OBD port OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4929 of 6000

6E–272

ENGINE DRIVEABILITY AND EMISSIONS

Rough, Unstable, or Incorrect Idle, Stalling Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine runs unevenly at idle. If severe, the engine or

vehicle may shake. Engine idle speed may vary in

RPM. Either condition may be severe enough to stall

the engine.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Go to Step 13Go to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check the PCM grounds for cleanliness, tightness

and proper routing. Refer to the PCM wiring

diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

5Observe the long term fuel trim on Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—Go to Step 6Go to Step 7

61. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

7Is the long term fuel trim significantly in the positive

range (lean condition)?

—Go to Step 8Go to Step 9

81. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for incorrect idle speed. Ensure that the

following conditions are present:

The engine is fully warm.

The accessories are “OFF.”

2. Using Tech 2, monitor the IAC position.

Is the IAC position within the specified values?Between 10

and 50

counts

Go to Step 11Go to Step 10

Page 4939 of 6000

6E–282

ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Steady pulsation or jerking that follows engine speed;

usually more pronounced as engine load increases.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Go to Step 13Go to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check the PCM grounds for clearness, tightness

and proper routing. Refer to the PCM wiring

diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

5Observe the long term fuel trim on Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—Go to Step 6Go to Step 7

61. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

7Is the long term fuel trim significantly in the positive

range (lean condition)?

—Go to Step 8Go to Step 9

81. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for incorrect idle speed. Ensure that the

following conditions are present:

The engine is fully warm.

The accessories are “off.”

2. Using Tech 2, monitor the IAC position.

Is the IAC position within the specified values?Between 5

and 50

counts

Go to Step 11Go to Step 10

Page 4942 of 6000

6E–285 ENGINE DRIVEABILITY AND EMISSIONS

Hesitation, Sag, Stumble Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Momentary lack of response as the accelerator is

pushed down. Can occur at any vehicle speed. Usually

most pronounced when first trying to make the vehicle

move, as from a stop sign. May cause the engine to stall

if severe enough.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check the fuel control heated oxygen sensors

(HO2S, B1S1 and B2S1). The fuel control heated

oxygen sensors (HO2S) should respond quickly to

different throttle positions. If they don’t, check them

for silicon or other contaminants from fuel or use of

improper RTV sealant. The sensors may have a

white powdery coating.

Silicon contamination causes a high but false

HO2S signal voltage (rich exhaust indication).

The PCM will then reduce the amount of fuel

delivered to the engine, causing a severe

driveability problem. For more information, refer

to

Powertrain Control Module (PCM) and Sensors.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check the fuel pressure. Refer to Fuel System

Pressure Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

6Observe the TP angle display on Tech 2 while slowly

increasing throttle pedal.

Does the TP angle display steadily increase from 0% at

closed throttle to 100% at WOT?

—Go to Step 7Go to Step 18

7Monitor the long term fuel trim on Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—Go to Step 8Go to Step 9

81. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

91. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

Page 5453 of 6000

6E–24

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnosis

Strategy-Based Diagnostics

Strategy-Based Diagnostics

The strategy-based diagnostic is a uniform approach to

repair all Electrical/Electronic (E/E) systems. The

diagnostic flow can always be used to resolve an E/E

system problem and is a starting point when repairs are

necessary. The following steps will instruct the technician

how to proceed with a diagnosis:

1. Verify the customer complaint.

To verify the customer complaint, the technician

should know the normal operation of the system.

2. Perform preliminary checks.

Conduct a thorough visual inspection.

Review the service history.

Detect unusual sounds or odors.

Gather diagnostic trouble code information to

achieve an effective repair.

3. Check bulletins and other service information.

This includes videos, newsletters, etc.

4. Refer to service information (manual) system

check(s).

“System checks” contain information on a system

that may not be supported by one or more DTCs.

System checks verify proper operation of the

system. This will lead the technician in an

organized approach to diagnostics.

5. Refer to service diagnostics.

DTC Stored

Follow the designated DTC chart exactly to make an

effective repair.

No DTC

Select the symptom from the symptom tables. Follow the

diagnostic paths or suggestions to complete the repair.

You may refer to the applicable component/system check

in the system checks.

No Matching Symptom

1. Analyze the complaint.

2. Develop a plan for diagnostics.

3. Utilize the wiring diagrams and the theory of

operation.

Call technical assistance for similar cases where repair

history may be available. Combine technician knowledge

with efficient use of the available service information.

Intermittents

Conditions that are not always present are called

intermittents. To resolve intermittents, perform the

following steps:

1. Observe history DTCs, DTC modes, and freezeframe

data.2. Evaluate the symptoms and the conditions described

by the customer.

3. Use a check sheet or other method to identify the

circuit or electrical system component.

4. Follow the suggestions for intermittent diagnosis

found in the service documentation.

Most scan tools, such as the Tech 2 and the DVM, have

data-capturing capabilities that can assist in detecting

intermittents.

No Trouble Found

This condition exists when the vehicle is found to operate

normally. The condition described by the customer may

be normal. Verify the customer complaint against another

vehicle that is operating normally. The condition may be

intermittent. Verify the complaint under the conditions

described by the customer before releasing the vehicle.

1. Re-examine the complaint.

When the complaint cannot be successfully found or

isolated, a re-evaluation is necessary. The complaint

should be re-verified and could be intermittent as

defined in

Intermittents, or could be normal.

2. Repair and verify.

After isolating the cause, the repairs should be made.

Validate for proper operation and verify that the

symptom has been corrected. This may involve road

testing or other methods to verify that the complaint

has been resolved under the following conditions:

Conditions noted by the customer.

If a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC was

set as noted in the Failure Records or Freeze

Frame data.

Verifying Vehicle Repair

Verification of the vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

IMPORTANT:Follow the steps below when you verify

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

1. Review and record the Failure Records and the

Freeze Frame data for the DTC which has been

diagnosed (Freeze Frame data will only be stored for

the MIL (“Check Engine” lamp) has been requested).

2. Clear the DTC(s).

3. Operate the vehicle within conditions noted in the

Failure Records and Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Page 5454 of 6000

6E–25 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

General Service Information

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold sensor

or switch is installed, it makes a wrong diagnosis and turn

on the MIL (“Check Engine” lamp).

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the MIL (“Check

Engine” lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lamp) to turn on if the vehicle is not

maintained properly. Restricted oil filters, fuel filters, and

crankcase deposits due to lack of oil changes or improper

oil viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics, vehicle

maintenance schedules must be more closely followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any diagnostic

procedure or diagnosing the cause of an emission test

failure. This can often lead to repairing a problem without

further steps. Use the following guidelines when

performing a visual/physical inspection:

Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

Inspect hoses that are difficult to see behind other

components.

Inspect all wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires,

contact with sharp edges or contact with hot exhaust

manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in an

incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-

tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.

Each bit of information can have one of two lengths: longor short. This allows vehicle wiring to be reduced by

transmitting and receiving multiple signals over a single

wire. The messages carried on Class II data streams are

also prioritized. If two messages attempt to establish

communications on the data line at the same time, only

the message with higher priority will continue. The device

with the lower priority message must wait.

On this vehicle the Tech 2 displays the actual values for

vehicle parameters. It will not be necessary to perform

any conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Comprehensive Component Monitor

Diagnostic Operation

Comprehensive component monitoring diagnostics are

required to operate engine properly.

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable. Accel

Position (AP) sensor that indicates high throttle position

at low engine loads or MAP voltage. Input components

may include, but are not limited to the following sensors:

Intake Air Temperature (IAT) Sensor

Crankshaft Position (CKP) Sensor

Intake throttle Position (ITP) Sensor

Engine Coolant Temperature (ECT) Sensor

Camshaft Position (CMP) Sensor

Manifold absolute Pressure (MAP) Sensor

Accel Position Sensor

Fuel Temp Sensor

Rail Pressure Sensor

Oil Temp Sensor

EGR Pressure Sensor

Vehicle Speed Sensor

Page 5456 of 6000

6E–27 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Non-Emissions related

Dose not request illumination of any lamp

Stores a History DTC on the first trip with a fail

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic test

fails

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

Engine Speed

Engine Load

Engine Coolant Temperature

Vehicle Speed

Intake Throttle Position

MAP

Injector Base Pulse Width

Loop Status

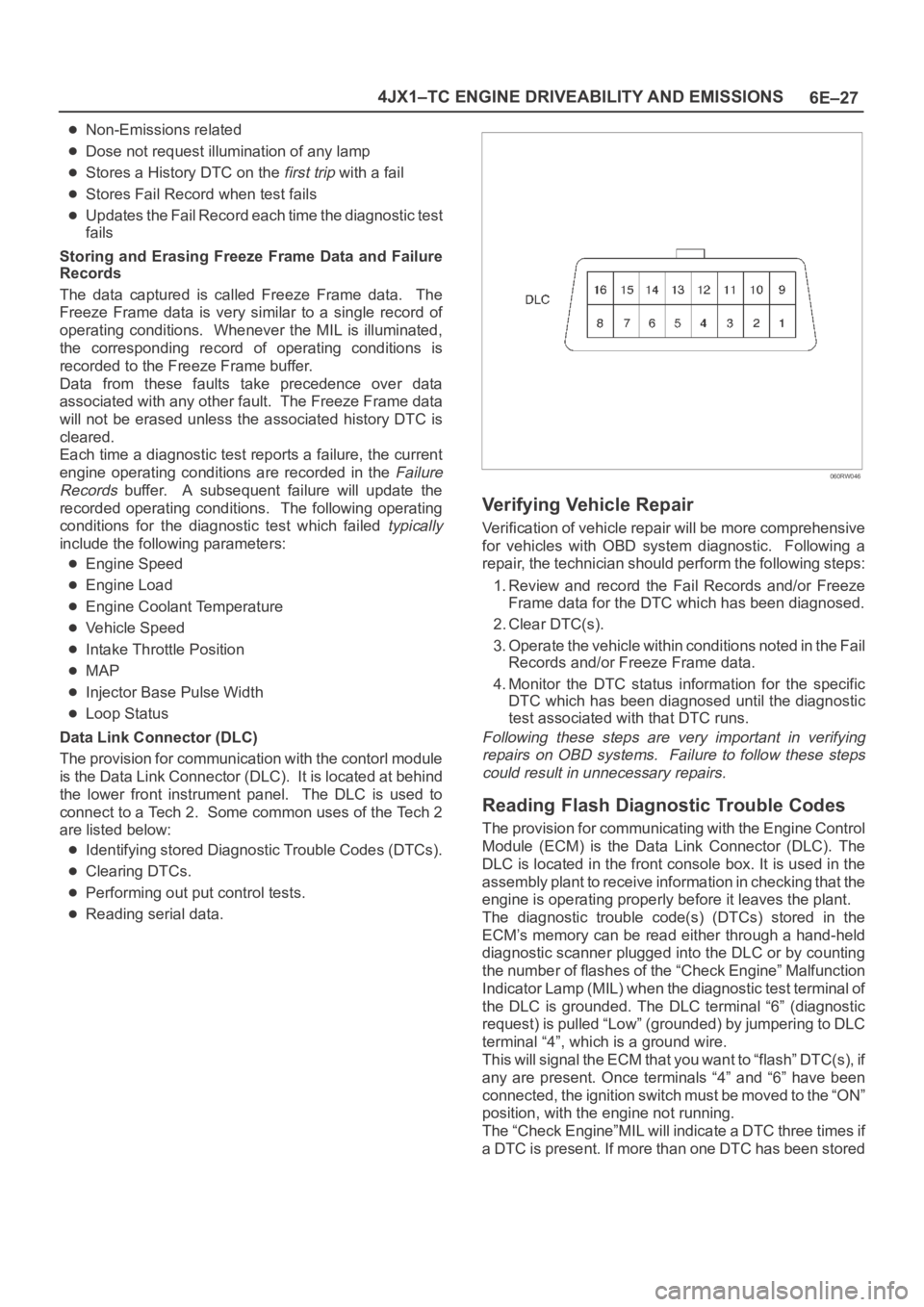

Data Link Connector (DLC)

The provision for communication with the contorl module

is the Data Link Connector (DLC). It is located at behind

the lower front instrument panel. The DLC is used to

connect to a Tech 2. Some common uses of the Tech 2

are listed below:

Identifying stored Diagnostic Trouble Codes (DTCs).

Clearing DTCs.

Performing out put control tests.

Reading serial data.

060RW046

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensive

for vehicles with OBD system diagnostic. Following a

repair, the technician should perform the following steps:

1. Review and record the Fail Records and/or Freeze

Frame data for the DTC which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the Fail

Records and/or Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). The

DLC is located in the front console box. It is used in the

assembly plant to receive information in checking that the

engine is operating properly before it leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-held

diagnostic scanner plugged into the DLC or by counting

the number of flashes of the “Check Engine” Malfunction

Indicator Lamp (MIL) when the diagnostic test terminal of

the DLC is grounded. The DLC terminal “6” (diagnostic

request) is pulled “Low” (grounded) by jumpering to DLC

terminal “4”, which is a ground wire.

This will signal the ECM that you want to “flash” DTC(s), if

any are present. Once terminals “4” and “6” have been

connected, the ignition switch must be moved to the “ON”

position, with the engine not running.

The “Check Engine”MIL will indicate a DTC three times if

a DTC is present. If more than one DTC has been stored

Page 5522 of 6000

6E–93 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description

The rail pressure control valve (RPCV) is built in the high

pressure oil circuit.

RPCV is an important device which is used to control oil

pressure in the HEUI system.

The circuit receives current through Engine 15A fuse from

the battery, current flowing in the order of RPCV.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1196 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Rail Pressure Control display on the Tech 2 while

moving connectors and wiring harnesses related to the

Rail Pressure Control. A change in the Rail Pressure

Control display will indicate the location of the fault.

If DTC P1196 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

DTC P1196 – RP System High Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Engine is running.

2. Observe the “Rail Pressure Control” display on the

Te c h 2 .

Is the action correct?

—Go to Step 4Go to Step 3

3Replace the RPCV.

Is the action complete?

—Verify repairGo to Step 4

41. Engine is running.

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P1196.

Does the Tech 2 indicate DTC P1196 failed this

ignition?

—Go to Step 5—

51. Check the 2 way valve.

2. Observe the “RP Control” display on the Tech 2.

Is the action correct?

—Go to Step 4Go to Step 6

6Replace the 2 way valve.

Is the action complete?

—Verify repair—

Page 5605 of 6000

6E–176

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Symptom Diagnosis

Preliminary Checks

Before using this section, perform the “On–Board

Diagnostic (OBD) System Check” and verify all of the

following items:

The powertrain control module (ECM) and

malfunction indicator lamp (MIL) (CHECK ENGINE

lamp) are operating correctly.

There are no DTC(s) stored.

Tech–2 data is within normal operating range. Refer

to

Typical Scan Data Values.

Verify the customer complaint and locate the correct

symptom in the table of contents. Perform the

procedure included in the symptom chart.

Visual/Physical Check

Several of the symptom procedures call for a careful

visual/physical check. This can lead to correcting a

problem without further checks and can save valuable

time.

This check should include the following items:

ECM grounds for cleanliness, tightness and proper

location.

Vacuum hoses for splits, kinks, and proper

connections, as shown on the “Vehicle Emission

Control Information” label. Check thoroughly for any

type of leak or restriction.

Air intake ducts for collapsed or damaged areas.

Injector wires for cracking, hardness, and carbon

tracking.

Wiring for proper connections, pinches and cuts.

Intermittents

IMPORTANT:An intermittent problem may or may not

turn on the malfunction indicator lamp (MIL) or store a

DTC. DO NOT use the Diagnostic Trouble Code (DTC)

charts for intermittent problems. The fault must be

present to locate the problem.

Most intermittent problems are caused by faulty electrical

connections or wiring. Perform a careful visual/physical

check for the following conditions:

Poor mating of the connector halves or a terminal not

fully seated in the connector (backed out).

Improperly formed or damaged terminal.

All connector terminals in the problem circuit should

be carefully checked for proper contact tension.

Poor terminal–to–wire connection. This requires

removing the terminal from the connector body to

check.

Road test the vehicle with a Digital Multimeter

(5-8840-0285-0) connected to a suspected circuit. An

abnormal voltage when the malfunction occurs is a good

indication that there is a fault in the circuit being

monitored.

Use a scan tool to help detect intermittent conditions. The

scan tools have several features that can be used to

locate an intermittent condition. Use the following feature

to find intermittent faults:

Using a Tech–2 “Freeze Frame” buffer or “Failure

Records” buffer can aid in locating an intermittent

condition. Review and record the information in the

freeze frame or failure record associated with the

intermittent DTC being diagnosed. The vehicle can

be driven within the conditions that were present

when the DTC originally set.

To check for loss of diagnostic code memory, disconnect

the MAP sensor and idle the engine until the MIL (CHECK

ENGINE lamp) comes on. DTC P0107 should be stored

and kept in memory when the ignition is turned “OFF.” If

not, the ECM is faulty. When this test is completed, make

sure that you clear the DTC P0107 from memory.

An intermittent MIL (CHECK ENGINE lamp) with no

stored DTC may be caused by the following:

MIL (CHECK ENGINE lamp) wire to ECM shorted to

ground.

Poor ECM grounds. Refer to the ECM wiring

diagrams.

Check for improper installation of electrical options such

as lights, cellular phones, etc.

Check for an open diode across the A/C compressor

clutch and check for other open diodes (refer to wiring

diagrams in

Electrical Diagnosis).

If problem has not been found, refer to

ECM Connector

Symptom

tables.

Page 5606 of 6000

6E–177 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Hard Start Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine cranks, but does not start for a long time. Does

eventually run, or may start but immediately stalls.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

4Check engine coolant temperature (ECT) sensor for

shift in value. After 8 hours with the hood up and the

engine not running, connect the scan tool. With the

ignition “ON” and the engine not running, compare

engine coolant temperature to manifold air

temperature.

Are ECT and MAT within the specified value of each

other?

5C ( 9F)Go to Step 8Go to Step 5

51. Using Tech–2, display the engine coolant

temperature and note the value.

2. Check the resistance of the engine coolant

temperature sensor.

3. Refer to

Engine Coolant Temperature Sensor

Temperature vs. Resistance

chart on DTC P0118

Diagnostic Support

for resistance specifications.

Is the resistance value near the resistance for the

temperature noted?

—Go to Step 7Go to Step 6

6Replace the ECT sensor.

Is the action complete?

—Verify repair—

7Locate and repair high resistance or poor connection in

the ECT signal circuit or the ECT sensor ground.

Is the action complete?

—Verify repair—

81. Injector Test

Operate the each injector by Tech 2 with the

ignition “ON” and check if the working noise

confirm.

2. If a problem is found, check the harness or replace

the injector.

Is the action complete?

—Verify repairGo to Step 9

9Check the oil rail pressure by Tech 2 at the cranking.

Is the pressure near the specified value?Less than 3

MPa

Go to Step 10Go to Step 11

10Check the oil leakage on the high oil pressure line.

If the oil leakage is found, repair as necessary.

Was the oil leakage found?

—Verify repairGo to Step 11

111. Check for water-or alcohol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

Page 5700 of 6000

7A–11 AUTOMATIC TRANSMISSION (4L30–E)

Fluid Condition

FLUID CONDITION

NORMAL*CONTAMINATED

COLORRED OR LIGHT

BROWNBROWNNON–TRANSPARENT

/ PINKBROWN

DRAIN

REQUIRED?NOYESYESYES

CONTAMINA–

TIONNONEVery small amount of

foreign material in

bottom of panContamination by

coolant or other sourceLarge pieces of metal

or other foreign

material in bottom of

pan

CORRECT

LEVEL AND

CONDITION

1. LOW LEVEL:

A. Add fluid to

obtain proper

level & check for

external leaks.

B. Correct cause of

leak.

2. HIGH LEVEL:

– Remove excess

fluid– Remove both pans

– Change filter

– Flush cooler

– Add new fluid

– Check level– Repair/replace

radiator cooler

–Transmission

overhaul required

– Check for:

Damaged plates

and seals

Contaminated

solenoids

– Flush cooler

– Add new fluid

– Check level

–Transmission

overhaul required

– Flush cooler and

cooler lines

– Add new fluid

– Check level

*Fluid should be changed according to maintenance

schedule.

Te s t D r i v i n g

Some 4L30–E automatic transmission complaints will

require a test drive as a part of the diagnostic procedure.

Some codes will not set unless the vehicle is moving. The

purpose of the test drive is to duplicate the customer’s

complaint condition and set a current Powertrain Control

Module (PCM) trouble code. Perform this procedure

before each 4L30–E automatic transmission repair, and

again after repairs are made.

IMPORTANT:

Duplicate the condition under which the customer’s

complaint was observed.

Depending on the complaint, the line pressure gauge

and the scan tool may be required during the test

drive.

During the test drive, it is important to record all

necessary data from the areas being monitored, for

use in diagnosis. Also listen for and note any unusual

noises.

The following procedure should be used to test drive

4L30–E automatic transmission complaint vehicles:

1. Turn the ignition ON without starting the engine.

Check that the “CHECK TRANS” lamp comes on for

approximately 2 seconds and then goes out and

remains out.

If the lamp is flashing, GOTO Check Trans Indicator

in Transmission Control System (4L30–E) section.

If no serial data is present, GOTO OBD System

Check. Refer to Driveability and Emissions in

Engine section.

If the lamp stays ON or stays OFF, GOTO “Check

Trans” Check in Transmission Control System

(4L30–E) section.

2. Drive the vehicle. During the test drive, be sure that

the transmission achieves normal operating

temperature (approx. 20 minutes).

Allow the transmission to go through all of its gear

ranges, checking shift timing and firmness. Duplicate

the owner’s complaint condition as closely as

possible during the test drive.

3. If, during the test drive, the “CHECK TRANS” lamp

comes on, use the scan tool to check for trouble

codes.

4. If, during the test drive, a problem is felt, but the

“CHECK TRANS” lamp does not come on and no

trouble codes are present, drive the vehicle with the

PCM disconnected (manually shifting the vehicle).

In Manual L, the vehicle operates in first gear.

In Manual 2, the vehicle operates in third gear.

In Manual 3 or “D”, the vehicle operates in fourth

gear.

If the problem still exists with the PCM disconnected,

refer to Mechanical/Hydraulic Diagnosis in this

section.

5. If no problem has been found at this point, check all

underhood connections that supply power to the PCM

and ignition fuses. Physically and visually inspect all

the PCM harness connectors for loose or corroded

terminals. Inspect the PCM ground points.