lock OPEL CROSSLAND X 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: CROSSLAND X, Model: OPEL CROSSLAND X 2018Pages: 257, PDF Size: 7.81 MB

Page 198 of 257

196Vehicle careLight assembly in the body

Detaching the light assembly

1. Unscrew the two screws that secure the light assembly.

2. Remove the light assembly bypulling it straight back.

3. Remove the three screws thatsecure the bulb carrier.

4. Version without LED

Remove the bulb by pulling and

replace.

Tail light/Brake light 1

Turn-signal light 2

Version with LED

Only turn signal light bulb can be

replaced.

Remove the bulb socket from the light assembly by turning it

anticlockwise.

Page 200 of 257

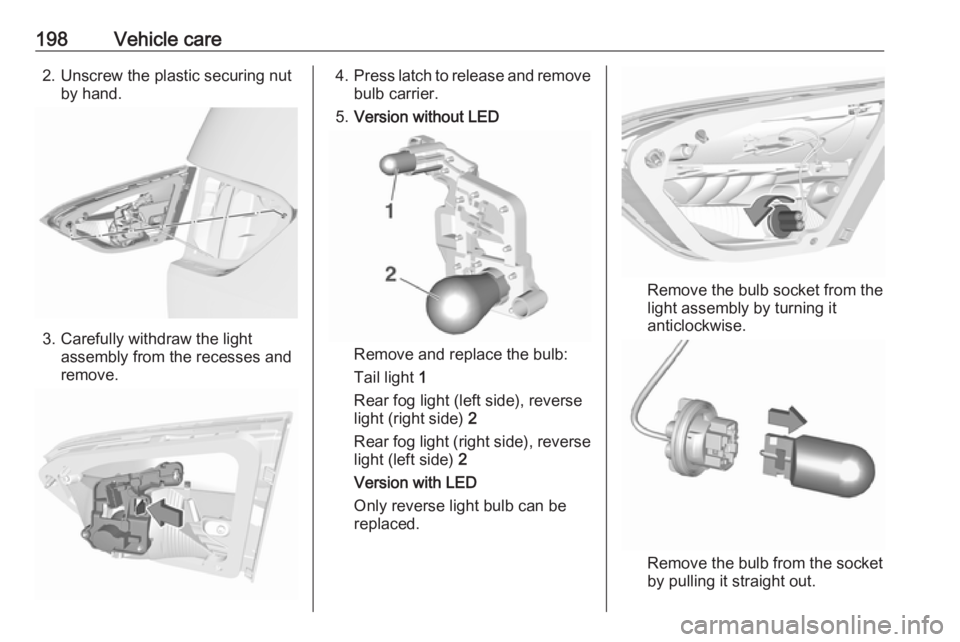

198Vehicle care2. Unscrew the plastic securing nutby hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Press latch to release and remove

bulb carrier.

5. Version without LED

Remove and replace the bulb:

Tail light 1

Rear fog light (left side), reverse

light (right side) 2

Rear fog light (right side), reverse

light (left side) 2

Version with LED

Only reverse light bulb can be

replaced.

Remove the bulb socket from the

light assembly by turning it

anticlockwise.

Remove the bulb from the socket by pulling it straight out.

Page 201 of 257

Vehicle care199Replace bulb.

Attaching the light assembly 1. Attach bulb carrier to the light assembly.

2. Attach the light assembly to thetailgate.

3. Secure the light assembly with the

plastic securing nut.

4. Attach the cover to the tailgate.

Side turn signal lights

To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder and replace it.

Page 202 of 257

200Vehicle care4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

The number plate light is designed as

LEDs and can not be changed. In

case of defective LEDs, have them

replaced by a workshop.

Interior lights

Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Instrument panel illumination

Have bulbs replaced by a workshop.Electrical system

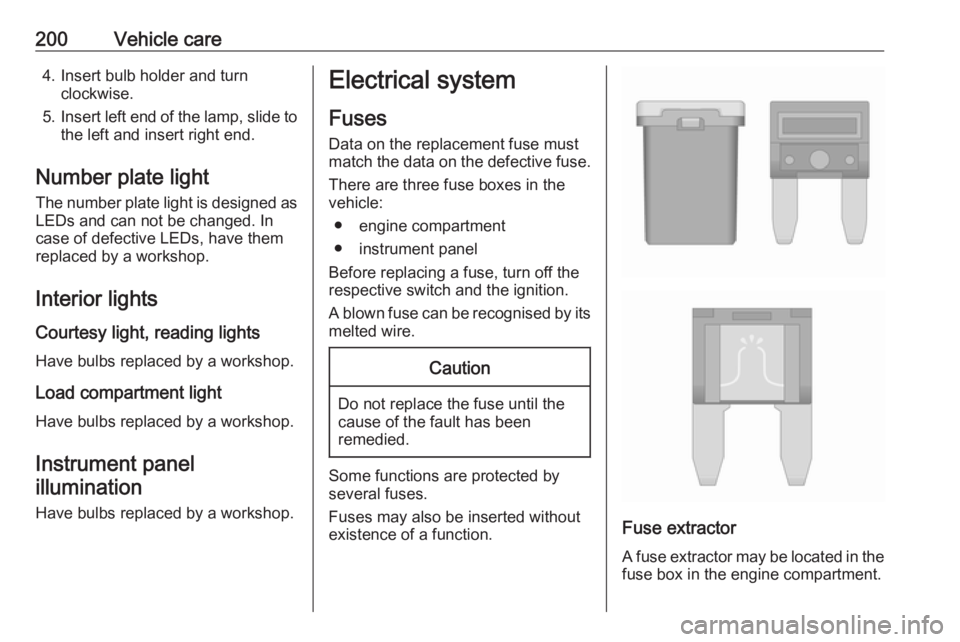

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● engine compartment

● instrument panel

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

Page 205 of 257

Vehicle care203

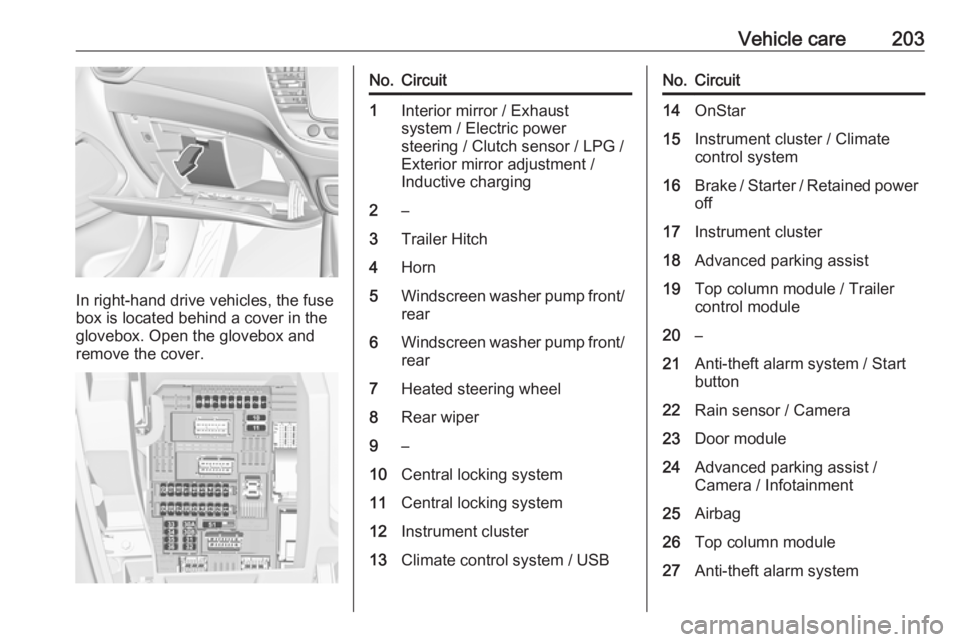

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox and

remove the cover.

No.Circuit1Interior mirror / Exhaust

system / Electric power

steering / Clutch sensor / LPG /

Exterior mirror adjustment /

Inductive charging2–3Trailer Hitch4Horn5Windscreen washer pump front/

rear6Windscreen washer pump front/ rear7Heated steering wheel8Rear wiper9–10Central locking system11Central locking system12Instrument cluster13Climate control system / USBNo.Circuit14OnStar15Instrument cluster / Climate

control system16Brake / Starter / Retained power off17Instrument cluster18Advanced parking assist19Top column module / Trailer

control module20–21Anti-theft alarm system / Start

button22Rain sensor / Camera23Door module24Advanced parking assist /

Camera / Infotainment25Airbag26Top column module27Anti-theft alarm system

Page 211 of 257

Vehicle care209For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as to reinitialise

the tyre deflation detection system

and make other vehicle modifications.

Tyre deflation detection system

3 207.

Have the label with tyre pressures

replaced.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Page 212 of 257

210Vehicle careTyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 195/65 R15 91 and

195/60 R16 89

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in the load

compartment below the floor cover.

1. Remove the sealant bottle and the

compressor.

2. Pull speed limit label from sealant

bottle and place it in driver's

visible area.

Page 216 of 257

214Vehicle care

● Note that the spare wheel issecured by the conical contact ofeach bolt if the wheel bolts for the

alloy wheels are used. In this

case, the washers do not come

into contact with the spare wheel.

1. Disengage wheel bolt caps with a

screwdriver and remove.

Steel wheels with cover: Pull off

the wheel cover.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the load compartment under the

rear floor cover.3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

Page 217 of 257

Vehicle care215the jacking point in a manner thatprevents it from slipping.

Ensure that the edge of the body

fits into the notch of the jack.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel bolts. 6. Change the wheel. Spare wheel 3 216.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

100 Nm for all wheels.

If the vehicle is equipped with

alloy wheels, note that the wheel

bolts can also be used for the steel spare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel bolt caps.11. Stow and secure the replaced wheel 3 216, the vehicle tools

3 205 and the adapter for the

locking wheel bolts 3 65.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform at the underbody.

Page 218 of 257

216Vehicle care

Front arm position of the lifting

platform at the underbody.

Spare wheel Mounting the temporary spare

wheel

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The temporary spare wheel has a

steel rim.

The temporary spare wheel is located in the load compartment beneath the

floor covering.

To remove: 1. Open the floor cover.

2. The temporary spare wheel is secured with a wing nut. Turn

wing nut anticlockwise and

remove the wheel.

There is a box with tools in the

right wall of the load

compartment. Vehicle tools 3 205

3. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

turning right back the wing nut and close the floor cover.

4. After a wheel change back to a full

size wheel, place the spare wheel outside up in the well and secure

with the wing nut.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full tyre in the rear.

Tyre chains 3 210.

Stowing a damaged full size

wheel in the load compartment

The spare wheel well is not designed

for other tyre sizes than the temporary spare wheel. A damaged full size

wheel must be stowed in the load