manual transmission OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2276 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–31

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.

5. This test checks for continuity between each

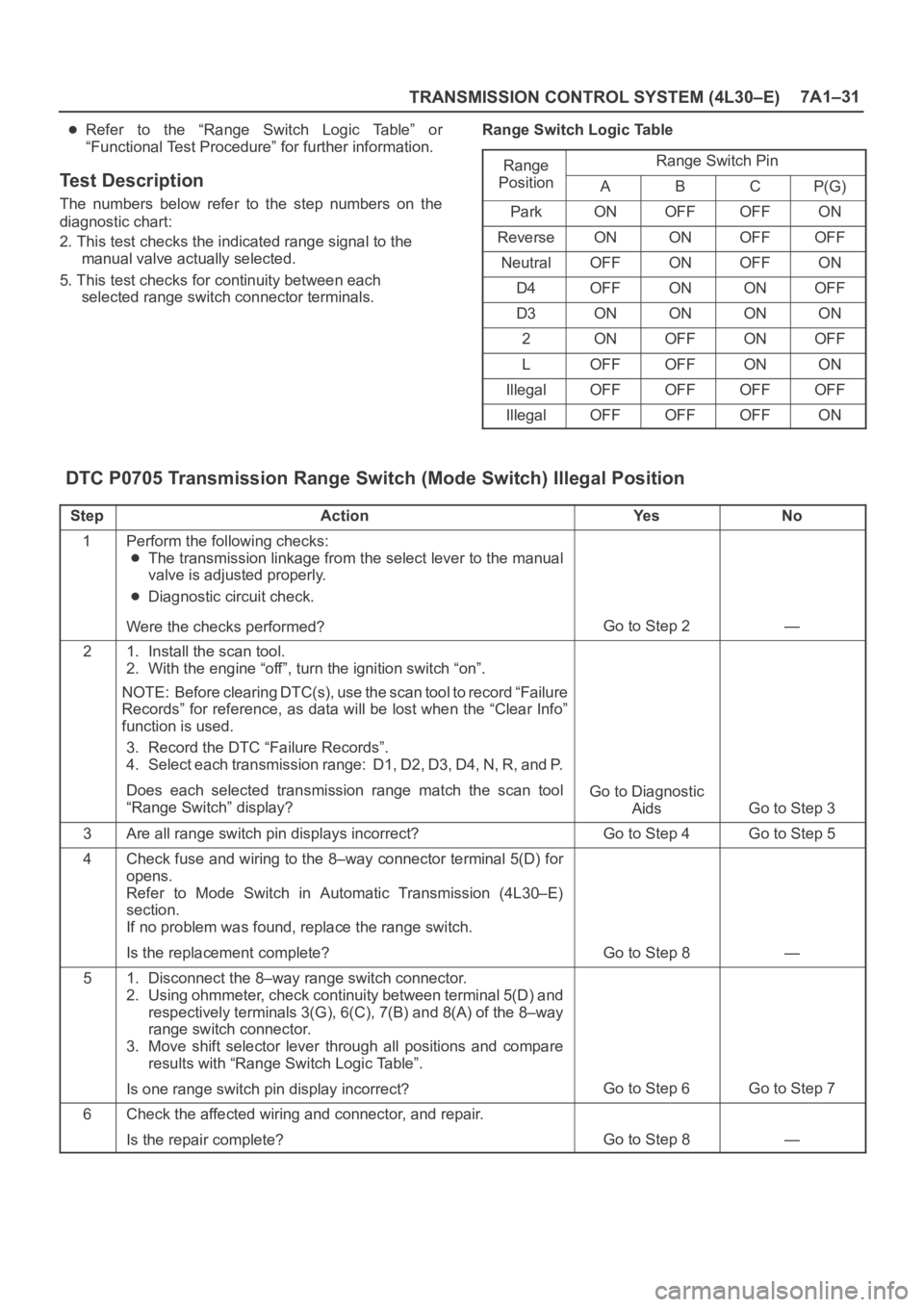

selected range switch connector terminals.Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—

Page 2278 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–33

DTC P0706 Transmission Range Switch (Mode Switch) Performance

D07RW031

Circuit Description

The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

l e v e r p o s i t i o n : P, R , N , D , 3 , 2 o r L . T h e s e l e c t o r l e v e r

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

The range switch is also used to provide the

information P or N to the engine crank wiring. The

engine can be cranked only if connector M–25

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

The range switch is also used to provide the backup

lamp power in reverse. This is why the mode switch is

supplied through a 10A fuse (C–3). This fuse can

burn due to a shot circuit in the backup lamp.

This DTC detects an invalid state of the range switch

or the range switch circuit by deciphering the range

switch inputs. This is a type “D” DTC.

Conditions For Setting The DTC

This DTC will set if any of the following conditions occurs:

Condition 1 (“R” bad position):

Engine is running.

No output speed DTCP0722, P0723.

Output speed greater then 3,200 RPM.

Range switch indicates “R”.

All conditions met for 4 seconds.

Condition 2 (“P” or “N” bad position):

Engine is running.

No TPS codes.

Engine speed is less than 3,000 RPM.

TP angle is greater than 20%.

Range switch indicates “P” or “N”.

All conditions met for 4 seconds.

Action Taken When The DTC Sets

Default to “D” position.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Page 2279 of 6000

7A1–34

TRANSMISSION CONTROL SYSTEM (4L30–E)

Diagnostic Aids

Refer to the accompanying chart for the normal range

signals and the illegal combinations.

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as well. Also check for a chafed wire that could short

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.5. This test checks for continuity between each

selected range switch connector terminals.

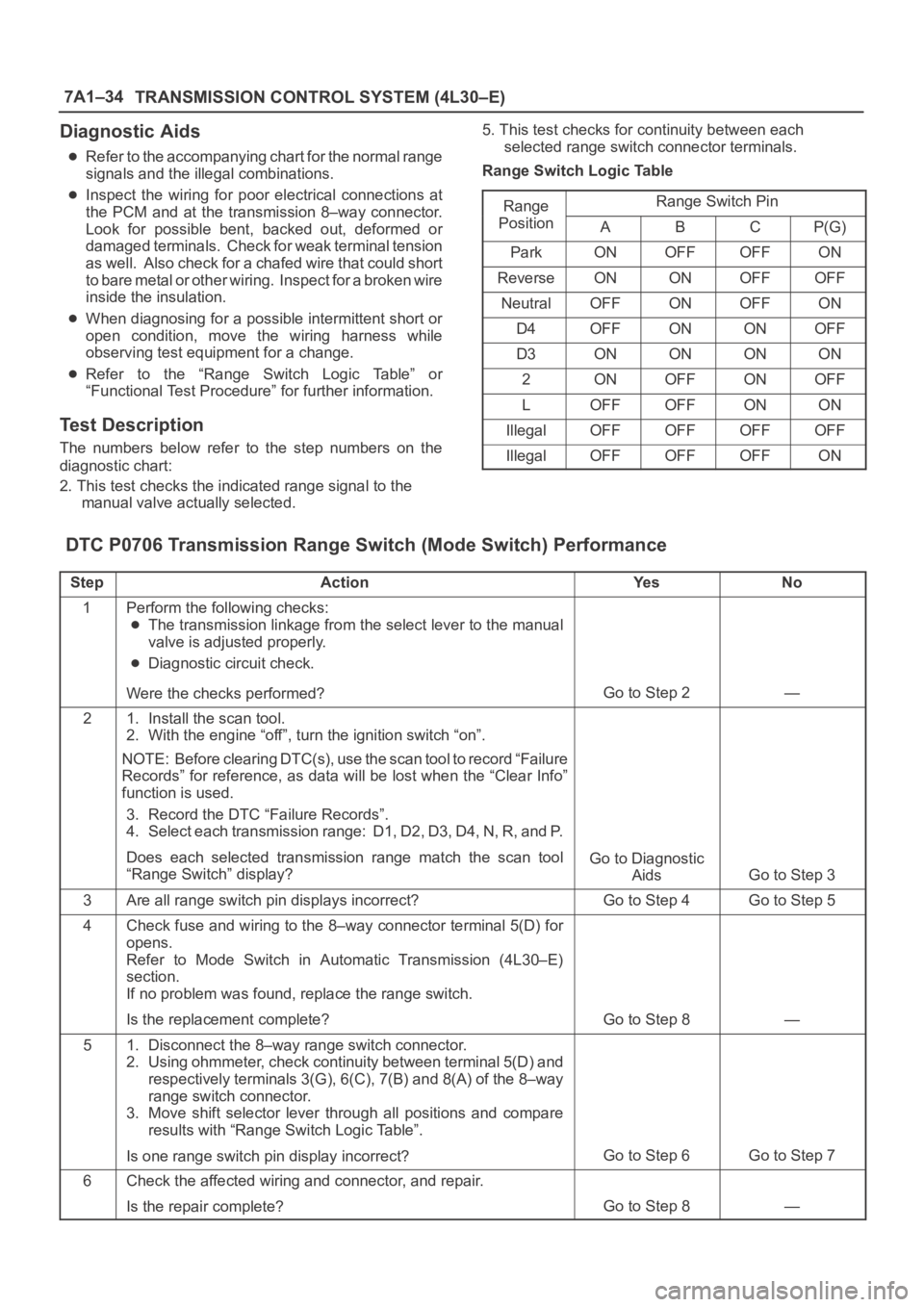

Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0706 Transmission Range Switch (Mode Switch) Performance

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—

Page 2319 of 6000

MANUAL TRANSMISSION7B–1

TRANSMISSION

MANUAL TRANSMISSION

CONTENTS

Service Precaution 7B–1. . . . . . . . . . . . . . . . . . . . . .

General Description 7B–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 7B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Transmission Assembly 7B–5. . . . . . . . . . .

Transmission and Associated Parts 7B–5. . . . . .

Removal 7B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7B–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Transfer Adapter) 7B–17. . . . . . . . . .

Removal 7B–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7B–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . Transmission (AR-5) 7B–18. . . . . . . . . . . . . . . . . . . . .

Disassembled View 7B–18. . . . . . . . . . . . . . . . . . . .

Disassembly 7B–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7B–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7B–41. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 7B–68. . . . . . . . . . . . .

General Specifications 7B–68. . . . . . . . . . . . . . . . .

Torque Specifications 7B–69. . . . . . . . . . . . . . . . . .

Special Tools 7B–72. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 2320 of 6000

7B–2MANUAL TRANSMISSION

General Description

(6VE1)

A07RW044

Page 2321 of 6000

MANUAL TRANSMISSION7B–3

(4JX1)

A07RW043

Page 2322 of 6000

7B–4MANUAL TRANSMISSION

Diagnosis

ConditionPossible causeCorrection

Abnormal noiseFlywheel pilot bearing wornReplace

Bearings worn or broken (Mainshaft,

counter shaft, and transfer shaft)Replace

Gear tooth contact surfaces worn or

scuffed (Mainshaft, counter shaft,

reverse idler gear and transfer gears)Replace

Splines worn (Mainshaft,

synchronizer clutch hub)Replace

Gear or bearing thrust face seizedReplace

Lack of backlash between meshing

gearsReplace

Hard ShiftingImproper clutch pedal free playReadjust

Change lever sliding portions wornRepair or replace

Regrease

Shift block, shift rod and/or control

box sliding faces wornReplace

Shift arm and synchronizer sleeve

groove wornReplace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)Replace worn parts

Synchronizer parts wornReplace

Walking or Jumping out of gearDetent ball wornReplace

Detent spring weakened or brokenReplace

Shift rod and/or control box sliding

faces wornReplace

Shift arm and synchronizer sleeve

groove wornReplace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)Replace worn parts

Bearings worn or brokenReplace

Splines worn (Mainshaft,

synchronizer hub)Replace

Synchronizer spring weakened or

brokenReplace

Oil leakageLoose drain plug(s) and/or filler

plug(s)Tighten

Replenish oil

Defective or improperly installed

gasket(s)Replace

Oil seal worn or scratchedReplace

Page 2323 of 6000

MANUAL TRANSMISSION7B–5

Manual Transmission Assembly

Transmission and Associated Parts

220RW108

Legend

(1) Gear Control Lever and Knob

(2) Transfer Control Lever and Knob

(3) Front Console Assembly

(4) Grommet Assembly

(5) Transfer Protector

(6) Rear Propeller Shaft

(7) Front Propeller Shaft

(8) Exhaust Pipe

(9) Backup Lamp, 4WD Indicator, and 1–2

Indicator Switch Harness Connector

(10) Speedometer Sensor and 2WD–4WD Actuator

Harness Connector(11) Slave Cylinder Heat Protector

(12) Harness Heat Protector

(13) Slave Cylinder

(14) Dust Cover

(15) Engine Rear Mount Nut

(16) Engine Rear Mount Bolt

(17) Engine Rear Mount

(18) Third Crossmember

(19) Flywheel Under Cover

(20) Transmission Retaining Bolt

(21) Transmission Assembly with Transfer Case

Page 2324 of 6000

7B–6MANUAL TRANSMISSION

Removal

NOTE: Before remove the transmission and transfer

assembly from the vehicle, change the transfer mode to

2WD using push button on dash panel.

1. Remove engine hood.

2. Disconnect battery ground cable.

3. Remove the gear control lever knob.

4. Remove the front console assembly.

5. Remove the grommet assembly.

6. Remove the transmission control lever and transfer

control lever.

235RW014

7. Raise and support the vehicle with suitable jack

stand.

8. Remove transfer protector.

9. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the flange at the both

front and rear side.

(4JX1)

401RW060

10. Remove the front propeller shaft.

NOTE: Apply alignment marks on the flange at both the

front and rear sides.

401RS003

11. Disconnect two oxygen sensor connectors from the

transmission harness (6VE1).

12.Remove the front and 3 way exhaust pipe (6VE1).

Remove the exhaust pipe with catalytic converter

(4JX1).

(4JX1)

150RW041

Page 2325 of 6000

MANUAL TRANSMISSION7B–7

13. Disconnect the backup lamp switch, 4WD indicator

switch and 1–2 indicator switch harness connectors.

826RW023

14. Disconnect the speedometer sensor and 2WD-4WD

actuator harness connectors.

826RW024