manual transmission OPEL FRONTERA 1998 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2356 of 6000

7B–38MANUAL TRANSMISSION

14. Pull out reverse shift rod from reverse shift arm

No.1.

NOTE: Be sure remove at the rear.

226RW055

15. Using a magnetic finger, remove the ball and

spring from reverse shift arm No.1.

226RW056

16. Remove the reverse shift arm No.2 E–ring.

Remove the reverse shift arm No.2 from reverse

shift arm No.1.

226RW089

17. Remove the 2 bolts and reverse shift arm bracket.

226RW054

Page 2357 of 6000

MANUAL TRANSMISSION7B–39

Inspection

1. Counter 5th gear radial clearance.

1. Install the following parts to the counter gear

shaft.

1. Counter 5th gear thrust washer pin (1).

2. Counter 5th gear thrust washer (2).

3. Counter 5th gear needle bearing( 3).

4. Counter 5th gear (4).

226RW088

2. Mount the counter gear shaft through the

aluminum plate in vise.

3. Using a dial indicator, measure the counter 5th

gear radial clearance.

Standard: 0.015 – 0.068 mm

(0.00059 – 0.00268 in)

226RW183

4. Using a inside dial indicator, measure the gear

inside diameter.

Standard: 38.015 – 38.040 mm

(1.49665 – 1.49763 in)

226RW085

2. 5th-reverse shift arm and hub sleeve No.3 clearance.

1. Using a vernier caliper, measure the 5th-reverse

shift arm thickness.

Reference: 10.2 mm (0.402 in)

2. Using a vernier caliper, measure the center

groove of hub sleeve No.3. Calculate the

clearance between the hub sleeve No.3 and shift

arm.

Standard: 0.26 – 0.84 mm (0.0102 – 0.0331 in)

Reference: Center groove dimension 10.5mm

(0.413 in)

226RW086

Page 2358 of 6000

7B–40MANUAL TRANSMISSION

3. Reverse block ring set.

1. Using a thickness gauge, measure the clearance

between the counter 5th gear spline piece and

reverse block ring.

Standard: 0.7 – 1.7 mm (0.028 – 0.067 in)

226RW084

4. Reverse idle gear and reverse idle gear shaft.

1. Mount the reverse idle gear and reverse idle gear

shaft in a vise.

2. Using a dial indicator, measure the reverse idle

gear radial clearance.

Standard: 0.040–0.082mm (0.0016–0.0032in)

226RW083

3. If the clearance exceeds the maximum, measure

the gear inside diameter and shaft diameter.

Standard

Shaft Diameter: 23.979 – 24.000 mm

(0.94405 – 0.94488 in)

Gear Diameter: 24.040 – 24.061 mm

(0.94645 – 0.94728 in)

226RW082

5. Reverse shift arm No.2 thrust clearance.

1. Using a thickness gauge, measure the clearance

between the reverse idle gear and shift arm No.2.

Standard: 0.05 – 0.35 mm (0.002 – 0.014 in)

226RW081

Page 2359 of 6000

MANUAL TRANSMISSION7B–41

Reassembly

1. Install the top gear shaft assembly.

1. Using installer 5–8840–2559–0 (J–42904) and a

press, install a new bearing.

NOTE: Outer race snap ring groove (1) toward front.

226RW196

2. Select a snap ring that will allow minimum axial

play.

Mark

Thickness

A2.10 – 2.15 mm (0.083 – 0.085 in)

B2.15 – 2.20 mm (0.085 – 0.087 in)

C2.20 – 2.25 mm (0.087 – 0.089 in)

D2.25 – 2.30 mm (0.089 – 0.091 in)

E2.30 – 2.35 mm (0.091 – 0.093 in)

F2.35 – 2.40 mm (0.093 – 0.095 in)

G2.40 – 2.45 mm (0.095 – 0.097 in)

226RW061

3. Using a snap ring expander, install the new snap

ring.

226RW062

4. Install the 4th block ring.

226RW063

Page 2360 of 6000

7B–42MANUAL TRANSMISSION

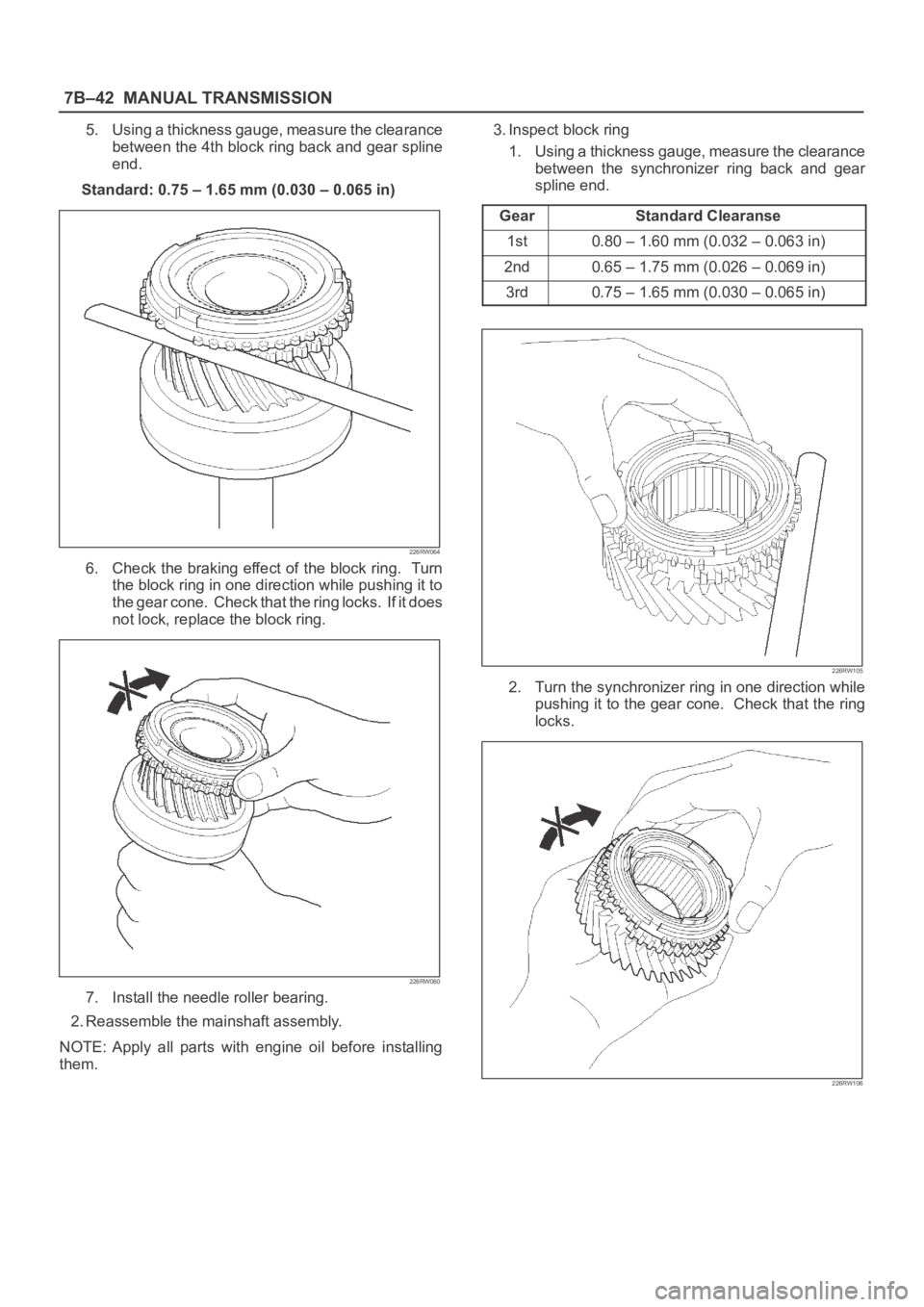

5. Using a thickness gauge, measure the clearance

between the 4th block ring back and gear spline

end.

Standard: 0.75 – 1.65 mm (0.030 – 0.065 in)

226RW064

6. Check the braking effect of the block ring. Turn

the block ring in one direction while pushing it to

the gear cone. Check that the ring locks. If it does

not lock, replace the block ring.

226RW060

7. Install the needle roller bearing.

2. Reassemble the mainshaft assembly.

NOTE: Apply all parts with engine oil before installing

them.3. Inspect block ring

1. Using a thickness gauge, measure the clearance

between the synchronizer ring back and gear

spline end.

Gear

Standard Clearanse

1st0.80–1.60mm (0.032–0.063in)

2nd0.65–1.75mm (0.026–0.069in)

3rd0.75–1.65mm (0.030–0.065in)

226RW105

2. Turn the synchronizer ring in one direction while

pushing it to the gear cone. Check that the ring

locks.

226RW106

Page 2361 of 6000

MANUAL TRANSMISSION7B–43

4. Inspect hub sleeve and shift arm.

1st–2nd shift arm

1. Using a vernier caliper, measure center groove of

the 1st–2nd shift arm.

Reference: 5.28 mm (0.208 in)

2. Using a vernier caliper, measure flange of the

reverse gear. Calculate the clearance between

the reverse gear and shift arm.

Reference: Reverse gear flange thickness 5.0

mm. (0.197 in)

Standard: 0.15 – 0.41 mm (0.006 – 0.016 in)

226RW093

3rd–4th shift arm

1. Using a vernier caliper, measure tip of the shift

arm thickness.

Reference: 10.0mm (0.39 in)

2. Using a vernier caliper, measure center groove of

the hub sleeve No.2. Calculate the clearance

between the hub sleeve No.2 and shift arm.

Reference: Center groove dimension 10.2 mm

(0.402 in)

Standard: 0.15 – 0.35 mm (0.006 – 0.014 in)

226RW095

5. Inspect clutch hub and hub sleeve.

1. Check for wear or damage.

2. Install the hub sleeve to the clutch hub, and check

sliding smoothly.

226RW094

6. Inspect gear inside diameter.

1. Using a inside dial indicator, measure the gear

inside diameter.

Gear

Standard Diameter

1st46.015 – 46.040 mm (1.8116 – 1.8126 in)

2nd53.015 – 53.040 mm (2.0872 – 2.0882 in)

3rd44.015 – 44.040 mm (1.7329 – 1.7339 in)

Page 2362 of 6000

7B–44MANUAL TRANSMISSION

226RW096

7. Inspect mainshaft.

1. Using a micrometer, measure the outer diameter

of the mainshaft journal.

Measure

Position

Standard

A37.984 – 38.000 mm (1.4954 – 1.4961 in)

B46.984 – 47.000 mm (1.8498 – 1.8504 in)

C38.979 – 38.995 mm (1.5346 – 1.5352 in)

226RW078

2. Using a micrometer, measure the mainshaft

flange thickness.

Standard: 5.0 mm (0.197 in)

226RW079

3. Install the mainshaft to V-blocks.

4. Use a dial indicator to measure the mainshaft

central portion run-out.

Standard: less than 0.015 mm (0.0006 in)

226RW097

Page 2363 of 6000

MANUAL TRANSMISSION7B–45

8. Install 3rd gear.

1. Install the 3rd gear needle bearing, 3rd gear and

3rd block ring to the mainshaft.

226RW098

9. Install the clutch hub No.2.

1. Install the clutch hub No.2 and hub sleeve No.2.

NOTE: Be careful the direction of the clutch hub No.2, as

shown.

2. Using a screwdriver, install 3 inserts and 2

springs.

NOTE: Position the insert springs so that their end gaps

are not in line.

226RW099

3. Using installer 5–8840–2553–0 (J–42797) and a

press, install the clutch nob No.2 and hub sleeve

No.2 to the mainshaft.NOTE:

Align the brock ring slots with the inserts.

Check that the gear rotates smoothly.

226RW206

4. Select a snap ring that will allow minimum axial

play.

Mark

Thickness

A1.80–1.85mm (0.071–0.073in)

B1.85–1.90mm (0.073–0.075in)

C1.90–1.95mm (0.075–0.077in)

D1.95–2.00mm (0.077–0.079in)

E2.00–2.05mm (0.079–0.081in)

F2.05–2.10mm (0.081–0.083in)

G2.10–2.15mm (0.083–0.085in)

226RW102

Page 2364 of 6000

7B–46MANUAL TRANSMISSION

5. Using a snap ring expander, install the new snap

ring.

NOTE: Be careful not to damage the bearing surface.

226RW101

6. Using a thickness gauge, inspect the 3rd gear

thrust clearance.

Standard: 0.10 – 0.25mm (0.004 – 0.010 in)

226RW103

10. Install the 2nd gear.

1. Install the synchronizer ring set No.1 to the 2nd

gear.

NOTE: Align the nail of middle ring with gear spline slots.

226RW104

2. Install the needle roller bearing, 2nd gear and 2nd

gear block ring set to the mainshaft.

226RW107

Page 2365 of 6000

MANUAL TRANSMISSION7B–47

11. Install the clutch hub No.1.

1. Install the 3 inserts and 3 insert springs to the

clutch hub No.1.

Reference: While pushing the insert spring

with a screwdriver, install the inserts.

226RW108

2. Install the clutch hub No.1 to the reverse gear.

NOTE: Check the clutch hub No.1 installing direction, as

shown.

226RW109

3. Using installer 5–8840–2554–0 (J–42798) and a

press, install the hub No.1 by retaining the

reverse gear.NOTE:

Align the projection of inner ring with hub No.1 slots.

Check that the gear rotates smoothly.

226RW205

4. Select a snap ring that will allow minimum axial

play.

Mark

Thickness

A2.30–2.35mm (0.091–0.093in)

B2.35–2.40mm (0.093–0.095in)

C2.40–2.45mm (0.095–0.097in)

D2.45–2.50mm (0.097–0.098in)

E2.50–2.55mm (0.098–0.100in)

F2.55–2.60mm (0.100–0.102in)

G2.60–2.65mm (0.102–0.104in)

226RW111