ignition OPEL CALIBRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 3 of 525

3Air cleaner - removal and

refitting

2

Removal

1Remove the air cleaner element, as

described in Chapter 1.

2Release the crankcase ventilation hose

from the plastic clip on the left-hand side of

the air cleaner body.

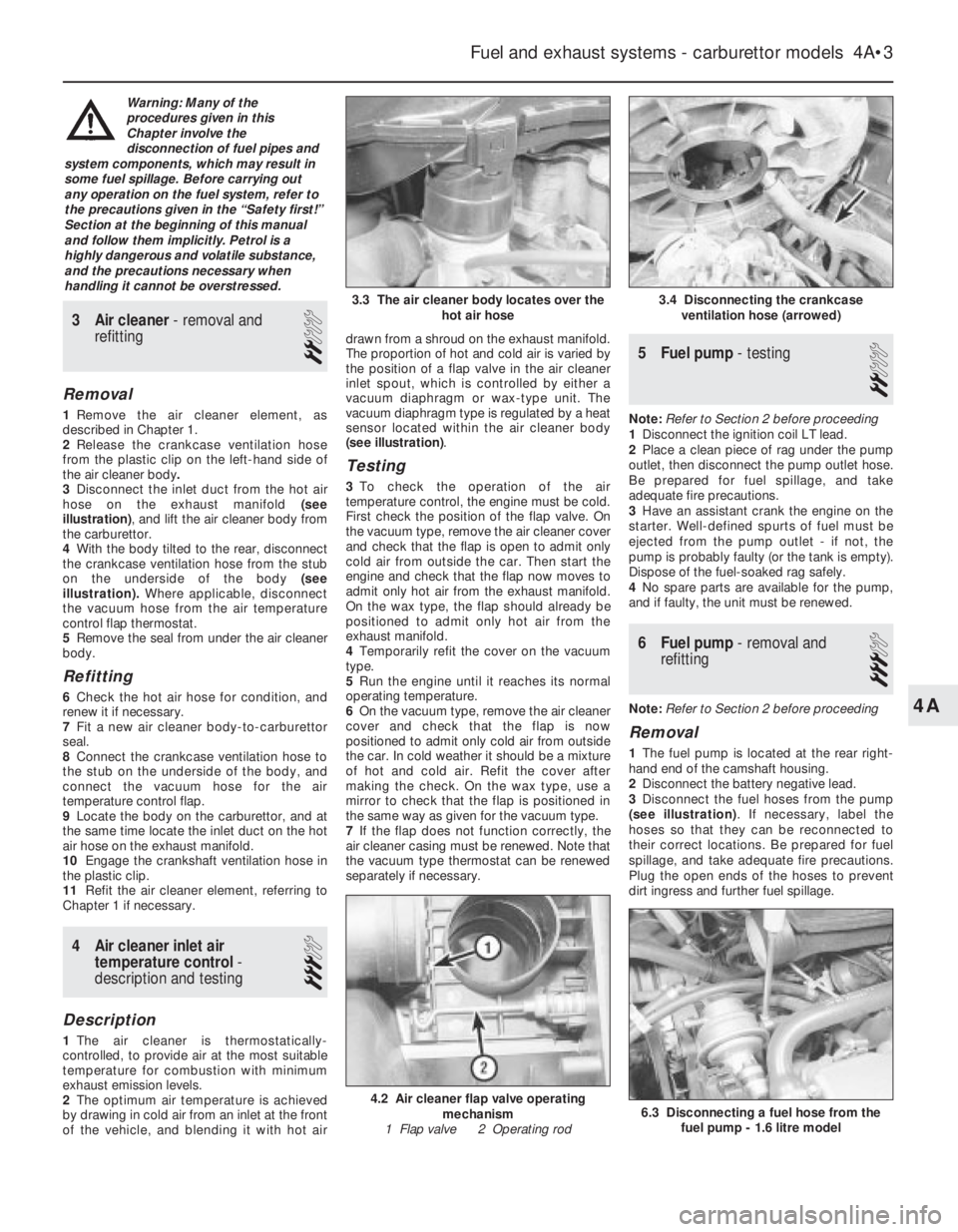

3Disconnect the inlet duct from the hot air

hose on the exhaust manifold (see

illustration), and lift the air cleaner body from

the carburettor.

4With the body tilted to the rear, disconnect

the crankcase ventilation hose from the stub

on the underside of the body (see

illustration).Where applicable, disconnect

the vacuum hose from the air temperature

control flap thermostat.

5Remove the seal from under the air cleaner

body.

Refitting

6Check the hot air hose for condition, and

renew it if necessary.

7Fit a new air cleaner body-to-carburettor

seal.

8Connect the crankcase ventilation hose to

the stub on the underside of the body, and

connect the vacuum hose for the air

temperature control flap.

9Locate the body on the carburettor, and at

the same time locate the inlet duct on the hot

air hose on the exhaust manifold.

10Engage the crankshaft ventilation hose in

the plastic clip.

11Refit the air cleaner element, referring to

Chapter 1 if necessary.

4Air cleaner inlet air

temperature control -

description and testing

3

Description

1The air cleaner is thermostatically-

controlled, to provide air at the most suitable

temperature for combustion with minimum

exhaust emission levels.

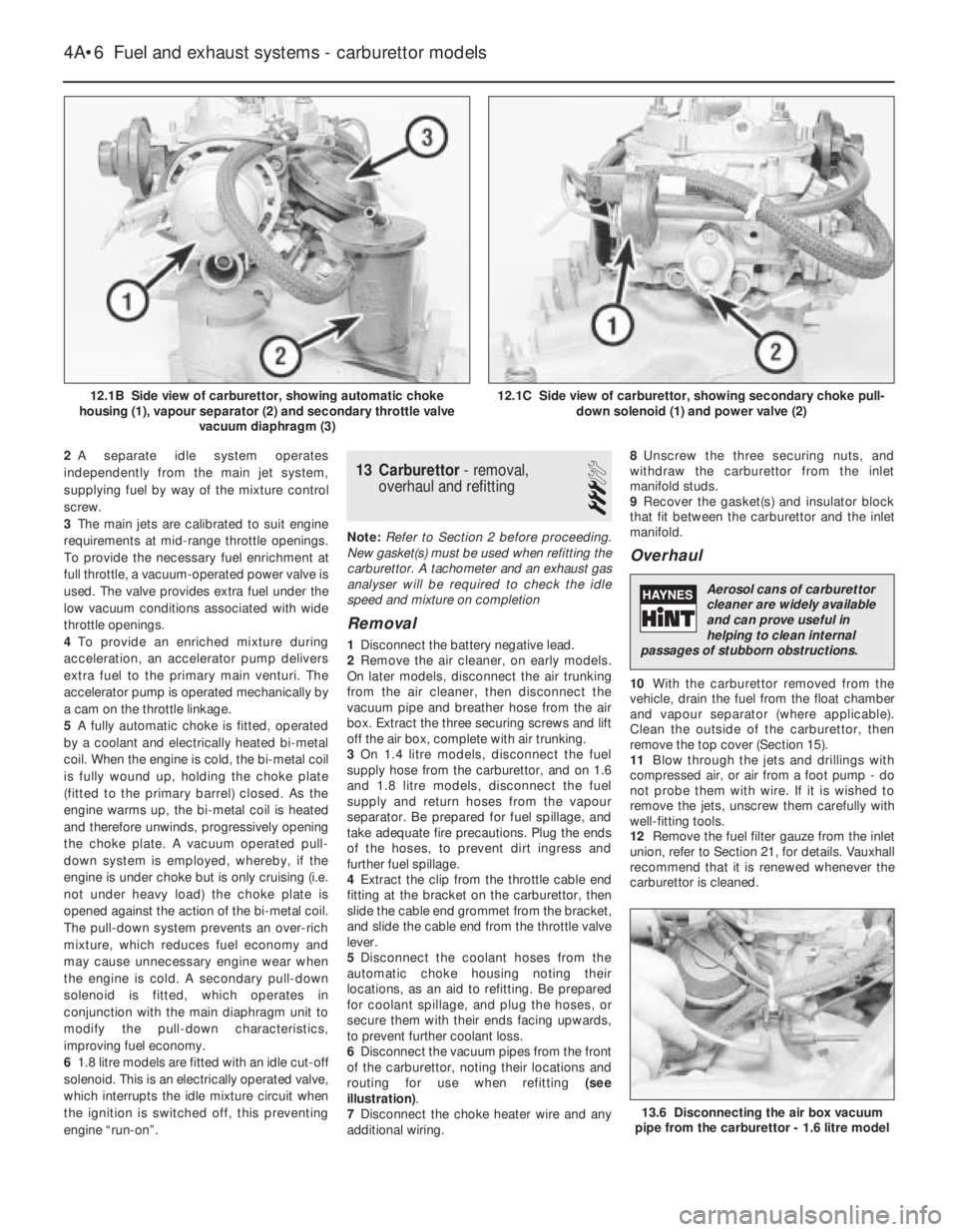

2The optimum air temperature is achieved

by drawing in cold air from an inlet at the front

of the vehicle, and blending it with hot airdrawn from a shroud on the exhaust manifold.

The proportion of hot and cold air is varied by

the position of a flap valve in the air cleaner

inlet spout, which is controlled by either a

vacuum diaphragm or wax-type unit. The

vacuum diaphragm type is regulated by a heat

sensor located within the air cleaner body

(see illustration).

Testing

3To check the operation of the air

temperature control, the engine must be cold.

First check the position of the flap valve. On

the vacuum type, remove the air cleaner cover

and check that the flap is open to admit only

cold air from outside the car. Then start the

engine and check that the flap now moves to

admit only hot air from the exhaust manifold.

On the wax type, the flap should already be

positioned to admit only hot air from the

exhaust manifold.

4Temporarily refit the cover on the vacuum

type.

5Run the engine until it reaches its normal

operating temperature.

6On the vacuum type, remove the air cleaner

cover and check that the flap is now

positioned to admit only cold air from outside

the car. In cold weather it should be a mixture

of hot and cold air. Refit the cover after

making the check. On the wax type, use a

mirror to check that the flap is positioned in

the same way as given for the vacuum type.

7If the flap does not function correctly, the

air cleaner casing must be renewed. Note that

the vacuum type thermostat can be renewed

separately if necessary.

5Fuel pump - testing

2

Note: Refer to Section 2 before proceeding

1Disconnect the ignition coil LT lead.

2Place a clean piece of rag under the pump

outlet, then disconnect the pump outlet hose.

Be prepared for fuel spillage, and take

adequate fire precautions.

3Have an assistant crank the engine on the

starter. Well-defined spurts of fuel must be

ejected from the pump outlet - if not, the

pump is probably faulty (or the tank is empty).

Dispose of the fuel-soaked rag safely.

4No spare parts are available for the pump,

and if faulty, the unit must be renewed.

6Fuel pump - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1The fuel pump is located at the rear right-

hand end of the camshaft housing.

2Disconnect the battery negative lead.

3Disconnect the fuel hoses from the pump

(see illustration). If necessary, label the

hoses so that they can be reconnected to

their correct locations. Be prepared for fuel

spillage, and take adequate fire precautions.

Plug the open ends of the hoses to prevent

dirt ingress and further fuel spillage.

Fuel and exhaust systems - carburettor models 4A•3

3.4 Disconnecting the crankcase

ventilation hose (arrowed)

6.3 Disconnecting a fuel hose from the

fuel pump - 1.6 litre model4.2 Air cleaner flap valve operating

mechanism

1 Flap valve 2 Operating rod

3.3 The air cleaner body locates over the

hot air hose

4A

Warning: Many of the

procedures given in this

Chapter involve the

disconnection of fuel pipes and

system components, which may result in

some fuel spillage. Before carrying out

any operation on the fuel system, refer to

the precautions given in the “Safety first!”

Section at the beginning of this manual

and follow them implicitly. Petrol is a

highly dangerous and volatile substance,

and the precautions necessary when

handling it cannot be overstressed.

Page 6 of 525

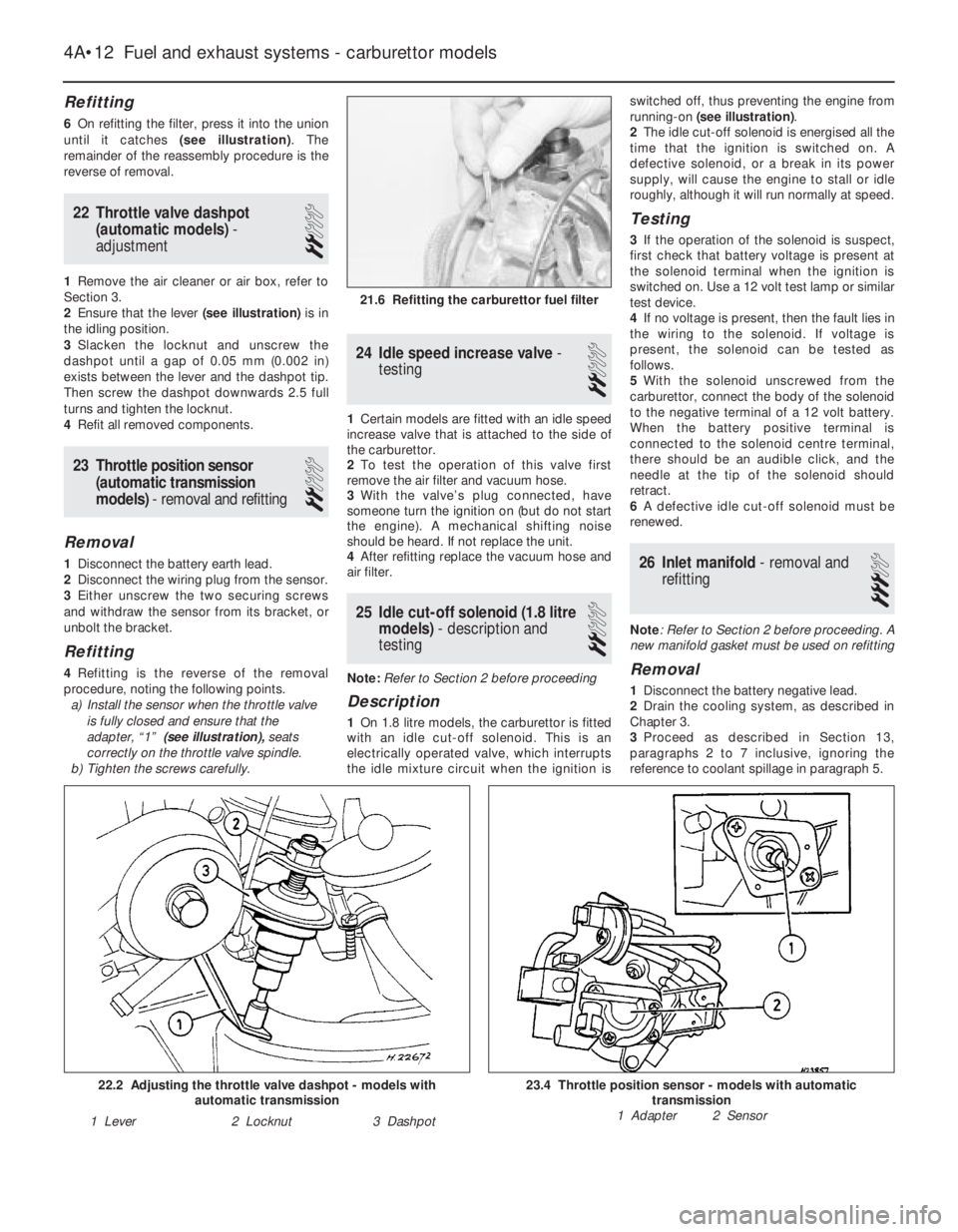

2A separate idle system operates

independently from the main jet system,

supplying fuel by way of the mixture control

screw.

3The main jets are calibrated to suit engine

requirements at mid-range throttle openings.

To provide the necessary fuel enrichment at

full throttle, a vacuum-operated power valve is

used. The valve provides extra fuel under the

low vacuum conditions associated with wide

throttle openings.

4To provide an enriched mixture during

acceleration, an accelerator pump delivers

extra fuel to the primary main venturi. The

accelerator pump is operated mechanically by

a cam on the throttle linkage.

5A fully automatic choke is fitted, operated

by a coolant and electrically heated bi-metal

coil. When the engine is cold, the bi-metal coil

is fully wound up, holding the choke plate

(fitted to the primary barrel) closed. As the

engine warms up, the bi-metal coil is heated

and therefore unwinds, progressively opening

the choke plate. A vacuum operated pull-

down system is employed, whereby, if the

engine is under choke but is only cruising (i.e.

not under heavy load) the choke plate is

opened against the action of the bi-metal coil.

The pull-down system prevents an over-rich

mixture, which reduces fuel economy and

may cause unnecessary engine wear when

the engine is cold. A secondary pull-down

solenoid is fitted, which operates in

conjunction with the main diaphragm unit to

modify the pull-down characteristics,

improving fuel economy.

61.8 litre models are fitted with an idle cut-off

solenoid. This is an electrically operated valve,

which interrupts the idle mixture circuit when

the ignition is switched off, this preventing

engine “run-on”.13Carburettor - removal,

overhaul and refitting

3

Note: Refer to Section 2 before proceeding.

New gasket(s) must be used when refitting the

carburettor. A tachometer and an exhaust gas

analyser will be required to check the idle

speed and mixture on completion

Removal

1Disconnect the battery negative lead.

2Remove the air cleaner, on early models.

On later models, disconnect the air trunking

from the air cleaner, then disconnect the

vacuum pipe and breather hose from the air

box. Extract the three securing screws and lift

off the air box, complete with air trunking.

3On 1.4 litre models, disconnect the fuel

supply hose from the carburettor, and on 1.6

and 1.8 litre models, disconnect the fuel

supply and return hoses from the vapour

separator. Be prepared for fuel spillage, and

take adequate fire precautions. Plug the ends

of the hoses, to prevent dirt ingress and

further fuel spillage.

4Extract the clip from the throttle cable end

fitting at the bracket on the carburettor, then

slide the cable end grommet from the bracket,

and slide the cable end from the throttle valve

lever.

5Disconnect the coolant hoses from the

automatic choke housing noting their

locations, as an aid to refitting. Be prepared

for coolant spillage, and plug the hoses, or

secure them with their ends facing upwards,

to prevent further coolant loss.

6Disconnect the vacuum pipes from the front

of the carburettor, noting their locations and

routing for use when refitting (see

illustration).

7Disconnect the choke heater wire and any

additional wiring.8Unscrew the three securing nuts, and

withdraw the carburettor from the inlet

manifold studs.

9Recover the gasket(s) and insulator block

that fit between the carburettor and the inlet

manifold.

Overhaul

10With the carburettor removed from the

vehicle, drain the fuel from the float chamber

and vapour separator (where applicable).

Clean the outside of the carburettor, then

remove the top cover (Section 15).

11Blow through the jets and drillings with

compressed air, or air from a foot pump - do

not probe them with wire. If it is wished to

remove the jets, unscrew them carefully with

well-fitting tools.

12Remove the fuel filter gauze from the inlet

union, refer to Section 21, for details. Vauxhall

recommend that it is renewed whenever the

carburettor is cleaned.

4A•6Fuel and exhaust systems - carburettor models

12.1B Side view of carburettor, showing automatic choke

housing (1), vapour separator (2) and secondary throttle valve

vacuum diaphragm (3)12.1C Side view of carburettor, showing secondary choke pull-

down solenoid (1) and power valve (2)

13.6 Disconnecting the air box vacuum

pipe from the carburettor - 1.6 litre model

Aerosol cans of carburettor

cleaner are widely available

and can prove useful in

helping to clean internal

passages of stubborn obstructions.

Page 7 of 525

13Clean any foreign matter from the float

chamber. Renew the float, the float needle

valve and seat if wear is evident, or if the float

is punctured or otherwise damaged. Check

that the needle valve closes completely before

the float reaches the top of its movement. See

Section 15, for details of float level checking.

14Renew the diaphragms in the part-load

enrichment valve and in the accelerator pump.

If additional pump or valve parts are supplied

in the overhaul kit, renew these parts also.

15Further dismantling is not recommended.

Pay particular attention to the throttle opening

mechanism arrangement if it is decided to

dismantle it; the interlocking arrangement is

important.

16Reassemble in the reverse order to

dismantling. Use new gaskets and seals

throughout; lubricate linkages with a smear of

molybdenum based grease.

Refitting

17Carry out the following procedure before

refitting.

a)Position the fast idle adjustment screw on

the highest step of the fast idle cam.

b)Use a gauge rod or twist drill of the

specified diameter to measure the

opening of the primary throttle valve.

c)Adjust if necessary at the fast idle

adjustment screw.

d)Note that this is a preliminary adjustment;

final adjustment of the fast idle speed

should take place with the engine running.

18Refitting is a reversal of removal, but

renew the gasket(s).

19After refitting, carry out the following

checks and adjustments.

20Check the throttle cable free play and

adjust if necessary, as described in Section 11.

21Check and if necessary top-up the

coolant level, as described in Chapter 3.

22Check and if necessary adjust the idle

speed and mixture, as described in Section 14.

14Idle speed and mixture -

adjustment

3

Note: Refer to Section 2 before proceeding.

To carry out the adjustments, an accurate

tachometer and an exhaust gas analyser (CO

meter) will be required

1To check the idle speed and mixture

adjustment, the following conditions must be

met:

a)The engine must be at normal operating

temperature

b)All electrical consumers (cooling fan,

heater blower, headlamps, etc.) must be

switched off

c)The ignition timing and spark plug gaps

must be correctly adjusted - see Chapters

1 and 5

d)The throttle cable free play must be

correctly adjusted - see Section 11

e)The air inlet trunking must be free from

leaks, and the air filter must be cleanf)On automatic models, always select

position, “P”.

2Connect a tachometer and an exhaust gas

analyser to the vehicle, according to the

equipment manufacturer’s instructions.

3Start the engine, and run it at 2000 rpm for

approximately 30 seconds, then allow it to

idle. If the idle speed is outside the specified

limits, adjust by means of the throttle stop

screw (see illustration).

4When the idle speed is correct, check the

CO level in the exhaust gas. If it is outside the

specified limits, adjust by means of the idle

mixture adjustment screw. In production, the

screw is covered by a tamperproof plug;

ensure that no local or national laws are being

broken before removing the plug (see

illustration).

5On automatic models, when position “D” is

selected (all electrical systems switched off),

the idle speed should not drop perceptibly. If

it does, the vehicle should be taken to a

Vauxhall dealer for the idle-up system to be

checked using special Vauxhall test

equipment.

6With the idle mixture correct, readjust the

idle speed if necessary.

7If the cooling fan cuts in during the

adjustment procedure, stop the adjustments,

and continue when the cooling fan stops.

8When both idle speed and mixture are

correctly set, stop the engine and disconnect

the test equipment.

9Fit a new tamperproof plug to the idle

mixture adjustment screw, where this is

required by law.

15Needle valve and float -

removal, inspection and

refitting

4

Note: Refer to Section 2 before proceeding. A

new carburettor top cover gasket must be

used on reassembly. A tachometer and an

exhaust gas analyser will be required to check

the idle speed and mixture on completion

Removal

1Disconnect the battery negative lead.

2Remove the round air cleaner, on

applicable models. On other models,

disconnect the air trunking from the air

cleaner, then disconnect the vacuum pipe and

breather hose from the air box. Extract the

three securing screws and lift off the air box,

complete with air trunking.

3Thoroughly clean all external dirt from the

carburettor.

4Disconnect the fuel supply hose at the

carburettor. Be prepared for fuel spillage, and

take adequate fire precautions. Plug the end

of the hose, to prevent dirt ingress and further

fuel spillage.

5Identify the automatic choke coolant hose

locations as an aid to refitting, then

disconnect the hoses. Be prepared for

coolant spillage, and either plug the hoses, or

secure them with their ends facing upwards,

to prevent further coolant loss.

6Disconnect the choke heater wiring plug.

7Disconnect the lower vacuum hoses from

the choke pull-down unit.

8Remove the four carburettor top cover

securing screws, noting their locations, as two

lengths of screw are used (see illustration).

9Lift off the top cover and recover the

gasket.

Inspection

10Hold the cover vertically, so that the float

is hanging from its pivot. Then tilt the cover

until the float needle valve is just closed - the

needle spring must not be compressed by the

weight of the float.

11Measure the distance, dimension x (see

illustration),from the bottom of the float to

the gasket surface on the top cover’s

Fuel and exhaust systems - carburettor models 4A•7

15.8 Carburettor top cover securing

screws (arrowed)14.4 Tamperproof plug (arrowed) covering

idle mixture adjustment screw

14.3 Carburettor idle speed adjustment

(throttle stop) screw (arrowed)

4A

Page 12 of 525

Refitting

6On refitting the filter, press it into the union

until it catches (see illustration). The

remainder of the reassembly procedure is the

reverse of removal.

22Throttle valve dashpot

(automatic models) -

adjustment

2

1Remove the air cleaner or air box, refer to

Section 3.

2Ensure that the lever (see illustration)is in

the idling position.

3Slacken the locknut and unscrew the

dashpot until a gap of 0.05 mm (0.002 in)

exists between the lever and the dashpot tip.

Then screw the dashpot downwards 2.5 full

turns and tighten the locknut.

4Refit all removed components.

23Throttle position sensor

(automatic transmission

models) - removal and refitting

2

Removal

1Disconnect the battery earth lead.

2Disconnect the wiring plug from the sensor.

3Either unscrew the two securing screws

and withdraw the sensor from its bracket, or

unbolt the bracket.

Refitting

4Refitting is the reverse of the removal

procedure, noting the following points.

a)Install the sensor when the throttle valve

is fully closed and ensure that the

adapter, “1” (see illustration),seats

correctly on the throttle valve spindle.

b)Tighten the screws carefully.

24Idle speed increase valve -

testing

2

1Certain models are fitted with an idle speed

increase valve that is attached to the side of

the carburettor.

2To test the operation of this valve first

remove the air filter and vacuum hose.

3With the valve’s plug connected, have

someone turn the ignition on (but do not start

the engine). A mechanical shifting noise

should be heard. If not replace the unit.

4After refitting replace the vacuum hose and

air filter.

25Idle cut-off solenoid (1.8 litre

models) - description and

testing

2

Note: Refer to Section 2 before proceeding

Description

1On 1.8 litre models, the carburettor is fitted

with an idle cut-off solenoid. This is an

electrically operated valve, which interrupts

the idle mixture circuit when the ignition isswitched off, thus preventing the engine from

running-on (see illustration).

2The idle cut-off solenoid is energised all the

time that the ignition is switched on. A

defective solenoid, or a break in its power

supply, will cause the engine to stall or idle

roughly, although it will run normally at speed.

Testing

3If the operation of the solenoid is suspect,

first check that battery voltage is present at

the solenoid terminal when the ignition is

switched on. Use a 12 volt test lamp or similar

test device.

4If no voltage is present, then the fault lies in

the wiring to the solenoid. If voltage is

present, the solenoid can be tested as

follows.

5With the solenoid unscrewed from the

carburettor, connect the body of the solenoid

to the negative terminal of a 12 volt battery.

When the battery positive terminal is

connected to the solenoid centre terminal,

there should be an audible click, and the

needle at the tip of the solenoid should

retract.

6A defective idle cut-off solenoid must be

renewed.

26Inlet manifold - removal and

refitting

3

Note: Refer to Section 2 before proceeding. A

new manifold gasket must be used on refitting

Removal

1Disconnect the battery negative lead.

2Drain the cooling system, as described in

Chapter 3.

3Proceed as described in Section 13,

paragraphs 2 to 7 inclusive, ignoring the

reference to coolant spillage in paragraph 5.

4A•12Fuel and exhaust systems - carburettor models

21.6 Refitting the carburettor fuel filter

23.4 Throttle position sensor - models with automatic

transmission

1 Adapter 2 Sensor22.2 Adjusting the throttle valve dashpot - models with

automatic transmission

1 Lever2 Locknut3 Dashpot

Page 15 of 525

12

Wiper blades

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 ins. Champion X-4803

Fuses

Rating:

Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 A

Blue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 A

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 A

Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 A

Torque wrench settingsNm lbf ft

Airbag unit to steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Airbag control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Brackets, passenger airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 16

Passenger airbag to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Steering to column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Chapter 12

Body electrical systems

Aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Aerial mast, electric - removal and refitting . . . . . . . . . . . . . . . . . . . .48

Airbag - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Airbag contact unit - removal and refitting . . . . . . . . . . . . . . . . . . . . .58

Airbag control unit - removal and refitting . . . . . . . . . . . . . . . . . . . . .61

Airbag unit, drivers side - removal and refitting . . . . . . . . . . . . . . . . .56

Airbag unit, passengers side - removal and refitting . . . . . . . . . . . . .59

Anti-theft alarm - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Anti-theft alarm system components - removal and refitting . . . . . . .54

Bracket, passenger airbag unit - removal and refitting . . . . . . . . . . .60

Brake lamp switch - removal and refitting . . . . . . . . . . . . . . . . . . . . .12

Central door locking components - removal and refitting . . . . . . . . .46

Check control system components - removal and refitting . . . . . . . .21

Cigarette lighter - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .15

Clock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Courtesy lamp switch - removal and refitting . . . . . . . . . . . . . . . . . . .10

Direction indicator/lighting switch - removal and refitting . . . . . . . . . .5

Electric door mirror switch - removal and refitting . . . . . . . . . . . . . . . .8

Electric window components - removal and refitting . . . . . . . . . . . . .44

Electric window controls - programming . . . . . . . . . . . . . . . . . . . . . .45

Electrical fault-finding - general information . . . . . . . . . . . . . . . . . . . . .2

Exterior lamp bulbs - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Facia panel switches - removal and refitting . . . . . . . . . . . . . . . . . . . .7

Front indicator lamp unit - removal and refitting . . . . . . . . . . . . . . . .29

Front foglamp - removal, refitting and adjustment . . . . . . . . . . . . . . .31

Fuses and relays - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . . .1

Handbrake “on” warning lamp switch - removal and refitting . . . . . .13

Headlamp aim adjustment motor - removal and refitting . . . . . . . . . .26

Headlamp dim-dip system - general, removal and refitting . . . . . . . .28

Headlamp unit - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .25

Headlamp washer fluid non-return valve - removal and refitting . . . .43Headlamp wiper motor - removal and refitting . . . . . . . . . . . . . . . . . .40

Headlamps - alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Heated front seats - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Horn(s) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Ignition switch and lock cylinder - removal and refitting . . . . . . . . . . .4

Instrument panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . .18

Instrument panel components - removal and refitting . . . . . . . . . . . .19

Interior lamp bulbs - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Interior lamps - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .23

Luggage compartment lamp switch - removal and refitting . . . . . . .11

Number plate lamp - removal and refitting . . . . . . . . . . . . . . . . . . . . .33

Oil pressure warning lamp switch - removal and refitting . . . . . . . . .14

Radio/cassette player - removal and refitting . . . . . . . . . . . . . . . . . . .50

Rear lamp unit - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .32

Reversing lamp switch . . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 7A

Side repeater lamp - removal and refitting . . . . . . . . . . . . . . . . . . . . .30

Speakers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Speedometer cable - removal and refitting . . . . . . . . . . . . . . . . . . . .52

Steering wheel (with airbag) - removal and refitting . . . . . . . . . . . . . .57

Sunroof motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .51

Sunroof operating switch - removal and refitting . . . . . . . . . . . . . . . . .9

Tailgate wiper motor - removal and refitting . . . . . . . . . . . . . . . . . . . .39

Trip computer components - removal and refitting . . . . . . . . . . . . . .20

Wash/wipe switch - removal and refitting . . . . . . . . . . . . . . . . . . . . . .6

Washer fluid reservoir - removal and refitting . . . . . . . . . . . . . . . . . . .41

Washer nozzles - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .37

Washer pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .42

Windscreen wiper motor and linkage - removal and refitting . . . . . . .38

Wiper arms - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Wiper blades - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Wiring diagrams - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

12•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 16 of 525

1General information and

precautions

The electrical system is of 12-volt negative

earth type. Power for the lights and all

electrical accessories is supplied by a

lead/acid type battery, which is charged by

the alternator.

This Chapter covers repair and service

procedures for the various electrical

components not associated with engine.

Information on the battery, alternator and

starter motor can be found in Chapter 5.

It should be noted that, before working on

any component in the electrical system, the

battery negative terminal should first be

disconnected, to prevent the possibility of

electrical short-circuits and/or fires.

Whenever the occasion arises, carefully

check the routing of the wiring harness,

ensuring that it is correctly secured by the

clips or ties provided so that it cannot chafe

against other components. Carefully check

points such as the clutch cable bracket,

clutch housing and harness support bracket,

the inlet manifold, the horn mounting bracket,

the starter motor terminals, and the rear

bumper and number plate lamp.

If evidence is found of the harness having

chafed against other components, repair the

damage and ensure that the harness is

secured or protected so that the problem

cannot occur again.

2Electrical fault-finding -

general information

Note:Refer to the precautions given in “Safety

first!” (at the beginning of this manual) and to

Section 1 of this Chapter before starting work.

The following tests relate to testing of the main

electrical circuits, and should not be used to

test delicate electronic circuits (such as anti-

lock braking systems), particularly where an

electronic control module is used.

A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links or circuit breakers

related to that component, and the wiring and

connectors that link the component to boththe battery and the chassis. To help to

pinpoint a problem in an electrical circuit,

wiring diagrams are included at the end of this

Chapter.

Before attempting to diagnose an electrical

fault, first study the appropriate wiring

diagram, to obtain a complete understanding

of the components included in the particular

circuit concerned. The possible sources of a

fault can be narrowed down by noting

whether other components related to the

circuit are operating properly. If several

components or circuits fail at one time, the

problem is likely to be related to a shared fuse

or earth connection.

Electrical problems usually stem from

simple causes, such as loose or corroded

connections, a faulty earth connection, a

blown fuse, a melted fusible link, or a faulty

relay (refer to Section 3 for details of testing

relays). Visually inspect the condition of all

fuses, wires and connections in a problem

circuit before testing the components. Use

the wiring diagrams to determine which

terminal connections will need to be checked,

to pinpoint the trouble-spot.

The basic tools required for electrical fault-

finding include the following:

a)a circuit tester or voltmeter (a 12-volt bulb

with a set of test leads can also be used

for certain tests).

b)a self-powered test light (sometimes

known as a continuity tester).

c)an ohmmeter (to measure resistance).

d)a battery.

e)a set of test leads.

f)a jumper wire, preferably with a circuit

breaker or fuse incorporated, which can

be used to bypass suspect wires or

electrical components.

Before attempting to locate a problem with

test instruments, use the wiring diagram to

determine where to make the connections.

To find the source of an intermittent wiring

fault (usually due to a poor or dirty

connection, or damaged wiring insulation), a

“wiggle” test can be performed on the wiring.

This involves wiggling the wiring by hand, to

see if the fault occurs as the wiring is moved.

It should be possible to narrow down the

source of the fault to a particular section of

wiring. This method of testing can be used in

conjunction with any of the tests described in

the following sub-Sections.

Apart from problems due to poor

connections, two basic types of fault can

occur in an electrical circuit - open-circuit, or

short-circuit.

Open-circuit faults are caused by a break

somewhere in the circuit, which prevents

current from flowing. An open-circuit fault will

prevent a component from working, but will

not cause the relevant circuit fuse to blow.

Short-circuit faults are caused by a “short”

somewhere in the circuit, which allows the

current flowing in the circuit to “escape” along

an alternative route, usually to earth. Short-

circuit faults are normally caused by abreakdown in wiring insulation, which allows a

feed wire to touch either another wire, or an

earthed component such as the bodyshell. A

short-circuit fault will normally cause the

relevant circuit fuse to blow.

Finding an open-circuit

To check for an open-circuit, connect one

lead of a circuit tester or voltmeter to either

the negative battery terminal or a known good

earth.

Connect the other lead to a connector in

the circuit being tested, preferably nearest to

the battery or fuse.

Switch on the circuit, remembering that

some circuits are live only when the ignition

switch is moved to a particular position.

If voltage is present (indicated either by the

tester bulb lighting or a voltmeter reading, as

applicable), this means that the section of the

circuit between the relevant connector and

the battery is problem-free.

Continue to check the remainder of the

circuit in the same fashion.

When a point is reached at which no

voltage is present, the problem must lie

between that point and the previous test point

with voltage. Most problems can be traced to

a broken, corroded or loose connection.

Finding a short-circuit

To check for a short-circuit, first disconnect

the load(s) from the circuit (loads are the

components that draw current from a circuit,

such as bulbs, motors, heating elements, etc.).

Remove the relevant fuse from the circuit,

and connect a circuit tester or voltmeter to the

fuse connections.

Switch on the circuit, remembering that

some circuits are live only when the ignition

switch is moved to a particular position.

If voltage is present (indicated either by the

tester bulb lighting or a voltmeter reading, as

applicable), this means that there is a short-

circuit.

If no voltage is present, but the fuse still

blows with the load(s) connected, this indicates

an internal fault in the load(s).

Finding an earth fault

The battery negative terminal is connected

to “earth” (the metal of the

engine/transmission and the car body), and

most systems are wired so that they only

receive a positive feed. The current returning

through the metal of the car body. This means

that the component mounting and the body

form part of that circuit. Loose or corroded

mountings can therefore cause a range of

electrical faults, ranging from total failure of a

circuit, to a puzzling partial fault. In particular,

lights may shine dimly (especially when

another circuit sharing the same earth point is

in operation). Motors (e.g. wiper motors or the

radiator cooling fan motor) may run slowly,

and the operation of one circuit may have an

affect on another. Note that on many vehicles,

earth straps are used between certain

components, such as the engine/transmission

and the body, usually where there is no metal-

12•2Body electrical systems

Warning: Before carrying out

any work on the electrical

system, read through the

precautions given in “Safety

first!” at the beginning of this manual, and

in Chapter 5.

Caution:If the radio/cassette player fitted

to the vehicle is one with an anti-theft

security code, as the standard unit is, refer

to “Radio/cassette player anti-theft system

- precaution”in the Reference Section of

this manual before disconnecting the

battery.

Page 17 of 525

to-metal contact between components, due

to flexible rubber mountings, etc.

To check whether a component is properly

earthed, disconnect the battery, and connect

one lead of an ohmmeter to a known good

earth point. Connect the other lead to the wire

or earth connection being tested. The

resistance reading should be zero; if not,

check the connection as follows.

If an earth connection is thought to be

faulty, dismantle the connection, and clean

back to bare metal both the bodyshell and the

wire terminal or the component earth

connection mating surface. Be careful to

remove all traces of dirt and corrosion, then

use a knife to trim away any paint, so that a

clean metal-to-metal joint is made. On

reassembly, tighten the joint fasteners

securely; if a wire terminal is being refitted,

use serrated washers between the terminal

and the bodyshell, to ensure a clean and

secure connection. When the connection is

remade, prevent the onset of corrosion in the

future by applying a coat of petroleum jelly or

silicone-based grease.

3Fuses and relays - general

Fuses

1Fuses are designed to break a circuit when

a predetermined current is reached, to protect

the components and wiring which could be

damaged by excessive current flow. Any

excessive current flow will be due to a fault in

the circuit, usually a short-circuit (Section 2).

2The main fuses and relays are located in a

panel at the lower right-hand side of the facia,

under a hinged cover (see illustration).

3The circuits protected by the various fuses

and relays are marked on the inside of the

panel cover.

4A blown fuse can be recognised from its

melted or broken wire.

5To remove a fuse, first ensure that the

relevant circuit is switched off. Then open the

cover and pull the relevant fuse or relay from the

panel (see illustration). If desired, the lower

end of the panel can be tilted forwards, after

releasing the retaining clips to improve access. 6Before renewing a blown fuse, trace and

rectify the cause, and always use a fuse of the

correct rating. Never substitute a fuse of a

higher rating, or make temporary repairs using

wire or metal foil, as more serious damage or

even fire could result.

7Spare fuses are provided in the blank

terminal positions in the fusebox.

8Note that the fuses are colour-coded, see

Specifications. Refer to the wiring diagrams

for details of the fuse ratings and the circuits

protected.

Relays

9A relay is an electrically operated switch,

which is used for the following reasons:

a)A relay can switch a heavy current

remotely from the circuit in which the

current is flowing, allowing the use of

lighter-gauge wiring and switch contacts.

b)A relay can receive more than one control

input, unlike a mechanical switch.

c)A relay can have a timer function - for

example, the intermittent wiper relay.

10Most of the relays are located at the rear

of the main fusebox (remove the securing

screws and pull the fusebox forwards to

improve access). The rear wiper motor relay is

located in the tailgate, behind the tailgate trim

panel. On some models, additional engine-

related relays are located in the relay box

mounted on the left-hand side of the engine

compartment.

11On certain models, additional relays are

located in a box at the left-hand rear of the

engine compartment (see illustration).

12If a circuit or system controlled by a relay

develops a fault, and the relay is suspect,

operate the system. If the relay is functioning, it

should be possible to hear it “click” as it is

energised. If this is the case, the fault lies with

the components or wiring of the system. If the

relay is not being energised, then either the

relay is not receiving a main supply or a

switching voltage, or the relay itself is faulty.

Testing is by the substitution of a known good

unit, but be careful - while some relays are

identical in appearance and in operation, others

look similar but perform different functions.

13To remove a relay, first ensure that the

relevant circuit is switched off. The relay can

then simply be pulled out from the socket,

and pushed back into position.

4Ignition switch and lock

cylinder - removal and

refitting

3

Removal

1Disconnect the battery negative lead.

2Turn the steering wheel as necessary to

expose the two front steering column shroud

securing screws, which are covered by plastic

caps. Prise out the caps and remove the

screws.

3Remove the three securing screws from the

underside of the lower column shroud, then

remove both the upper and lower shrouds.

4To remove the lock cylinder, insert the

ignition key and turn it to position “II”.

5Insert a thin rod into the hole in the lock

housing, then press the rod to release the

detent spring, and pull out the lock cylinder

using the key.

6The ignition switch is secured to the

steering lock housing by two grub screws.

Disconnect the wiring plug, and remove the

screws to extract the switch (see illustration).

Removal of the steering wheel, may aid

removal. Refer to Chapter 10 or Section 57, as

applicable. It is recommended that the switch

and the lock cylinder are not both removed at

the same time, so that their mutual alignment

is not lost.

Refitting

7Refitting is a reversal of removal.

Body electrical systems 12•3

3.11 Relays in engine compartment box -

2.0 litre SRi model shown

4.6 Removing an ignition switch securing

screw

3.5 Removing a fuse -

2.0 litre model shown3.2 Main fuses and relays in facia panel -

2.0 litre SRi model shown

12

Page 28 of 525

2Disconnect the washer hose and withdraw

the nozzle.

Refitting

3To refit, reconnect the washer hose to the

nozzle, and push the nozzle into its locating

hole.

4The nozzles can be adjusted by inserting a

pin into the jet, and swivelling it to the

required position.

1991-on models

5The nozzles on all later models are fitted

with twin jets.

6On some later models, the nozzles are

heated; the circuit is fed through fuse 29 and

is live whenever the ignition is switched on.

Current is regulated by a Positive

Temperature Coefficient (PTC) resistor that

takes outside temperature into account.

38Windscreen wiper motor and

linkage - removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arms, as described in

Section 36.

3Remove the windscreen cowl panel, as

described in Chapter 11.

4Disconnect the wiring plug from the motor

(see illustration). 5Unscrew the three bolts securing the

motor/linkage assembly to the body, then

withdraw the assembly (see illustrations).

6If desired, the motor can be removed from

the linkage by unscrewing the three securing

bolts. Do not attempt to dismantle the linkage.

Refitting

7Refitting is a reversal of removal.

39Tailgate wiper motor -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arm, as described in

Section 36.

3Extract the securing screws, and remove

the rear tailgate trim panel.

4Disconnect the motor wiring plug.

5Unscrew the two motor securing bolts,

noting the earth leads under the bolt heads

(see illustration).

6Manipulate the motor assembly from the

tailgate.

Refitting

7Refitting is a reversal of removal, ensuring

that the cut-out in the drive spindle rubber

seal engages with the notch in the drive

spindle (see illustration).

40Headlamp wiper motor -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arm, as described in

Section 36.

3Remove the headlamp, as described in

Section 25.

4Disconnect the motor wiring plug.

5Unscrew the two bolts securing the motor

mounting bracket to the body panel, then

withdraw the motor (see illustrations).

Refitting

6Refitting is a reversal of removal.

12•14Body electrical systems

38.4 Disconnecting the windscreen wiper

motor wiring plug

38.5B . . . then withdraw the assembly

40.5B . . . and withdraw the motor40.5A Unscrew the headlamp wiper motor

securing bolts . . .39.7 Cut-out in tailgate wiper motor drive

spindle rubber seal must engage with

notch in drive spindle

39.5 Tailgate wiper motor assembly. Note

earth leads under heads of securing bolts

38.5A Unscrew the windscreen wiper

motor/linkage assembly securing bolts . .

Page 30 of 525

Centre console-mounted

switches

Removal

5The switches must be removed as a

complete assembly, and cannot be

dismantled. If one of the switches is faulty, the

complete assembly must be renewed.

6Remove the rear section of the centre

console, as described in Chapter 11.

7Release the securing clips, and withdraw

the switch assembly through the top of the

centre console.

Refitting

8Refitting is a reversal of removal.

Operating motors

9Remove the door window regulator, as

described in Chapter 11.

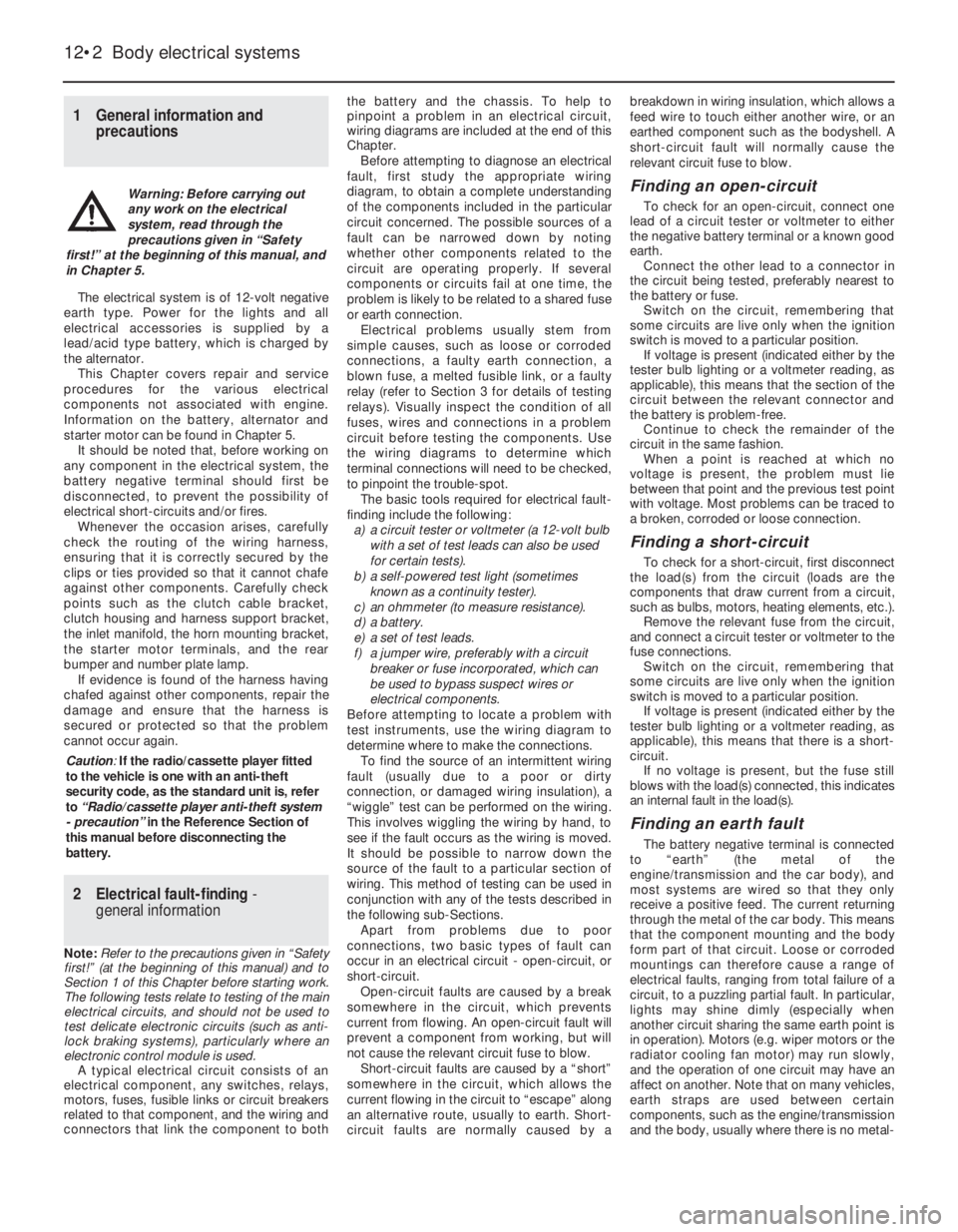

10To remove the motor assembly from the

front door window regulator, unscrew the

three motor securing nuts, and the single

screw securing the pulse pick-up unit to the

regulator assembly. Withdraw the motor,

complete with the pulse pick-up unit. Note

that if the motor or pick-up unit is/are faulty,

the two components must be renewed as an

assembly, as no spare parts are available (see

illustration).

11The motor assembly fitted to the rear door

window regulator is an integral part of the

regulator, and no attempt should be made at

dismantling. If faulty, the complete

motor/regulator assembly must be renewed,

as no spares are available.

45Electric window controls -

programming

1

1Whenever the battery is disconnected, or any

of the electric window components are removed,

on completion of work, the electric window

controls must be programmed as follows.

2Close all doors, and switch on the ignition.

3Close one of the windows by pressing the

relevant operating switch. Press and hold the

switch for a further five seconds after the

relevant window has fully closed.4Repeat the procedure for the remaining

window(s).

46Central door locking

components -removal and

refitting

3

1Disconnect the battery negative lead.

Electronic control module

Removal

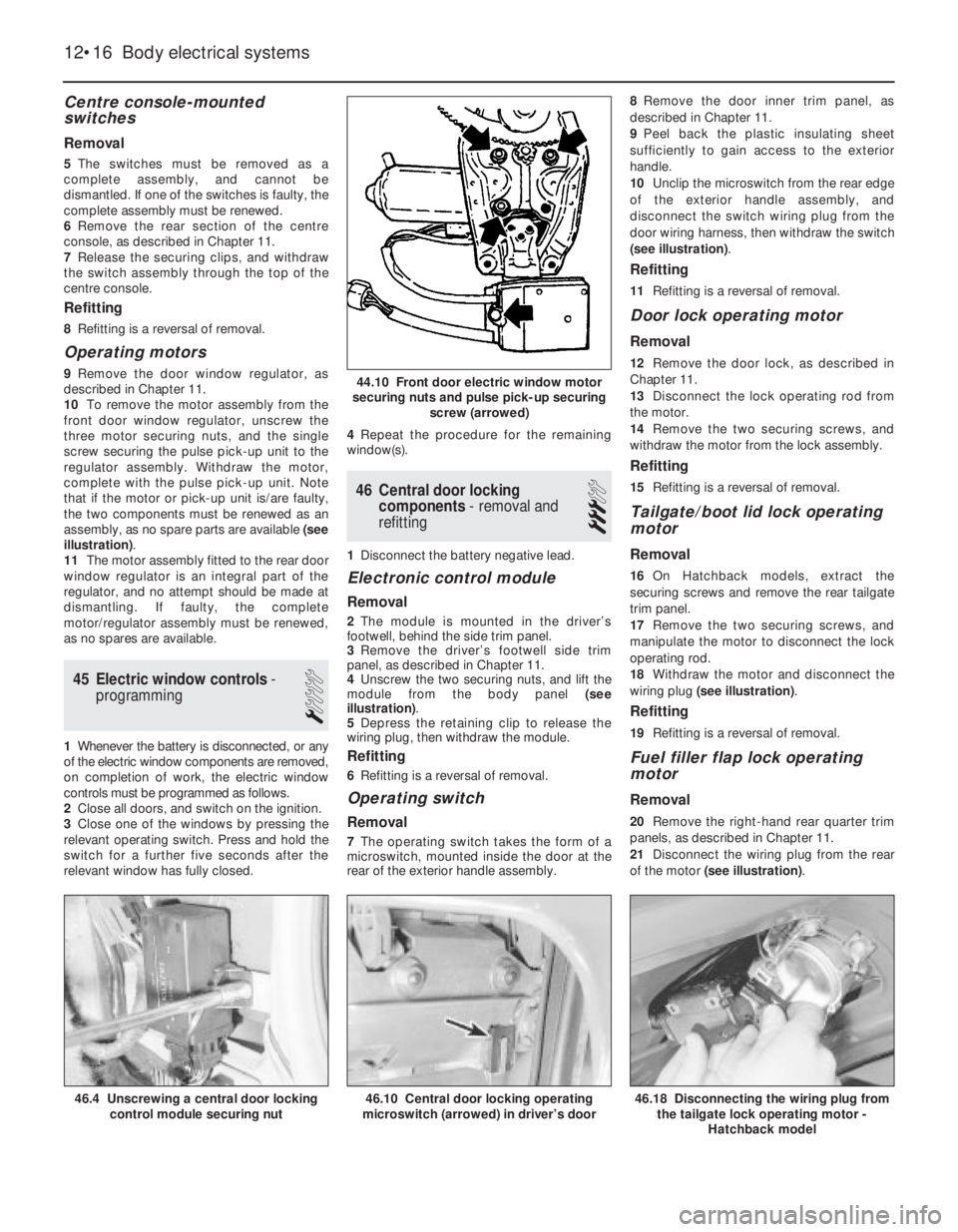

2The module is mounted in the driver’s

footwell, behind the side trim panel.

3Remove the driver’s footwell side trim

panel, as described in Chapter 11.

4Unscrew the two securing nuts, and lift the

module from the body panel (see

illustration).

5Depress the retaining clip to release the

wiring plug, then withdraw the module.

Refitting

6Refitting is a reversal of removal.

Operating switch

Removal

7The operating switch takes the form of a

microswitch, mounted inside the door at the

rear of the exterior handle assembly.8Remove the door inner trim panel, as

described in Chapter 11.

9Peel back the plastic insulating sheet

sufficiently to gain access to the exterior

handle.

10Unclip the microswitch from the rear edge

of the exterior handle assembly, and

disconnect the switch wiring plug from the

door wiring harness, then withdraw the switch

(see illustration).

Refitting

11Refitting is a reversal of removal.

Door lock operating motor

Removal

12Remove the door lock, as described in

Chapter 11.

13Disconnect the lock operating rod from

the motor.

14Remove the two securing screws, and

withdraw the motor from the lock assembly.

Refitting

15Refitting is a reversal of removal.

Tailgate/boot lid lock operating

motor

Removal

16On Hatchback models, extract the

securing screws and remove the rear tailgate

trim panel.

17Remove the two securing screws, and

manipulate the motor to disconnect the lock

operating rod.

18Withdraw the motor and disconnect the

wiring plug (see illustration).

Refitting

19Refitting is a reversal of removal.

Fuel filler flap lock operating

motor

Removal

20Remove the right-hand rear quarter trim

panels, as described in Chapter 11.

21Disconnect the wiring plug from the rear

of the motor (see illustration).

12•16Body electrical systems

44.10 Front door electric window motor

securing nuts and pulse pick-up securing

screw (arrowed)

46.10 Central door locking operating

microswitch (arrowed) in driver’s door46.18 Disconnecting the wiring plug from

the tailgate lock operating motor -

Hatchback model46.4 Unscrewing a central door locking

control module securing nut

Page 34 of 525

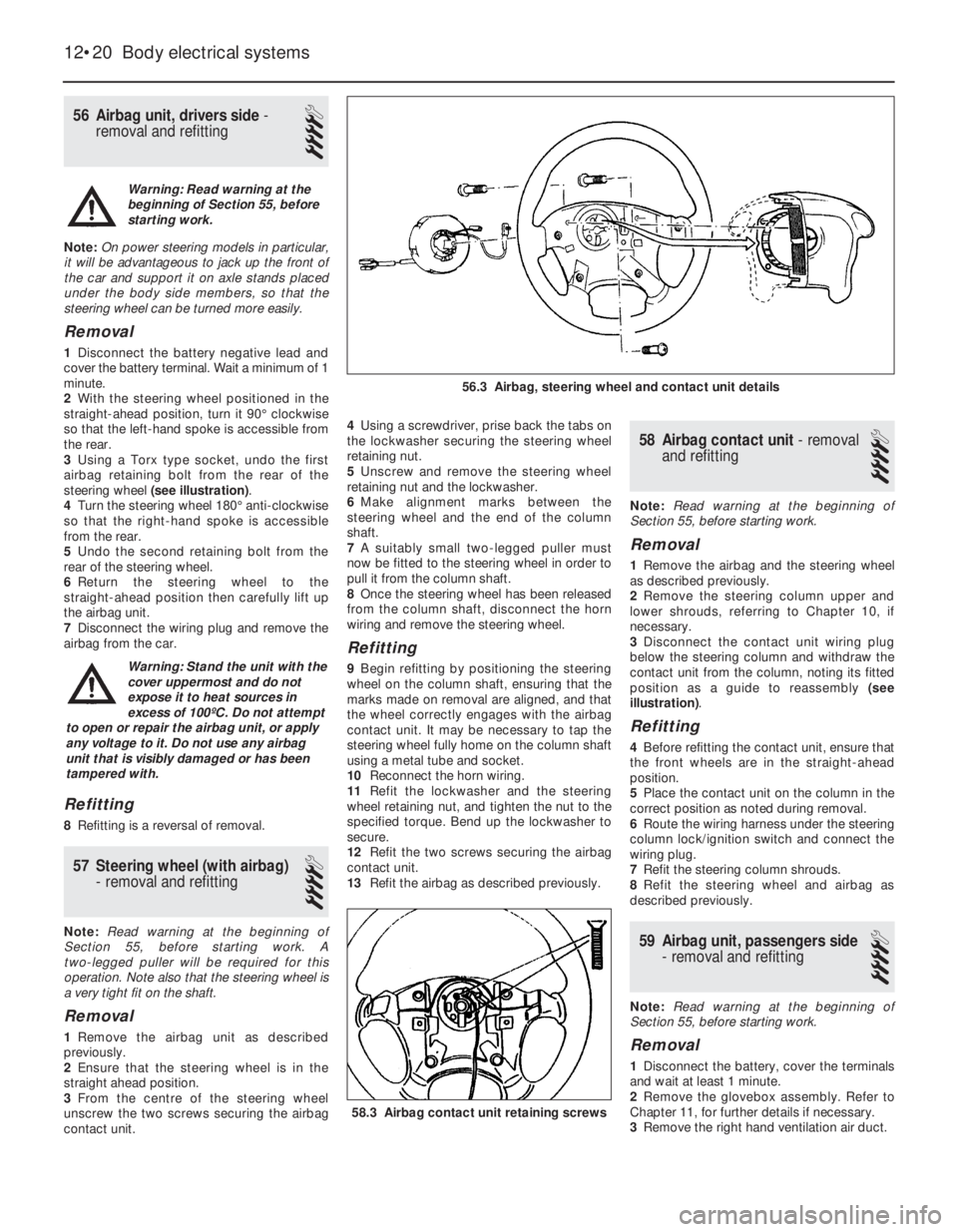

56Airbag unit, drivers side -

removal and refitting

4

Note:On power steering models in particular,

it will be advantageous to jack up the front of

the car and support it on axle stands placed

under the body side members, so that the

steering wheel can be turned more easily.

Removal

1Disconnect the battery negative lead and

cover the battery terminal. Wait a minimum of 1

minute.

2With the steering wheel positioned in the

straight-ahead position, turn it 90°clockwise

so that the left-hand spoke is accessible from

the rear.

3Using a Torx type socket, undo the first

airbag retaining bolt from the rear of the

steering wheel (see illustration).

4Turn the steering wheel 180°anti-clockwise

so that the right-hand spoke is accessible

from the rear.

5Undo the second retaining bolt from the

rear of the steering wheel.

6Return the steering wheel to the

straight-ahead position then carefully lift up

the airbag unit.

7Disconnect the wiring plug and remove the

airbag from the car.

Refitting

8Refitting is a reversal of removal.

57Steering wheel (with airbag)

-removal and refitting

4

Note: Read warning at the beginning of

Section 55, before starting work. A

two-legged puller will be required for this

operation. Note also that the steering wheel is

a very tight fit on the shaft.

Removal

1Remove the airbag unit as described

previously.

2Ensure that the steering wheel is in the

straight ahead position.

3From the centre of the steering wheel

unscrew the two screws securing the airbag

contact unit.4Using a screwdriver, prise back the tabs on

the lockwasher securing the steering wheel

retaining nut.

5Unscrew and remove the steering wheel

retaining nut and the lockwasher.

6Make alignment marks between the

steering wheel and the end of the column

shaft.

7A suitably small two-legged puller must

now be fitted to the steering wheel in order to

pull it from the column shaft.

8Once the steering wheel has been released

from the column shaft, disconnect the horn

wiring and remove the steering wheel.

Refitting

9Begin refitting by positioning the steering

wheel on the column shaft, ensuring that the

marks made on removal are aligned, and that

the wheel correctly engages with the airbag

contact unit. It may be necessary to tap the

steering wheel fully home on the column shaft

using a metal tube and socket.

10Reconnect the horn wiring.

11Refit the lockwasher and the steering

wheel retaining nut, and tighten the nut to the

specified torque. Bend up the lockwasher to

secure.

12Refit the two screws securing the airbag

contact unit.

13Refit the airbag as described previously.

58Airbag contact unit -removal

and refitting

4

Note: Read warning at the beginning of

Section 55, before starting work.

Removal

1Remove the airbag and the steering wheel

as described previously.

2Remove the steering column upper and

lower shrouds, referring to Chapter 10, if

necessary.

3Disconnect the contact unit wiring plug

below the steering column and withdraw the

contact unit from the column, noting its fitted

position as a guide to reassembly (see

illustration).

Refitting

4Before refitting the contact unit, ensure that

the front wheels are in the straight-ahead

position.

5Place the contact unit on the column in the

correct position as noted during removal.

6Route the wiring harness under the steering

column lock/ignition switch and connect the

wiring plug.

7Refit the steering column shrouds.

8Refit the steering wheel and airbag as

described previously.

59Airbag unit, passengers side

- removal and refitting

4

Note: Read warning at the beginning of

Section 55, before starting work.

Removal

1Disconnect the battery, cover the terminals

and wait at least 1 minute.

2Remove the glovebox assembly. Refer to

Chapter 11, for further details if necessary.

3Remove the right hand ventilation air duct.

12•20Body electrical systems

58.3 Airbag contact unit retaining screws

56.3 Airbag, steering wheel and contact unit details

Warning: Read warning at the

beginning of Section 55, before

starting work.

Warning: Stand the unit with the

cover uppermost and do not

expose it to heat sources in

excess of 100ºC. Do not attempt

to open or repair the airbag unit, or apply

any voltage to it. Do not use any airbag

unit that is visibly damaged or has been

tampered with.