ECU OPEL CROSSLAND X 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: CROSSLAND X, Model: OPEL CROSSLAND X 2018Pages: 257, PDF Size: 7.81 MB

Page 207 of 257

Vehicle care205No.Circuit1Heated rear window2Heated exterior mirrors3Front power window4Driver's door control unit5Rear power window6Heated seats7–8Infotainment9–10Power outlet rear11–12–Vehicle tools

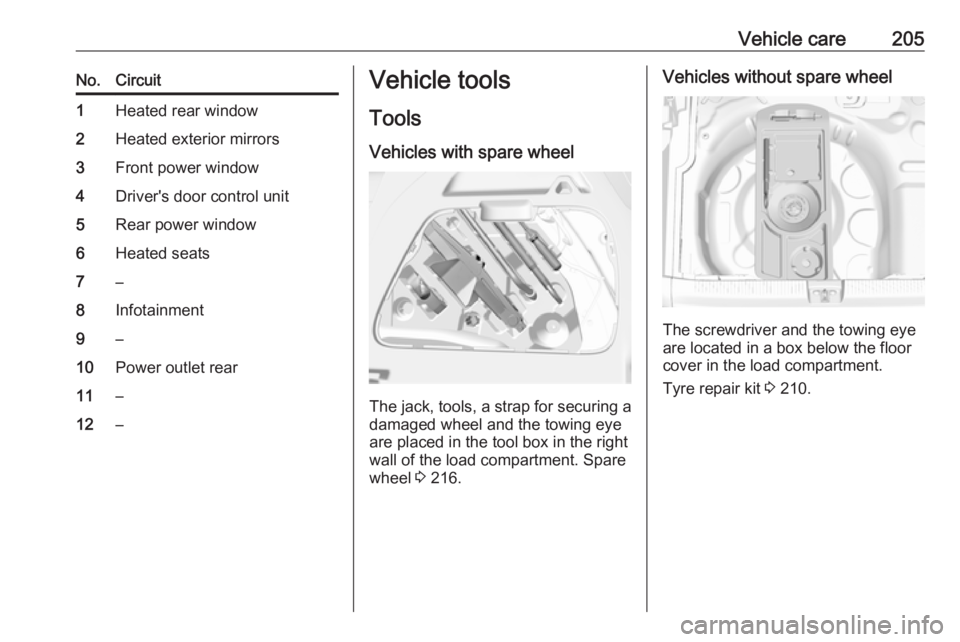

Tools

Vehicles with spare wheel

The jack, tools, a strap for securing a damaged wheel and the towing eye

are placed in the tool box in the right

wall of the load compartment. Spare

wheel 3 216.

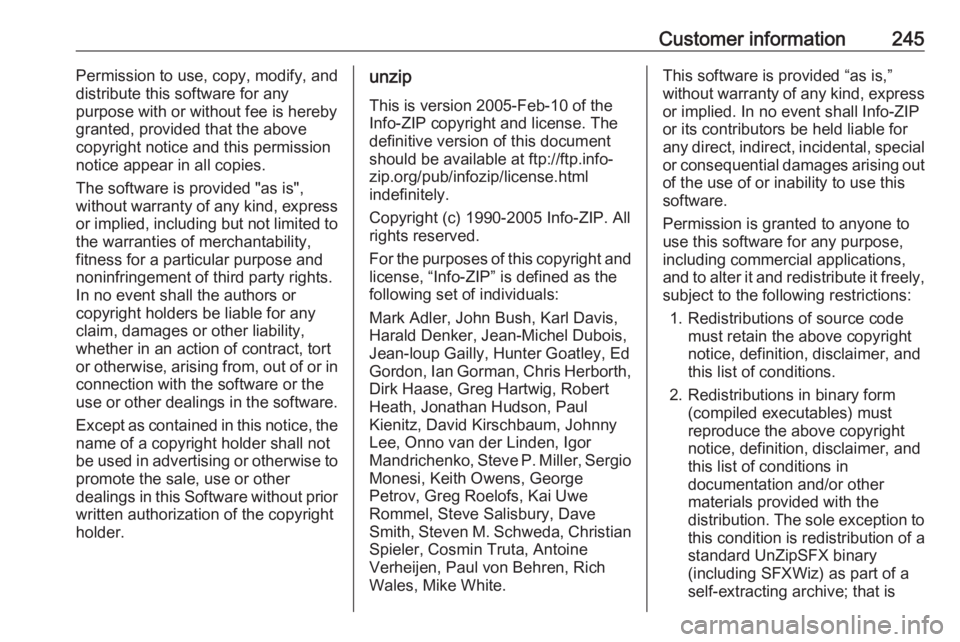

Vehicles without spare wheel

The screwdriver and the towing eye

are located in a box below the floor

cover in the load compartment.

Tyre repair kit 3 210.

Page 216 of 257

214Vehicle care

● Note that the spare wheel issecured by the conical contact ofeach bolt if the wheel bolts for the

alloy wheels are used. In this

case, the washers do not come

into contact with the spare wheel.

1. Disengage wheel bolt caps with a

screwdriver and remove.

Steel wheels with cover: Pull off

the wheel cover.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the load compartment under the

rear floor cover.3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

Page 217 of 257

Vehicle care215the jacking point in a manner thatprevents it from slipping.

Ensure that the edge of the body

fits into the notch of the jack.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel bolts. 6. Change the wheel. Spare wheel 3 216.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

100 Nm for all wheels.

If the vehicle is equipped with

alloy wheels, note that the wheel

bolts can also be used for the steel spare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel bolt caps.11. Stow and secure the replaced wheel 3 216, the vehicle tools

3 205 and the adapter for the

locking wheel bolts 3 65.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform at the underbody.

Page 218 of 257

216Vehicle care

Front arm position of the lifting

platform at the underbody.

Spare wheel Mounting the temporary spare

wheel

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The temporary spare wheel has a

steel rim.

The temporary spare wheel is located in the load compartment beneath the

floor covering.

To remove: 1. Open the floor cover.

2. The temporary spare wheel is secured with a wing nut. Turn

wing nut anticlockwise and

remove the wheel.

There is a box with tools in the

right wall of the load

compartment. Vehicle tools 3 205

3. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

turning right back the wing nut and close the floor cover.

4. After a wheel change back to a full

size wheel, place the spare wheel outside up in the well and secure

with the wing nut.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full tyre in the rear.

Tyre chains 3 210.

Stowing a damaged full size

wheel in the load compartment

The spare wheel well is not designed

for other tyre sizes than the temporary spare wheel. A damaged full size

wheel must be stowed in the load

Page 219 of 257

Vehicle care217compartment and secured with a

strap. Vehicle tools 3 205. To secure

the wheel:

1. Position the wheel outside up close to one sidewall of the load

compartment.

2. Place the loop end of the strap through the front lashing eye on

the appropriate side.

3. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.

4. Insert the strap through the spokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear lashing

eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

Page 247 of 257

Customer information245Permission to use, copy, modify, and

distribute this software for any

purpose with or without fee is hereby

granted, provided that the above

copyright notice and this permission

notice appear in all copies.

The software is provided "as is",

without warranty of any kind, express

or implied, including but not limited to

the warranties of merchantability,

fitness for a particular purpose and

noninfringement of third party rights.

In no event shall the authors or

copyright holders be liable for any

claim, damages or other liability,

whether in an action of contract, tort

or otherwise, arising from, out of or in connection with the software or the

use or other dealings in the software.

Except as contained in this notice, the name of a copyright holder shall not

be used in advertising or otherwise to

promote the sale, use or other

dealings in this Software without prior

written authorization of the copyright

holder.unzip

This is version 2005-Feb-10 of the

Info-ZIP copyright and license. The

definitive version of this document

should be available at ftp://ftp.info-

zip.org/pub/infozip/license.html

indefinitely.

Copyright (c) 1990-2005 Info-ZIP. All

rights reserved.

For the purposes of this copyright and

license, “Info-ZIP” is defined as the

following set of individuals:

Mark Adler, John Bush, Karl Davis,

Harald Denker, Jean-Michel Dubois,

Jean-loup Gailly, Hunter Goatley, Ed

Gordon, Ian Gorman, Chris Herborth, Dirk Haase, Greg Hartwig, Robert

Heath, Jonathan Hudson, Paul

Kienitz, David Kirschbaum, Johnny

Lee, Onno van der Linden, Igor

Mandrichenko, Steve P. Miller, Sergio Monesi, Keith Owens, George

Petrov, Greg Roelofs, Kai Uwe

Rommel, Steve Salisbury, Dave

Smith, Steven M. Schweda, Christian

Spieler, Cosmin Truta, Antoine

Verheijen, Paul von Behren, Rich

Wales, Mike White.This software is provided “as is,”

without warranty of any kind, express or implied. In no event shall Info-ZIP

or its contributors be held liable for

any direct, indirect, incidental, special

or consequential damages arising out

of the use of or inability to use this

software.

Permission is granted to anyone to

use this software for any purpose,

including commercial applications,

and to alter it and redistribute it freely,

subject to the following restrictions:

1. Redistributions of source code must retain the above copyright

notice, definition, disclaimer, and

this list of conditions.

2. Redistributions in binary form (compiled executables) must

reproduce the above copyright

notice, definition, disclaimer, and

this list of conditions in

documentation and/or other

materials provided with the

distribution. The sole exception to this condition is redistribution of a

standard UnZipSFX binary

(including SFXWiz) as part of a

self-extracting archive; that is

Page 250 of 257

248Customer information● vehicle reactions in particulardriving situations ( e.g. inflation of

an airbag, activation of the

stability regulation system)

● environmental conditions (e.g. temperature)

These data are exclusively technical

and help identifying and correcting

errors as well as optimising vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with these

data.

If services are used (e.g. repair

works, service processes, warranty

cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data are deleted from

the error storage module or they are

constantly overwritten.When using the vehicle, situations

may occur in which these technical

data related to other information

(accident report, damages on the

vehicle, witness statements etc.) may be associated with a specific person -possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular

vehicle data from the vehicle.

Radio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in Opel

vehicles does not use or record

personal information or link with any

other Opel system containing

personal information.

Page 256 of 257

254UUltrasonic parking assist............. 161

Upholstery .................................. 223

Using this manual ..........................3

V Valet mode ................................... 98

Vehicle battery ........................... 190

Vehicle checks............................ 187

Vehicle data ................................ 230

Vehicle data recording and privacy ..................................... 247

Vehicle dimensions .................... 237

Vehicle Identification Number ....228

Vehicle jack ................................ 205

Vehicle messages .....................102

Vehicle personalisation .............103

Vehicle security ............................ 32

Vehicle specific data ......................3

Vehicle storage ........................... 186

Vehicle tools ............................... 205

Vehicle unlocking ........................... 6

Vehicle weight ........................... 236

Ventilation ................................... 120

W

Warning chimes .........................102

Warning lights ............................... 85

Warning triangle .......................... 71

Washer and wiper systems .........14

Washer fluid ............................... 189Wheel changing .........................213

Wheel covers ............................. 209

Wheels and tyres .......................206

Windows ....................................... 37

Windscreen................................... 37 Windscreen wiper/washer ...........76

Winter tyres ............................... 206

Wiper blade replacement ..........192