brake light OPEL COMBO 2010 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2010, Model line: COMBO, Model: OPEL COMBO 2010Pages: 212, PDF Size: 2.49 MB

Page 126 of 212

120 Driving and operationSelf testing

When the engine is started and the vehicle

starts off, the system performs a self-check,

which may be audible.

Fault

Have cause of fault remedied by a

workshop. The system’s integrated self

diagnostics allow faults to be quickly

remedied.

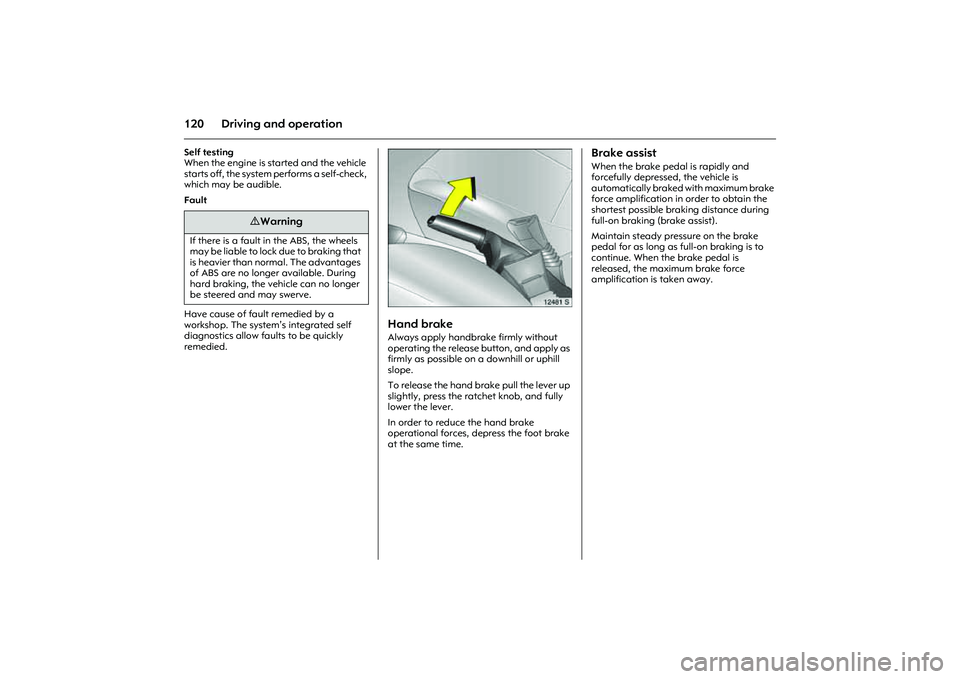

Picture no: 12481s.tif

Hand brake Always apply handbrake firmly without

operating the release button, and apply as

firmly as possible on a downhill or uphill

slope.

To release the hand brake pull the lever up

slightly, press the ratchet knob, and fully

lower the lever.

In order to reduce the hand brake

operational forces, depress the foot brake

at the same time.

Brake assist When the brake pedal is rapidly and

forcefully depressed, the vehicle is

automatically braked with maximum brake

force amplification in order to obtain the

shortest possible braking distance during

full-on braking (brake assist).

Maintain steady pressure on the brake

pedal for as long as full-on braking is to

continue. When the brake pedal is

released, the maximum brake force

amplification is taken away.

9 Warning

If there is a fault in the ABS, the wheels

may be liable to lock due to braking that

is heavier than normal. The advantages

of ABS are no longer available. During

hard braking, the vehicle can no longer

be steered and may swerve.

Page 132 of 212

126 Driving and operationTowing equipment

3

Only use towing equipment that has been

approved for your vehicle. Entrust

retrofitting of towing equipment to a

workshop. It may be necessary to make

changes that affect the cooling system,

heat shields or other equipment.

Installation dimensions of towing

equipment 3197.

Towing equipment with fixed coupling

ball bar3

In the case of trailers/caravans with brake,

attach break-away stopping cable to eye

to right of coupling ball bar. Caravan/trailer towingCaravan and trailer loads

1)

The permissible caravan/trailer loads are

vehicle and engine-dependent maximum

values which must not be exceeded. The

actual caravan/trailer load is the difference

between the actual gross weight of the

caravan/trailer and the actual coupling

socket load with the caravan/trailer

coupled.

The permissible caravan/trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients up to

max. 12 %. The permitted caravan/trailer load applies

up to the specified incline and up to an

altitude of 1000 metres above sea level.

Since engine power decreases as altitude

increases because of the air becoming

thinner, therefore reducing climbing ability,

the permitted towing weight also

decreases by 10 % for every 1000 metres

of additional altitude. The towing weight

does not have to be reduced when driving

on roads with slight inclines (less than 8 %,

e. g. motorways).

The permissible gross train weight must not

be exceeded. This weight is specified on

the identification plate 3182. Coupling socket load

The coupling socket load is the load

exerted by the trailer/caravan on the

coupling ball. It can be varied by changing

the weight distribution when loading the

trailer/caravan.

The maximum permissible coupling socket

load (50 kg) is specified on the towing

equipment identification plate and in the

vehicle documents. Always aim for the

maximum load, especially in the case of

heavy caravans/trailers. The coupling

socket load should never fall below 25 kg.

When measuring the coupling socket load,

make sure that the drawbar of the loaded

trailer/caravan is at the same height as it

will be when the trailer/caravan is coupled

with the towing vehicle loaded. Particularly

important for trailers/caravans with

tandem axle.

Rear axle load during towing

The permissible axle loads must not be

exceeded. 1)Observe national regulations.

Page 133 of 212

127

Driving and operation

Picture no: 13228s.tif

Driving characteristics, towing tips

In the case of trailers/caravans with brakes,

attach breakaway stopping cable to eye.

Before attaching the trailer/caravan,

lubricate the ball of the trailer/caravan

towing device. However, do not lubricate

the ball if a stabiliser, which acts on the

coupling ball, is being used to damp

hunting.

Check caravan/trailer lighting before

starting to drive. The fog tail lamps on the

vehicle are deactivated when towing a

caravan or trailer. Caravans/trailers with LED turn signals

require a provision that make bulb

replacement as with standard bulbs

possible.

Handling is greatly influenced by the

loading of the trailer/caravan. Loads

should therefore be secured so that they

cannot slip and be placed in the centre of

the trailer/caravan if possible, i.e. above

the axle.

In the case of trailers with low driving

stability, do not exceed a speed of

80 km/h; the use of a friction-type

stabiliser is highly recommended.

If the trailer/caravan starts to sway, drive

more slowly, do not attempt to correct the

steering and brake sharply if necessary.

If it is necessary to apply the brakes fully,

depress the brake pedal as hard as

possible.

Remember that the braking distance for

vehicles towing caravans/trailers with and

without brake is always greater than that

for vehicles not towing a caravan/trailer. When driving downhill, drive in the same

gear as if driving uphill and drive at a

similar speed.

Adjust tyre pressure to the value specified

for full load 3121, 3191.

Page 143 of 212

137

Self-help, vehicle care

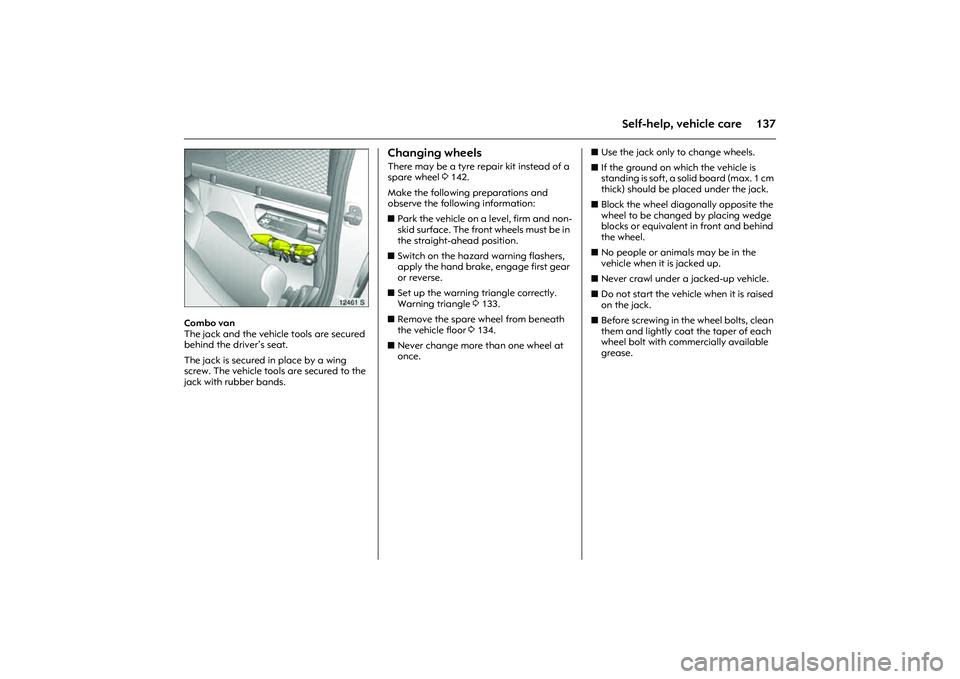

Picture no: 12461s.tif

Combo van

The jack and the vehicle tools are secured

behind the driver’s seat.

The jack is secured in place by a wing

screw. The vehicle tools are secured to the

jack with rubber bands.

Changing wheels There may be a tyre repair kit instead of a

spare wheel 3142.

Make the following preparations and

observe the following information:

zPark the vehicle on a level, firm and non-

skid surface. The front wheels must be in

the straight-ahead position.

zSwitch on the hazard warning flashers,

apply the hand brake, engage first gear

or reverse.

zSet up the warning triangle correctly.

Warning triangle 3133.

zRemove the spare wheel from beneath

the vehicle floor 3134.

zNever change more than one wheel at

once. zUse the jack only to change wheels.

zIf the ground on which the vehicle is

standing is soft, a solid board (max. 1 cm

thick) should be placed under the jack.

zBlock the wheel diagonally opposite the

wheel to be changed by placing wedge

blocks or equivalent in front and behind

the wheel.

zNo people or animals may be in the

vehicle when it is jacked up.

zNever crawl under a jacked-up vehicle.

zDo not start the vehicle when it is raised

on the jack.

zBefore screwing in the wheel bolts, clean

them and lightly coat the taper of each

wheel bolt with commercially available

grease.

Page 163 of 212

157

Self-help, vehicle care

Picture no: 12449s.tif

Tail lamps 1. Disengage cover by pressing retaining

lugs and remove.

Picture no: 13725s.tif

2. Detach plug connector from bulb

mounting.

3. Grip the bulb housing from the outside,

slacken the two knurled nuts using the

wheel bolt spanner 3 and unscrew by

hand.

4. Detach bulb housing.

5. Press retaining lugs on bulb mounting

together and remove bulb mounting, as

shown in illustration 13726 S.

Picture no: 13726s.tif

Lamps from top to bottom:

6. Remove bulb from socket.

7. Insert a new bulb. Engage the bulb

mounting in the bulb housing. Insert the

bulb housing into the vehicle body.

Screw the fixing nuts onto setscrews by

hand and tighten. Engage the plug

connector. Place the cover in position

and close. Reversing light/brake light

Turn signal lamp

Reversing light

Fog tail lamp (country-specific version:

fog tail lamp at one side only).

Page 168 of 212

162 Self-help, vehicle careExterior lights

Headlamp and other lamp lens are made

of plastic. Do not use any abrasive or

caustic agents, do not use an ice scraper,

and do not clean them dry.

Plastic and rubber parts

Plastic and rubber parts can be cleaned

with the same cleaner as used to clean the

body. Use interior cleaner if necessary. Do

not use any other agent. Avoid solvents

and petrol in particular. Do not use high-

pressure jet cleaners.

Interior and upholstery

Clean the vehicle interior, including the

instrument panel fascia, using interior

cleaner.

The instrument panel is only to be cleaned

with a soft, damp cloth.

Clean the fabric upholstery with a vacuum

cleaner and brush. Remove stains with an

upholstery cleaner.

Clean seat belts with lukewarm water or

interior cleaner. Windows and windscreen wiper blades

Use a soft lint-free cloth or chamois leather

together with window cleaner and insect

remover.

When cleaning the rear window, make sure

the heating element inside the window is

not damaged.

For mechanical removal of ice, use a sharp-

edged ice scraper. Press the scraper firmly

against the glass so that no dirt can get

under it and scratch the glass.

Clean smearing wiper blades with a soft

cloth and window cleaner.

Locks

The locks are lubricated at the factory

using a high quality lock cylinder grease.

Use de-icing agent only where absolutely

necessary, as this removes grease and

impairs lock function. After using de-icing

agent, have the locks regreased by a

workshop. Engine compartment

Clean painted surfaces in the engine

compartment like any other painted

surface.

For best results, wash and wax the engine

compartment before and after winter.

Before washing the engine, cover the

alternator and brake fluid reservoir with

plastic sheeting.

When washing the engine with a steam-jet

cleaner, do not direct the steam jet at

components of the Anti-lock Braking

System 3, the automatic air conditioning

system 3 or the belt drive and its

components.

After an engine wash, have all engine room

components preserved thoroughly by a

workshop using protective wax.

Do not use high-pressure jet cleaners.

Caution

Close Velcro fasteners as open Velcro

fasteners on clothing could damage

seat upholstery.

Page 171 of 212

165 Opel Service, maintenance

European service plan⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

302

603

904

1205

150

Visually inspect control, lighting and signal devices as well as airbags;

check steering column lock and ignition switchxxxxx

Remote control: replace batteries (don’t forget the spare key) every 2 years

Check and correct windscreen wipers, windscreen washer system and headlamp

washer systemxxxxx

Check and correct coolant level and frost protection (pale orange)

2)

Note freeze protection temperature in the Service and Warranty Booklet

(confirmation box)

2)If loss is great/leaks are present, carry out follow-up work with customer consent.

xxxxx

Check water hoses for leaks and check to make sure they are firmly seated x x x x x

Check and correct brake fluid level

2) xxx

Check battery clamps to make sure they are firmly seated and check the battery eye x x x x x

Vehicle System Check with TECH 2 x x x x x

Replace pollen filter or active charcoal filter x x

⊕o

if the air is heavily polluted or there are high levels of airborne dust, sand or pollen,

the air-conditioning system will produce an odourVerbal arrangement between the

customer and Opel Partner

Replace the air filter element every 4 years/60,000 km

⊕

Replace spark plugsevery 4 years/60,000 km

Z 16 YNGevery 2 years/30,000 km

Visually inspect the ribbed V-belt every 2 years/60,000 km

⊕

Replace ribbed V-belt

Y 13 DTJ, Z 13 DTJ, Y 13 DT, Z 13 DT, Z 17 DTH every 10 years/150,000 km

⊕

Check valve play and adjust

Z16 XEP, Z 17 DTHevery 10 years/150,000 km

Page 173 of 212

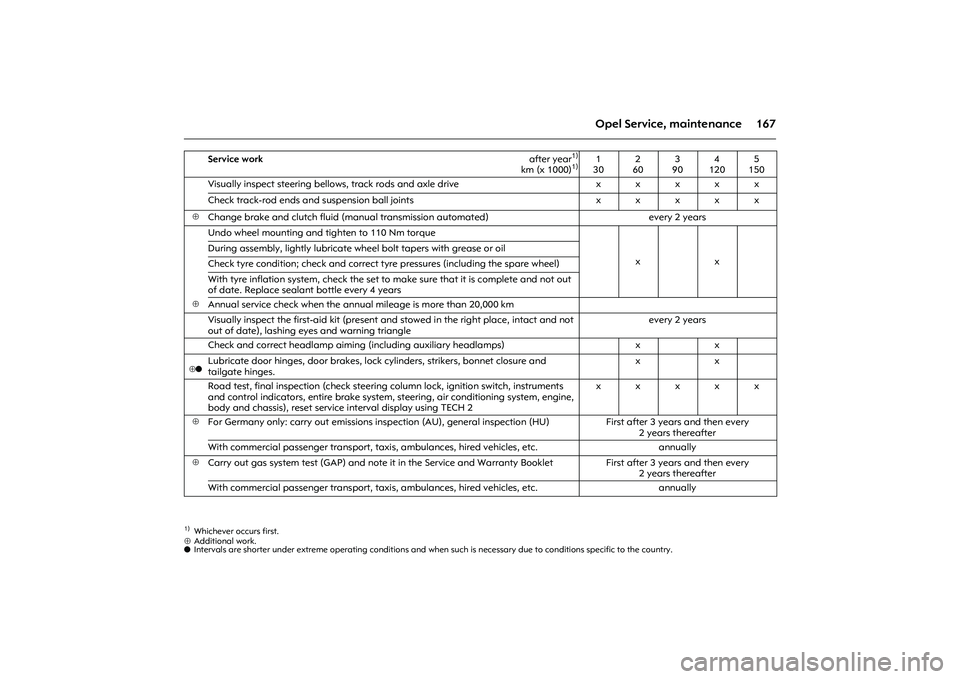

167 Opel Service, maintenance

⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

302

603

904

1205

150

Visually inspect steering bellows, track rods and axle drive xxxxx

Check track-rod ends and suspension ball joints xxxxx

⊕

Change brake and clutch fluid (manual transmission automated) every 2 years

Undo wheel mounting and tighten to 110 Nm torque

xx During assembly, lightly lubricate wheel bolt tapers with grease or oil

Check tyre condition; check and correct tyre pressures (including the spare wheel)

With tyre inflation system, check the set to make sure that it is complete and not out

of date. Replace sealant bottle every 4 years

⊕

Annual service check when the annual mileage is more than 20,000 km

Visually inspect the first-aid kit (present and stowed in the right place, intact and not

out of date), lashing eyes and warning triangleevery 2 years

Check and correct headlamp aiming (including auxiliary headlamps) x x

⊕o

Lubricate door hinges, door brakes, lock cylinders, strikers, bonnet closure and

tailgate hinges.xx

Road test, final inspection (check steering column lock, ignition switch, instruments

and control indicators, entire brake system, steering, air conditioning system, engine,

body and chassis), reset service interval display using TECH 2xxxxx

⊕

For Germany only: carry out emissions inspection (AU), general inspection (HU) First after 3 years and then every

2 years thereafter

With commercial passenger transport, taxis, ambulances, hired vehicles, etc. annually

⊕

Carry out gas system test (GAP) and note it in the Service and Warranty Booklet First after 3 years and then every

2 years thereafter

With commercial passenger transport, taxis, ambulances, hired vehicles, etc. annually

Page 174 of 212

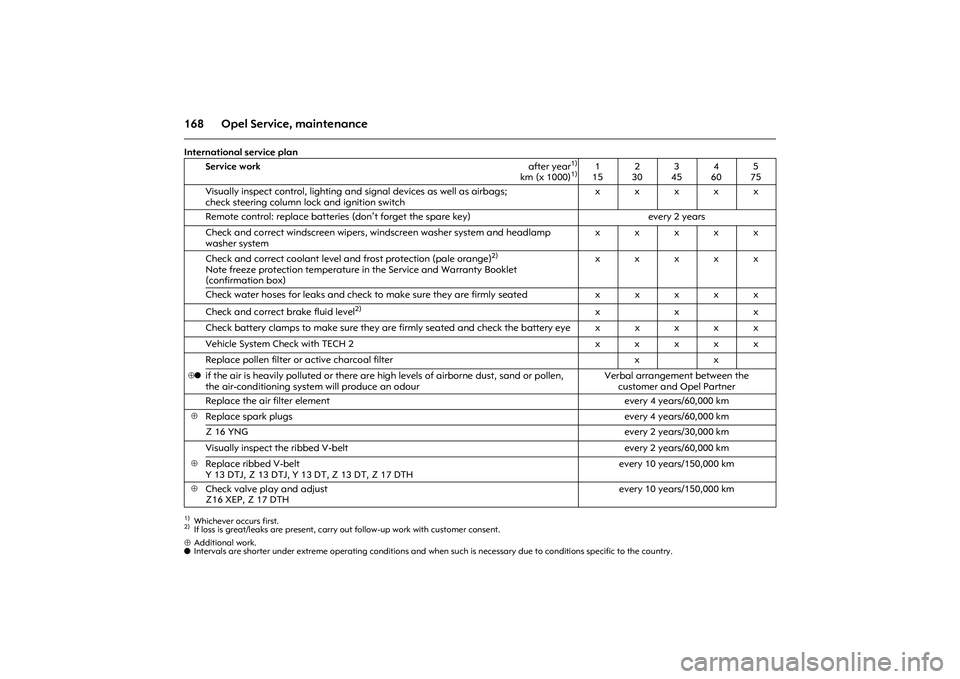

168 Opel Service, maintenanceInternational service plan⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

152

303

454

605

75

Visually inspect control, lighting and signal devices as well as airbags;

check steering column lock and ignition switchxxxxx

Remote control: replace batteries (don’t forget the spare key) every 2 years

Check and correct windscreen wipers, windscreen washer system and headlamp

washer systemxxxxx

Check and correct coolant level and frost protection (pale orange)

2)

Note freeze protection temperature in the Service and Warranty Booklet

(confirmation box)

2)If loss is great/leaks are present, carry out follow-up work with customer consent.

xxxxx

Check water hoses for leaks and check to make sure they are firmly seated x x x x x

Check and correct brake fluid level

2) xxx

Check battery clamps to make sure they are firmly seated and check the battery eye x x x x x

Vehicle System Check with TECH 2 x x x x x

Replace pollen filter or active charcoal filter x x

⊕o

if the air is heavily polluted or there are high levels of airborne dust, sand or pollen,

the air-conditioning system will produce an odourVerbal arrangement between the

customer and Opel Partner

Replace the air filter element every 4 years/60,000 km

⊕

Replace spark plugsevery 4 years/60,000 km

Z 16 YNGevery 2 years/30,000 km

Visually inspect the ribbed V-belt every 2 years/60,000 km

⊕

Replace ribbed V-belt

Y 13 DTJ, Z 13 DTJ, Y 13 DT, Z 13 DT, Z 17 DTH every 10 years/150,000 km

⊕

Check valve play and adjust

Z16 XEP, Z 17 DTHevery 10 years/150,000 km

Page 176 of 212

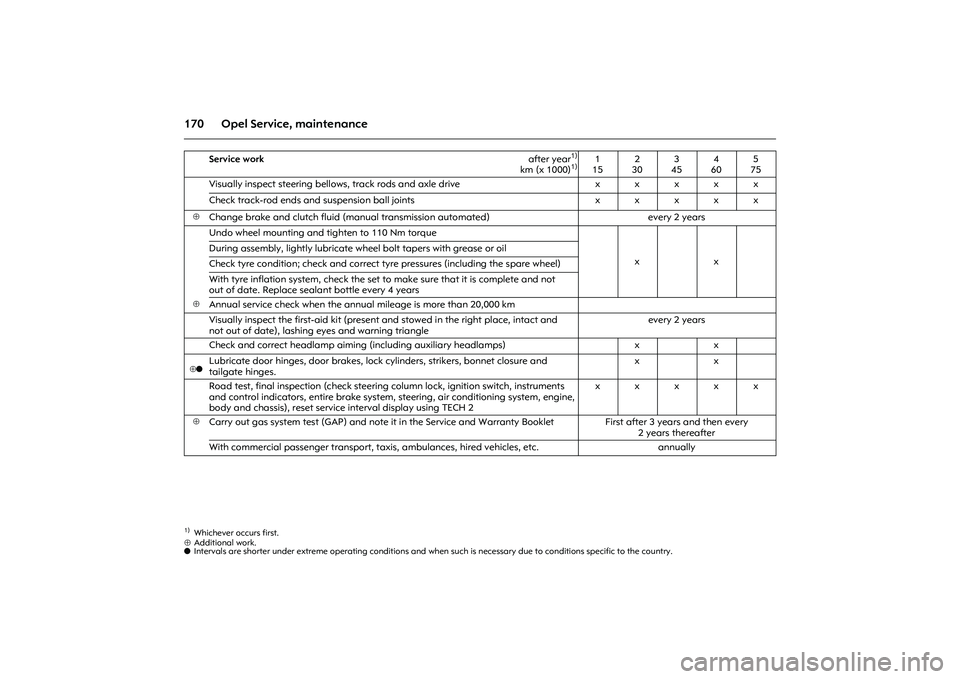

170 Opel Service, maintenance⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

152

303

454

605

75

Visually inspect steering bellows, track rods and axle drive x x x x x

Check track-rod ends and suspension ball joints x x x x x

⊕

Change brake and clutch fluid (manual transmission automated) every 2 years

Undo wheel mounting and tighten to 110 Nm torque

xx During assembly, lightly lubricate wheel bolt tapers with grease or oil

Check tyre condition; check and correct tyre pressures (including the spare wheel)

With tyre inflation system, check the set to make sure that it is complete and not

out of date. Replace sealant bottle every 4 years

⊕

Annual service check when the annual mileage is more than 20,000 km

Visually inspect the first-aid kit (present and stowed in the right place, intact and

not out of date), lashing eyes and warning triangleevery 2 years

Check and correct headlamp aiming (including auxiliary headlamps) x x

⊕o

Lubricate door hinges, door brakes, lock cylinders, strikers, bonnet closure and

tailgate hinges.xx

Road test, final inspection (check steering column lock, ignition switch, instruments

and control indicators, entire brake system, steering, air conditioning system, engine,

body and chassis), reset service interval display using TECH 2xxxxx

⊕

Carry out gas system test (GAP) and note it in the Service and Warranty Booklet First after 3 years and then every

2 years thereafter

With commercial passenger transport, taxis, ambulances, hired vehicles, etc. annually