clock OPEL FRONTERA 1998 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5283 of 6000

6A – 10 ENGINE MECHANICAL

8. Check the engine oil level and replenish to the

specified level if required.

9. Start the engine and check for oil leakage from the

main oil filter.

FUEL SYSTEM

Fuel filter

Replacement Procedure

1. Loosen the used fuel filter by turning it

counterclockwise with the filter wrench.

Filter Wrench : 5-8840-0203-0

2. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Turn the fuel filter until the sealing face comes in

contact with the O-ring.

5. Turn the fuel filter with a filter wrench 2/3 of a turn

until sealed.

Filter Wrench: 5-8840-0203-0Legend

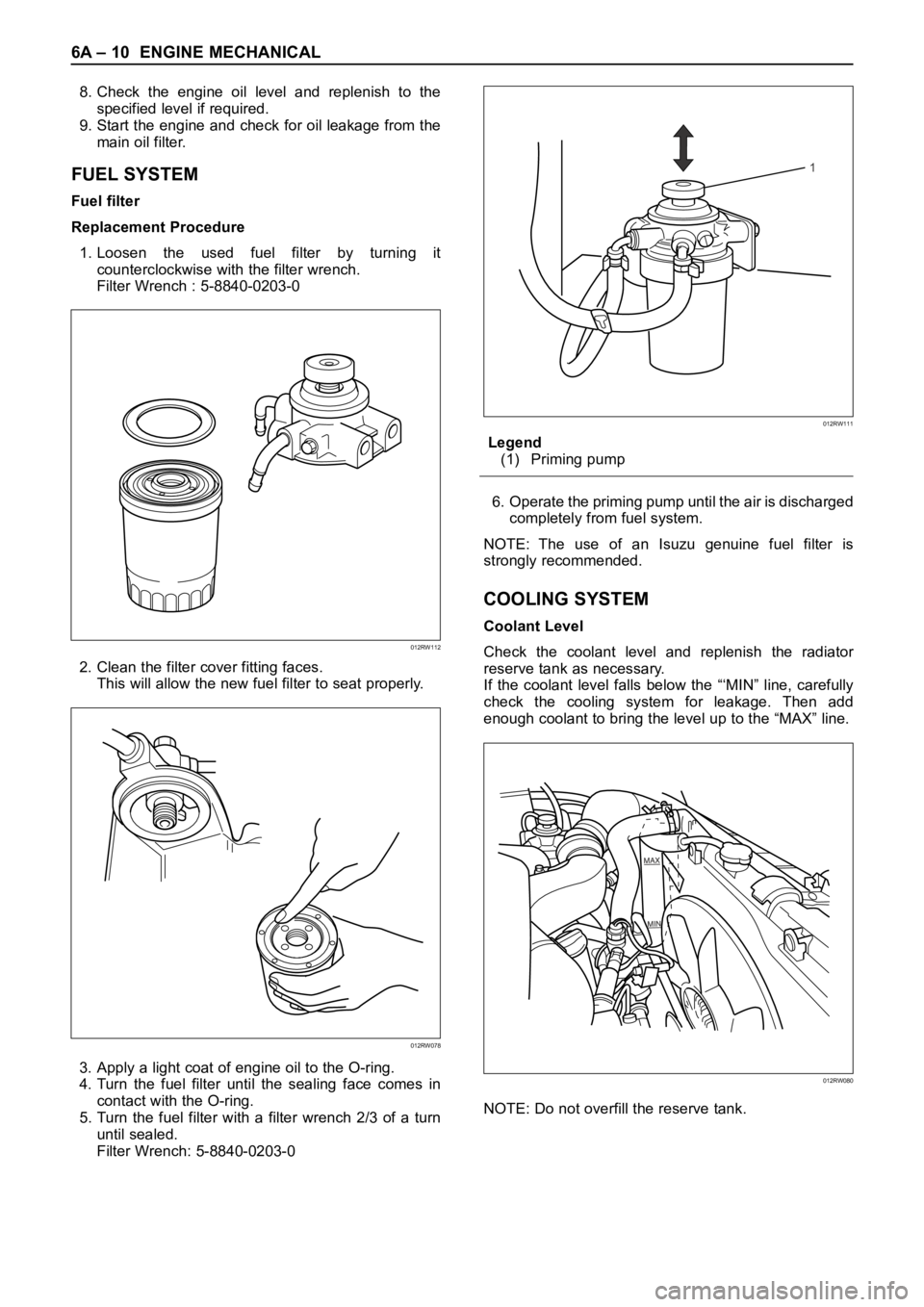

(1) Priming pump

6. Operate the priming pump until the air is discharged

completely from fuel system.

NOTE: The use of an Isuzu genuine fuel filter is

strongly recommended.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator

reserve tank as necessary.

If the coolant level falls below the “‘MIN” line, carefully

check the cooling system for leakage. Then add

enough coolant to bring the level up to the “MAX” line.

NOTE: Do not overfill the reserve tank.

012RW112

012RW078

1

012RW111

012RW080

Page 5425 of 6000

6D – 22 ENGINE ELECTRICAL

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in

the front cover.2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified

torque.

Torque: 111 Nꞏm (82 lb ft)

066RS022

066RS010

MAIN DATA AND SPECIFICATIONS

General Specifications

Model LR160-734B LR-170-760

Battery voltage V 12

Rated output A 60 70

Direction of rotation Clockwise

(as viewed from pulley side)

Rated rotation speed rpm 5,000

Maximum speed rpm 18,000

Page 5758 of 6000

7A–69 AUTOMATIC TRANSMISSION (4L30–E)

Sprag Unit

Disassembled View

248RS009

Legend

(1) Retaining Ring

(2) Sprag Outer Race

(3) Ring(4) Sprag Assembly

(5) Ring

(6) Third Clutch Hub and Sun Gear Assembly

Disassembly

1. Remove the sprag outer race, retaining ring, and

sprag assembly from the third clutch hub and sun

gear assembly.

2. Remove the rings and sprag assembly from the sprag

outer race.

Inspection And Repair

Visual Check:

If any damage, deformation or wear is found, replace the

damaged part.

Reassembly

NOTE: Flared shoulder of the sprag cage faces the sun

gear. This procedure must be followed exactly to be sure

that the sprag assembly is installed properly.

1. Install rings and sprag assembly onto the third clutch

hub and sun gear.

2. Install sprag outer race and retaining ring assembly

over the sprag cage assembly.

Place third clutch hub and sun gear assembly on a

flat surface, sun gear facing up. Place sprag outer

race and sprag assembly over the sun gear

assembly, push down and turn the input sun

counterclockwise at the same time. NOTE: Check correct rotation by holding the sun gear in

your left hand and turning the outer race. The outer sprag

race should turn freely towards you and should lock

turning away from you.

248RS010

Page 5896 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–115

252L100003

252L100004

252L100005

252L100016

Important operations

Check operation of one-way clutch

Hold the OD direct clutch drum and turn the input shaft.

The input shaft should turn freely clockwise and should lock

counterclockwise.

(1): Free

(2): Lock

1. OD direct clutch assembly

Remove OD direct clutch assembly from OD planetary

gear.

2. Thrust bearing

Then remove thrust bearing with the race from OD direct

clutch drum.

Check piston stroke of OD direct clutch (C-O)

Place the oil pump onto the torque conver ter, and then

place the OD direct clutch assembly onto the oil pump.

Use a dial indicator, measure the OD direct clutch piston

stroke applying and releasing the compressed air (4– 8 kg/

cm

2, 57– 114 psi, 392– 785 kPa) as shown.

mm (in.)

Piston stroke1.85– 2.15

(0.0728– 0.0847)

Page 5906 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–125

252L100015

252L100004

252L100003

15. Thrust bearing

Coat the assembled bearing and race with petroleum jelly

and install it with the race side facing downward.

16. OD direct clutch assembly

Align the flukes of discs in the direct clutch .

Install the OD direct clutch assembly onto the OD planetary

gear.

Check operation of one-way clutch.

Hold the OD direct clutch drum and turn the input shaft.

The input shaft should turn freely clockwise and should lock

counterclockwise.

(1): Free

(2): Lock Assembled bearing and race (Reference) mm (in.)

Inside diameter 28.9 (1.138)

Outside diameter 50.2 (1.976)

Page 5935 of 6000

7A–154 AUTOMATIC TRANSMISSION (AW30-40LE)

248RY00051

248RY00052

248RY00053

248RY00054

Important operations

Check operation of No.1 one–way clutch

Hold the planetary sun gear and turn the second brake

hub. The second brake hub should turn freely clockwise

and should lock counterclockwise.

(1) : Free

(2) : Lock

3. Oil seal ring (Metal)

Remove two oil seal rings.

4. Snap ring

Remove the snap ring with snap ring pliers.

INSPECTION AND REPAIR

Check planetary sun gear bushing

Using a dial indicator, measure the inside diameter of the

planetary sun gear bushing.

If the inside diameter is greater than the maximum, replace

the planetary sun gear.mm (in.)

Maximum inside diameter 27.08 (1.0661)

Page 5938 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–157

248RY00057

248RY00058

248RY00051

5. Thrust washer (plastic)

Install thrust washer.

NOTE:

Make sure that the lugs fit into the holes on the sun gear

input drum.

6. One–way clutch and second brake hub

Install assembled No.1 one–way clutch and second brake

hub onto planetary sun gear as shown.

Check operation of No.1 one–way clutch

Hold the planetary sun gear and turn the second brake

hub. The second brake hub should turn freely clockwise

and should lock counterclockwise.

(1) : Free

(2) : Lock

Page 5945 of 6000

7A–164 AUTOMATIC TRANSMISSION (AW30-40LE)

247RY00028

247RY00029

247RY00030

247RY00031

Important operations

3. Oil seal ring

Remove oil seal ring from output shaft.

5. Rear planetary gear assembly

Remove rear planetary gear from rear planetary ring gear.

Check operation of No.2 one–way clutch

Hold the planetary gear and turn the one–way clutch inner

race. The one–way clutch inner race should turn freely

counterclockwise and should lock clockwise.

(1) : Lock

(2) : Free

6. One–way clutch inner race

Remove the one–way clutch inner race from the rear

planetary gear.

Page 5949 of 6000

7A–168 AUTOMATIC TRANSMISSION (AW30-40LE)

247RY00039

247RY00040

247RY00041

247RY00029

7. Snap ring

Install snap ring.

8. One–way clutch inner race

While turning counterclockwise, install one–way clutch

inner race to rear planetary gear.

Check operation of one–way clutch

Hold the planetary gear and turn the one–way clutch inner

race. The one–way clutch inner race should turn freely

counterclockwise and should lock clockwise.

(1) : Lock

(2) : Free

9. Rear planetary gear assembly

Install rear planetary gear onto rear planetary ring gear.

Page 5962 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–181

241RY00018

TORQUE CONVERTER

INSPECTION AND REPAIR

Insert special tool in end of torque converter

Insert a turning tool into the inner race of the one–way

clutch.

One–way clutch testing tool : 5–8840–2168–0 (J–35467)

Insert the stopper so that it fits in the notch of the converter

hub and outer race of the one–way clutch.

Test one–way clutch

The clutch should lock when turned counterclockwise, and

rotate freely and smoothly clockwise. Less than 25kgꞏcm

(22 Ibꞏin) of torque should be required to rotate the clutch

clockwise. If necessary, clean the conver ter and retest the

clutch. Replace the converter if the clutch still fails the test.