turn signal OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4679 of 6000

6E–22

ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “D”

(For except EXPORT and SOUTH AFRICA)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

D1Injector Cylinder #2GRN/ORNB+B+General Description and

Operation, Fuel Injector

D2Torque Converter Clutch

(TCC)BRN/BLU0.0 V0.0 VOn-Vehicle Service, Torque

Converter Clutch

D3Injector Cylinder #1GRN/WHTB+B+General Description and

Operation, Fuel Injector

D4Serial Data (8192)ORN5.0 V5.0 VChassis Electrical

D5Ignition Control, Cylinder

#5RED/YEL0.0 V0.1 VGeneral Description and

Operation, Ignition Coil

D6Ignition Control, Cylinder

#3RED/BLUE0.0 V0.0 VGeneral Description and

Operation, Ignition Coil

D7VSS Input / IMOB

ResponseWHT/BLK0.0 V0.1 V

(at rest)Chassis Electrical

D8Sensor Ground 5V

Reference A ReturnGRN0.0 V0.0 VAppropriate Sensor

D9Sensor Ground 5 V

Reference B ReturnGRY0.0 V0.0 VAppropriate Sensor

D10Mass Air Flow (MAF)YEL4.9 V4.2 VGeneral Description, Mass

Air Flow Sensor

D11Camshaft Position SensorWHT5.0 V or less

than 1.0 V4.6 VGeneral Description and

Operation, Camshaft

Position Sensor

D12Not Used————

D13Not Used————

D14Bank 1 HO2S 1 LowGRN0.0 V0.1 VGeneral Description and

Operation, Fuel HO2S 1

D15Bank 1 HO2S 1 SignalRED0.4 V0.1-0.9 VGeneral Description and

Operation, Fuel HO2S 1

D16Not Used————

Page 4695 of 6000

6E–38

ENGINE DRIVEABILITY AND EMISSIONS

General Service Information

OBD Serviceablity Issues

The list of non-vehicle faults that could affect the

performance of the OBD system has been compiled.

These non-vehicle faults vary from environmental

conditions to the quality of fuel used.

The illumination of the MIL (“Check Engine” lamp) due to

a non-vehicle fault could lead to misdiagnosis of the

vehicle, increased warranty expense and customer

dissatisfaction. The following list of non-vehicle faults

does not include every possible fault and may not apply

equally to all product lines.

Fuel Quality

Using fuel with the wrong octane rating for your vehicle

may cause driveability problems. Many of the major fuel

companies advertise that using “premium” gasoline will

improve the performance of your vehicle. Most premium

fuels use alcohol to increase the octane rating of the fuel.

Although alcohol-enhanced fuels may raise the octane

rating, the fuel’s ability to turn into vapor in cold

temperatures deteriorates. This may affect the starting

ability and cold driveability of the engine.

Low fuel levels can lead to fuel starvation, lean engine

operation, and eventually engine misfire.

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Something as simple as a

high-performance exhaust system that affects exhaust

system back pressure could potentially interfere with the

operation of the EGR valve and thereby turn on the MIL

(“Check Engine” lamp). Small leaks in the exhaust

system near the post catalyst oxygen sensor can also

cause the MIL (“Check Engine” lamp) to turn on.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the MIL (“Check

Engine” lamp).

Environment

Temporary environmental conditions, such as localized

flooding, will have an effect on the vehicle ignition system.

If the ignition system is rain-soaked, it can temporarily

cause engine misfire and turn on the MIL (“Check Engine”

lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lamp) to turn on if the vehicle is not

maintained properly. Restricted air filters, fuel filters, and

crankcase deposits due to lack of oil changes or improper

oil viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics, vehicle

maintenance schedules must be more closely followed.Related System Faults

Many of the OBD system diagnostics will not run if the

PCM detects a fault on a related system or component.

One example would be that if the PCM detected a Misfire

fault, the diagnostics on the catalytic converter would be

suspended until Misfire fault was repaired. If the Misfire

fault was severe enough, the catalytic converter could be

damaged due to overheating and would never set a

Catalyst DTC until the Misfire fault was repaired and the

Catalyst diagnostic was allowed to run to completion. If

this happens, the customer may have to make two trips to

the dealership in order to repair the vehicle.

Maintenance Schedule

Refer to the Maintenance Schedule.

Visual / Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any diagnostic

procedure or diagnosing the cause of an emission test

failure. This can often lead to repairing a problem without

further steps. Use the following guidelines when

performing a visual/physical inspection:

Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

Inspect hoses that are difficult to see behind other

components.

Inspect all wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires,

contact with sharp edges or contact with hot exhaust

manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in an

incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-

tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.

Each bit of information can have one of two lengths: long

or short. This allows vehicle wiring to be reduced by

transmitting and receiving multiple signals over a single

wire. The messages carried on Class II data streams are

also prioritized. If two messages attempt to establish

communications on the data line at the same time, only

the message with higher priority will continue. The device

with the lower priority message must wait. The most

significant result of this regulation is that it provides Tech 2

manufacturers with the capability to access data from any

make or model vehicle that is sold.

Page 4722 of 6000

6E–65 ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor Diagnosis

The Tech 2 has two data displays available for diagnosing

the knock sensor (KS) system. The two displays are

described as follows:

“Knock Retard” indicates the number of degrees that

the spark timing is being retarded due to a knock

condition.

“KS Noise Channel” indicates the current voltage level

being monitored on the noise channel.

DTCs P0325 and P0327 are designed to diagnose the KS

module, the knock sensor, and the related wiring. The

problems encountered with the KS system should set a

DTC. However, if no DTC was set but the KS system is

suspect because of a detonation complaint, refer to

Detonation/Spark Knock in Symptoms.

Powertrain Control Module (PCM)

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the PCM terminal connections.

The terminals may have to be removed from the

connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms p o r t i o n o f

the manual and make a careful physical inspection of

all component and wiring associated with the affected

system.

There is a shorted solenoid, relay coil, or harness.

S o l e n o i d s a n d r e l a y s a r e t u r n e d “ O N ” a n d “ O F F ” b y t h e

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay to

be inoperative.

Multiple PCM Information Sensor

DTCS Set

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The engine coolant temperature (ETC) sensor

The intake air temperature (IAT) sensor

The transmission fluid temperature (TFT) sensor

The PCM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The exhaust gas recirculating (EGR) pintle position

sensor

The throttle position (TP) sensor

The manifold absolute pressure (MAP) sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

IMPORTANT:Be sure to inspect PCM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0108

P0113

P0118

P0123

P0560

P0712

P0406

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

P0108

P0113

P0118

P0123

P0712

P0406

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0107

P0122

In the 5-volt reference circuit A, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0122

In the 5-volt reference circuit B, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0107

Check for the following conditions:

Page 4723 of 6000

6E–66

ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM. Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damage terminals,

and a poor terminal-to-wire connection.

Damaged harness. Inspect the wiring harness for

damage. If the harness is not damaged, observe an

affected sensor’s displayed value on the Tech 2 with

the ignition “ON” and the engine “OFF” while you move

the connectors and the wiring harnesses related to the

following sensors:

IAT

ECT

TP

MAP

EGR

TFT

Multiple PCM Information Sensor DTCs Set

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Turn the ignition “OFF,” disconnect the PCM.

2. Turn the ignition “ON,” check the 5 volt reference A

circuit for the following conditions:

A poor connection at the PCM.

An open between the PCM connector and the

splice.

A short to ground.

A short to voltage.

Is there an open or short?

—Go to Step 3Go to Step 4

3Repair the open or short.

Is the action complete?

—Verify repair—

4Check the sensor ground circuit for the following

conditions:

A poor connection at the PCM or the affected

sensors.

An open between the PCM connector and the

affected sensors.

Is there an open or a poor connection?

—Go to Step 5Go to Step 6

5Repair the open or the poor connection.

Is the action complete?

—Verify repair—

6Measure the voltage between the EGR pintle position

sensor signal circuit at the PCM harness connector and

ground.

Does the voltage measure near the specified value?

0 VGo to Step 7Go to Step 12

7Measure the voltage between the MAP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 8Go to Step 15

8Measure the voltage between the TP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 9Go to Step 16

9Measure the voltage between the IAT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 10Go to Step 17

10Measure the voltage between the ECT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 11Go to Step 18

Page 4753 of 6000

6E–96

ENGINE DRIVEABILITY AND EMISSIONS

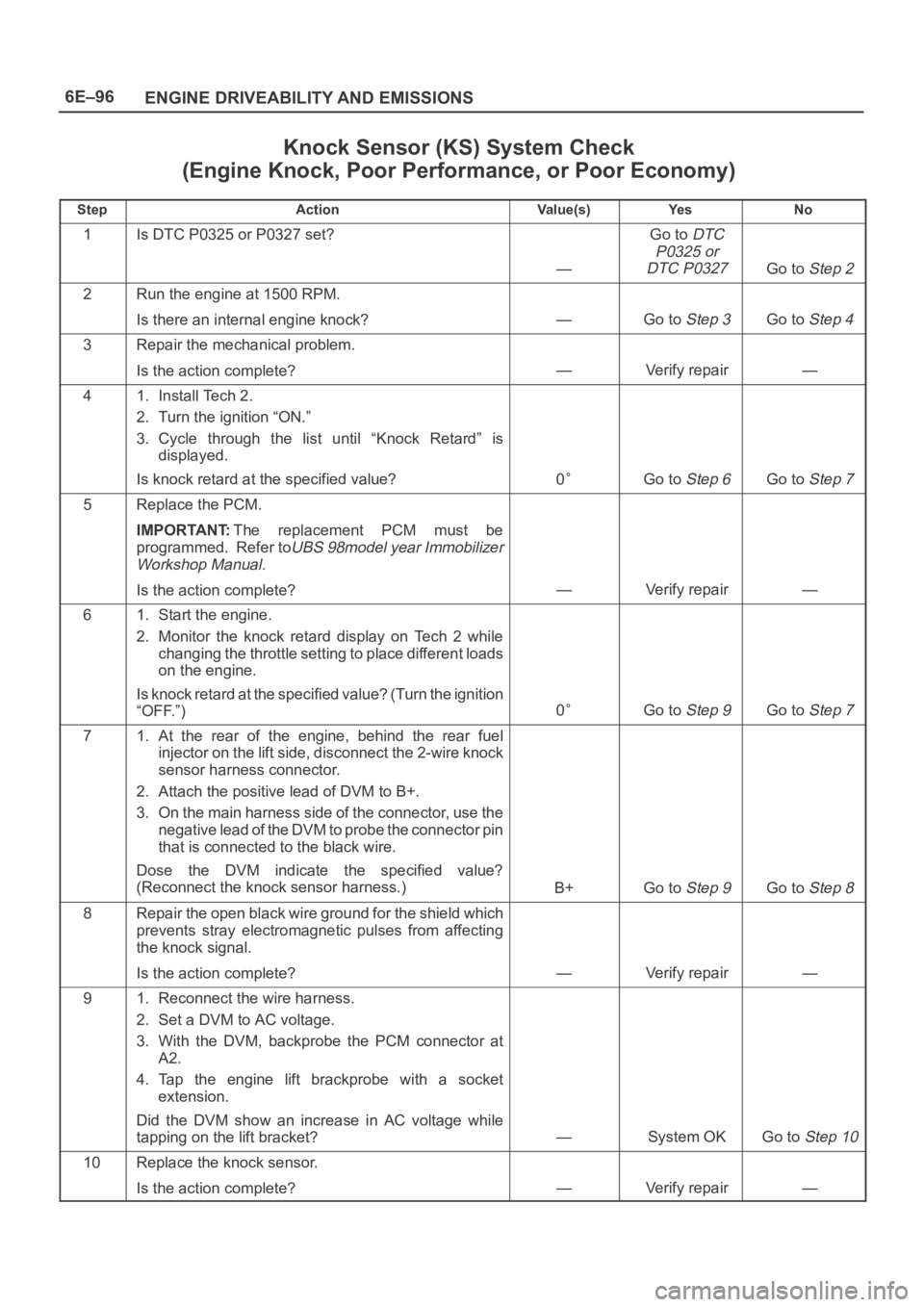

Knock Sensor (KS) System Check

(Engine Knock, Poor Performance, or Poor Economy)

StepActionVa l u e ( s )Ye sNo

1Is DTC P0325 or P0327 set?

—

Go to DTC

P0325 or

DTC P0327

Go to Step 2

2Run the engine at 1500 RPM.

Is there an internal engine knock?

—Go to Step 3Go to Step 4

3Repair the mechanical problem.

Is the action complete?

—Verify repair—

41. Install Tech 2.

2. Turn the ignition “ON.”

3. Cycle through the list until “Knock Retard” is

displayed.

Is knock retard at the specified value?

0Go to Step 6Go to Step 7

5Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

61. Start the engine.

2. Monitor the knock retard display on Tech 2 while

changing the throttle setting to place different loads

on the engine.

Is knock retard at the specified value? (Turn the ignition

“OFF.”)

0Go to Step 9Go to Step 7

71. At the rear of the engine, behind the rear fuel

injector on the lift side, disconnect the 2-wire knock

sensor harness connector.

2. Attach the positive lead of DVM to B+.

3. On the m ain harness side of the connector, use th e

negative lead of the DVM to probe the connector pin

that is connected to the black wire.

Dose the DVM indicate the specified value?

(Reconnect the knock sensor harness.)

B+Go to Step 9Go to Step 8

8Repair the open black wire ground for the shield which

prevents stray electromagnetic pulses from affecting

the knock signal.

Is the action complete?

—Verify repair—

91. Reconnect the wire harness.

2. Set a DVM to AC voltage.

3. With the DVM, backprobe the PCM connector at

A2.

4. Tap the engine lift brackprobe with a socket

extension.

Did the DVM show an increase in AC voltage while

tapping on the lift bracket?

—System OKGo to Step 10

10Replace the knock sensor.

Is the action complete?

—Verify repair—

Page 4762 of 6000

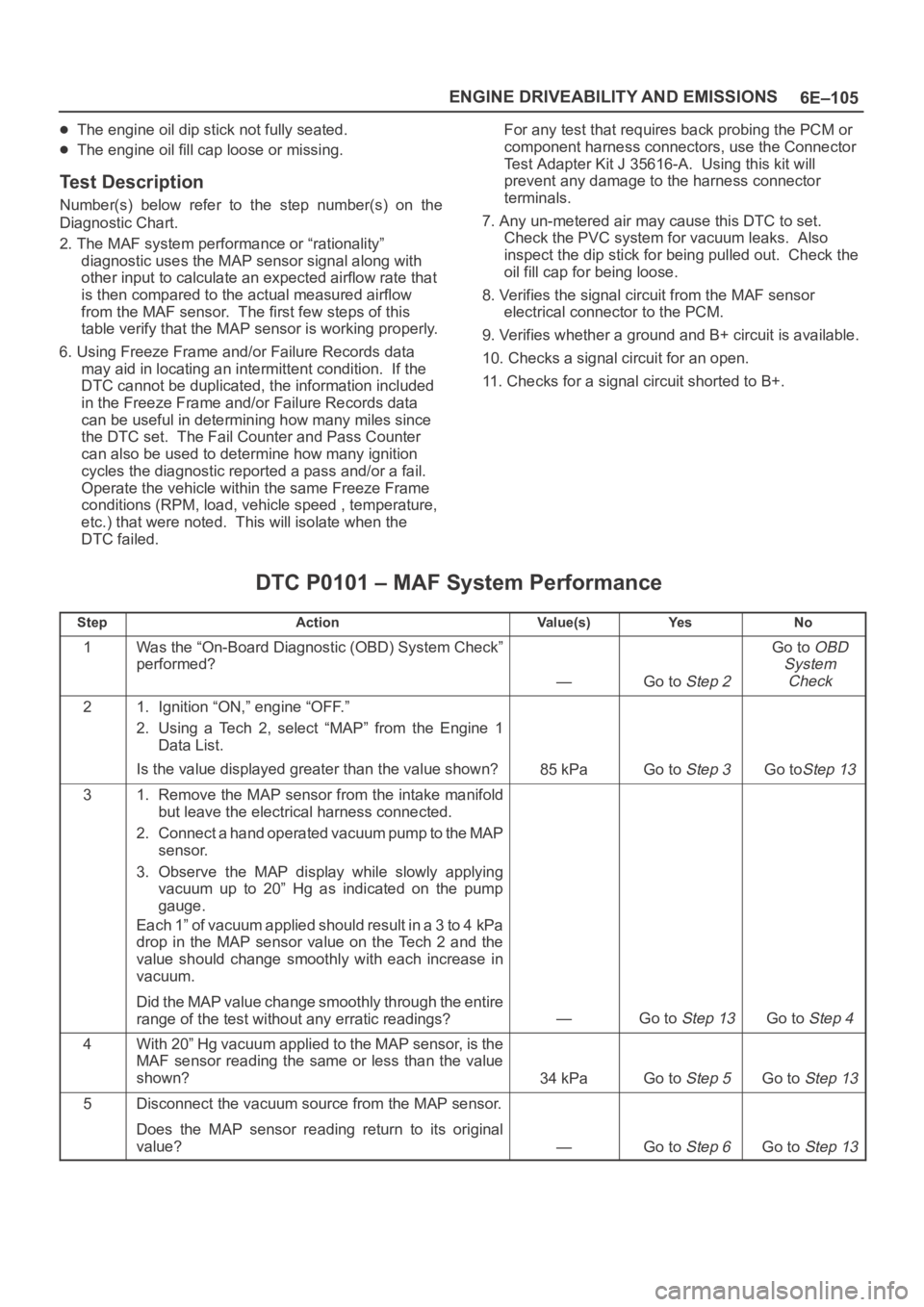

6E–105 ENGINE DRIVEABILITY AND EMISSIONS

The engine oil dip stick not fully seated.

The engine oil fill cap loose or missing.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. The MAF system performance or “rationality”

diagnostic uses the MAP sensor signal along with

other input to calculate an expected airflow rate that

is then compared to the actual measured airflow

from the MAF sensor. The first few steps of this

table verify that the MAP sensor is working properly.

6. Using Freeze Frame and/or Failure Records data

may aid in locating an intermittent condition. If the

DTC cannot be duplicated, the information included

in the Freeze Frame and/or Failure Records data

can be useful in determining how many miles since

the DTC set. The Fail Counter and Pass Counter

can also be used to determine how many ignition

cycles the diagnostic reported a pass and/or a fail.

Operate the vehicle within the same Freeze Frame

conditions (RPM, load, vehicle speed , temperature,

etc.) that were noted. This will isolate when the

DTC failed.For any test that requires back probing the PCM or

component harness connectors, use the Connector

Test Adapter Kit J 35616-A. Using this kit will

prevent any damage to the harness connector

terminals.

7. Any un-metered air may cause this DTC to set.

Check the PVC system for vacuum leaks. Also

inspect the dip stick for being pulled out. Check the

oil fill cap for being loose.

8. Verifies the signal circuit from the MAF sensor

electrical connector to the PCM.

9. Verifies whether a ground and B+ circuit is available.

10. Checks a signal circuit for an open.

11. Checks for a signal circuit shorted to B+.

DTC P0101 – MAF System Performance

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Using a Tech 2, select “MAP” from the Engine 1

Data List.

Is the value displayed greater than the value shown?

85 kPaGo to Step 3Go toStep 13

31. Remove the MAP sensor from the intake manifold

but leave the electrical harness connected.

2. Connect a hand operated vacuum pump to the MAP

sensor.

3. Observe the MAP display while slowly applying

vacuum up to 20” Hg as indicated on the pump

gauge.

Each 1” of vacuum applied should result in a 3 to 4 kPa

drop in the MAP sensor value on the Tech 2 and the

value should change smoothly with each increase in

vacuum.

Did the MAP value change smoothly through the entire

range of the test without any erratic readings?

—Go to Step 13Go to Step 4

4With 20” Hg vacuum applied to the MAP sensor, is the

MAF sensor reading the same or less than the value

shown?

34 kPaGo to Step 5Go to Step 13

5Disconnect the vacuum source from the MAP sensor.

Does the MAP sensor reading return to its original

value?

—Go to Step 6Go to Step 13

Page 4797 of 6000

6E–140

ENGINE DRIVEABILITY AND EMISSIONS

HO2S, causing the system to appear lean. Check for

exhaust leaks that may cause a false lean condition to

be indicated.

MAF sensor – The system can go lean if the MAF

sensor signal indicates an engine airfiow

measurement that is not correct. Disconnect the MAF

sensor to see if the lean condition is corrected. If so,

replace the MAF sensor.

Fuel contamination – Water, even in small amounts,

can be delivered to the fuel injectors. The water can

cause a lean exhaust to be indicated. Excessive

alcohol in the fuel can also cause this condition. Refer

to

Fuel System Diagnosis for the procedure to check

for fuel contamination.

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to step numbers on the diagnostic

chart.

3. DTC P0131 failing during operation may indicate a

condition described in the “Diagnostic Aids” above.

If the DTC P0131 test passes while the Failure

Records conditions are being duplicated, an

intermittent condition is indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0131 –HO2S Circuit Low Voltage Bank 1 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install the Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within the parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

4. Using a Tech 2, monitor Bank 1 HO2S 1 voltage.

Does the Bank 1 HO2S 1 voltage remain below the

specified value?

22 mVGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P0131 until the DTC P0131 test runs.

Note test result.

Does Tech 2 indicate DTC P0131 failed this ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Turn the ignition “OFF.”

2. Disconnect the PCM.

3. Check the Bank 1 HO2S 1 high and low circuits for a

short to ground or a short to the heater ground

circuit.

Are the Bank 1 HO2S 1 signal circuits shorted to

ground?

—Go to Step 5Go to Step 6

5Repair the Bank 1 HO2S 1 signal circuit.

Is the action complete?

—Verify repair—

61. Turn the ignition “OFF,” HO2S 1 and PCM

disconnected.

2. Check for continuity between the high and low

signal circuits.

Was there continuity between the high and low circuits?

—Go to Step 7Go to Step 8

7Repair the short between the high and low circuits.

Is the action complete?

—Verify repair—

Page 4803 of 6000

6E–146

ENGINE DRIVEABILITY AND EMISSIONS

indicates a signal line shorted to ground or signal lines

shorted together. Disconnect the HO2S and connect

a test light between the HO2S ignition feed and heater

ground circuits. If the test light does not light for 2

seconds when the ignition is turned on, repair the open

ignition feed or sensor ground circuit as necessary. If

the test light lights and the HO2S signal and low circuits

are OK, replace the HO2S.

Intermittent test – With the Ignition “ON,” monitor the

HO2S signal voltage while moving the wiring harness

and related connectors. If the fault is induced, the

HO2S signal voltage will change. This may help isolate

the location of the malfunction.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. If the DTC P0134 test passes while the Failure

Records conditions are being duplicated, an

intermittent conditions is indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0134 –HO2S Circuit Insufficient Activity Bank 1 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install Tech 2.

2. Run the engine at operating temperature.

3. Operate the engine above 1200 RPM for two

minutes.

Does Tech 2 indicate Bank 1 HO2S 1 voltage varying

outside the specified values?

400-500 mVGo to Step 3Go to Step 4

31. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “Specific DTC” info for DTC

P0134 until the DTC P0134 test runs.

4. Note the test result.

Does Tech 2 indicate DTC P0134 failed this ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

4Check for a damaged harness.

Was a problem found?

—Verify repairGo to Step 5

5Check for poor Bank 1 HO2S 1 high and low circuit

terminal connections at the Bank 1 HO2S 1 harness

connector and replace terminal(s) if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 6

6Check for poor Bank 1 HO2S 1 high and low circuit

terminal connections at the PCM and replace terminals

if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 7

71. Ignition “OFF.”

2. With the PCM disconnected, check continuity of the

Bank 1 HO2S 1 high circuit.

3. If the Bank 1 HO2S 1 high circuit measures over 5.0

ohms, repair open or poor connection as necessary.

Was a Bank 1 HO2S 1 high circuit problem found and

corrected?

—Verify repairGo to Step 8

Page 4806 of 6000

6E–149 ENGINE DRIVEABILITY AND EMISSIONS

exhaust leaks that may cause a false lean condition to

be indicated.

MAF sensor –The system can go lean if the MAF

sensor signal indicates an engine airflow

measurement that is not correct. Disconnect the MAF

sensor to see if the lean condition is corrected. If so,

replace the MAF sensor.

Fuel contamination – Water, even in small amounts,

can be delivered to the fuel injectors. The water can

cause a lean exhaust to be indicated. Excessive

alcohol in the fuel can also cause this condition. Refer

to

Fuel System Diagnosis for the procedure to check

for fuel contamination.

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. DTC P0151 failing during operation may indicate a

condition described in the “Diagnostic Aids” above.

If the DTC P0151 test passes while the Failure

Records conditions are being duplicated, an

intermittent condition is indicate.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0151 – HO2S Circuit Low Voltage Bank 2 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within the parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

4. Using Tech 2, monitor Bank 2 HO2S 1 voltage.

Does the Bank 2 HO2S 1 voltage remain below the

specified value?

22 mVGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “Specific DTC” info for DTC

P0151 until the DTC P0151 test runs.

4. Note test result.

Does Tech 2 indicate DTC P0151 failed this ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Turn ignition “OFF.”

2. Disconnect the PCM.

3. Check the Bank 2 HO2S 1 high and low signal

circuits for a short to ground or a short to the heater

ground circuit.

Were Bank 2 HO2S 1 signal circuits shorted?

—Go to Step 5Go to Step 6

5Repair the Bank 2 HO2S 1 signal circuit.

Is the action complete?

—Verify repair—

61. Ignition “OFF.”

2. Leave the PCM and HO2S 1 disconnected.

3. Check for continuity between the high and low

signal circuits.

Was there continuity between the high and low circuits?

—Go to Step 7Go to Step 8

7Repair the short between the high and low circuits.

Is the action complete?

—Verify repair—

Page 4827 of 6000

6E–170

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0201 Injector 1 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When a

driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0201 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0201 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0201 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 1 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.