ECU OPEL CALIBRA 1988 Service Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 103 of 525

26DIS module - removal and

refitting

3

Note: Refer to Section 3 before proceeding.

Removal

1Disconnect the battery negative lead.

2Disconnect the HT leads from the module

terminals noting their locations to ensure

correct refitting. Note that the HT lead cylinder

numbers are stamped on the module, next to

each terminal, and similar numbers appear on

each HT lead.

3Disconnect the module wiring plug.

4On X16 SZ engines, undo the three screws

and remove the module from the camshaft

housing. On C20 XE engines, undo the bolts

securing the DIS module mounting bracket tothe cylinder head and remove the module and

bracket. Note the installed position of DIS

module on its mounting bracket, undo the four

securing screws and separate the module

from the bracket.

Refitting

5Refitting is a reversal of removal.

27Camshaft phase sensor (C20

XE engine) -removal and

refitting

3

Note: Refer to Section 3 before proceeding.

Removal

1The camshaft phase sensor is mounted on

the end of the cylinder head in the position

normally occupied by the distributor.2Disconnect the battery negative lead.

3Disconnect the wiring plug then undo the

phase sensor securing bolts.

4Withdraw the phase sensor from the

cylinder head, then undo the bolt and remove

the phase sensor disc from the end of the

camshaft.

Refitting

5Refitting is a reversal of removal.

5•16Engine electrical systems

Page 106 of 525

Aluminium or plastic mesh, or glass fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll and

trim it to the approximate size and shape

required. Then pull off the backing paper (if

used) and stick the tape over the hole. It can

be overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs filling and

re-spraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally those proprietary kits that contain a

tin of filler paste and a tube of resin hardener

are best for this type of repair. These can be

used directly from the tube. A wide, flexible

plastic or nylon applicator will be found

invaluable for imparting a smooth and well-

contoured finish to the surface of the filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack)

otherwise the filler will set too rapidly or too

slowly. Using the applicator apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

filler surface. When a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long the paste will become sticky and begin to

“pick up” on the applicator. Continue to add

thin layers of filler paste at twenty-minute

intervals until the level of the filler is just proud

of the surrounding bodywork.

Once the filler has hardened, excess can be

removed using a metal plane or file. From then

on, progressively finer grades of abrasive

paper should be used, starting with a 40

grade production paper and finishing with 400

grade wet-and-dry paper. Always wrap the

abrasive paper around a flat rubber, cork, or

wooden block otherwise the surface of the

filler will not be completely flat. During the

smoothing of the filler surface the wet-and-dry

paper should be periodically rinsed in water.

This will ensure that a very smooth finish is

imparted to the filler at the final stage.

At this stage the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork.

Rinse the repair area with clean water, until all

the dust produced by the rubbing-down

operation has gone.Spray the whole repair area with a light coat

of primer. This will show up any imperfections

in the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and again smooth the surface

with abrasive paper. If bodystopper is used, it

can be mixed with cellulose thinners to form a

thin paste that is ideal for filling small holes.

Repeat this spray and repair procedure until

you are satisfied that the surface of the filler,

and the feathered edge of the paintwork are

perfect. Clean the repair area with clean water

and allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out

in a warm, dry, windless and dust free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust that would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight miss-match in paint colours.

Bodywork fittings (e.g. chrome strips, door

handles, etc.), will also need to be masked off.

Use genuine masking tape and several

thicknesses of newspaper for the masking

operations.

Before beginning to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint rather

than one thick one. Using 400 grade

wet-and-dry paper, rub down the surface of

the primer until it is smooth. While doing this,

the work area should be thoroughly doused

with water, and the wet-and-dry paper

periodically rinsed in water. Allow to dry

before spraying on more paint.

Spray on the top coat, again building up the

thickness by using several thin layers of paint.

Start spraying in the centre of the repair area

and then work outwards, with a side-to-side

motion, until the whole repair area and about

2 inches of the surrounding original paintwork

is covered. Remove all masking material 10 to

15 minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then using a paintwork renovator or a

very fine cutting paste, blend the edges of the

paint into the existing paintwork. Finally, apply

wax polish.

Plastic components

With the use of more and more plastic body

components (e.g. bumpers, spoilers, and in

some cases major body panels), repair of

more serious damage to such items has

become a matter of either entrusting repair

work to a specialist in this field, or renewing

complete components. Repair of suchdamage by the DIY owner is not feasible

owing to the cost of the equipment and

materials required for effecting such repairs.

The basic technique involves making a groove

along the line of the crack in the plastic using

a rotary burr in a power drill. The damaged

part is then welded back together by using a

hot air gun to heat up and fuse a plastic filler

rod into the groove. Any excess plastic is then

removed and the area rubbed down to a

smooth finish. It is important that a filler rod of

the correct plastic is used, as body

components can be made of a variety of

different types (e.g. polycarbonate, ABS,

polypropylene).

Damage of a less serious nature (abrasions,

minor cracks, etc.), can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions this

is used in similar fashion to the bodywork filler

used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will have a problem of

finding a paint for finishing which is

compatible with the type of plastic used. At

one time the use of a universal paint was not

possible owing to the complex range of

plastics come across in body component

applications. Standard paints, generally, will

not bond to plastic or rubber satisfactorily, but

special paints are available to match any

plastic or rubber finish can be obtained from

dealers. However, it is now possible to obtain

a plastic body parts finishing kit that consists

of a pre-primer treatment, a primer and

coloured top coat. Full instructions are

normally supplied with a kit, but the method of

use is to first apply the pre-primer to the

component concerned and allow it to dry for

up to 30 minutes. Then the primer is applied

and left to dry for about an hour before finally

applying the special coloured top coat. The

result is a correctly coloured component

where the paint will flex with the plastic or

rubber, a property that standard paint does

not normally possess.

5Major body damage - repair

5

Major impact or rust damage should only

be repaired by a Vauxhall dealer or other

competent specialist. Alignment jigs are

needed for successful completion of such

work, superficially effective repairs may leave

dangerous weaknesses in the structure.

Distorted components can also impose

severe stresses on steering and suspension

components with consequent premature

failure.

Bodywork and fittings 11•3

11

Page 107 of 525

6Bonnet - removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2On models fitted with an underbonnet lamp,

disconnect the battery negative lead, then

prise the lamp from the bonnet and disconnect

the wiring. If the bonnet is to be refitted, to aid

routing of the wiring on refitting, tie a length of

string to the end of the wiring. Then withdraw

the wiring through the bonnet and untie the

string, leaving it in position in the bonnet.

3Similarly, disconnect the windscreen

washer fluid hose from the connector in the

bonnet, but tie the string to the connector, to

prevent it from slipping into an inaccessible

position in the bonnet.

4Mark the position of the hinges on the

bonnet.

5With the help of an assistant, support the

weight of the bonnet, then unscrew the

securing bolts from the hinges, and lift the

bonnet from the vehicle (see illustration). If the

bonnet is to be refitted, rest it carefully on rags

or cardboard, to avoid damaging the paint.

6If a new bonnet is to be fitted, transfer all

the serviceable fittings (rubber buffers, lock

striker, etc.), to it.

7If desired, the bonnet hinges can be

removed from the vehicle, after unscrewing

the three bolts in each case securing them to

the upper flanges of the front wings.

Refitting

8Refitting is a reversal of removal,

remembering the following points.

9Align the hinges with the previously made

marks on the bonnet.10If the original bonnet is being refitted,

draw the windscreen washer fluid hose, and

where applicable, the underbonnet lamp

wiring, through the bonnet using the string.

11If the lock striker has been disturbed,

adjust it to the dimension shown (see

illustration), then tighten the locknut.

12If necessary, adjust the hinge bolts and

the front rubber buffers until a good fit is

obtained with the bonnet shut.

7Bonnet lock components -

removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2The bonnet lock hook is riveted to the

bonnet, and removal involves drilling out the

rivet. Secure the hook assembly with a new

rivet when refitting.

3To remove the bonnet lock striker from the

bonnet, loosen the locknut, then unscrew the

striker and recover the washers and spring.

When refitting, adjust the striker dimension as

described in Section 6, paragraph 11, before

tightening the locknut.

4To remove the locking spring, disconnect

the end of the bonnet release cable from the

spring. Then unhook the end of the spring

from the slot in the front body panel, and

manipulate the spring out through the top of

the panel, taking care not to damage the paint.

Refitting

5Refitting is a reversal of removal.

6On completion, close the bonnet and check

that the lock and the bonnet release

mechanism operate satisfactorily.

8Bonnet lock release cable -

removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2Unscrew the release cable clip from the

front body panel.

3Disconnect the end of the release cable

from the locking spring under the front body

panel.

4Disconnect the release cable from the

release handle in the driver’s footwell. If

necessary, remove the release handle from its

retainer for access to the cable end.

5Pull the cable assembly through the

grommet in the engine compartment

bulkhead into the engine compartment.

6Release the cable from any remaining clips

and cable-ties, and withdraw it from the

engine compartment.

Refitting

7Refitting is a reversal of removal, but ensure

that the cable is correctly routed, and on

completion check the release mechanism for

satisfactory operation.

9Boot lid (Saloon models) -

removal and refitting

2

Removal

1Open the bonnet lid fully.

2On models with central locking, disconnect

the battery negative lead then disconnect the

wiring from the lock solenoid. If the boot lid is

11•4Bodywork and fittings

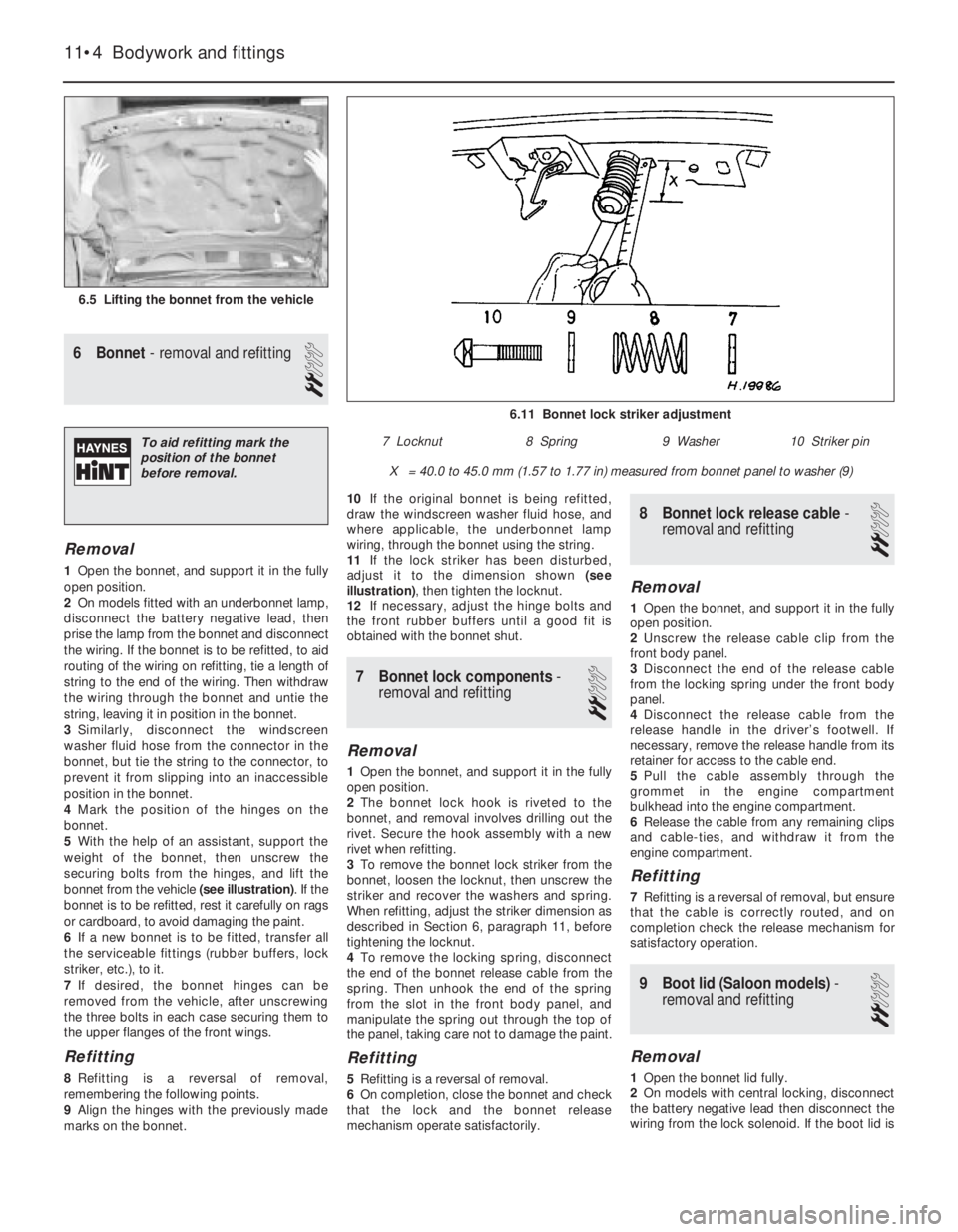

6.5 Lifting the bonnet from the vehicle

6.11 Bonnet lock striker adjustment

X = 40.0 to 45.0 mm (1.57 to 1.77 in) measured from bonnet panel to washer (9)

7 Locknut8 Spring9 Washer10 Striker pinTo aid refitting mark the

position of the bonnet

before removal.

Page 108 of 525

to be refitted, tie a length of string to the end

of the wiring. Then feed the wiring through the

boot lid and untie the string, leaving it in

position in the boot lid to assist refitting.

3Mark the position of the hinges on the boot

lid.

4With the help of an assistant, support the

weight of the boot lid, then unscrew the

securing bolts from the hinges, and lift the

boot lid from the vehicle. If the boot lid is to be

refitted, rest it carefully on rags or cardboard,

to avoid damaging the paint.

5If a new boot lid is to be fitted, transfer all

the serviceable fittings (rubber buffers, lock

mechanism, etc.), to it.

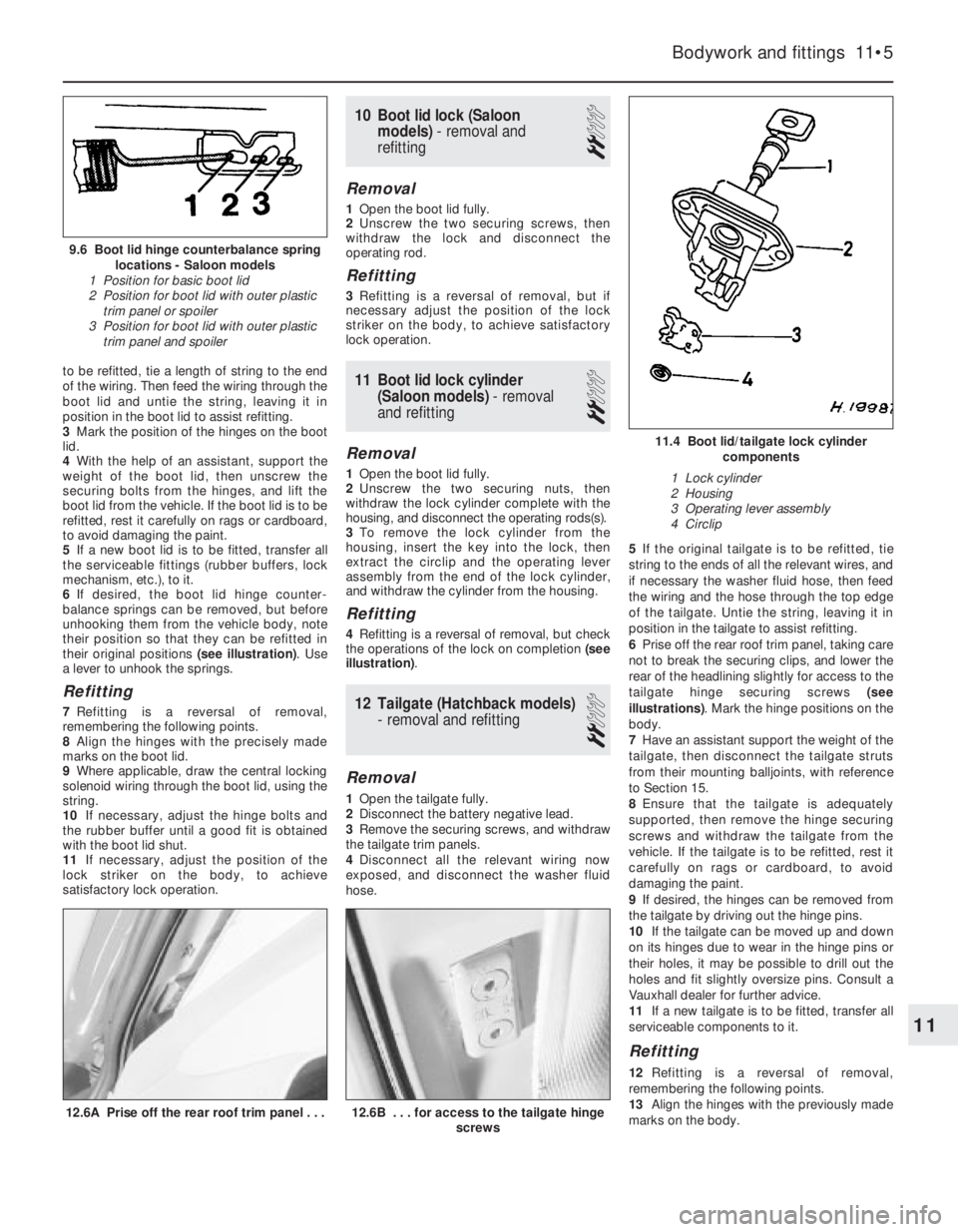

6If desired, the boot lid hinge counter-

balance springs can be removed, but before

unhooking them from the vehicle body, note

their position so that they can be refitted in

their original positions (see illustration). Use

a lever to unhook the springs.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Align the hinges with the precisely made

marks on the boot lid.

9Where applicable, draw the central locking

solenoid wiring through the boot lid, using the

string.

10If necessary, adjust the hinge bolts and

the rubber buffer until a good fit is obtained

with the boot lid shut.

11If necessary, adjust the position of the

lock striker on the body, to achieve

satisfactory lock operation.

10Boot lid lock (Saloon

models) - removal and

refitting

2

Removal

1Open the boot lid fully.

2Unscrew the two securing screws, then

withdraw the lock and disconnect the

operating rod.

Refitting

3Refitting is a reversal of removal, but if

necessary adjust the position of the lock

striker on the body, to achieve satisfactory

lock operation.

11Boot lid lock cylinder

(Saloon models) - removal

and refitting

2

Removal

1Open the boot lid fully.

2Unscrew the two securing nuts, then

withdraw the lock cylinder complete with the

housing, and disconnect the operating rods(s).

3To remove the lock cylinder from the

housing, insert the key into the lock, then

extract the circlip and the operating lever

assembly from the end of the lock cylinder,

and withdraw the cylinder from the housing.

Refitting

4Refitting is a reversal of removal, but check

the operations of the lock on completion (see

illustration).

12Tailgate (Hatchback models)

-removal and refitting

2

Removal

1Open the tailgate fully.

2Disconnect the battery negative lead.

3Remove the securing screws, and withdraw

the tailgate trim panels.

4Disconnect all the relevant wiring now

exposed, and disconnect the washer fluid

hose.5If the original tailgate is to be refitted, tie

string to the ends of all the relevant wires, and

if necessary the washer fluid hose, then feed

the wiring and the hose through the top edge

of the tailgate. Untie the string, leaving it in

position in the tailgate to assist refitting.

6Prise off the rear roof trim panel, taking care

not to break the securing clips, and lower the

rear of the headlining slightly for access to the

tailgate hinge securing screws (see

illustrations). Mark the hinge positions on the

body.

7Have an assistant support the weight of the

tailgate, then disconnect the tailgate struts

from their mounting balljoints, with reference

to Section 15.

8Ensure that the tailgate is adequately

supported, then remove the hinge securing

screws and withdraw the tailgate from the

vehicle. If the tailgate is to be refitted, rest it

carefully on rags or cardboard, to avoid

damaging the paint.

9If desired, the hinges can be removed from

the tailgate by driving out the hinge pins.

10If the tailgate can be moved up and down

on its hinges due to wear in the hinge pins or

their holes, it may be possible to drill out the

holes and fit slightly oversize pins. Consult a

Vauxhall dealer for further advice.

11If a new tailgate is to be fitted, transfer all

serviceable components to it.

Refitting

12Refitting is a reversal of removal,

remembering the following points.

13Align the hinges with the previously made

marks on the body.

Bodywork and fittings 11•5

12.6B . . . for access to the tailgate hinge

screws12.6A Prise off the rear roof trim panel . . .

11.4 Boot lid/tailgate lock cylinder

components

1 Lock cylinder

2 Housing

3 Operating lever assembly

4 Circlip

9.6 Boot lid hinge counterbalance spring

locations - Saloon models

1 Position for basic boot lid

2 Position for boot lid with outer plastic

trim panel or spoiler

3 Position for boot lid with outer plastic

trim panel and spoiler

11

Page 109 of 525

14If the original tailgate is being refitted,

draw the wiring and washer fluid hose (where

applicable) through the tailgate, using the

string.

15If necessary, adjust the hinge bolts and

the rubber buffers, to obtain a good fit when

the tailgate is shut.

16If necessary, adjust the position of the

lock striker on the body, to achieve

satisfactory lock operation.

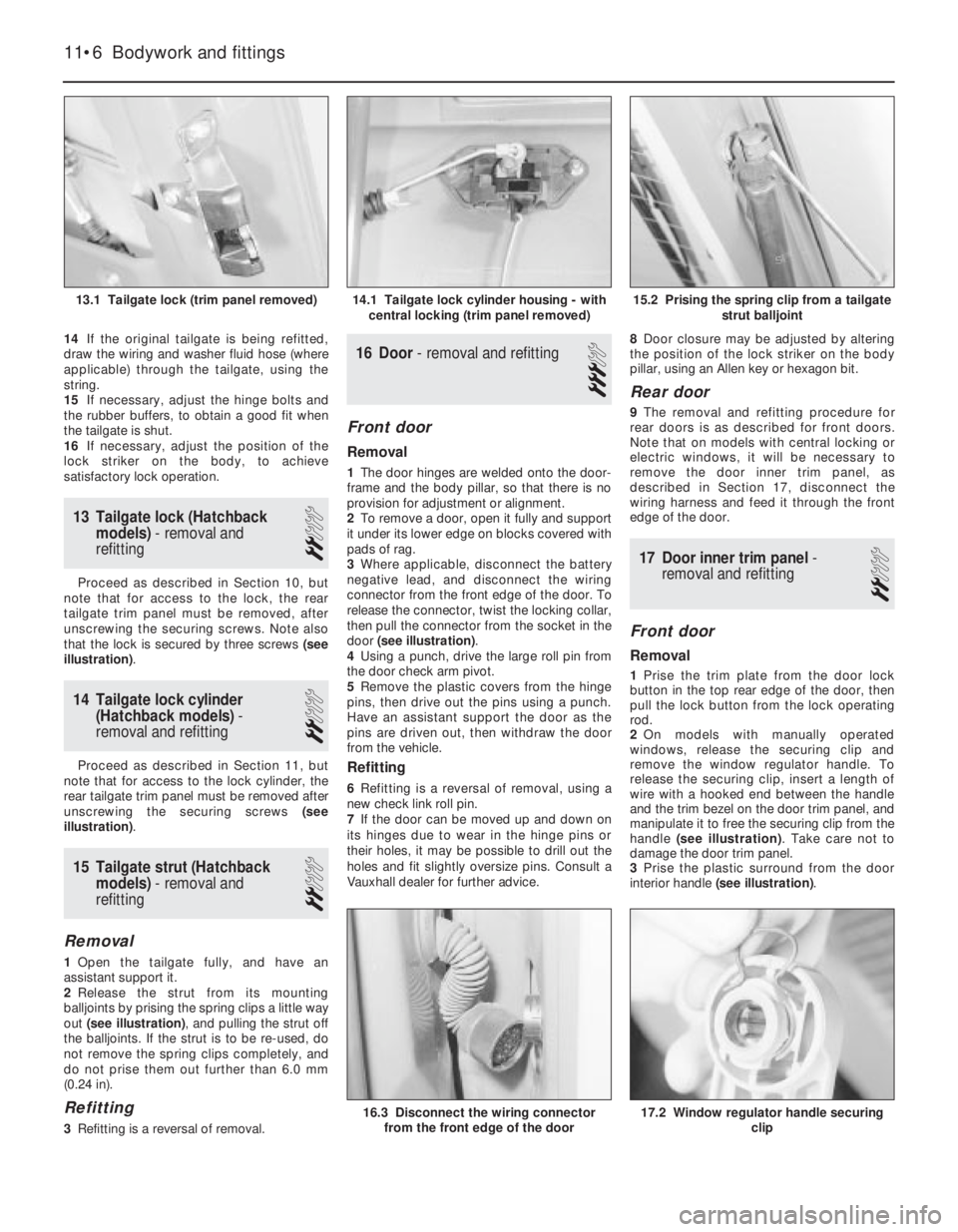

13Tailgate lock (Hatchback

models) - removal and

refitting

2

Proceed as described in Section 10, but

note that for access to the lock, the rear

tailgate trim panel must be removed, after

unscrewing the securing screws. Note also

that the lock is secured by three screws (see

illustration).

14Tailgate lock cylinder

(Hatchback models) -

removal and refitting

2

Proceed as described in Section 11, but

note that for access to the lock cylinder, the

rear tailgate trim panel must be removed after

unscrewing the securing screws (see

illustration).

15Tailgate strut (Hatchback

models) - removal and

refitting

2

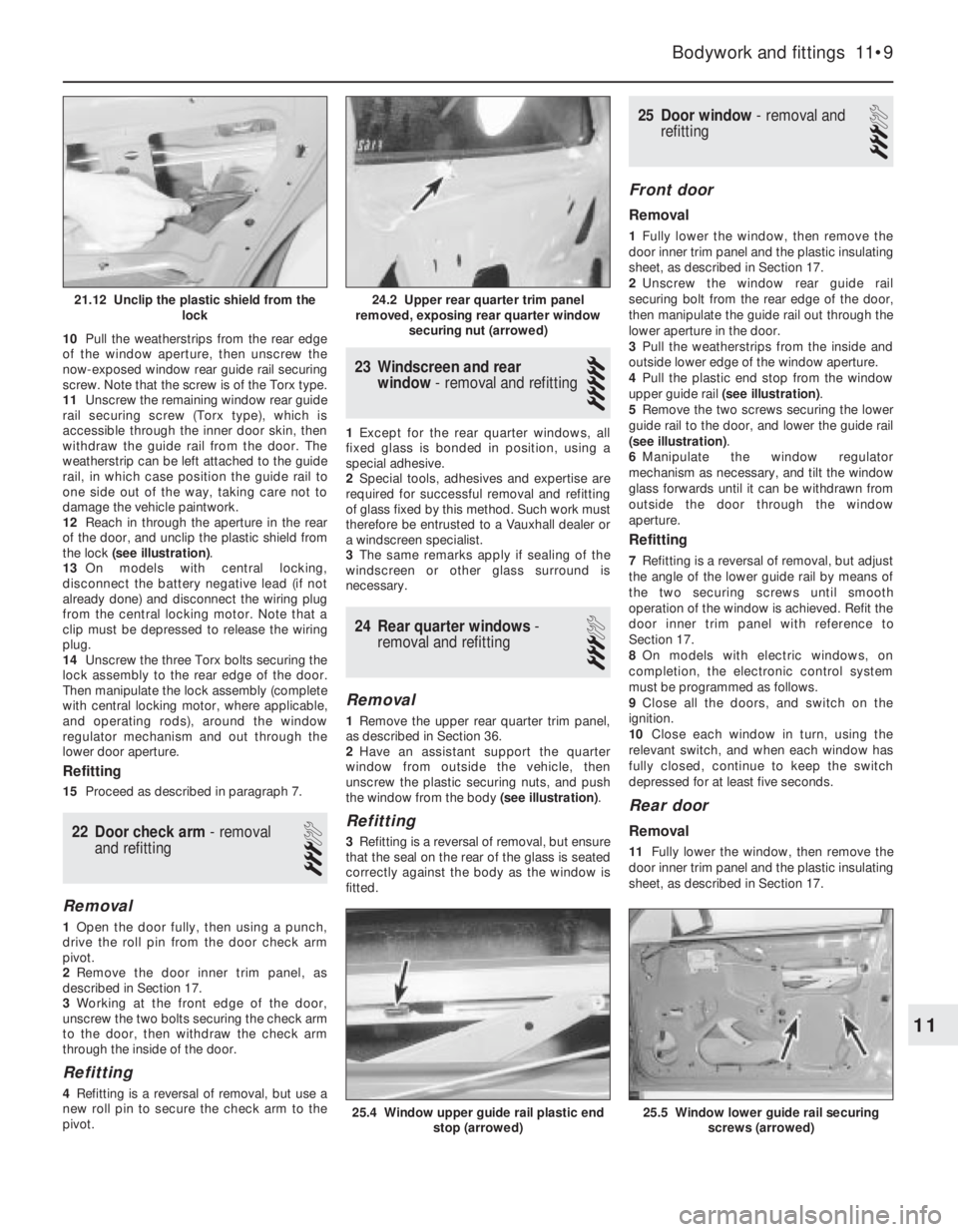

Removal

1Open the tailgate fully, and have an

assistant support it.

2Release the strut from its mounting

balljoints by prising the spring clips a little way

out (see illustration), and pulling the strut off

the balljoints. If the strut is to be re-used, do

not remove the spring clips completely, and

do not prise them out further than 6.0 mm

(0.24 in).

Refitting

3Refitting is a reversal of removal.

16Door - removal and refitting

3

Front door

Removal

1The door hinges are welded onto the door-

frame and the body pillar, so that there is no

provision for adjustment or alignment.

2To remove a door, open it fully and support

it under its lower edge on blocks covered with

pads of rag.

3Where applicable, disconnect the battery

negative lead, and disconnect the wiring

connector from the front edge of the door. To

release the connector, twist the locking collar,

then pull the connector from the socket in the

door (see illustration).

4Using a punch, drive the large roll pin from

the door check arm pivot.

5Remove the plastic covers from the hinge

pins, then drive out the pins using a punch.

Have an assistant support the door as the

pins are driven out, then withdraw the door

from the vehicle.

Refitting

6Refitting is a reversal of removal, using a

new check link roll pin.

7If the door can be moved up and down on

its hinges due to wear in the hinge pins or

their holes, it may be possible to drill out the

holes and fit slightly oversize pins. Consult a

Vauxhall dealer for further advice.8Door closure may be adjusted by altering

the position of the lock striker on the body

pillar, using an Allen key or hexagon bit.

Rear door

9The removal and refitting procedure for

rear doors is as described for front doors.

Note that on models with central locking or

electric windows, it will be necessary to

remove the door inner trim panel, as

described in Section 17, disconnect the

wiring harness and feed it through the front

edge of the door.

17Door inner trim panel -

removal and refitting

2

Front door

Removal

1Prise the trim plate from the door lock

button in the top rear edge of the door, then

pull the lock button from the lock operating

rod.

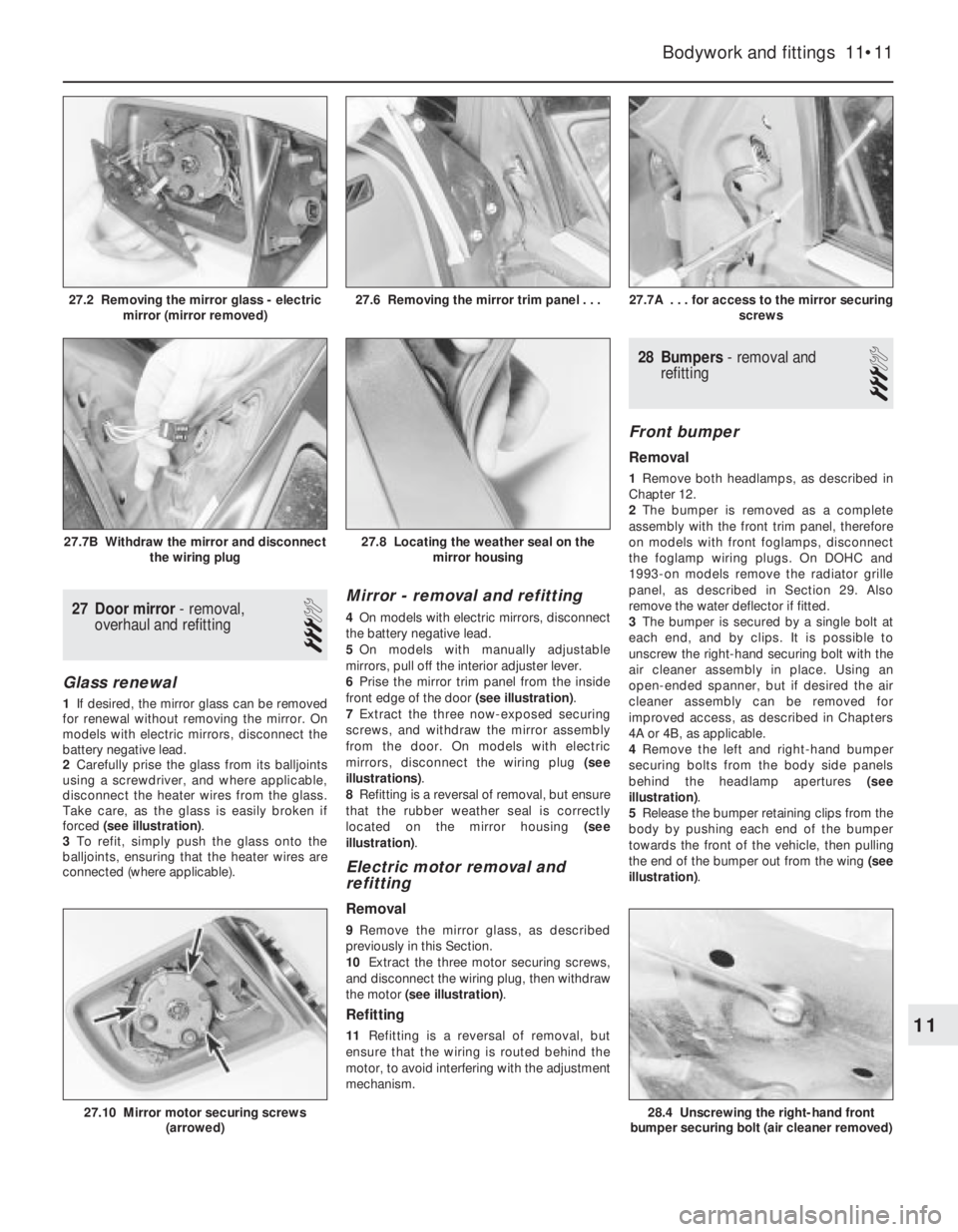

2On models with manually operated

windows, release the securing clip and

remove the window regulator handle. To

release the securing clip, insert a length of

wire with a hooked end between the handle

and the trim bezel on the door trim panel, and

manipulate it to free the securing clip from the

handle (see illustration). Take care not to

damage the door trim panel.

3Prise the plastic surround from the door

interior handle (see illustration).

11•6Bodywork and fittings

15.2 Prising the spring clip from a tailgate

strut balljoint

17.2 Window regulator handle securing

clip16.3 Disconnect the wiring connector

from the front edge of the door

14.1 Tailgate lock cylinder housing - with

central locking (trim panel removed)13.1 Tailgate lock (trim panel removed)

Page 110 of 525

4Remove the seven trim panel securing

screws that are located along the bottom

edge of the door, and around the bottom

edge of the armrest/hand grip. Release the

door pocket clip, which is located below and

to the rear of the door pocket, out of view.

5The remaining nine plastic clips securing

the trim panel to the door must now be

released. This can be done using a

screwdriver, but it is preferable to use a

forked tool, to minimise the possibility of

damage to the trim panel and the clips. The

clips are located around the outer edge of the

trim panel.

6Once the clips have been released, pull the

trim panel away from the door, and push the

large clip at the rear of the door pocket

rearwards to allow the trim panel to be

withdrawn.

7When working on the driver’s door of

models with electric door mirrors, it will be

necessary to disconnect the mirror switch

wiring connectors as the trim panel is

withdrawn. Disconnect the battery negative

lead before disconnecting the connector, and

note the position of the connector in the

bracket at the top of the door (see

illustration).

8Similarly on models with door-mounted

kerb lights, prise out the lamp and disconnect

the wiring.

9The plastic insulating sheet can be removed

from the door after removing the loudspeaker

(referring to Chapter 12 if necessary), and the

door trim panel rear securing clip, which is

attached to the door by a single screw. Take

care not to damage the sheet.10The door pocket can be removed from the

door trim panel by the three securing screws

that are accessible from the rear of the trim

panel, and releasing the single clip.

11If desired, the door assist handle can be

prised free from the door trim panel. Take

care not to damage the securing clips.

Refitting

12Refitting is a reversal of removal,

remembering the following points.

13If the plastic insulating sheet has been

removed from the door make sure that it is

refitted intact, and securely glued to the door.

If the sheet is damaged or detached,

rainwater may leak into the vehicle or damage

the door trim.

14Where applicable, ensure that the door

mirror switch wiring connector is correctly

positioned in its bracket before refitting the

trim panel.

15Ensure that all the trim panel securing

clips engage as the panel is refitted, and if any

of the clips were broken during removal,

renew them on refitting.

Rear door

Removal

16Proceed as described in paragraphs 1 to 3

inclusive.

17On models with a door-mounted electric

window operating switch, disconnect the

battery negative lead, then carefully prise the

switch from the door trim panel and

disconnect the wiring plug.

18Remove the three trim panel securing

screws. Two are located under the interior

handle surround, and the third is situated at

the base of the door assist handle.

19Proceed as described in paragraph 5.

20Once the securing clips have been

released, pull the trim panel away from the

door (see illustration).

21If desired, the plastic insulating sheet can

be removed from the door by peeling it back

from the door skin. Take care not to damage

the sheet.

22If desired, the door assist handle can be

prised free from the door trim panel. Take

care not to damage the securing clips.

Refitting

23Refitting is a reversal of removal,

remembering the following points.24If the plastic insulating sheet has been

removed from the door, make sure that it is

refitted intact, and securely glued to the door.

If the sheet is damaged or detached,

rainwater may leak into the vehicle or damage

the door trim.

25Where applicable, ensure that the electric

window switch wiring is routed so that it does

not foul the window regulator mechanism.

26Ensure that all the trim panel securing

clips engage as the panel is refitted, and if any

of the clips were broken during removal,

renew them on refitting.

18Door interior handle -

removal and refitting

2

Removal

1Remove the door inner trim panel, as

described in Section 17.

2Slide the handle assembly rearwards to free

it from the door, then unhook the operating

rod, and withdraw the assembly.

Refitting

3Refitting is a reversal of removal, but

check the mechanism for satisfactory

operation before refitting the door inner trim

panel, then refit the trim panel with reference

to Section 17.

19Door exterior handle -

removal and refitting

3

Front door

Removal

1Remove the door inner trim panel, as

described in Section 17.

2Peel back the plastic insulating sheet

sufficiently to gain access to the exterior

handle.

3Unscrew the two nuts securing the exterior

handle to the door.

4When working on the driver’s door of

models with central locking, unclip the

microswitch from the rear edge of the exterior

handle assembly.

5Release the two lower retaining clips, then

manipulate the exterior handle assembly

through the outside of the door, and

disconnect the operating rods.

Refitting

6Refitting is a reversal of removal, but check

the operation of the mechanism before

refitting the door inner trim panel, and refit the

trim panel with reference to Section 17.

Rear door

Removal

7Fully lower the window, then continue as

described in paragraphs 1 and 2.

Bodywork and fittings 11•7

17.20 Removing a rear door inner trim

panel17.7 Mirror switch wiring connector in

bracket at top of door

17.3 Remove the plastic surround from the

door interior handle

11

Page 111 of 525

8Pull the weatherstrip from the rear edge of

the window aperture, then unscrew the now

exposed window rear guide rail securing

screw. Note that the screw is of the Torx type.

9Unscrew the remaining window rear guide

rail securing screw (Torx type) which is

accessible through the inner door skin, then

withdraw the guide rail from the door. The

weatherstrip can be left attached to the guide

rail, in which case position the guide rail to

one side out of the way, taking care not to

damage the vehicle paintwork.

10Reach in through the aperture in the rear

of the door, and unclip the plastic shield from

the door lock.

11Unscrew the three Torx type lock securing

bolts from the rear edge of the door, and

lower the lock assembly inside the door.

12Unscrew the two nuts securing the

exterior handle to the door.

13Release the two lower retaining clips, then

manipulate the exterior handle through the

outside of the door, and disconnect the

operating rods.

Refitting

14Refitting is a reversal of removal, but

check the operation of the door lock, handle

and window regulator mechanisms before

refitting the door trim panel, and refit the trim

panel with reference to Section 17.

20Door lock barrel - removal

and refitting

3

Removal

1Remove the door exterior handle, as

described in Section 19.

2Insert the key into the lock, then extract the

circlip from the end of the lock cylinder (see

illustration).

3Withdraw the lock cylinder using the key,

and recover the lever assembly (see

illustrations).

Refitting

4 Refitting is a reversal of removal, but check

the operation of the door lock, handle and

window regulator mechanisms before refitting

the door trim panel, and refit the trim panel

with reference to Section 17.

21Door lock -removal and

refitting

3

Front door

Removal

1Remove the door inner trim panel, as

described in Section 17.

2Unscrew the door trim panel rear securing

clip, and peel the plastic insulating sheet back

from the rear end of the door. Take care not to

damage the sheet.

3Working through the apertures in the door,

disconnect the operating rods from the

interior and exterior handles, and release the

clips on the door, where applicable (see

illustration).

4Reach in through the lower door aperture

and unclip the plastic shield from the lock.

5On models with central locking, lower the

window half way. Disconnect the battery

negative lead and working through the lower

aperture in the door, disconnect the wiring

plug from the central locking motor. Note that

a clip must be depressed to release the wiring

plug.

6Unscrew the three Torx bolts securing the

lock assembly to the rear edge of the door.

Then manipulate the lock assembly (complete

with central locking motor, where applicable,

and operating rods), around the window

regulator mechanism and out through the

lower door aperture (see illustration).

Refitting

7Refitting is a reversal of removal, but check

the operation of the door lock, handle, and

window regulator mechanisms before refitting

the door trim panel, and refit the trim panel

with reference to Section 17. If the lock

operation is not satisfactory, note that the

exterior handle operating rod can be adjusted

by turning the knurled plastic adjuster wheel

at the end of the rod (see illustration).

Rear door

Removal

8Fully lower the window, then remove the

door inner trim panel and the plastic insulating

sheet, as described in Section 17.

9Working through the apertures in the door,

disconnect the operating rods from the

interior and exterior handles, and from the

lock button bellcrank.

11•8Bodywork and fittings

20.2 Extract the circlip from the end of the

lock cylinder . . .20.3B . . . and recover the lever assembly

21.7 Exterior handle operating rod

adjuster wheel (arrowed) at lock end of rod21.6 Removing the lock assembly - model

with central locking

21.3 View of removed door lock and

exterior handle assembly, showing

operating rod attachments

20.3A . . . then withdraw the lock cylinder

using the key . . .

Page 112 of 525

10Pull the weatherstrips from the rear edge

of the window aperture, then unscrew the

now-exposed window rear guide rail securing

screw. Note that the screw is of the Torx type.

11Unscrew the remaining window rear guide

rail securing screw (Torx type), which is

accessible through the inner door skin, then

withdraw the guide rail from the door. The

weatherstrip can be left attached to the guide

rail, in which case position the guide rail to

one side out of the way, taking care not to

damage the vehicle paintwork.

12Reach in through the aperture in the rear

of the door, and unclip the plastic shield from

the lock (see illustration).

13On models with central locking,

disconnect the battery negative lead (if not

already done) and disconnect the wiring plug

from the central locking motor. Note that a

clip must be depressed to release the wiring

plug.

14Unscrew the three Torx bolts securing the

lock assembly to the rear edge of the door.

Then manipulate the lock assembly (complete

with central locking motor, where applicable,

and operating rods), around the window

regulator mechanism and out through the

lower door aperture.

Refitting

15Proceed as described in paragraph 7.

22Door check arm -removal

and refitting

3

Removal

1Open the door fully, then using a punch,

drive the roll pin from the door check arm

pivot.

2Remove the door inner trim panel, as

described in Section 17.

3Working at the front edge of the door,

unscrew the two bolts securing the check arm

to the door, then withdraw the check arm

through the inside of the door.

Refitting

4Refitting is a reversal of removal, but use a

new roll pin to secure the check arm to the

pivot.

23Windscreen and rear

window - removal and refitting

5

1Except for the rear quarter windows, all

fixed glass is bonded in position, using a

special adhesive.

2Special tools, adhesives and expertise are

required for successful removal and refitting

of glass fixed by this method. Such work must

therefore be entrusted to a Vauxhall dealer or

a windscreen specialist.

3The same remarks apply if sealing of the

windscreen or other glass surround is

necessary.

24Rear quarter windows -

removal and refitting

3

Removal

1Remove the upper rear quarter trim panel,

as described in Section 36.

2Have an assistant support the quarter

window from outside the vehicle, then

unscrew the plastic securing nuts, and push

the window from the body (see illustration).

Refitting

3Refitting is a reversal of removal, but ensure

that the seal on the rear of the glass is seated

correctly against the body as the window is

fitted.

25Door window - removal and

refitting

3

Front door

Removal

1Fully lower the window, then remove the

door inner trim panel and the plastic insulating

sheet, as described in Section 17.

2Unscrew the window rear guide rail

securing bolt from the rear edge of the door,

then manipulate the guide rail out through the

lower aperture in the door.

3Pull the weatherstrips from the inside and

outside lower edge of the window aperture.

4Pull the plastic end stop from the window

upper guide rail (see illustration).

5Remove the two screws securing the lower

guide rail to the door, and lower the guide rail

(see illustration).

6Manipulate the window regulator

mechanism as necessary, and tilt the window

glass forwards until it can be withdrawn from

outside the door through the window

aperture.

Refitting

7Refitting is a reversal of removal, but adjust

the angle of the lower guide rail by means of

the two securing screws until smooth

operation of the window is achieved. Refit the

door inner trim panel with reference to

Section 17.

8On models with electric windows, on

completion, the electronic control system

must be programmed as follows.

9Close all the doors, and switch on the

ignition.

10Close each window in turn, using the

relevant switch, and when each window has

fully closed, continue to keep the switch

depressed for at least five seconds.

Rear door

Removal

11Fully lower the window, then remove the

door inner trim panel and the plastic insulating

sheet, as described in Section 17.

Bodywork and fittings 11•9

25.4 Window upper guide rail plastic end

stop (arrowed)25.5 Window lower guide rail securing

screws (arrowed)

24.2 Upper rear quarter trim panel

removed, exposing rear quarter window

securing nut (arrowed)21.12 Unclip the plastic shield from the

lock

11

Page 113 of 525

12Pull the weatherstrip from the rear edge of

the window aperture, then unscrew the now

exposed window rear guide rail securing

screw (see illustration). Note that the screw

is of the Torx type.

13Unscrew the remaining window rear guide

rail securing screw (Torx type), which is

accessible through the inner door skin, then

withdraw the guide rail from the door (see

illustrations). The weatherstrip can be left

attached to the guide rail, in which case

position the guide rail to one side out of the

way, taking care not to damage the vehicle

paintwork.

14Pull the weatherstrips from the inside and

outside lower edge of the window aperture

(see illustration).

15Manipulate the window regulator

mechanism as necessary, and tilt the window

glass forwards until it can be withdrawn from

outside the door through the window aperture

(see illustration).

Refitting

16Refitting is a reversal of removal, but refit

the door inner trim panel with reference to

Section 17.

17On models with electric windows, on

completion the electronic control system

must be programmed, as described in

paragraphs 9 and 10.

26Door window regulator -

removal and refitting

3

Front door

Removal

1Lower the window halfway, then remove

the door inner trim panel and the plastic

insulating sheet, as described in Section 17.

2Support the window in the half-open

position by placing a wooden prop under it,

ensuring that the prop is clear of the regulator

mechanism.

3Drill out the rivets securing the regulator

mechanism to the door, using an 8.5 mm

(0.34 in) diameter drill. Take care not to

damage the door panel.

4Pull the plastic end stop from the window

upper guide rail.5Remove the two screws securing the lower

guide rail to the door, and lower the guide rail.

6On models with electric windows,

disconnect the battery negative lead (if not

already done), then disconnect the wiring plug

from the central locking motor.

7Carefully manipulate the window regulator

assembly out through the lower aperture in

the door.

Refitting

8Refitting is a reversal of removal,

remembering the following points.

9Ensure that the regulator arms are correctly

positioned in the guide rails before securing

the regulator assembly to the door (see

illustration).

10Secure the regulator assembly to the

door, using new rivets.

11Adjust the angle of the lower guide rail by

means of the two securing screws, until

smooth operation of the window is achieved.

12Refit the door inner trim panel with

reference to Section 17.

13On models with electric windows, on

completion, the electronic control system

must be programmed, as described in

Section 25, paragraphs 9 and 10.

Rear door

Removal

14Proceed as described in paragraphs 1 to 3

inclusive, and paragraphs 6 and 7.

Refitting

15Refitting is a reversal of removal,

remembering the following points.

16Ensure that the regulator arm is correctly

positioned in the guide rail before securing the

regulator assembly to the door.

17Secure the regulator assembly to the

door, using new rivets.

18Check the regulator mechanism for

satisfactory operation before refitting the door

trim panel, then refit the panel with reference

to Section 17.

19On models with electric windows, on

completion, the electronic control system

must be programmed, as described in

Section 25, paragraphs 9 and 10.

11•10Bodywork and fittings

25.12 Unscrewing the window rear guide

securing screw25.13B . . . then withdraw the guide rail

from the door

26.9 Front door window regulator and

guide components

1 Regulator mechanism securing rivets

2 Lower guide rail securing screws

3 Upper guide rail and stop

25.15 Withdrawing the window glass from

the door25.14 Pulling the inside weatherstrip from

the window aperture

25.13A Remove the remaining securing

screw . . .

Page 114 of 525

27Door mirror - removal,

overhaul and refitting

3

Glass renewal

1If desired, the mirror glass can be removed

for renewal without removing the mirror. On

models with electric mirrors, disconnect the

battery negative lead.

2Carefully prise the glass from its balljoints

using a screwdriver, and where applicable,

disconnect the heater wires from the glass.

Take care, as the glass is easily broken if

forced (see illustration).

3To refit, simply push the glass onto the

balljoints, ensuring that the heater wires are

connected (where applicable).

Mirror -removal and refitting

4On models with electric mirrors, disconnect

the battery negative lead.

5On models with manually adjustable

mirrors, pull off the interior adjuster lever.

6Prise the mirror trim panel from the inside

front edge of the door (see illustration).

7Extract the three now-exposed securing

screws, and withdraw the mirror assembly

from the door. On models with electric

mirrors, disconnect the wiring plug (see

illustrations).

8Refitting is a reversal of removal, but ensure

that the rubber weather seal is correctly

located on the mirror housing (see

illustration).

Electric motor removal and

refitting

Removal

9Remove the mirror glass, as described

previously in this Section.

10Extract the three motor securing screws,

and disconnect the wiring plug, then withdraw

the motor (see illustration).

Refitting

11Refitting is a reversal of removal, but

ensure that the wiring is routed behind the

motor, to avoid interfering with the adjustment

mechanism.

28Bumpers - removal and

refitting

3

Front bumper

Removal

1Remove both headlamps, as described in

Chapter 12.

2The bumper is removed as a complete

assembly with the front trim panel, therefore

on models with front foglamps, disconnect

the foglamp wiring plugs. On DOHC and

1993-on models remove the radiator grille

panel, as described in Section 29. Also

remove the water deflector if fitted.

3The bumper is secured by a single bolt at

each end, and by clips. It is possible to

unscrew the right-hand securing bolt with the

air cleaner assembly in place. Using an

open-ended spanner, but if desired the air

cleaner assembly can be removed for

improved access, as described in Chapters

4A or 4B, as applicable.

4Remove the left and right-hand bumper

securing bolts from the body side panels

behind the headlamp apertures (see

illustration).

5Release the bumper retaining clips from the

body by pushing each end of the bumper

towards the front of the vehicle, then pulling

the end of the bumper out from the wing (see

illustration).

Bodywork and fittings 11•11

27.7A . . . for access to the mirror securing

screws

28.4 Unscrewing the right-hand front

bumper securing bolt (air cleaner removed)27.10 Mirror motor securing screws

(arrowed)

27.8 Locating the weather seal on the

mirror housing27.7B Withdraw the mirror and disconnect

the wiring plug

27.6 Removing the mirror trim panel . . .27.2 Removing the mirror glass - electric

mirror (mirror removed)

11