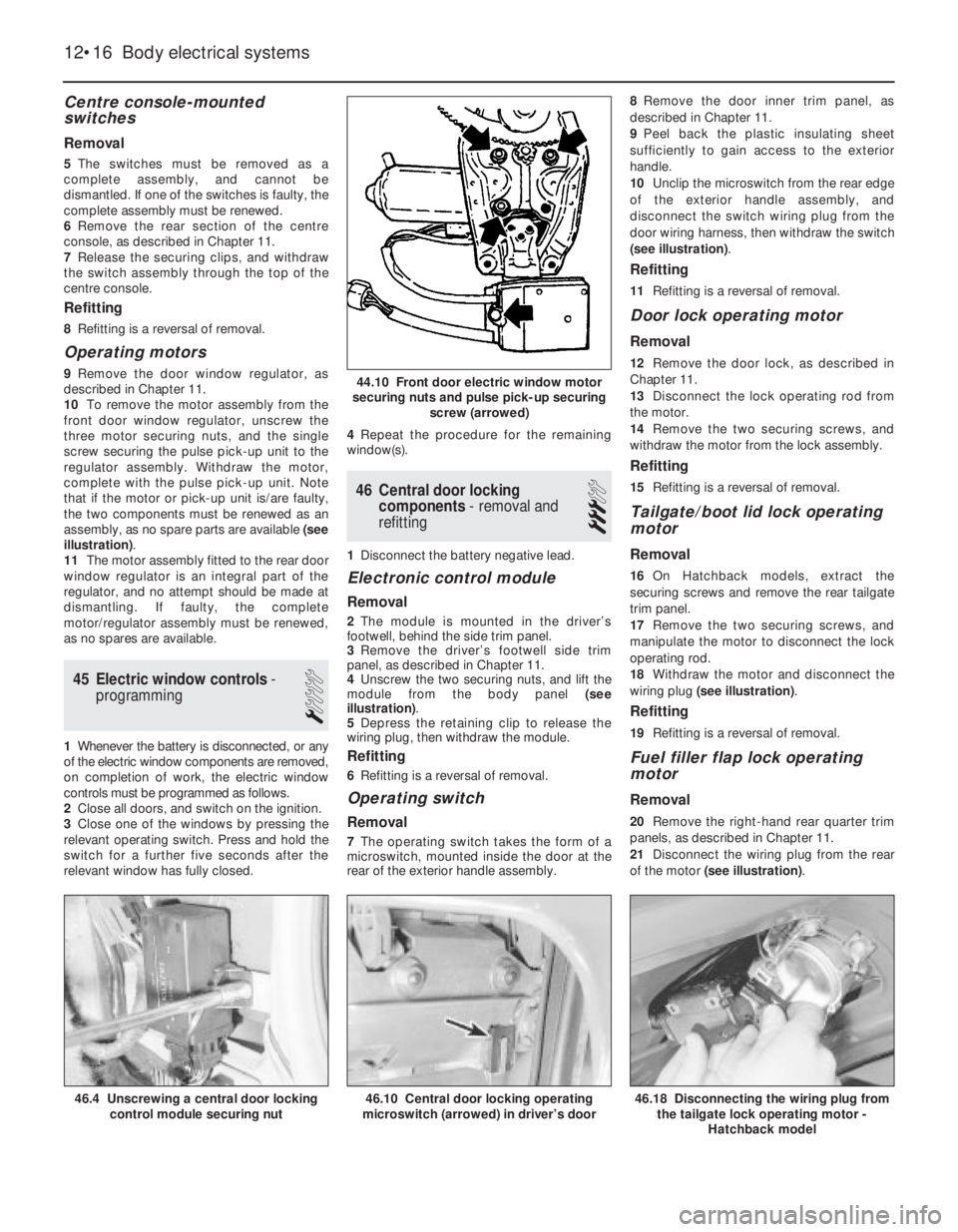

1The wiper blades should be renewed when

they no longer clean the glass effectively.

2Lift the wiper arm away from the glass. On

some models it may be more convenient to do

this with the bonnet open.

3With the blade at 90°to the arm, depress

the spring clip and slide the blade from the

hook (see illustration).

4If necessary, extract the two metal inserts

and unhook the wiper rubber.

Refitting

5Refitting is a reversal of removal, but where

applicable, make sure that the cut-outs in the

metal inserts securing the rubber to the blade

face each other.

36Wiper arms - removal and

refitting

2

Windscreen and rear window

wipers

Removal

1The wiper motor should be in its parked

position before removing the wiper arm. Mark

the position of the blade on the glass with

adhesive tape as a guide to refitting.

2Lift the hinged covers, and remove the nuts

and washers securing the arms to the

spindles.

3Prise the arms from the spindles, using a

screwdriver if necessary. Take care not to

damage the paintwork.

Refitting

4Refitting is a reversal of removal. Note that

the passenger side wiper arm is longer than

that fitted to the driver’s side. Ensure that the

arms are fitted to their correct locations, as

incorrect installation can cause the blades to

foul one another when being used (see

illustration).

Headlamp wipers

5The procedure is as described in

paragraphs 1 to 4, but the washer hose must

be disconnected from the stub on the body

panel.

37Washer nozzles - removal

and refitting

1

Models up to 1990

Removal

1To remove a nozzle, carefully prise it from

its location using a thin-bladed screwdriver.

Take care not to damage the paintwork.

Body electrical systems 12•13

34.24 . . . then remove the relevant bulb

36.4 Windscreen wiper arms -

1992-on models35.3 Removing a wiper blade

34.28 . . . then remove the bulb34.27 Unclip the lens from the rear

number plate lamp . . .

34.23 Release the rear lamp unit

bulbholder retaining clips . . .34.19 Withdrawing a foglamp bulb

12

Page 28 of 525

2Disconnect the washer hose and withdraw

the nozzle.

Refitting

3To refit, reconnect the washer hose to the

nozzle, and push the nozzle into its locating

hole.

4The nozzles can be adjusted by inserting a

pin into the jet, and swivelling it to the

required position.

1991-on models

5The nozzles on all later models are fitted

with twin jets.

6On some later models, the nozzles are

heated; the circuit is fed through fuse 29 and

is live whenever the ignition is switched on.

Current is regulated by a Positive

Temperature Coefficient (PTC) resistor that

takes outside temperature into account.

38Windscreen wiper motor and

linkage - removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arms, as described in

Section 36.

3Remove the windscreen cowl panel, as

described in Chapter 11.

4Disconnect the wiring plug from the motor

(see illustration). 5Unscrew the three bolts securing the

motor/linkage assembly to the body, then

withdraw the assembly (see illustrations).

6If desired, the motor can be removed from

the linkage by unscrewing the three securing

bolts. Do not attempt to dismantle the linkage.

Refitting

7Refitting is a reversal of removal.

39Tailgate wiper motor -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arm, as described in

Section 36.

3Extract the securing screws, and remove

the rear tailgate trim panel.

4Disconnect the motor wiring plug.

5Unscrew the two motor securing bolts,

noting the earth leads under the bolt heads

(see illustration).

6Manipulate the motor assembly from the

tailgate.

Refitting

7Refitting is a reversal of removal, ensuring

that the cut-out in the drive spindle rubber

seal engages with the notch in the drive

spindle (see illustration).

40Headlamp wiper motor -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arm, as described in

Section 36.

3Remove the headlamp, as described in

Section 25.

4Disconnect the motor wiring plug.

5Unscrew the two bolts securing the motor

mounting bracket to the body panel, then

withdraw the motor (see illustrations).

Refitting

6Refitting is a reversal of removal.

12•14Body electrical systems

38.4 Disconnecting the windscreen wiper

motor wiring plug

38.5B . . . then withdraw the assembly

40.5B . . . and withdraw the motor40.5A Unscrew the headlamp wiper motor

securing bolts . . .39.7 Cut-out in tailgate wiper motor drive

spindle rubber seal must engage with

notch in drive spindle

39.5 Tailgate wiper motor assembly. Note

earth leads under heads of securing bolts

38.5A Unscrew the windscreen wiper

motor/linkage assembly securing bolts . .

Page 29 of 525

41Washer fluid reservoir -

removal and refitting

2

1Disconnect the battery negative lead.

Models without headlamp wash

Removal

2Disconnect the wiring from the washer

pump.

3Disconnect the washer fluid hose from the

pump. Be prepared for fluid spillage.

4Remove the screw(s) securing the reservoir

to the body, and withdraw the reservoir.

Refitting

5Refitting is a reversal of removal.

Models with headlamp wash

Removal

6On models with headlamp wash, the

reservoir is in two sections, the upper section,

which can be removed from the engine

compartment, and the lower section, which

must be removed from under the wheel arch.

7Disconnect the wiring from the headlamp

wash non-return valve in the top of the

reservoir.

8Disconnect the washer fluid hoses from the

non-return valve. Be prepared for fluid spillage.

9Remove the screw securing the upper

section of the reservoir to the wing panel.

10Loosen the plastic collar securing the

upper section of the reservoir to the lower

section, then withdraw the upper section of

the reservoir from the engine compartment.

11To remove the lower section of the

reservoir, continue as follows.

12Apply the handbrake, then jack up the

front of the vehicle, and support on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.

13Remove the securing screws, and

withdraw the plastic cover from thebumper/front wing to expose the lower

section of the reservoir.

14Remove the horns, (Section 22).

15Remove the wheel arch liner, (Chapter 11).

16Disconnect the wiring and the fluid hoses

from the washer pump. Be prepared for fluid

spillage.

17Unscrew the bolts securing the

horn/reservoir support bracket and the

reservoir to the body, then withdraw the

bracket and the reservoir (see illustration).

Refitting

18Refitting is a reversal of removal.

42Washer pump -removal and

refitting

2

1Disconnect the battery negative lead.

Models without headlamp wash

Removal

2Disconnect the wiring and the fluid hose

from the pump. Be prepared for fluid spillage.

3Pull the pump from the reservoir, being

prepared for fluid spillage if the reservoir still

contains fluid.

4Examine the condition of the sealing

grommet, and renew if necessary, and clean the

gauze filter at the end of the pump pick-up tube.

Refitting

5Refitting is a reversal of removal.

Models with headlamp wash

6Apply the handbrake, then jack up the front

of the vehicle, and support on axle stands

positioned under the body side members.

7Remove the securing screws, and withdraw

the plastic cover from the bumper/front wing

to expose the lower section of the fluid

reservoir.

8Remove the wheel arch liner, (Chapter 11).

9Proceed as described in paragraphs 2 to 5

inclusive.

43Headlamp washer fluid

non-return valve -removal

and refitting

2

Removal

1The valve is located on a bracket attached

to the upper section of the washer fluid

reservoir (see illustration).

2Disconnect the battery negative lead.

3Disconnect the wiring and the fluid hoses

from the valve. Be prepared for fluid spillage.

4Remove the screw securing the valve

bracket to the reservoir, and withdraw the

valve.

Refitting

5Refitting is a reversal of removal.

44Electric window components

- removal and refitting

3

Note: Whenever any of the electric window

components are removed, after refitting the

components, the electric window controls

must be programmed, as described in

Section 45.

1Disconnect the battery negative lead.

Rear door-mounted switches

Removal

2Prise the plastic surround from the door

interior handle.

3Carefully prise the switch from its location,

and disconnect the wiring plug.

Refitting

4Refitting is a reversal of removal, but make

sure that the wiring is routed so that it does

not foul the electric window or lock operating

components.

Body electrical systems 12•15

43.1 Headlamp washer fluid non-return valve (arrowed)41.17 Horn/washer fluid reservoir support bracket securing bolt

(arrowed) - model with headlamp wash

12

Page 30 of 525

Centre console-mounted

switches

Removal

5The switches must be removed as a

complete assembly, and cannot be

dismantled. If one of the switches is faulty, the

complete assembly must be renewed.

6Remove the rear section of the centre

console, as described in Chapter 11.

7Release the securing clips, and withdraw

the switch assembly through the top of the

centre console.

Refitting

8Refitting is a reversal of removal.

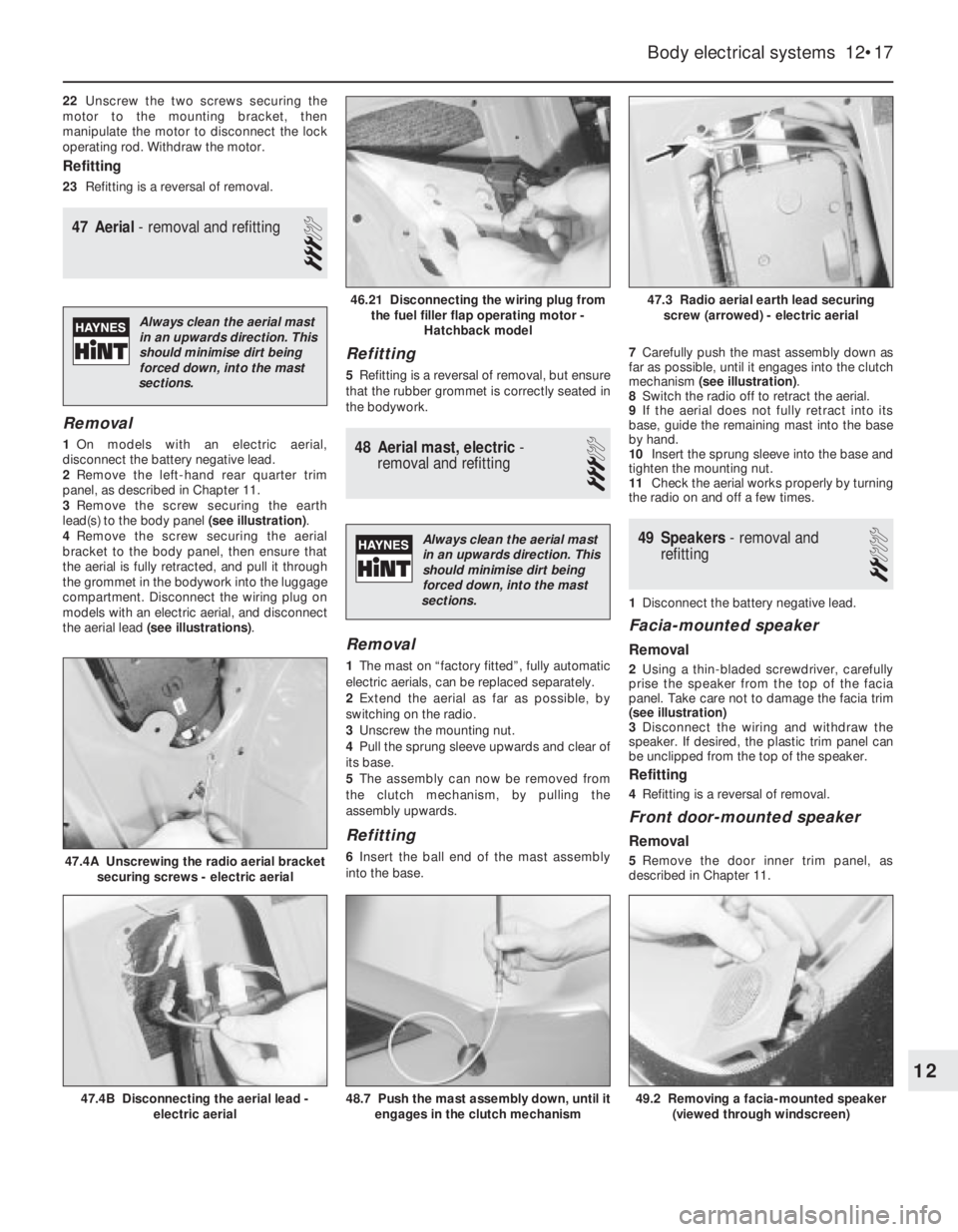

Operating motors

9Remove the door window regulator, as

described in Chapter 11.

10To remove the motor assembly from the

front door window regulator, unscrew the

three motor securing nuts, and the single

screw securing the pulse pick-up unit to the

regulator assembly. Withdraw the motor,

complete with the pulse pick-up unit. Note

that if the motor or pick-up unit is/are faulty,

the two components must be renewed as an

assembly, as no spare parts are available (see

illustration).

11The motor assembly fitted to the rear door

window regulator is an integral part of the

regulator, and no attempt should be made at

dismantling. If faulty, the complete

motor/regulator assembly must be renewed,

as no spares are available.

45Electric window controls -

programming

1

1Whenever the battery is disconnected, or any

of the electric window components are removed,

on completion of work, the electric window

controls must be programmed as follows.

2Close all doors, and switch on the ignition.

3Close one of the windows by pressing the

relevant operating switch. Press and hold the

switch for a further five seconds after the

relevant window has fully closed.4Repeat the procedure for the remaining

window(s).

46Central door locking

components -removal and

refitting

3

1Disconnect the battery negative lead.

Electronic control module

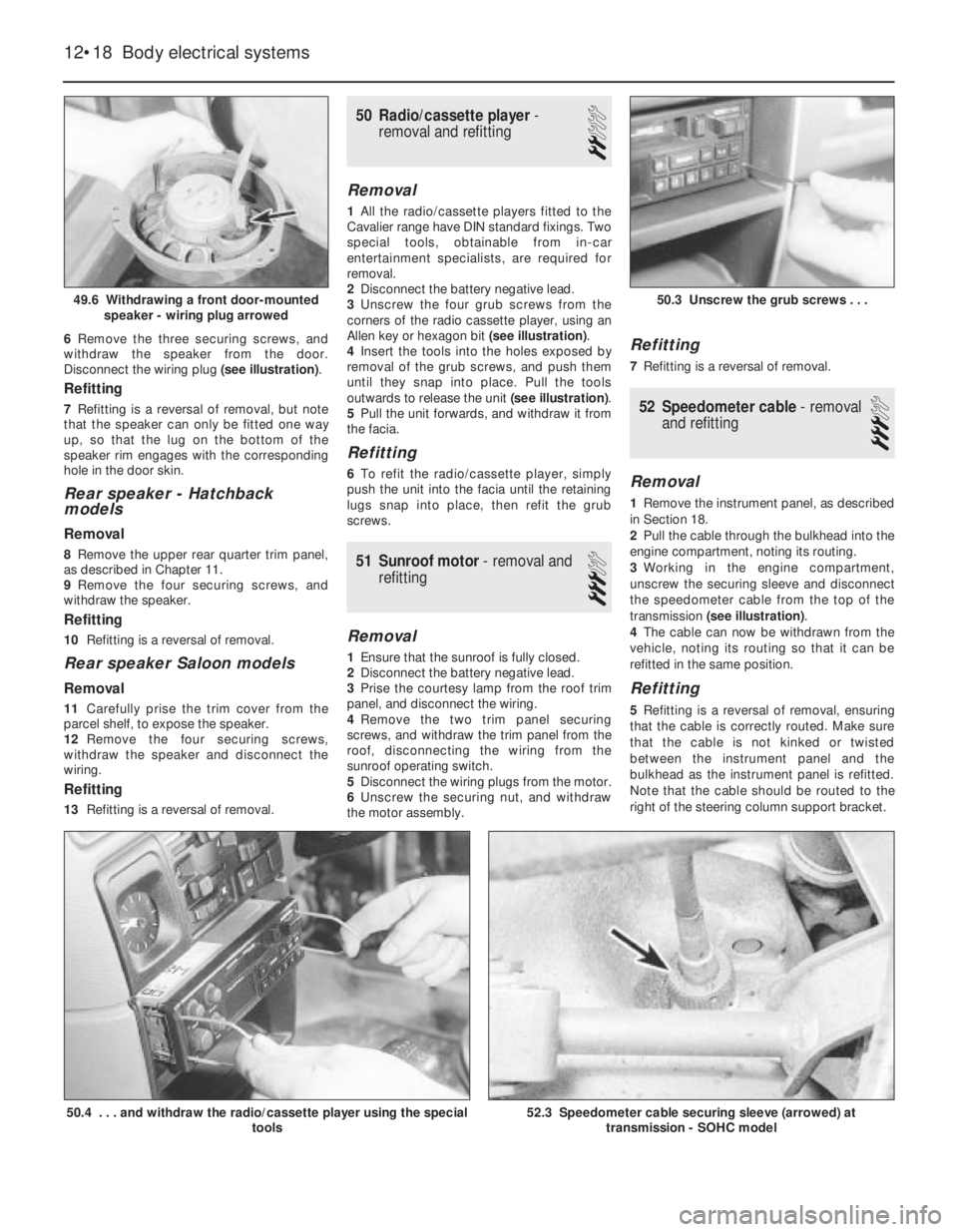

Removal

2The module is mounted in the driver’s

footwell, behind the side trim panel.

3Remove the driver’s footwell side trim

panel, as described in Chapter 11.

4Unscrew the two securing nuts, and lift the

module from the body panel (see

illustration).

5Depress the retaining clip to release the

wiring plug, then withdraw the module.

Refitting

6Refitting is a reversal of removal.

Operating switch

Removal

7The operating switch takes the form of a

microswitch, mounted inside the door at the

rear of the exterior handle assembly.8Remove the door inner trim panel, as

described in Chapter 11.

9Peel back the plastic insulating sheet

sufficiently to gain access to the exterior

handle.

10Unclip the microswitch from the rear edge

of the exterior handle assembly, and

disconnect the switch wiring plug from the

door wiring harness, then withdraw the switch

(see illustration).

Refitting

11Refitting is a reversal of removal.

Door lock operating motor

Removal

12Remove the door lock, as described in

Chapter 11.

13Disconnect the lock operating rod from

the motor.

14Remove the two securing screws, and

withdraw the motor from the lock assembly.

Refitting

15Refitting is a reversal of removal.

Tailgate/boot lid lock operating

motor

Removal

16On Hatchback models, extract the

securing screws and remove the rear tailgate

trim panel.

17Remove the two securing screws, and

manipulate the motor to disconnect the lock

operating rod.

18Withdraw the motor and disconnect the

wiring plug (see illustration).

Refitting

19Refitting is a reversal of removal.

Fuel filler flap lock operating

motor

Removal

20Remove the right-hand rear quarter trim

panels, as described in Chapter 11.

21Disconnect the wiring plug from the rear

of the motor (see illustration).

12•16Body electrical systems

44.10 Front door electric window motor

securing nuts and pulse pick-up securing

screw (arrowed)

46.10 Central door locking operating

microswitch (arrowed) in driver’s door46.18 Disconnecting the wiring plug from

the tailgate lock operating motor -

Hatchback model46.4 Unscrewing a central door locking

control module securing nut

Page 31 of 525

22Unscrew the two screws securing the

motor to the mounting bracket, then

manipulate the motor to disconnect the lock

operating rod. Withdraw the motor.

Refitting

23Refitting is a reversal of removal.

47Aerial - removal and refitting

3

Removal

1On models with an electric aerial,

disconnect the battery negative lead.

2Remove the left-hand rear quarter trim

panel, as described in Chapter 11.

3Remove the screw securing the earth

lead(s) to the body panel (see illustration).

4Remove the screw securing the aerial

bracket to the body panel, then ensure that

the aerial is fully retracted, and pull it through

the grommet in the bodywork into the luggage

compartment. Disconnect the wiring plug on

models with an electric aerial, and disconnect

the aerial lead (see illustrations).

Refitting

5Refitting is a reversal of removal, but ensure

that the rubber grommet is correctly seated in

the bodywork.

48Aerial mast, electric -

removal and refitting

3

Removal

1The mast on “factory fitted”, fully automatic

electric aerials, can be replaced separately.

2Extend the aerial as far as possible, by

switching on the radio.

3Unscrew the mounting nut.

4Pull the sprung sleeve upwards and clear of

its base.

5The assembly can now be removed from

the clutch mechanism, by pulling the

assembly upwards.

Refitting

6Insert the ball end of the mast assembly

into the base.7Carefully push the mast assembly down as

far as possible, until it engages into the clutch

mechanism (see illustration).

8Switch the radio off to retract the aerial.

9If the aerial does not fully retract into its

base, guide the remaining mast into the base

by hand.

10Insert the sprung sleeve into the base and

tighten the mounting nut.

11Check the aerial works properly by turning

the radio on and off a few times.

49Speakers - removal and

refitting

2

1Disconnect the battery negative lead.

Facia-mounted speaker

Removal

2Using a thin-bladed screwdriver, carefully

prise the speaker from the top of the facia

panel. Take care not to damage the facia trim

(see illustration)

3Disconnect the wiring and withdraw the

speaker. If desired, the plastic trim panel can

be unclipped from the top of the speaker.

Refitting

4Refitting is a reversal of removal.

Front door-mounted speaker

Removal

5Remove the door inner trim panel, as

described in Chapter 11.

Body electrical systems 12•17

47.4A Unscrewing the radio aerial bracket

securing screws - electric aerial

49.2 Removing a facia-mounted speaker

(viewed through windscreen)48.7 Push the mast assembly down, until it

engages in the clutch mechanism47.4B Disconnecting the aerial lead -

electric aerial

47.3 Radio aerial earth lead securing

screw (arrowed) - electric aerial46.21 Disconnecting the wiring plug from

the fuel filler flap operating motor -

Hatchback model

12

Always clean the aerial mast

in an upwards direction. This

should minimise dirt being

forced down, into the mast

sections.

Always clean the aerial mast

in an upwards direction. This

should minimise dirt being

forced down, into the mast

sections.

Page 32 of 525

6Remove the three securing screws, and

withdraw the speaker from the door.

Disconnect the wiring plug (see illustration).

Refitting

7Refitting is a reversal of removal, but note

that the speaker can only be fitted one way

up, so that the lug on the bottom of the

speaker rim engages with the corresponding

hole in the door skin.

Rear speaker -Hatchback

models

Removal

8Remove the upper rear quarter trim panel,

as described in Chapter 11.

9Remove the four securing screws, and

withdraw the speaker.

Refitting

10Refitting is a reversal of removal.

Rear speaker Saloon models

Removal

11Carefully prise the trim cover from the

parcel shelf, to expose the speaker.

12Remove the four securing screws,

withdraw the speaker and disconnect the

wiring.

Refitting

13Refitting is a reversal of removal.

50Radio/cassette player -

removal and refitting

2

Removal

1All the radio/cassette players fitted to the

Cavalier range have DIN standard fixings. Two

special tools, obtainable from in-car

entertainment specialists, are required for

removal.

2Disconnect the battery negative lead.

3Unscrew the four grub screws from the

corners of the radio cassette player, using an

Allen key or hexagon bit (see illustration).

4Insert the tools into the holes exposed by

removal of the grub screws, and push them

until they snap into place. Pull the tools

outwards to release the unit (see illustration).

5Pull the unit forwards, and withdraw it from

the facia.

Refitting

6To refit the radio/cassette player, simply

push the unit into the facia until the retaining

lugs snap into place, then refit the grub

screws.

51Sunroof motor - removal and

refitting

3

Removal

1Ensure that the sunroof is fully closed.

2Disconnect the battery negative lead.

3Prise the courtesy lamp from the roof trim

panel, and disconnect the wiring.

4Remove the two trim panel securing

screws, and withdraw the trim panel from the

roof, disconnecting the wiring from the

sunroof operating switch.

5Disconnect the wiring plugs from the motor.

6Unscrew the securing nut, and withdraw

the motor assembly.

Refitting

7Refitting is a reversal of removal.

52Speedometer cable - removal

and refitting

3

Removal

1Remove the instrument panel, as described

in Section 18.

2Pull the cable through the bulkhead into the

engine compartment, noting its routing.

3Working in the engine compartment,

unscrew the securing sleeve and disconnect

the speedometer cable from the top of the

transmission (see illustration).

4The cable can now be withdrawn from the

vehicle, noting its routing so that it can be

refitted in the same position.

Refitting

5Refitting is a reversal of removal, ensuring

that the cable is correctly routed. Make sure

that the cable is not kinked or twisted

between the instrument panel and the

bulkhead as the instrument panel is refitted.

Note that the cable should be routed to the

right of the steering column support bracket.

12•18Body electrical systems

49.6 Withdrawing a front door-mounted

speaker - wiring plug arrowed

50.4 . . . and withdraw the radio/cassette player using the special

tools52.3 Speedometer cable securing sleeve (arrowed) at

transmission - SOHC model

50.3 Unscrew the grub screws . . .

Page 34 of 525

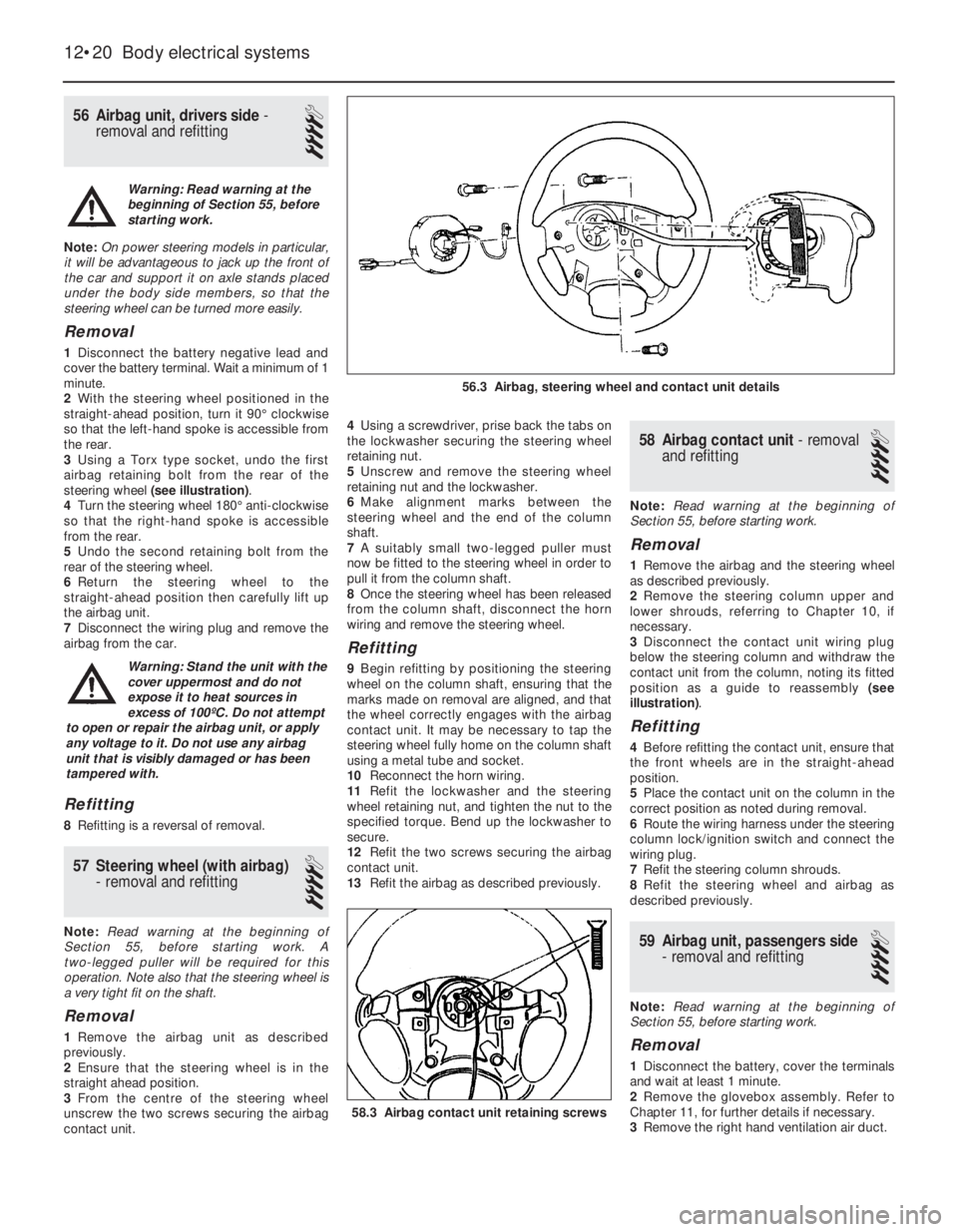

56Airbag unit, drivers side -

removal and refitting

4

Note:On power steering models in particular,

it will be advantageous to jack up the front of

the car and support it on axle stands placed

under the body side members, so that the

steering wheel can be turned more easily.

Removal

1Disconnect the battery negative lead and

cover the battery terminal. Wait a minimum of 1

minute.

2With the steering wheel positioned in the

straight-ahead position, turn it 90°clockwise

so that the left-hand spoke is accessible from

the rear.

3Using a Torx type socket, undo the first

airbag retaining bolt from the rear of the

steering wheel (see illustration).

4Turn the steering wheel 180°anti-clockwise

so that the right-hand spoke is accessible

from the rear.

5Undo the second retaining bolt from the

rear of the steering wheel.

6Return the steering wheel to the

straight-ahead position then carefully lift up

the airbag unit.

7Disconnect the wiring plug and remove the

airbag from the car.

Refitting

8Refitting is a reversal of removal.

57Steering wheel (with airbag)

-removal and refitting

4

Note: Read warning at the beginning of

Section 55, before starting work. A

two-legged puller will be required for this

operation. Note also that the steering wheel is

a very tight fit on the shaft.

Removal

1Remove the airbag unit as described

previously.

2Ensure that the steering wheel is in the

straight ahead position.

3From the centre of the steering wheel

unscrew the two screws securing the airbag

contact unit.4Using a screwdriver, prise back the tabs on

the lockwasher securing the steering wheel

retaining nut.

5Unscrew and remove the steering wheel

retaining nut and the lockwasher.

6Make alignment marks between the

steering wheel and the end of the column

shaft.

7A suitably small two-legged puller must

now be fitted to the steering wheel in order to

pull it from the column shaft.

8Once the steering wheel has been released

from the column shaft, disconnect the horn

wiring and remove the steering wheel.

Refitting

9Begin refitting by positioning the steering

wheel on the column shaft, ensuring that the

marks made on removal are aligned, and that

the wheel correctly engages with the airbag

contact unit. It may be necessary to tap the

steering wheel fully home on the column shaft

using a metal tube and socket.

10Reconnect the horn wiring.

11Refit the lockwasher and the steering

wheel retaining nut, and tighten the nut to the

specified torque. Bend up the lockwasher to

secure.

12Refit the two screws securing the airbag

contact unit.

13Refit the airbag as described previously.

58Airbag contact unit -removal

and refitting

4

Note: Read warning at the beginning of

Section 55, before starting work.

Removal

1Remove the airbag and the steering wheel

as described previously.

2Remove the steering column upper and

lower shrouds, referring to Chapter 10, if

necessary.

3Disconnect the contact unit wiring plug

below the steering column and withdraw the

contact unit from the column, noting its fitted

position as a guide to reassembly (see

illustration).

Refitting

4Before refitting the contact unit, ensure that

the front wheels are in the straight-ahead

position.

5Place the contact unit on the column in the

correct position as noted during removal.

6Route the wiring harness under the steering

column lock/ignition switch and connect the

wiring plug.

7Refit the steering column shrouds.

8Refit the steering wheel and airbag as

described previously.

59Airbag unit, passengers side

- removal and refitting

4

Note: Read warning at the beginning of

Section 55, before starting work.

Removal

1Disconnect the battery, cover the terminals

and wait at least 1 minute.

2Remove the glovebox assembly. Refer to

Chapter 11, for further details if necessary.

3Remove the right hand ventilation air duct.

12•20Body electrical systems

58.3 Airbag contact unit retaining screws

56.3 Airbag, steering wheel and contact unit details

Warning: Read warning at the

beginning of Section 55, before

starting work.

Warning: Stand the unit with the

cover uppermost and do not

expose it to heat sources in

excess of 100ºC. Do not attempt

to open or repair the airbag unit, or apply

any voltage to it. Do not use any airbag

unit that is visibly damaged or has been

tampered with.

Page 53 of 525

Wiring diagrams 12•39

12

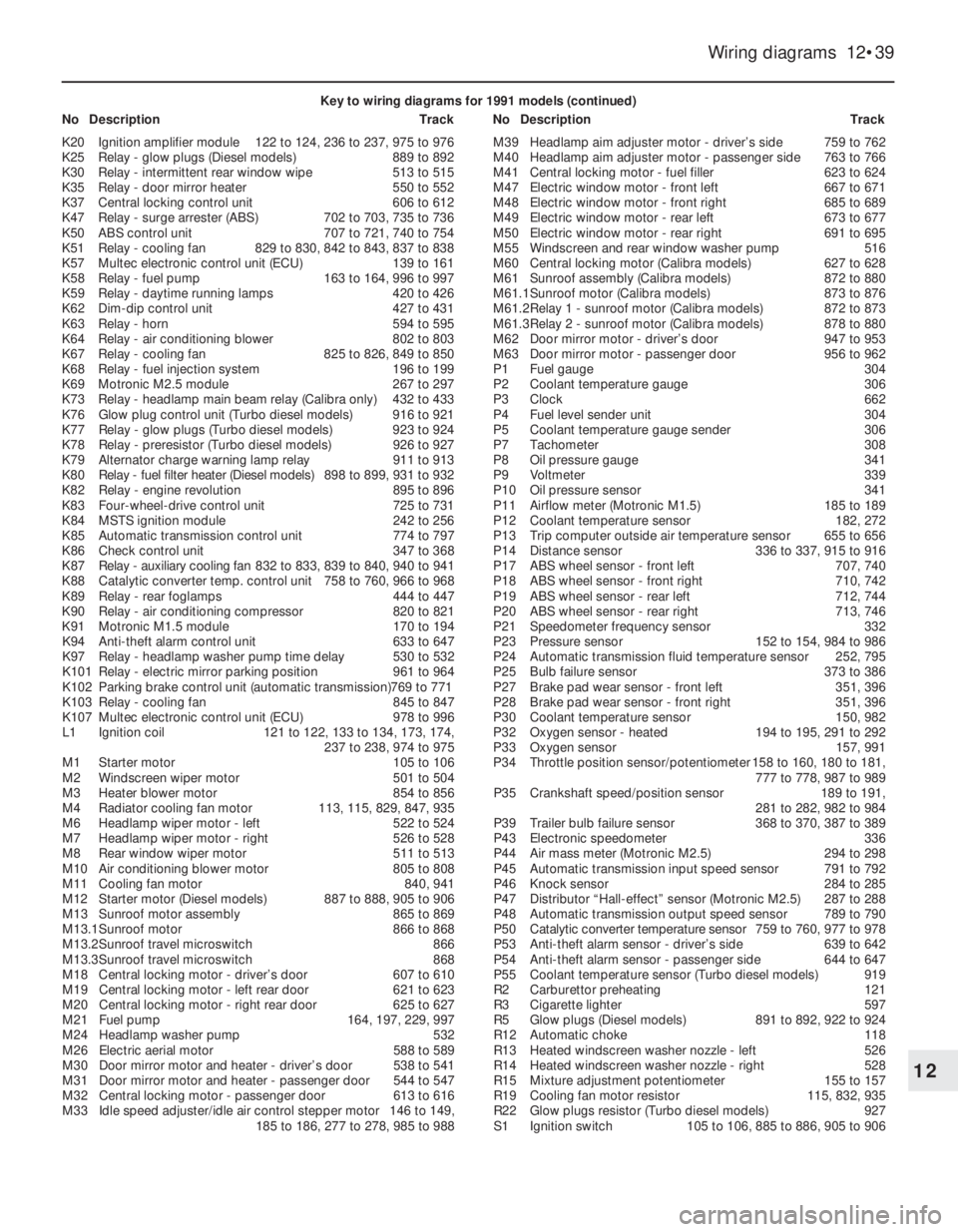

Key to wiring diagrams for 1991 models (continued)

NoDescriptionTrackNoDescriptionTrack

K20Ignition amplifier module122 to 124, 236 to 237, 975 to 976

K25Relay - glow plugs (Diesel models)889 to 892

K30Relay - intermittent rear window wipe513 to 515

K35Relay - door mirror heater550 to 552

K37Central locking control unit606 to 612

K47Relay - surge arrester (ABS)702 to 703, 735 to 736

K50ABS control unit707 to 721, 740 to 754

K51Relay - cooling fan829 to 830, 842 to 843, 837 to 838

K57Multec electronic control unit (ECU)139 to 161

K58Relay - fuel pump163 to 164, 996 to 997

K59Relay - daytime running lamps420 to 426

K62Dim-dip control unit427 to 431

K63Relay - horn594 to 595

K64Relay - air conditioning blower802 to 803

K67Relay - cooling fan825 to 826, 849 to 850

K68Relay - fuel injection system196 to 199

K69Motronic M2.5 module267 to 297

K73Relay - headlamp main beam relay (Calibra only)432 to 433

K76Glow plug control unit (Turbo diesel models)916 to 921

K77Relay - glow plugs (Turbo diesel models)923 to 924

K78Relay - preresistor (Turbo diesel models)926 to 927

K79Alternator charge warning lamp relay911 to 913

K80Relay - fuel filter heater (Diesel models)898 to 899, 931 to 932

K82Relay - engine revolution895 to 896

K83Four-wheel-drive control unit725 to 731

K84MSTS ignition module242 to 256

K85Automatic transmission control unit774 to 797

K86Check control unit347 to 368

K87Relay - auxiliary cooling fan832 to 833, 839 to 840, 940 to 941

K88Catalytic converter temp. control unit758 to 760, 966 to 968

K89Relay - rear foglamps444 to 447

K90Relay - air conditioning compressor820 to 821

K91Motronic M1.5 module170 to 194

K94Anti-theft alarm control unit633 to 647

K97Relay - headlamp washer pump time delay530 to 532

K101Relay - electric mirror parking position961 to 964

K102Parking brake control unit (automatic transmission)769 to 771

K103Relay - cooling fan845 to 847

K107Multec electronic control unit (ECU)978 to 996

L1Ignition coil121 to 122, 133 to 134, 173, 174,

237 to 238, 974 to 975

M1Starter motor105 to 106

M2Windscreen wiper motor501 to 504

M3Heater blower motor854 to 856

M4Radiator cooling fan motor113, 115, 829, 847, 935

M6Headlamp wiper motor - left522 to 524

M7Headlamp wiper motor - right526 to 528

M8Rear window wiper motor511 to 513

M10Air conditioning blower motor805 to 808

M11Cooling fan motor840, 941

M12Starter motor (Diesel models)887 to 888, 905 to 906

M13Sunroof motor assembly865 to 869

M13.1Sunroof motor866 to 868

M13.2Sunroof travel microswitch866

M13.3Sunroof travel microswitch868

M18Central locking motor - driver’s door607 to 610

M19Central locking motor - left rear door621 to 623

M20Central locking motor - right rear door625 to 627

M21Fuel pump164, 197, 229, 997

M24Headlamp washer pump532

M26Electric aerial motor588 to 589

M30Door mirror motor and heater - driver’s door538 to 541

M31Door mirror motor and heater - passenger door544 to 547

M32Central locking motor - passenger door613 to 616

M33Idle speed adjuster/idle air control stepper motor146 to 149,

185 to 186, 277 to 278, 985 to 988M39Headlamp aim adjuster motor - driver’s side759 to 762

M40Headlamp aim adjuster motor - passenger side763 to 766

M41Central locking motor - fuel filler623 to 624

M47Electric window motor - front left667 to 671

M48Electric window motor - front right685 to 689

M49Electric window motor - rear left673 to 677

M50Electric window motor - rear right691 to 695

M55Windscreen and rear window washer pump516

M60Central locking motor (Calibra models)627 to 628

M61Sunroof assembly (Calibra models)872 to 880

M61.1Sunroof motor (Calibra models)873 to 876

M61.2Relay 1 - sunroof motor (Calibra models)872 to 873

M61.3Relay 2 - sunroof motor (Calibra models)878 to 880

M62Door mirror motor - driver’s door947 to 953

M63Door mirror motor - passenger door956 to 962

P1Fuel gauge304

P2Coolant temperature gauge306

P3Clock662

P4Fuel level sender unit304

P5Coolant temperature gauge sender306

P7Tachometer308

P8Oil pressure gauge341

P9Voltmeter339

P10Oil pressure sensor341

P11Airflow meter (Motronic M1.5)185 to 189

P12Coolant temperature sensor182, 272

P13Trip computer outside air temperature sensor655 to 656

P14Distance sensor336 to 337, 915 to 916

P17ABS wheel sensor - front left707, 740

P18ABS wheel sensor - front right710, 742

P19ABS wheel sensor - rear left712, 744

P20ABS wheel sensor - rear right713, 746

P21Speedometer frequency sensor332

P23Pressure sensor152 to 154, 984 to 986

P24Automatic transmission fluid temperature sensor252, 795

P25Bulb failure sensor373 to 386

P27Brake pad wear sensor - front left351, 396

P28Brake pad wear sensor - front right351, 396

P30Coolant temperature sensor150, 982

P32Oxygen sensor - heated194 to 195, 291 to 292

P33Oxygen sensor157, 991

P34Throttle position sensor/potentiometer158 to 160, 180 to 181,

777 to 778, 987 to 989

P35Crankshaft speed/position sensor189 to 191,

281 to 282, 982 to 984

P39Trailer bulb failure sensor368 to 370, 387 to 389

P43Electronic speedometer336

P44Air mass meter (Motronic M2.5)294 to 298

P45Automatic transmission input speed sensor791 to 792

P46Knock sensor284 to 285

P47Distributor “Hall-effect” sensor (Motronic M2.5)287 to 288

P48Automatic transmission output speed sensor789 to 790

P50Catalytic converter temperature sensor759 to 760, 977 to 978

P53Anti-theft alarm sensor - driver’s side639 to 642

P54Anti-theft alarm sensor - passenger side644 to 647

P55Coolant temperature sensor (Turbo diesel models)919

R2Carburettor preheating121

R3Cigarette lighter597

R5Glow plugs (Diesel models)891 to 892, 922 to 924

R12Automatic choke118

R13Heated windscreen washer nozzle - left526

R14Heated windscreen washer nozzle - right528

R15Mixture adjustment potentiometer155 to 157

R19Cooling fan motor resistor115, 832, 935

R22Glow plugs resistor (Turbo diesel models)927

S1Ignition switch105 to 106, 885 to 886, 905 to 906

Page 90 of 525

HEI (High Energy Ignition)

system

5This comprises of a breakerless distributor

and an electronic switching/amplifier module

along with the coil and spark plugs.

6The electrical impulse that is required to

switch off the low tension circuit is generated

by a magnetic trigger coil in the distributor. A

trigger wheel rotates within a magnetic stator,

the magnetic field being provided by a

permanent magnet. The magnetic field across

the two poles (stator arm and trigger wheel) is

dependent on the air gap between the two

poles. When the air gap is at its minimum, the

trigger wheel arm is directly opposite the

stator arm, and this is the trigger point. As the

magnetic flux between the stator arm and

trigger wheel varies, a voltage is induced in the

trigger coil mounted below the trigger wheel.

This voltage is sensed and then amplified by

the electronic module, and used to switch off

the low tension circuit. There is one trigger arm

and one stator arm for each cylinder.

7The ignition advance is a function of the

distributor, and is controlled both

mechanically and by a vacuum-operated

system. The mechanical governor mechanism

consists of two weights that move out from

the distributor shaft due to centrifugal force as

the engine speed rises. As the weights move

outwards, they rotate the trigger wheel

relative to the distributor shaft and so

advance the spark. The weights are held in

position by two light springs, and it is the

tension of the springs that is largely

responsible for correct spark advancement.

8The vacuum control consists of a

diaphragm, one side of which is connected by

way of a small-bore hose to the carburettor,

and the other side to the distributor.

Depression in the inlet manifold and

carburettor, which varies with engine speed

and throttle position, causes the diaphragm to

move, so moving the baseplate and

advancing or retarding the spark. A fine

degree of control is achieved by a spring in

the diaphragm assembly.

MSTS-i (Microprocessor-

controlled Spark Timing System)

9This system comprises a “Hall-effect”

distributor (or a crankshaft speed/position

sensor on X 16 SZ models), a manifold pressure

sensor, an oil temperature sensor, and a

module, along with the coil and spark plugs.

10On 1.6 litre models, the electrical impulse

that is required to switch off the low tension

circuit is generated by a sensor in the

distributor. A trigger vane rotates in the gap

between a permanent magnet and the sensor.

The trigger vane has four cut-outs, one for

each cylinder. When one of the trigger vane

cut-outs is in line with the sensor, magnetic

flux can pass between the magnet and the

sensor. When a trigger vane segment is in line

with the sensor, the magnetic flux is diverted

through the trigger vane away from thesensor. The sensor senses the change in

magnetic flux, and sends an impulse to the

MSTS-i module, which switches off the low

tension circuit.

11On 1.8 litre models, the electrical impulse

that is required to switch off the low tension

circuit is generated by a crankshaft

speed/position sensor, which is activated by a

toothed wheel on the crankshaft. The toothed

wheel has 35 equally spaced teeth, with a gap

in the 36th position. The gap is used by the

sensor to determine the crankshaft position

relative to TDC (top dead centre) of No 1 piston.

12Engine load information is supplied to the

MSTS-i module by a pressure sensor, which

is connected to the carburettor by a vacuum

pipe. Additional information is supplied by an

oil temperature sensor. The module selects

the optimum ignition advance setting based

on the information received from the sensors.

The degree of advance can thus be constantly

varied to suit the prevailing engine conditions.

Multec, with MSTS-i

13The ignition system is fully electronic in

operation and incorporates the Electronic

Control Unit (ECU) mounted in the driver’s

footwell. A distributor (driven off the camshaft

left-hand end and incorporating the amplifier

module) as well as the octane coding plug,

the spark plugs, HT leads, ignition HT coil and

associated wiring.

14The ECU controls both the ignition system

and the fuel injection system, integrating the

two in a complete engine management

system. Refer to Chapters 4B and 4C for

further information that is not detailed here.

15For ignition the ECU receives information

in the form of electrical impulses or signals

from the distributor (giving it the engine speed

and crankshaft position), from the coolant

temperature sensor (giving it the engine

temperature) and from the manifold absolute

pressure sensor (giving it the load on the

engine). In addition, the ECU receives input

from the octane coding plug (to provide

ignition timing appropriate to the grade of fuel

used) and from, where fitted, the automatic

transmission control unit (to smooth gear

changing by retarding the ignition as changes

are made).

16All these signals are compared by the

ECU with set values pre-programmed

(mapped) into its memory. Considering this

information, the ECU selects the ignition

timing appropriate to those values and

controls the ignition HT coil by way of the

amplifier module accordingly.

17The system is so sensitive that, at idle

speed, the ignition timing may be constantly

changing; this should be remembered if trying

to check the ignition timing.

18The system fitted to C18 NZ models, is

similar to that described above, except that

the amplifier module is separate. The ECU

determines engine speed and crankshaft

position using a sensor mounted in the

right-hand front end of the engine’s cylinderblock; this registers with a 58-toothed disc

mounted on the crankshaft so that the gap left

by the missing two teeth provides a reference

point, so enabling the ECU to recognise TDC.

19Note that this simplifies the distributor’s

function, which is merely to distribute the HT

pulse to the appropriate spark plug; it has no

effect whatsoever on the ignition timing.

DIS (Direct Ignition System)

20On all X16 SZ engines, and on C20 XE

(DOHC) engines from 1993-on, a DIS (Direct

Ignition System) module is used in place of

the distributor and coil. On the X16 SZ engine

the DIS module is attached to the camshaft

housing in the position normally occupied by

the distributor. On the C20 XE engine, a

camshaft phase sensor is attached to the

cylinder head at the non-driven end of the

exhaust camshaft, in the position normally

occupied by the distributor. The DIS module

is attached, by a bracket, to the cylinder head

at the non-driven end of the inlet camshaft.

21The DIS module consists of two ignition

coils and an electronic control module housed

in a cast casing. Each ignition coil supplies

two spark plugs with HT voltage. One spark is

provided in a cylinder with its piston on the

compression stroke, and one spark is

provided to a cylinder with its piston on the

exhaust stroke. This means that a “wasted

spark” is supplied to one cylinder during each

ignition cycle, but this has no detrimental

effect. This system has the advantage that

there are no moving parts (therefore there is

no wear), and the system is largely

maintenance-free.

Motronic M4.1 and M1.5

22This system controls both the ignition and

the fuel injection systems.

23The Motronic module receives information

from a crankshaft speed/position sensor, an

engine coolant temperature sensor mounted

in the thermostat housing. A throttle position

sensor, an airflow meter, and on models fitted

with a catalytic converter, an oxygen sensor

mounted in the exhaust system (Chapter 4C).

24The module provides outputs to control

the fuel pump, fuel injectors, idle speed and

ignition circuit. Using the inputs from the

various sensors, the module computes the

optimum ignition advance, and fuel injector

pulse duration, to suit the prevailing engine

conditions. This system gives very accurate

control of the engine under all conditions,

improving fuel consumption and driveability,

and reducing exhaust gas emissions.

25Further details of the fuel injection system

components are given in Chapter 4B.

Motronic M2.5 and M2.8

26The system is similar to that described for

SOHC models, with the following differences.

27Along with the crankshaft speed/position

sensor, a “Hall-effect” distributor is used

(similar to that described in this Section, with

the MSTS-i system).

Engine electrical systems 5•3

5

Page 91 of 525

28The system also incorporates a separate

ignition amplifier module that transmits

amplified signals from the main system

module to trigger the HT pulse from the

ignition coil. The module is mounted on the

ignition coil’s bracket/baseplate.

29Additionally, the Motronic module

receives information from a cylinder

block-mounted knock sensor, which senses

“knocking” (or pre-ignition) just as it begins to

occur, enabling the module to retard the

ignition timing, thus preventing engine

damage.

Simtec 56.1

30This system uses increased amount of

electronic components instead of mechanical

parts as sensors and actuators with the

Simtec engine management system. This

provides more precise operating data as well

as greater problem free motoring.

31The control unit is equipped with

electronic ignition control. Called ‘Micropro-

cessor Spark Timing System, inductive

triggered’, (or MSTS-i), and means that the

mechanical high voltage distributor is no

longer needed. It is located behind the trim

panel, on the right-hand side footwell (door

pillar).

32The ignition coil is replaced by a dual

spark ignition coil, which is switched directly

by the output stages in the control unit.

33A camshaft sensor will maintain

emergency operation, should the crankshaft

inductive pulse pick-up, malfunction. These

sense TDC (‘Top Dead Centre’), crankshaft

angle and engine speed. The signals are used

by the control unit to calculate ignition point

and for fuel injection.

34The ‘hot film airflow meter’ determines the

mass of air taken in by the engine. The system

uses this information to calculate the correct

amount of fuel needed for injection in the

engine.

35The air inlet temperature sensor (NTC), is

fitted in the air inlet duct between the air

cleaner and the hot mass air flow meter.

36A controlled canister purge valve is

actuated by the system. The tank ventilation is

monitored closely with the Lambda control (or

oxygen sensor) and adaptation by the

computer within the control unit.

37A knock control system is also fitted. This

eliminates the need for octane number

adjustment, as it is performed automatically

through the control unit.

3Electrical system -

precautions

1It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. Along with the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.

2Always remove rings, watches, etc. before

working on the electrical system. Even with

the battery disconnected, discharge could

occur if a component live terminal is earthed

through a metal object. This could cause a

shock or nasty burn.

3Do not reverse the battery connections.

Components such as the alternator, or any

other component having semi-conductor

circuitry, could be irreparably damaged.

4If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

5Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

6The battery leads and alternator wiring

must be disconnected before carrying out any

electric welding on the vehicle.

7Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

8Engine management modules are very

sensitive components, and certain

precautions must be taken, to avoid damage

to the module when working on a vehicle

equipped with an engine management

system, as follows.

9When carrying out welding operations on

the vehicle using electric welding equipment,

the battery and alternator should be

disconnected.

10Although underbonnet-mounted modules

will tolerate normal underbonnet conditions,

they can be adversely affected by excess heat

or moisture. If using welding equipment or

pressure washing equipment near the

module, take care not to direct heat, or jets of

water or steam, at the module. If this cannot

be avoided, remove the module from the

vehicle, and protect its wiring plug with a

plastic bag.

11Before disconnecting any wiring, or

removing components, always ensure that the

ignition is switched off.

12Do not attempt to improvise fault

diagnosis procedures using a test lamp or

multimeter, as irreparable damage could be

caused to the module.13After working on ignition/engine

management system components, ensure

that all wiring is correctly reconnected before

reconnecting the battery or switching on the

ignition.

14Any ignition system that uses a

“Hall-effect” generator in the distributor,

cannot be tested. Test equipment that uses

its own power source (e.g. an ohmmeter),

when connected to the distributor or the

“Hall-effect” generator, will be damaged.

4Ignition system testing -

general

3

Note: Refer to Section 3 before proceeding.

Always switch off the ignition before

disconnecting or connecting any component

and when using a multi-meter to check

resistances. Any voltmeter or multi-meter

used to test ignition system components must

have an impedance of 10 meg ohms or

greater

1Electronic ignition system components are

normally very reliable. Most faults are far more

likely to be due to loose or dirty connections,

or to “tracking” of HT voltage due to dirt,

dampness or damaged insulation than to

component failure. Always check all wiring

thoroughly before condemning an electrical

component and work methodically to

eliminate all other possibilities before deciding

that a particular component is faulty.

2The old practice of checking for a spark by

holding the live end of a HT lead a short

distance away from the engine is not

recommended. Not only is there a high risk of

a powerful electric shock, but the ignition coil

or amplifier module will be damaged.

Similarly, never try to “diagnose” misfires by

pulling off one HT lead at a time. Note also

that the ECU is at risk if the system is

triggered with an open (i.e., not properly

earthed) HT circuit; ECU’s are very expensive

to replace, so take care!

3If you are in any doubt as to your skill and

ability to test an ignition system component or

if you do not have the required equipment,

take the vehicle to a suitably equipped

Vauxhall dealer. It is better to pay the labour

charges involved in having the vehicle

checked by an expert than to risk damage to

the system or to yourself.

4If the engine either will not turn over at all,

or only turns very slowly, check the battery

and starter motor. Connect a voltmeter across

the battery terminals (meter positive probe to

battery positive terminal) and disconnect the

ignition coil HT lead from the distributor cap

and earth. Note the voltage reading obtained

while turning over the engine on the starter for

(no more than) ten seconds. If the reading

obtained is less than approximately 9.5 volts,

check the battery, battery connections, starter

motor and charging system.

5•4Engine electrical systems

Warning: The HT voltage

generated by an electronic

ignition system is extremely

high and, in certain

circumstances, could prove fatal. Take

care to avoid receiving electric shocks

from the HT side of the ignition system.

Do not handle HT leads, or touch the

distributor or coil, when the engine is

running. If tracing faults in the HT circuit,

use well-insulated tools to manipulate live

leads