turn signal OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4866 of 6000

6E–209 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0352 Ignition 2 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 2

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 2 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 2, it will set a DTC P0352.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58 X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous spark events.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0352 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 4869 of 6000

6E–212

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0353 Ignition 3 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 3

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 3 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 3, it will set a DTC P0353.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous spark events.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0353 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 4872 of 6000

6E–215 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0354 Ignition 4 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 4

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 4 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 4, it will set a DTC P0354.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous spark events.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0354 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 4875 of 6000

6E–218

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0355 Ignition 5 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 5

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 5 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 5, it will set a DTC P0355.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous spark events.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0355 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 4878 of 6000

6E–221 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0356 Ignition 6 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 6

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 6 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 6, it will set a DTC P0356.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous circuit monitoring.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0356 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 4891 of 6000

6E–234

ENGINE DRIVEABILITY AND EMISSIONS

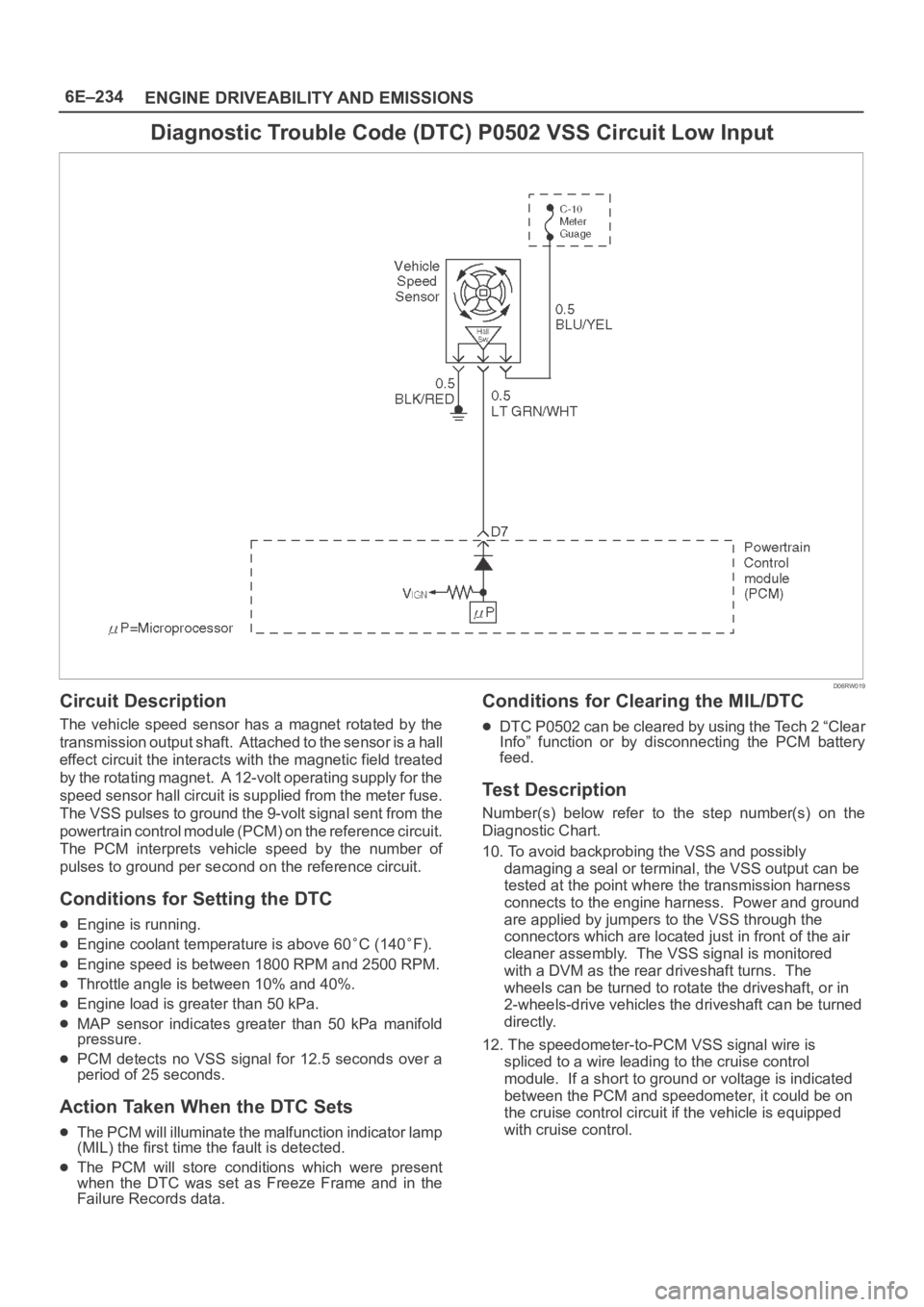

Diagnostic Trouble Code (DTC) P0502 VSS Circuit Low Input

D06RW019

Circuit Description

The vehicle speed sensor has a magnet rotated by the

transmission output shaft. Attached to the sensor is a hall

effect circuit the interacts with the magnetic field treated

by the rotating magnet. A 12-volt operating supply for the

speed sensor hall circuit is supplied from the meter fuse.

The VSS pulses to ground the 9-volt signal sent from the

powertrain control module (PCM) on the reference circuit.

The PCM interprets vehicle speed by the number of

pulses to ground per second on the reference circuit.

Conditions for Setting the DTC

Engine is running.

Engine coolant temperature is above 60C (140F).

Engine speed is between 1800 RPM and 2500 RPM.

Throttle angle is between 10% and 40%.

Engine load is greater than 50 kPa.

MAP sensor indicates greater than 50 kPa manifold

pressure.

PCM detects no VSS signal for 12.5 seconds over a

period of 25 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0502 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

10. To avoid backprobing the VSS and possibly

damaging a seal or terminal, the VSS output can be

tested at the point where the transmission harness

connects to the engine harness. Power and ground

are applied by jumpers to the VSS through the

connectors which are located just in front of the air

cleaner assembly. The VSS signal is monitored

with a DVM as the rear driveshaft turns. The

wheels can be turned to rotate the driveshaft, or in

2-wheels-drive vehicles the driveshaft can be turned

directly.

12. The speedometer-to-PCM VSS signal wire is

spliced to a wire leading to the cruise control

module. If a short to ground or voltage is indicated

between the PCM and speedometer, it could be on

the cruise control circuit if the vehicle is equipped

with cruise control.

Page 4900 of 6000

6E–243 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepNo Ye s Va l u e ( s ) Action

12Check for leaks at the exhaust manifold.

Are there leaks at the exhaust manifold?

—Go to Step 13Go to Step 14

13Tighten the bolts to specifications or replace the

manifold if necessary.

Is your action complete?

—Go to Step 2—

14Visually/physically inspect the following items:

Ensure that the Bank 2 HO2S 1 is securely

installed.

Check for corrosion on terminals.

Check terminal tension (at Bank 2 HO2S 1 and at

the PCM).

Check for damaged wiring.

Was a problem found in any of the above areas?

—Go to Step 18Go to Step 15

151. Disconnect Bank 1 HO2S 1.

2. Ignition “ON.”

3. Using a DVM at the PCM side of the HO2S 1

connector, measure the voltage between the high

signal circuit and ground.

Also measure the voltage between the low signal

circuit and ground.

Are both voltages in the specified range?

3-4 V

Go to Step

16

Go to Step 19

161. With Bank 1 HO2S 1 disconnected, jumper the high

and low (PCM side) signal circuits to ground.

2. Ignition “ON.”

3. Using Tech 2, monitor the Bank 2 HO2S 1 voltage.

Does the scan too indicate less than 10 mV and

immediately return to about 450 mV when the jumper is

removed?

—Go to Step 21Go to Step 22

17Replace affected heated oxygen sensors.

NOTE: Before replacing sensors, the cause of the

contamination must be determined and corrected.

Fuel contamination.

Use of improper RTV sealant.

Engine oil/coolant consumption.

Is the action complete?

—Verify repair—

18Repair condition as necessary.

Is the action complete?

—Verify repair—

19Check for faulty PCM connections or terminal damage.

Is the action complete?

—Verify repairGo to Step 20

20Repair open, short or grounded signal circuit.

Is the action complete?

—Verify repair—

Page 4905 of 6000

6E–248

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1380 ABS Rough Road ABS System Fault

Circuit Description

The powertrain control module (PCM) monitors ABS fault

signal. When PCM receives fault signal, PCM will set

DTC P1380.

Conditions for Setting the DTC

Vehicle speed is more than 5 mph.

Load is less than 99%.

Engine revolution is less than 6250 rpm.

PCM receives ABS fault signals from ABS unit.

Ignition on.

Misfire DTCs exist.

100 test failures within 120 test samples.

Action Taken When the DTC Sets

The PCM will store DTC 1380 only, no MIL turn on.

Conditions for Clearing the MIL/DTC

A history DTC P1380 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC 1380 can be cleared by using Tech-2 or

disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

PCM and ABS communication line short circuit to other

line may cause faulty signal. Inspect communication

line.

Follow ABS ECU diagnosis procedure, refer to ABS

procedure page.

DTC P1380 – ABS Rough Road ABS System Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P1380 and Misfire DTCs until the DTC P1380 and

Misfire DTCs test runs. Note the result.

Does the Tech 2 indicates DTC P1380 and Misfire

DTCs failed this ignition?

—

Refer to ABS

diagnosis

After inspect

ABS, unit re-

peat

Step 2

Still problem

exists, go to

Step 3

Clear DTC by

Te c h 2

3Check short circuit among communication line of

PCM/ABS and others.

Was short circuit?

—

Repair wiring

Verify repair

Go to Step 4

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4906 of 6000

6E–249 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1404 EGR Closed Stuck

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to commands from the PCM, and to

detect a fault if current pintle zero position is different from

the learned zero position. If the PCM detects a pintle

position signal indicates more than 30 % different

between current zero position and the learned zero

position and more than 5 seconds, and this condition

meet 3 times during trip, then the PCM will set DTC

P1404.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

Intake Air temp is more than 3C.

Desire EGR position is 0.

Difference EGR pintle position between current and

the learned zero is more than 30 % last more than 5

seconds, and meet three time to the above condition

during a trip. Then it trigger the PCM lights on.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after consecutive 2nd trip in which the fault is

detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P1404 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Excessive carbon deposit on EGR valve shaft or/and

foreign material may cause no return to EGR valve

fully seated. Those carbon deposit may occur by

unusual port operation. Remove foreign material

or/and excessive carbon deposit on EGR valve shaft

may make return to EGR valve fully seated.

Poor connection or damaged harness – Inspect the

wiring harness for damage. Same as P1406

description

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 4992 of 6000

6E–335 ENGINE DRIVEABILITY AND EMISSIONS

General Description

General Description (PCM and

Sensors)

58X Reference PCM Input

The powertrain control module (PCM) uses this signal

from the crankshaft position (CKP) sensor to calculate

engine RPM and crankshaft position at all engine speeds.

The PCM also uses the pulses on this circuit to initiate

injector pulses. If the PCM receives no pulses on this

circuit, DTC P0337 will set. The engine will not start and

run without using the 58X reference signal.

A/C Request Signal

This signal tells the PCM when the A/C mode is selected

at the A/C control head. The PCM uses this to adjust the

idle speed before turning “ON” the A/C clutch. The A/C

compressor will be inoperative if this signal is not

available to the PCM.

Refer to

A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for the A/C electrical system.

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor provides a signal

used by the powertrain control module (PCM) to calculate

the ignition sequence. The CKP sensor initiates the 58X

reference pulses which the PCM uses to calculate RPM

and crankshaft position.

Refer to

Electronic Ignition System for additional

information.

0013

Camshaft Position (CMP) Sensor and

Signal

The camshaft position (CMP) sensor sends a CMP signal

t o t h e P C M . T h e P C M u s e s t h i s s i g n a l a s a “ s y n c p u l s e ” t otrigger the injectors in the proper sequence. The PCM

uses the CMP signal to indicate the position of the #1

piston during its power stroke. This allows the PCM to

calculate true sequential fuel injection (SFI) mode of

operation. If the PCM detects an incorrect CMP signal

while the engine is running, DTC P0341 will set. If the

CMP signal is lost while the engine is running, the fuel

injection system will shift to a calculated sequential fuel

injection mode based on the last fuel injection pulse, and

the engine will continue to run. As long as the fault is

present, the engine can be restarted. It will run in the

calculated sequential mode with a 1-in-6 chance of the

injector sequence being correct.

Refer to

DTC P0341 for further information.

0014

Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature (ECT) sensor is a

thermistor (a resistor which changes value based on

temperature) mounted in the engine coolant stream. Low

coolant temperature produces a high resistance of

100,000 ohms at –40

C (–40F). High temperature

causes a low resistance of 70 ohms at 130

C (266F).

The PCM supplies a 5-volt signal to the ECT sensor

through resistors in the PCM and measures the voltage.

The signal voltage will be high when the engine is cold and

low when the engine is hot. By measuring the voltage, the

PCM calculates the engine coolant temperature. Engine

coolant temperature affects most of the systems that the

PCM controls.

Tech 2 displays engine coolant temperature in degrees.

After engine start-up, the temperature should rise steadily

to about 85

C (185F). It then stabilizes when the

thermostat opens. If the engine has not been run for

several hours (overnight), the engine coolant

temperature and intake air temperature displays should

be close to each other. A hard fault in the engine coolant

sensor circuit will set DTC P0177 or DTC P0118. An

intermittent fault will set a DTC P1114 or P1115.