engine overheat OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1467 of 6000

6E–350

ENGINE DRIVEABILITY AND EMISSIONS

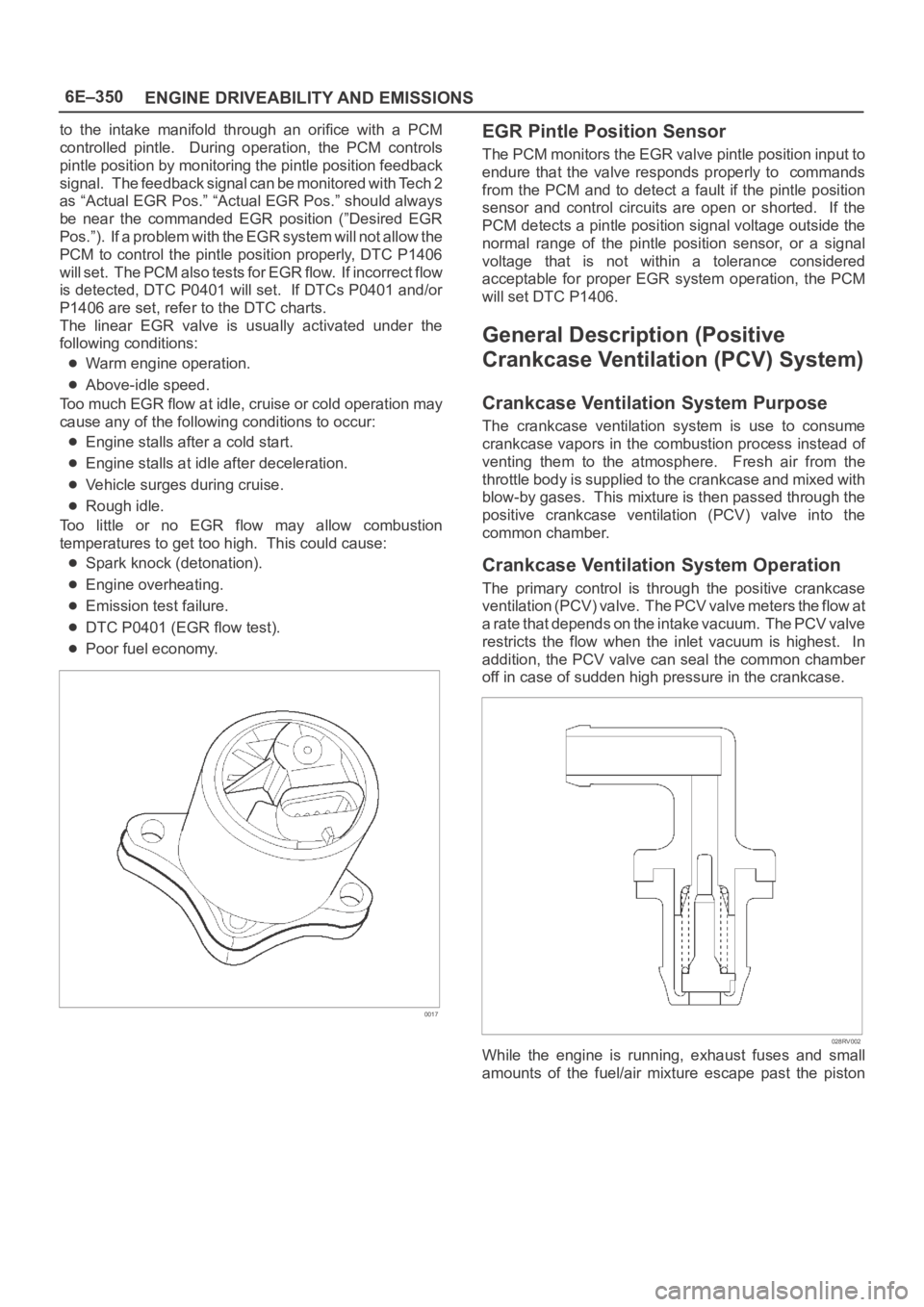

to the intake manifold through an orifice with a PCM

controlled pintle. During operation, the PCM controls

pintle position by monitoring the pintle position feedback

signal. The feedback signal can be monitored with Tech 2

as “Actual EGR Pos.” “Actual EGR Pos.” should always

be near the commanded EGR position (”Desired EGR

Pos.”). If a problem with the EGR system will not allow the

PCM to control the pintle position properly, DTC P1406

will set. The PCM also tests for EGR flow. If incorrect flow

is detected, DTC P0401 will set. If DTCs P0401 and/or

P1406 are set, refer to the DTC charts.

The linear EGR valve is usually activated under the

following conditions:

Warm engine operation.

Above-idle speed.

Too much EGR flow at idle, cruise or cold operation may

cause any of the following conditions to occur:

Engine stalls after a cold start.

Engine stalls at idle after deceleration.

Vehicle surges during cruise.

Rough idle.

Too little or no EGR flow may allow combustion

temperatures to get too high. This could cause:

Spark knock (detonation).

Engine overheating.

Emission test failure.

DTC P0401 (EGR flow test).

Poor fuel economy.

0017

EGR Pintle Position Sensor

The PCM monitors the EGR valve pintle position input to

endure that the valve responds properly to commands

from the PCM and to detect a fault if the pintle position

sensor and control circuits are open or shorted. If the

PCM detects a pintle position signal voltage outside the

normal range of the pintle position sensor, or a signal

voltage that is not within a tolerance considered

acceptable for proper EGR system operation, the PCM

will set DTC P1406.

General Description (Positive

Crankcase Ventilation (PCV) System)

Crankcase Ventilation System Purpose

The crankcase ventilation system is use to consume

crankcase vapors in the combustion process instead of

venting them to the atmosphere. Fresh air from the

throttle body is supplied to the crankcase and mixed with

blow-by gases. This mixture is then passed through the

positive crankcase ventilation (PCV) valve into the

common chamber.

Crankcase Ventilation System Operation

The primary control is through the positive crankcase

v e n t i l a t i o n ( P C V ) v a l v e . T h e PCV valve meters the flow at

a rate that depends on the intake vacuum. The PCV valve

restricts the flow when the inlet vacuum is highest. In

addition, the PCV valve can seal the common chamber

off in case of sudden high pressure in the crankcase.

028RV002

While the engine is running, exhaust fuses and small

amounts of the fuel/air mixture escape past the piston

Page 1474 of 6000

6F–3 ENGINE EXHAUST

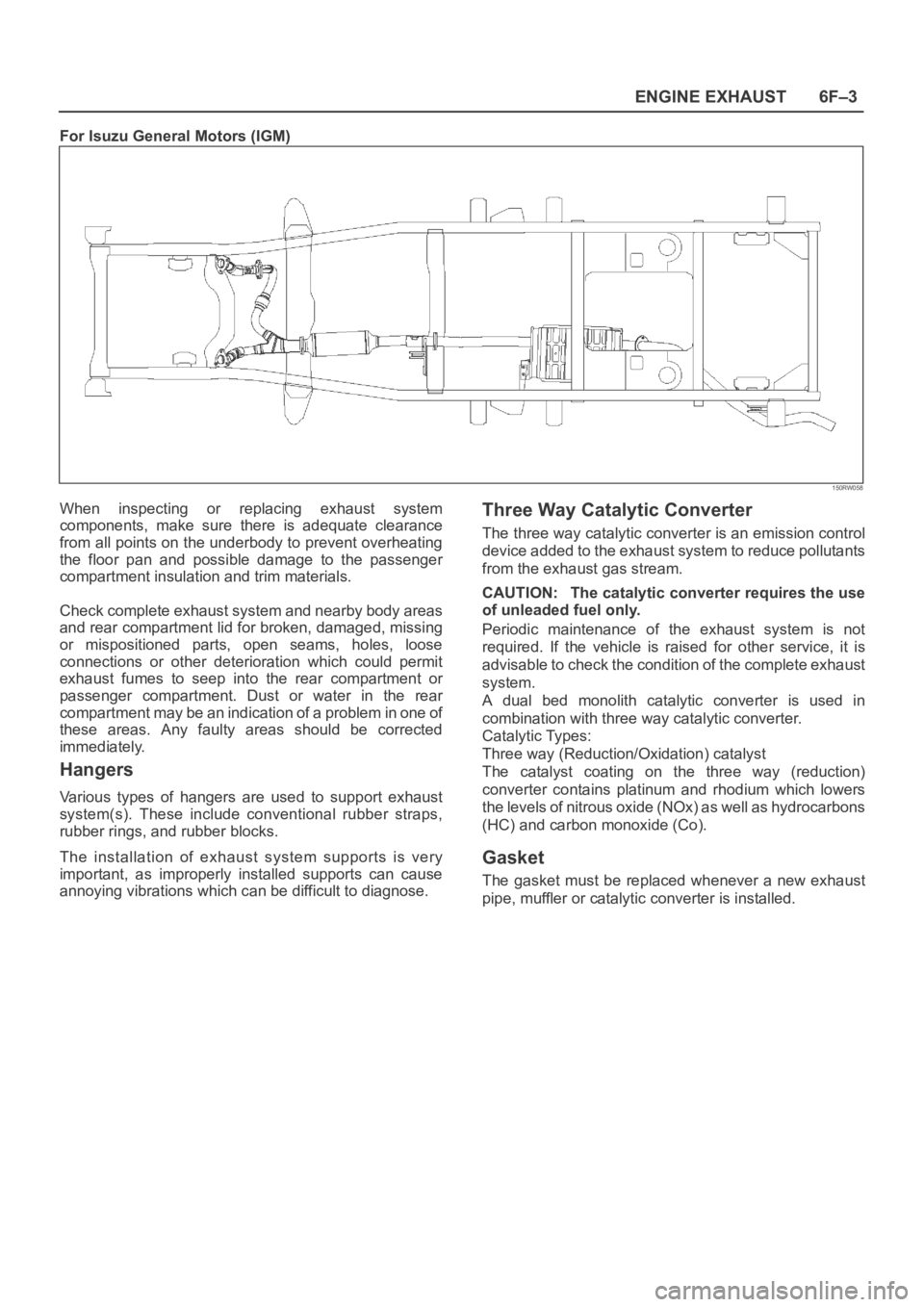

For Isuzu General Motors (IGM)

150RW058

When inspecting or replacing exhaust system

components, make sure there is adequate clearance

from all points on the underbody to prevent overheating

the floor pan and possible damage to the passenger

compartment insulation and trim materials.

Check complete exhaust system and nearby body areas

and rear compartment lid for broken, damaged, missing

or mispositioned parts, open seams, holes, loose

connections or other deterioration which could permit

exhaust fumes to seep into the rear compartment or

passenger compartment. Dust or water in the rear

compartment may be an indication of a problem in one of

these areas. Any faulty areas should be corrected

immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps,

rubber rings, and rubber blocks.

The installation of exhaust system supports is very

important, as improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

Three Way Catalytic Converter

The three way catalytic converter is an emission control

device added to the exhaust system to reduce pollutants

from the exhaust gas stream.

CAUTION: The catalytic converter requires the use

of unleaded fuel only.

Periodic maintenance of the exhaust system is not

required. If the vehicle is raised for other service, it is

advisable to check the condition of the complete exhaust

system.

A dual bed monolith catalytic converter is used in

combination with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction)

converter contains platinum and rhodium which lowers

the levels of nitrous oxide (NOx) as well as hydrocarbons

(HC) and carbon monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust

pipe, muffler or catalytic converter is installed.

Page 1838 of 6000

ENGINE COOLING 6B – 5

ENGINE COOLANT CHANGE

PROCEDURE

1. To change engine coolant, make sure that the

engine is cool.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

2. Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

NOTE: For best results it is suggested that the engine

cooling system be flushed at least once a year. It is

advisable to flush the interior of the cooling system

including the radiator before using anti-freeze

(ethylene-glycol based).

Replace damaged rubber hoses as the engine anti-

freeze coolant is liable to leak out even minor cracks.

Isuzu recommends using Isuzu genuine anti-freeze

(ethylene-glycol based) or equivalent, for the cooling

system and not add any inhibitors or additives.

CAUTION:

A failure to correctly fill the engine cooling system

in changing or topping off coolant may sometimes

cause the coolant to overflow from the filler neck

even before the engine and radiator are completely

full.

If the engine runs under this condition, shortage of

coolant may possibly result in engine overheating.

To avoid such trouble, the following precautions

should be taken in filling the system.

3. To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter than the filler neck. Otherwise air between

the filler neck and the filling hose will block entry,

preventing the system from completely filling up.

4. Keep a filling rate of 9 liter/min. or less. Filling over

this maximum rate may force air inside the engine

and radiator.

And also, the coolant overflow will increase, making

it difficult to determine whether or not the system is

completely full.

5. After filling the system full, pull out the filling hose

and check to see if air trapped in the system is

dislodged and the coolant level goes down. Should

the coolant level go down, repeat topping-off until

there is no more drop in the coolant level.

6. Directly after filling the radiator, fill the reservoir to

the maximum level.

7. Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

8. After tightening radiator cap, warm up the engine at

about 2,000 rpm.

Set heater adjustment to the highest temperature

position, and let the coolant circulate also into

heater water system.

9. Check to see the thermostat has opened by the

needle position of a water thermometer, conduct a

5-minute idle again and stop the engine.

10. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant be found, check the

coolant system and reservoir tank hose for leakage.

11. Fill the coolant into the reservoir tank up to “MAX”

line.

Page 1842 of 6000

ENGINE COOLING 6B – 9

RADIATOR

REMOVAL

1. Disconnect battery ground cable

2. Loosen drain plug to drain coolant.

3. Radiator Hose

1) Disconnect lower hose and upper hose from the

engine.

4. Fan Guide

1) Remove clips on both sides and the bottom lock.

5. Reservoir Tank Hose

1) Disconnect the hose from radiator.

6. Bracket

7. Radiator Assembly

1) Remove the radiator assembly upward by the

hoses taking care not to damage the radiator

core by the fan blade.

2) Remove rubber cushions on both sides of the

bottom.

INSPECTION

Radiator Cap

1) Measure the valve opening pressure with the

radiator cap tester. Replace the radiator cap if it

exceeds the standard.

Valve opening pressure: 93.2 – 122.7 kPa

(0.95 – 1.25 kg/cm

2/

13.5 – 17.8 psi)

Check the condition of the negative pressure valve in

the center of the valve seat side of the cap. If the valve

seat does not move smoothly due to rust or dust, clean

and replace the radiator cap.Radiator Core

1) Deformed radiator fins could reduce radiation

effects, resulting in overheating. Straighten the fins.

In such a case, take care not to damage the fin

roots.

2) Remove dust and other foreign materials.

Flushing the Radiator

1) Wash the inside of radiator and the coolant

passage with water and a neutral detergent.

Remove all scales and rust.

110RW017

110RS006

Page 2124 of 6000

ENGINE EXHAUST 6F – 1

ENGINE EXHAUST

CONTENTS

CAUTION: Exhaust system components must have

enough clearance from the underbody to prevent

overheating of the floor pan and possible damage to the passenger compartment, insulation and trim

materials.

General Description . . . . . . . . . . . . . . . . . . 6F–2

Hangers . . . . . . . . . . . . . . . . . . . . . . . . . 6F–2

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . 6F–2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . 6F–3

Front Exhaust Pipe . . . . . . . . . . . . . . . . . 6F–3Center Exhaust Pipe . . . . . . . . . . . . . . . . 6F–5

Exhaust Silencer . . . . . . . . . . . . . . . . . . . 6F–6

Rear Exhaust Pipe . . . . . . . . . . . . . . . . . 6F–7

Page 2125 of 6000

6F – 2 ENGINE EXHAUST

GENERAL DESCRIPTION

150RW070

When inspecting or replacing exhaust system

components, make sure there is adequate clearance

from all points on the underbody to prevent overheating

of the floor pan and possible damage to the passenger

compartment insulation and trim materials.

Check complete exhaust system and nearby body

areas and rear compartment lid for broken, damaged,

missing or mispositioned parts, open seams, holes

loose connections or other deterioration which could

permit exhaust fumes to seep into the rear

compartment or passenger compartment. Dust or water

in the rear compartment may be an indication of a

problem in one of these areas. Any faulty areas should

be corrected immediately.HANGERS

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps,

rubber rings, and rubber blocks.

The installation of exhaust system supports is very

important, as improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

GASKET

The gasket must be replaced whenever a new exhaust

pipe, muffler or exhaust throttle is installed.

Page 4507 of 6000

6A–11

ENGINE MECHANICAL

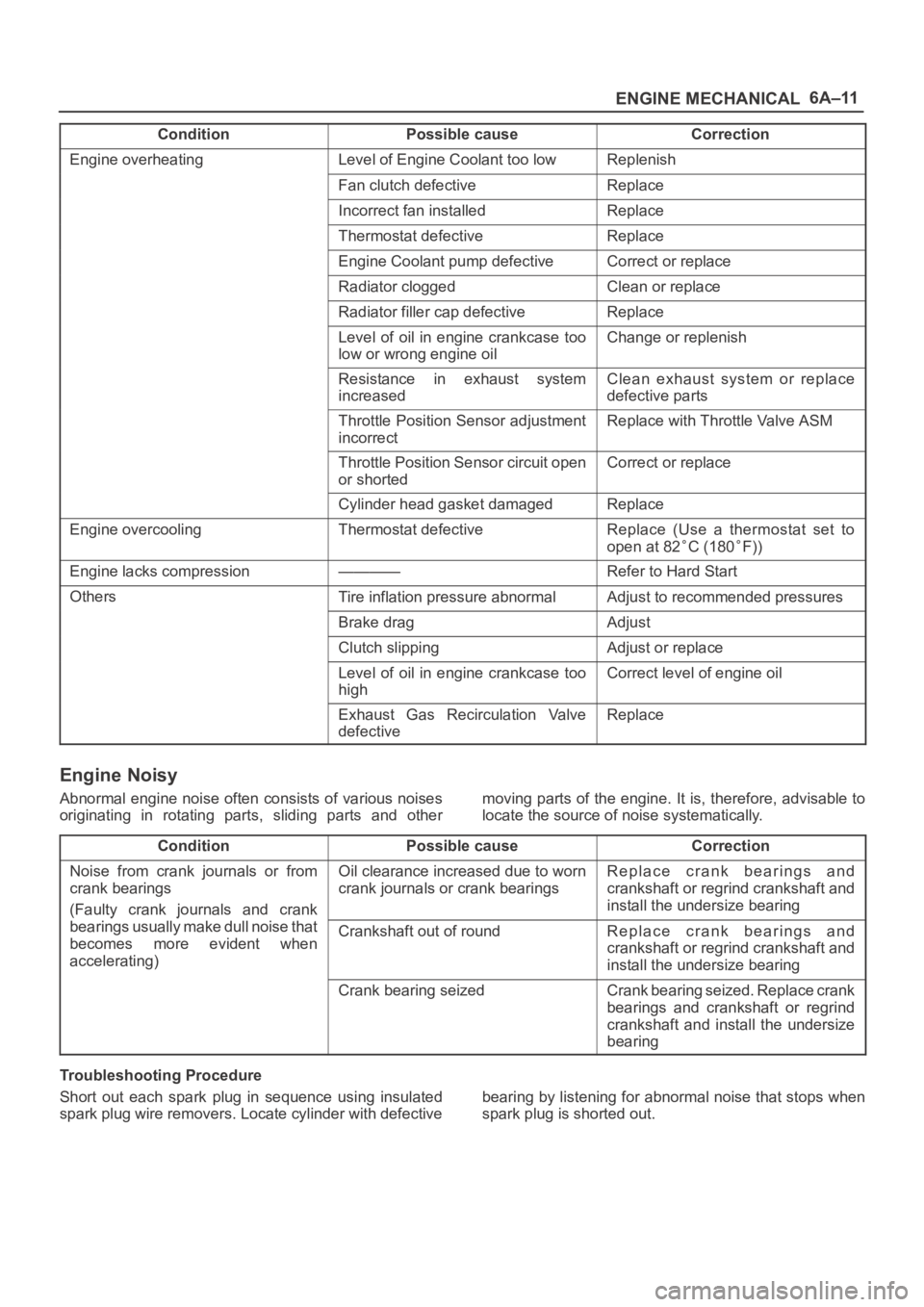

Condition CorrectionPossible cause

Engine overheatingLevel of Engine Coolant too lowReplenish

Fan clutch defectiveReplace

Incorrect fan installedReplace

Thermostat defectiveReplace

Engine Coolant pump defectiveCorrect or replace

Radiator cloggedClean or replace

Radiator filler cap defectiveReplace

Level of oil in engine crankcase too

low or wrong engine oilChange or replenish

Resistance in exhaust system

increasedClean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrectReplace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shortedCorrect or replace

Cylinder head gasket damagedReplace

Engine overcoolingThermostat defectiveReplace (Use a thermostat set to

open at 82

C (180F))

Engine lacks compression————Refer to Hard Start

OthersTire inflation pressure abnormalAdjust to recommended pressures

Brake dragAdjust

Clutch slippingAdjust or replace

Level of oil in engine crankcase too

highCorrect level of engine oil

Exhaust Gas Recirculation Valve

defectiveReplace

Engine Noisy

Abnormal engine noise often consists of various noises

originating in rotating parts, sliding parts and othermoving parts of the engine. It is, therefore, advisable to

locate the source of noise systematically.

Condition

Possible causeCorrection

Noise from crank journals or from

crank bearings

(Faulty crank journals and crankOil clearance increased due to worn

crank journals or crank bearingsReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

yj

bearings usually make dull noise that

becomes more evident when

accelerating)Crankshaft out of roundReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crank bearing seizedCrank bearing seized. Replace crank

bearings and crankshaft or regrind

crankshaft and install the undersize

bearing

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with defectivebearing by listening for abnormal noise that stops when

spark plug is shorted out.

Page 4509 of 6000

6A–13

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine knockingPreignition due to use of spark plugs

of inadequate heat rangeInstall Spark Plugs of adequate heat

range

Carbon deposits in combustion

chambersClean

Fuel too low in octane ratingReplace fuel

Wide Open Throttle enrichment

system failureRefer to Section 6E

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Engine overheatingRefer to “Engine Lacks Power”

OthersWater pump defectiveReplace

Drive belt slippingReplace auto tentioner or drive belt

Abnormal Combustion

ConditionPossible causeCorrection

Trouble in fuel systemFuel pressure control valve defectiveReplace

Fuel filter cloggedReplace

Fuel pump cloggedClean or replace

Fuel tank or fuel pipe cloggedClean or replace

Fuel injector cloggedClean or replace

Fuel pump relay defectiveReplace

Power supply cable for fuel pump

broken or poor connectionsReconnect, correct or replace

Mass Airflow (MAF) sensor circuit

open or defectiveCorrect or replace

MAF Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or shortedCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature (ECT)

Sensor circuit open or shortedCorrect or replace

ECT Sensor defectiveReplace

Throttle Position Sensor adjustment

incorrectReadjust

Throttle Position Sensor defectiveReplace

Throttle Position Sensor connector

poor connectionsReconnect

Vehicle Speed Sensor cable poor

connections or defectiveCorrect or replace

Vehicle Speed Sensor loosely fixedFix tightly

Vehicle Speed Sensor in wrong

contact or defectiveReplace

Powertrain Control Module cable

poor connections or defectiveCorrect or replace

Page 4597 of 6000

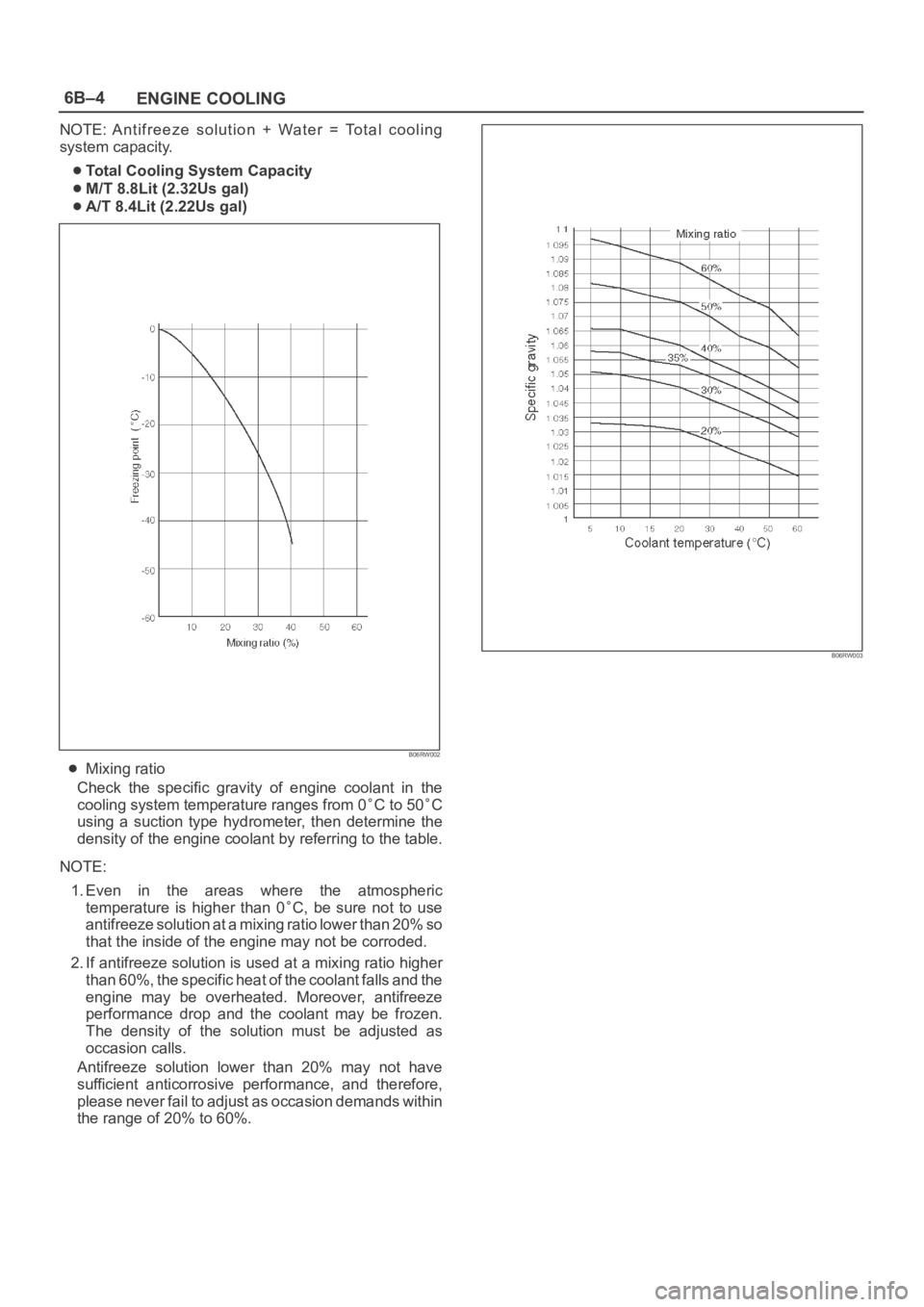

6B–4

ENGINE COOLING

NOTE: Antifreeze solution + Water = Total cooling

system capacity.

Total Cooling System Capacity

M/T 8.8Lit (2.32Us gal)

A/T 8.4Lit (2.22Us gal)

B06RW002

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system temperature ranges from 0

C to 50C

using a suction type hydrometer, then determine the

density of the engine coolant by referring to the table.

NOTE:

1. Even in the areas where the atmospheric

temperature is higher than 0

C, be sure not to use

antifreeze solution at a mixing ratio lower than 20% so

that the inside of the engine may not be corroded.

2. If antifreeze solution is used at a mixing ratio higher

than 60%, the specific heat of the coolant falls and the

engine may be overheated. Moreover, antifreeze

performance drop and the coolant may be frozen.

The density of the solution must be adjusted as

occasion calls.

Antifreeze solution lower than 20% may not have

sufficient anticorrosive performance, and therefore,

please never fail to adjust as occasion demands within

the range of 20% to 60%.

B06RW003

Page 4598 of 6000

ENGINE COOLING6B–5

Diagnosis

Engine Cooling Trouble

ConditionPossible causeCorrection

Engine overheatingLow Engine Coolant levelReplenish

Incorrect fan installedReplace

Thermo meter unit faultyReplace

Faulty thermostatReplace

Faulty Engine Coolant temperature

sensorRepair or replace

Clogged radiatorClean or replace

Faulty radiator capReplace

Low engine oil level or use of

improper engine oilReplenish or change oil

Clogged exhaust systemClean exhaust system or replace

faulty parts

Faulty Throttle Position sensorReplace throttle valve assembly

Open or shorted Throttle Position

sensor circuitRepair or replace

Damaged cylinder head gasketReplace

Engine overcoolingFaulty thermostatReplace

Engine slow to warm–upFaulty thermostatReplace

Thermo unit faultyReplace