Seat OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3433 of 6000

SEAT BELT SYSTEM 9A–13

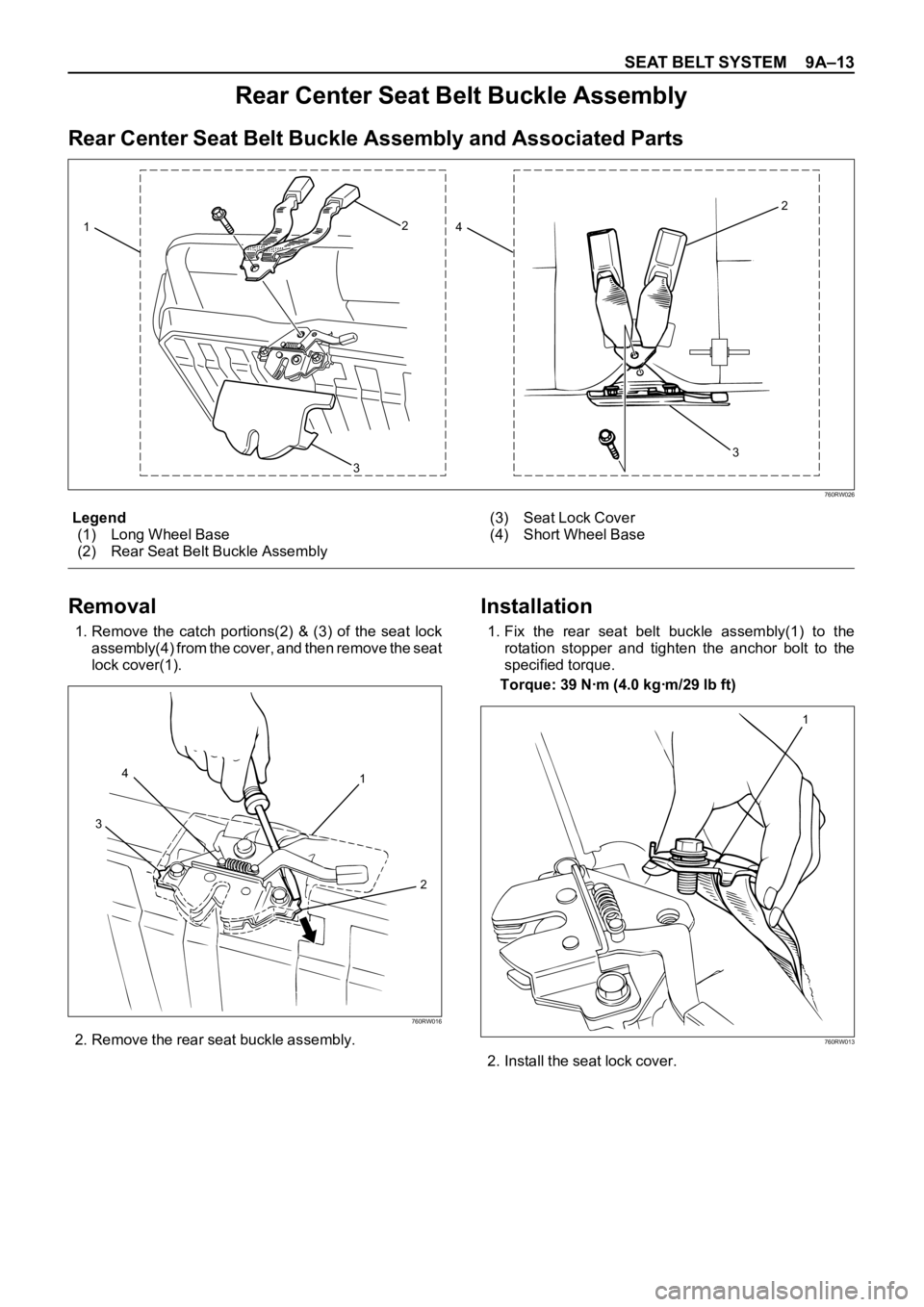

Rear Center Seat Belt Buckle Assembly

Rear Center Seat Belt Buckle Assembly and Associated Parts

2

2

1

4

3

3

760RW026

Legend

(1) Long Wheel Base

(2) Rear Seat Belt Buckle Assembly(3) Seat Lock Cover

(4) Short Wheel Base

Removal

1. Remove the catch portions(2) & (3) of the seat lock

assembly(4) from the cover, and then remove the seat

lock cover(1).

2. Remove the rear seat buckle assembly.

Installation

1. Fix the rear seat belt buckle assembly(1) to the

rotation stopper and tighten the anchor bolt to the

specified torque.

Torque: 39 Nꞏm (4.0 kgꞏm/29 lb ft)

2. Install the seat lock cover.

1

2 4

3

760RW016

1

760RW013

Page 3434 of 6000

9A–14 SEAT BELT SYSTEM

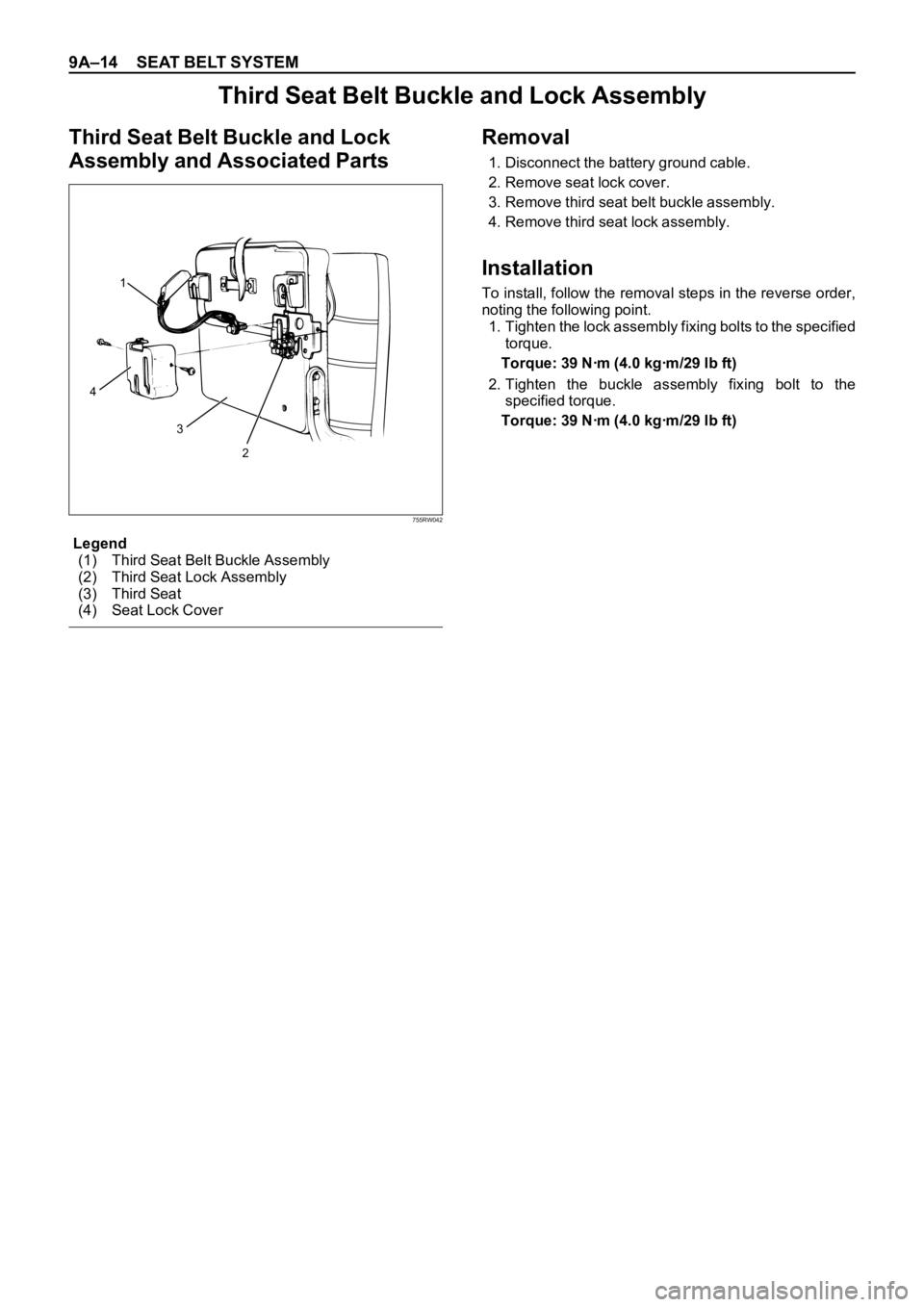

Third Seat Belt Buckle and Lock Assembly

Third Seat Belt Buckle and Lock

Assembly and Associated PartsRemoval

1. Disconnect the battery ground cable.

2. Remove seat lock cover.

3. Remove third seat belt buckle assembly.

4. Remove third seat lock assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Tighten the lock assembly fixing bolts to the specified

torque.

Torque: 39 Nꞏm (4.0 kgꞏm/29 lb ft)

2. Tighten the buckle assembly fixing bolt to the

specified torque.

Torque: 39 Nꞏm (4.0 kgꞏm/29 lb ft)1

4

3

2

755RW042

Legend

(1) Third Seat Belt Buckle Assembly

(2) Third Seat Lock Assembly

(3) Third Seat

(4) Seat Lock Cover

Page 3435 of 6000

SEAT BELT SYSTEM 9A–15

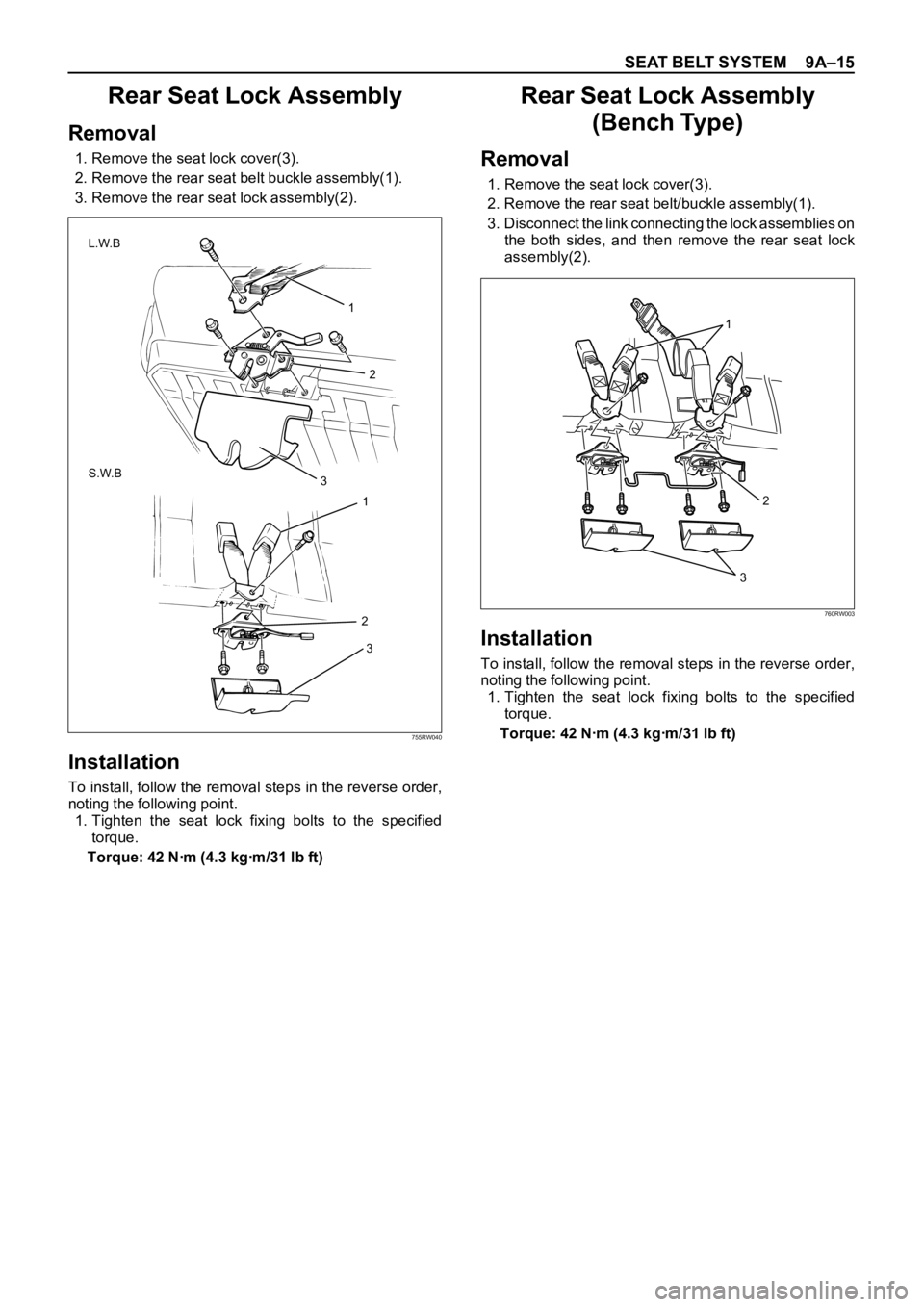

Rear Seat Lock Assembly

Removal

1. Remove the seat lock cover(3).

2. Remove the rear seat belt buckle assembly(1).

3. Remove the rear seat lock assembly(2).

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Tighten the seat lock fixing bolts to the specified

torque.

Torque: 42 Nꞏm (4.3 kgꞏm/31 lb ft)

L.W.B

1

2

S.W.B

1

2

3

3

755RW040

Rear Seat Lock Assembly

(Bench Type)

Removal

1. Remove the seat lock cover(3).

2. Remove the rear seat belt/buckle assembly(1).

3. Disconnect the link connecting the lock assemblies on

the both sides, and then remove the rear seat lock

assembly(2).

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Tighten the seat lock fixing bolts to the specified

torque.

Torque: 42 Nꞏm (4.3 kgꞏm/31 lb ft)

1

2

3

760RW003

Page 3436 of 6000

9A–16 SEAT BELT SYSTEM

Rear Seat Strikers

Removal

1. Fold the rear seat assembly to the front direction.

2. Remove the luggage floor box(1) (LꞏWꞏB).

Remove the striker cover(3) (SꞏWꞏB).

3. Remove the rear seat striker(2).

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Tighten the striker fixing bolts to the specified torque.

Torque: 40 Nꞏm (4.1 kgꞏm/30 lb ft)

L.W.B

1

2

S.W.B

3

2

755RW045

Removal

1. Disconnect the battery ground cable.

2. Remove the striker cover (1).

3. Remove the third seat striker (2).

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Tighten the striker fixing nuts to the specified torque.

Torque: 39 Nꞏm (4.0 kgꞏm/29 lb ft)

Third Seat Striker

1

2

755RW041

Page 3437 of 6000

SEAT BELT SYSTEM 9A–17

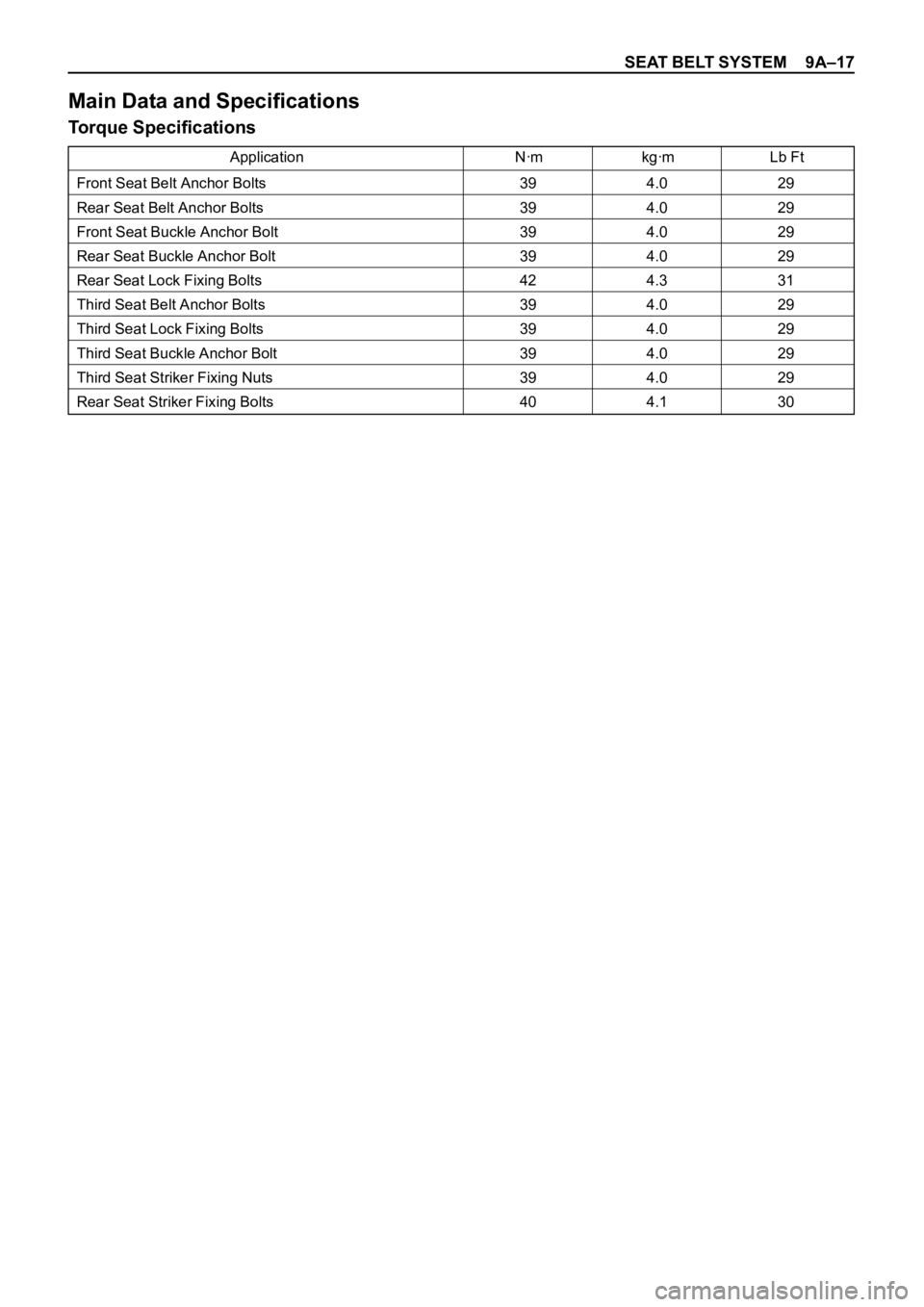

Front Seat Belt Anchor Bolts

Rear Seat Belt Anchor Bolts

Front Seat Buckle Anchor Bolt

Rear Seat Buckle Anchor Bolt

Rear Seat Lock Fixing Bolts

Third Seat Belt Anchor Bolts

Third Seat Lock Fixing Bolts

Third Seat Buckle Anchor Bolt

Third Seat Striker Fixing Nuts

Rear Seat Striker Fixing Bolts

Main Data and Specifications

Torque Specifications

A p p l i c a t i o n N ꞏm k g ꞏm L b F t

39

39

39

39

42

39

39

39

39

404.0

4.0

4.0

4.0

4.3

4.0

4.0

4.0

4.0

4.129

29

29

29

31

29

29

29

29

30

Page 3438 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–1

RESTRAINTS

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

CONTENTS

Service Precaution 9J–1. . . . . . . . . . . . . . . . . . . . . .

General Description 9J–2. . . . . . . . . . . . . . . . . . . . .

SRS Component And Wiring Location View 9J–4.

Component Description 9J–4. . . . . . . . . . . . . . . . . .

Definitions 9J–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 9J–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Connector Body Face Views 9J–9. . . . . . . . .

Repairs And Inspections Required After

An Accident 9J–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

On–Vehicle Service 9J–10. . . . . . . . . . . . . . . . . . . . . .

Air Bag Assembly Handling / Shipping

/ Scrapping 9J–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretensioner Seat Belt Handling / Shipping

/ Scrapping. 9J–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 9J–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precautions for SRS Component

Service 9J–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Connectors 9J–31. . . . . . . . . . . . . . . . . . . . . . . .

Sensing And Diagnostic Module (SDM) 9J–33. . . .

Service Precautions 9J–33. . . . . . . . . . . . . . . . . . .

Removal 9J–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Air Bag Assembly 9J–35. . . . . . . . . . . . . . . . .

Service Precautions 9J–35. . . . . . . . . . . . . . . . . . .

Removal 9J–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel 9J–37. . . . . . . . . . . . . . . . . . . . . . . . . Service Precautions 9J–37. . . . . . . . . . . . . . . . . . .

Removal 9J–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Coil Assembly 9J–39. . . . . . . . . . . . . . . . . . . . . .

Service Precautions 9J–39. . . . . . . . . . . . . . . . . . .

Removal 9J–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Coil Replacement Procedure 9J–42. . . . . . . . .

Removal 9J–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Disconnect the horn terminal 9J–43. . . . .

How to Connect Horn Terminal 9J–43. . . . . . . . . .

Installation 9J–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Column 9J–44. . . . . . . . . . . . . . . . . . . . . . . .

Service Precautions 9J–44. . . . . . . . . . . . . . . . . . .

Removal 9J–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Passenger Air Bag Assembly 9J–48. . . . . . . . . . . . .

Service Precautions 9J–48. . . . . . . . . . . . . . . . . . .

Removal 9J–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretensioner Seat Belt (If so equipped) 9J–49. . . .

Service Precaution 9J–49. . . . . . . . . . . . . . . . . . . .

Parts Location 9J–49. . . . . . . . . . . . . . . . . . . . . . . .

Removal 9J–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 9J–50. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 3439 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–2

General Description

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. Fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

Restraint Devices

827RW006

Legend

(1) Deployed Air Bag

(2) Knee Bolster

(3) Seat Belt

The Supplemental Restraint System (SRS) helps

supplement the protection offered by the driver and front

passenger seat belts by deploying an air bag from the

center of the steering wheel and from the top of the right

side of the instrument panel.

The air bag deploys when the vehicle is involved in a

frontal crash of sufficient force up to 30 degrees off the

centerline of the vehicle. To further absorb the crash

energy there is a knee bolster located beneath the

instrument panel for both the driver and passenger, and

the steering column is collapsible.

827RW005

Page 3443 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–6

825RS017

Air Bag Assemblies

The air bag assembly consist of an inflatable air bag

assembly and an inflator (a canister of gas–generating

material and an initiating device). When the vehicle is in a

frontal crash of sufficient force.

The SDM causes current flow through the deployment

loops. Current passing through the inflator ignites the

material in the air bag assembly. The gas produced from

this reaction rapidly inflates the air bag assembly.

There is a shorting clip on the driver air bag assembly

connector which connects the SRS coil assembly. The

shorting clip shorts across the driver air bag assembly

circuits when driver air bag assembly connector is

disconnected.

The circuit to the driver air bag assembly is shorted in this

way to help prevent unwanted deployment of the air bag

when servicing the driver air bag assembly, the steering

column or other SRS components.

827RS008There is a shorting clip on the passenger air bag

assembly connector which connects to the SRS harness.The shorting clip shorts across the passenger air bag

assembly circuit when the passenger air bag assembly

connector is disconnected. The circuit to the passenger

air bag assembly is shorted in this way to help prevent

unwanted deployment of the air bag when servicing the

passenger air bag assembly, the instrument panel or

other SRS components.

827RS001

Seat Belt with Pretensioner (If so

equipped)

The seat belt comprises a seat belt and a cylinder (a

cylinder filled with powder and an ignition device). In

cases of frontal collision which cause a shock exceeding

a specified level, the controller lets current flow to the

inflation circuit. The current ignites the cylinder of the seat

belt, producing gas. The gas helps tighten the seat belt to

restrain firmly the driver’s upper half in his seat.

760RW033

Page 3444 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–7

Steering Column

The steering column absorbs energy and is designed to

compress in a frontal crash to decrease the chance of

injury to the driver.

431RW019

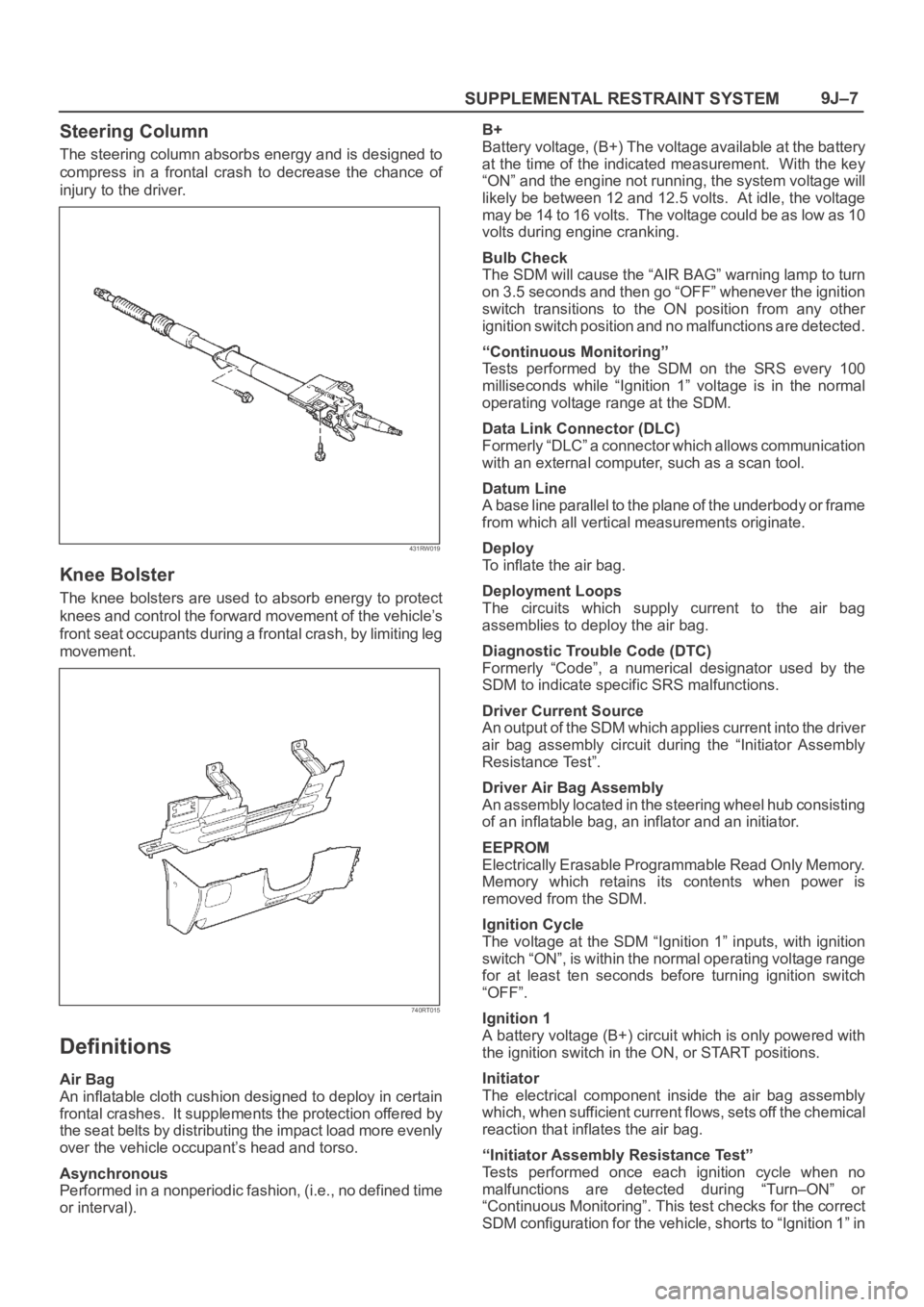

Knee Bolster

The knee bolsters are used to absorb energy to protect

knees and control the forward movement of the vehicle’s

front seat occupants during a frontal crash, by limiting leg

movement.

740RT015

Definitions

Air Bag

An inflatable cloth cushion designed to deploy in certain

frontal crashes. It supplements the protection offered by

the seat belts by distributing the impact load more evenly

over the vehicle occupant’s head and torso.

Asynchronous

Performed in a nonperiodic fashion, (i.e., no defined time

or interval).B+

Battery voltage, (B+) The voltage available at the battery

at the time of the indicated measurement. With the key

“ON” and the engine not running, the system voltage will

likely be between 12 and 12.5 volts. At idle, the voltage

may be 14 to 16 volts. The voltage could be as low as 10

volts during engine cranking.

Bulb Check

The SDM will cause the “AIR BAG” warning lamp to turn

on 3.5 seconds and then go “OFF” whenever the ignition

switch transitions to the ON position from any other

ignition switch position and no malfunctions are detected.

“Continuous Monitoring”

Tests performed by the SDM on the SRS every 100

milliseconds while “Ignition 1” voltage is in the normal

operating voltage range at the SDM.

Data Link Connector (DLC)

Formerly “DLC” a connector which allows communication

with an external computer, such as a scan tool.

Datum Line

A base line parallel to the plane of the underbody or frame

from which all vertical measurements originate.

Deploy

To inflate the air bag.

Deployment Loops

The circuits which supply current to the air bag

assemblies to deploy the air bag.

Diagnostic Trouble Code (DTC)

Formerly “Code”, a numerical designator used by the

SDM to indicate specific SRS malfunctions.

Driver Current Source

An output of the SDM which applies current into the driver

air bag assembly circuit during the “Initiator Assembly

Resistance Test”.

Driver Air Bag Assembly

An assembly located in the steering wheel hub consisting

of an inflatable bag, an inflator and an initiator.

EEPROM

Electrically Erasable Programmable Read Only Memory.

Memory which retains its contents when power is

removed from the SDM.

Ignition Cycle

The voltage at the SDM “Ignition 1” inputs, with ignition

switch “ON”, is within the normal operating voltage range

for at least ten seconds before turning ignition switch

“OFF”.

Ignition 1

A battery voltage (B+) circuit which is only powered with

the ignition switch in the ON, or START positions.

Initiator

The electrical component inside the air bag assembly

which, when sufficient current flows, sets off the chemical

reaction that inflates the air bag.

“Initiator Assembly Resistance Test”

Tests performed once each ignition cycle when no

malfunctions are detected during “Turn–ON” or

“Continuous Monitoring”. This test checks for the correct

SDM configuration for the vehicle, shorts to “Ignition 1” in

Page 3446 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–9

SRS Connector Body Face Views

D09RW016

Legend

(1) SDM

(2) Driver Air Bag Assembly

(3) Passenger Air Bag Assembly

(4) “Air Bag” Warning Lamp

(5) SRS Coil Assembly

(6) DLC

(7) Connector between Chassis Harness and

Pretensioner Harness for Driver Seat Belt (If so

equipped)(8) Connector between Chassis Harness and

Pretensioner Harness for Passenger Seat Belt

(If so equipped)

(9) Connector between Pretensioner Harness and

driver side Pretensioner Seat Belt (If so

equipped)

(10) Connector between Pretensioner Harness and

passenger side Pretensioner Seat Belt (If so

equipped)

Repairs And Inspections Required

After An Accident

NOTE: If any SRS components are damaged, they must

be replaced. If SRS component mounting points are

damaged, they must be replaced.

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from an

a u t h o r i z e d d e a l e r ; t h e y m a y b e u s e d f o r S R S r e p a i r s .

Do not attempt to service the SDM, the SRS coil

assembly, or the air bag assembly. Service of these

items is by replacement only.

Verify the part number of replacement air bag

assembly.CAUTION: Never use the air bag assembly from

another vehicle. Use only the air bag assembly for

Trooper.

CAUTION: Proper operation of the sensors and

supplemental restraint system (SRS) requires that

any repairs to the vehicle structure return it to the

original production configuration. Deployment

requires, at a minimum, replacement of the SDM, air

bag assembly and dimensional inspection of the

steering column. Any visible damage to the SDM

mounting bracket (s) requires replacement, and the

steering column must be dimensionally inspected,

whether deployment occurred or not.