horn OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1191 of 6000

6E–74

ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

D06RW00006

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The powertrain control

module (PCM) turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cased by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Inspect the PCM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

If the engine cranks but will not run, check for an open

PCM ignition or battery feed, or a poor PCM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty PCM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

PCM ground terminals to ensure that a good ground

is present. Refer to

PCM Terminal End View for

terminal locations of the PCM ground circuits.

12.In this step, temporarily substitute a known good

relay for the PCM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

Page 1204 of 6000

6E–87 ENGINE DRIVEABILITY AND EMISSIONS

Fuel System Electrical Test

StepNo Ye s Va l u e ( s ) Action

9Check for short or open between the PCM and the fuel

pump relay.

Was a problem found?

—Verify repairGo to Step 10

101. Check the fuel pump relay circuit for a poor terminal

connection at the PCM.

2. If a problem is found, replace terminal as necessary.

Was a problem found?

—Verify repairGo to Step 11

11Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

121. Reconnect the fuel pump relay.

2. Disconnect the fuel pump electrical connector at the

fuel tank.

3. Using a test light connected to ground, probe the

fuel pump feed wire (harness side).

4. Command the fuel pump “ON” with Tech 2.

Did the light illuminate for 2 seconds?

—Go to Step 15Go to Step 13

131. Honk the horn to verify that the horn relay is

functioning.

2. Substitute the horn relay for the fuel pump relay.

3. Leave the test light connected as in step 12.

4. Command the fuel pump “ON” with Tech 2.

Did the test light illuminate for 2 seconds when the fuel

pump was commanded “ON?”

—Go to Step 17Go to Step 14

141. Re-connect the horn relay in its proper location.

2. Check for a short circuit, blown fuse or open circuit

between the relay and the fuel tank.

Is the action complete?

—Verify repair—

151. With the fuel pump electrical connector at the fuel

tank disconnected, connect a test light between the

feed wire and the ground wire (harness side).

2. Command the fuel pump “ON” with Tech 2.

Did the test light illuminate for 2 seconds?

—Go to Step 18Go to Step 16

16Repair the open circuit in the fuel pump ground wire.

Is the action complete?

—Verify repair—

171. Re-connect the horn relay in its proper location.

2. Replace the fuel pump relay.

Is the action complete?

—Verify repair—

18Replace the fuel pump.

Is the action complete?

—Verify repair—

Page 1440 of 6000

6E–323 ENGINE DRIVEABILITY AND EMISSIONS

11. Connect the fuel filler fuse at the tank.

12. Connect the air breather hose at the tank.

TS23796

13. Fill the fuel tank with fuel.

14. Tighten the fuel filler cap.

15. Connect the negative battery cable.

Throttle Body (TB)

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the cooling system. Refer to

Cooling System.

3. Remove the accelerator cable assembly. Refer to

Accelerator Cable in Engine Speed Control System..

4. Disconnect the electrical connectors:

Throttle position (TP) sensor.

Idle air control (IAC) solenoid.

Intake air temperature (IAT) sensor. Refer to

Intake Air Temperature Sensor.

035RW023

5. Disconnect the vacuum hose below the air horn.

6. Remove the intake air duct clamp.

7. Disconnect the intake air duct.

8. Disconnect the coolant lines from the throttle body.

9. Remove the bolts from the common chamber.

10. Remove the throttle body from the common chamber.

11. Remove the gasket from the upper intake manifold.

035RW024

12. Remove the IAC. Refer to Idle Air Control (IAC)

Solenoid

.

13. Remove the TP sensor. Refer to

Throttle Position

(TP) Sensor

.

Inspection Procedure

NOTE: Do not use solvent of any type when you clean the

gasket surfaces on the intake manifold and the throttle

body assembly. The gasket surfaces and the throttle

body assembly may be damaged as a result.

If the throttle body gasket needs to be replaced,

remove any gasket material that may be stuck to the

mating surfaces of the manifold.

Do not leave any scratches in the aluminum casting.

Installation Procedure

1. Install the TP sensor. Refer to Throttle Position (TP)

Sensor

.

2. Install the IAC. Refer to

Idle Air Control (IAC)

Solenoid

.

3. Install the gasket on the common chamber.

4. Install the throttle body on the common chamber.

Page 1937 of 6000

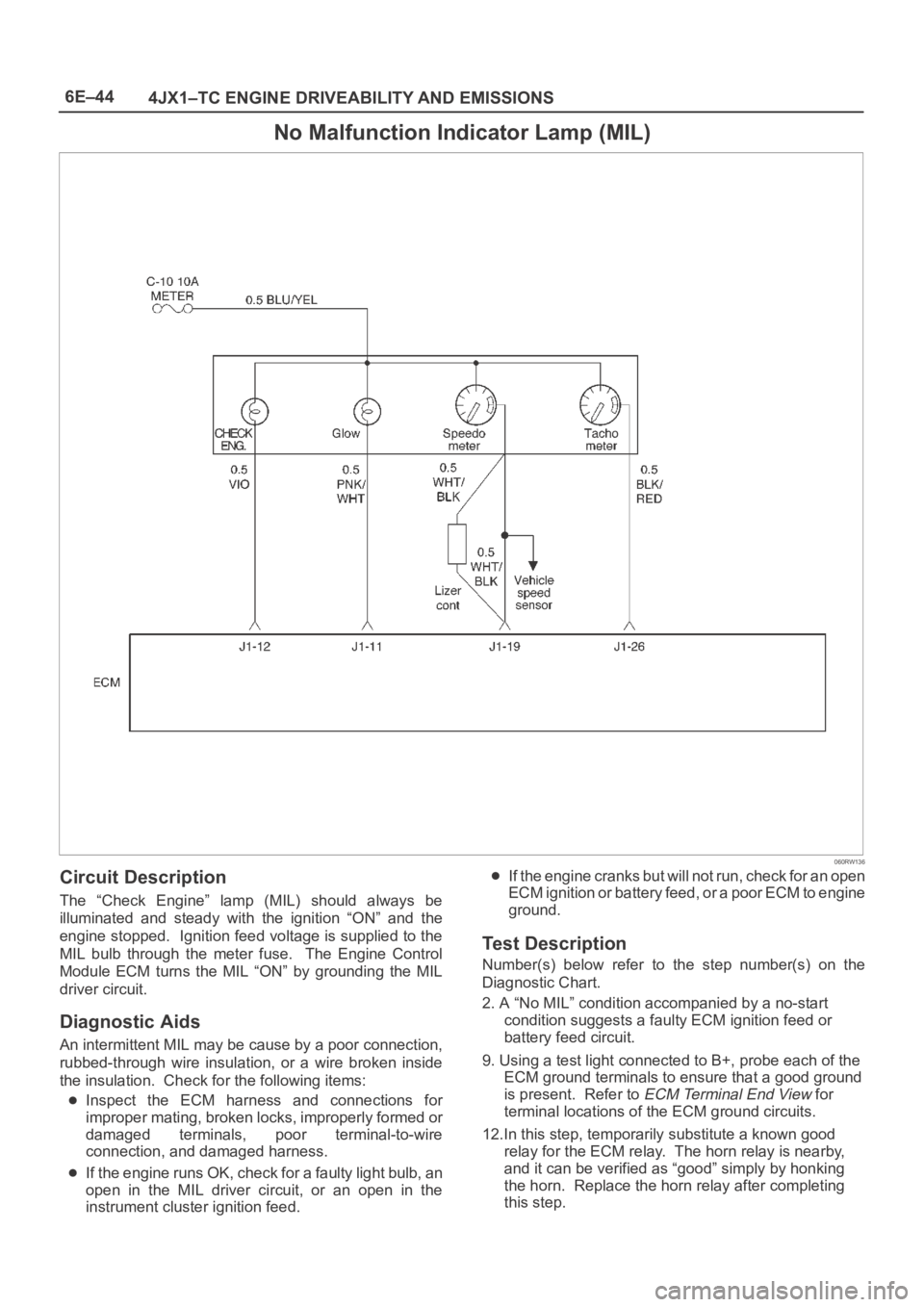

6E–44

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

060RW136

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The Engine Control

Module ECM turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cause by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Inspect the ECM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire

connection, and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

If the engine cranks but will not run, check for an open

ECM ignition or battery feed, or a poor ECM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty ECM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

ECM ground terminals to ensure that a good ground

is present. Refer to

ECM Terminal End View for

terminal locations of the ECM ground circuits.

12.In this step, temporarily substitute a known good

relay for the ECM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

Page 2648 of 6000

HORN ANTI-THEFT

HORNFOG

LIGHT 2.0

G/O5.0

W3.0

W

5.0

W5.0

W5.0

W5.0

W

5.0

W 5.0

W5.0

W5.0

W 3.0

W

3.0

W 3.0

R/B F-3 15A

HORN

HAZARD

TA I L R E L AY

(1)(2)

HEADLIGHT

AC GENERATOR

(B) 0.85

R/BF-12 15A

TA I L

ILLUMI

0.85

OF-7 15A

ANTI-

THEFT

5.0

W 5.0

W3.0

Y/RF-8 20A

FRT FOG

LIGHTING

RELAY RELAY & FUSE BOX

3.0

W

1

X-1

4

3X-1

X-1

2

H-21

H-2

1

H-14

D08RWB14

Page 2649 of 6000

HORN ANTI-THEFT

HORNFOG

LIGHT 2.0

G/O5.0

W

5.0

W5.0

W5.0

W5.0

W

5.0

W 5.0

W5.0

W5.0

W 3.0

W

3.0

W 3.0

R/B F-3 15A

HORN

HAZARD

HEADLIGHT

AC GENERATOR

(B)

0.85

OF-1 15A

ANTI-

THEFT

5.0

W 5.0

W3.0

Y/RF-8 20A

FRT FOG

LIGHTING

RELAY RELAY & FUSE BOX

3.0

W

1

X-1

4

3X-1

X-1

2

H-21

H-2

1

H-14

D08RWC55

Page 2656 of 6000

H

HORN ANTI-THEFT

HORNFOG

LIGHTTAIL RELAY

(1) (2) 2.0

G/O5.0

W5.0

W5.0

W

5.0

W5.0

W5.0

W5.0

W

5.0

W 5.0

W5.0

W5.0

W

3.0

W F-3 15A

HORN

HAZARDI

AC GENERATOR

(B) 3.0

Y/RF-8 20A

FRT FOG

5.0

W

0.85

R/BF-12 15A

TA I L

ILLUMI

0.85

OF-7 15A

ANTI-THEFT

RELAY & FUSE BOX

2

H-21

H-2

1

H-14

K

J

D08RWB19

Page 2657 of 6000

H

HORN ANTI-THEFT

HORNFOG

LIGHT 2.0

G/O5.0

W5.0

W5.0

W

5.0

W5.0

W5.0

W5.0

W

5.0

W 5.0

W5.0

W5.0

W

3.0

W F-3 15A

HORN

HAZARDI

AC GENERATOR

(B) 3.0

Y/RF-8 20A

FRT FOG

0.85

OF-1 15A

ANTI-THEFT

RELAY & FUSE BOX

2

H-21

H-2

1

H-14

K

J

D08RWC52

Page 2787 of 6000

I-115

B-53

B1

H-2716

H-257

B-53

2 L

H-25100.85

R/B0.85

G/O

H-1612

HAZARD

WARNING

SW

TURN SIGNAL

LIGHT SWFLASHER

UNIT

0.85

G/B0.85

G/B

0.85

G/B0.85

P/B

0.85

P/B2.0

G/O0.3

R/G 0.85

G/R

ILLUMINATION

CONTROLLER

(3) 0.85

P/B 2.0

LG/B 0.5

B

1.25

B2.0

LG/B

2.0

LG/B

2.0

LG/B2.0

B/R2.0

B/R

0.85

R/B 0.85

R/B2.0

G/O

5.0

W BATT.(+)

F-3 15A

HORN,HAZARD3.0

B/Y STARTER SW

(IG1)

C-3 10A

TURN

BACK

B-12

B-12

4

B-12

5 3

LR

A

I-11I-11I-11I-11

64 2 1

I-117I-118I-11 TAIL RELAY

(4) BACK UP

LIGHT

3

B

B-53

3 E

HORN RELAY

(2)

H-276H-2710

B-19

BODY-RH

D08RW683

Page 2791 of 6000

I-115

B-53

B1

H-204

H-202

B-53

2 L

H-25170.85

R/B0.85

G/O

H-1614

HAZARD

WARNING

SW

TURN SIGNAL

LIGHT SWFLASHER

UNIT

0.85

G/B0.85

G/B

0.85

G/B0.85

P/B

0.85

P/B2.0

G/O0.3

R/G 0.85

G/R

ILLUMINATION

CONTROLLER

(3) 0.85

P/B 2.0

LG/B 0.5

B

1.25

B2.0

LG/B

2.0

LG/B

2.0

LG/B2.0

B/R2.0

B/R

0.85

R/B 0.85

R/B2.0

G/O

5.0

W BATT.(+)

F-3 15A

HORN,HAZARD3.0

B/Y STARTER SW

(IG1)

C-3 10A

TURN

BACK

B-12

B-12

4

B-12

5 3

LR

A

I-11I-11I-11I-11

64 2 1

I-117I-118I-11 TAIL RELAY

(4) BACK UP

LIGHT

3

B

B-53

3 E

HORN RELAY

(2)

H-2519H-2520

B-19

BODY-LH

D08RW872