jump start OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1870 of 6000

ENGINE ELECTRICAL 6D – 3

ON-VEHICLE SERVICE

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the rate

of charge reduced if the battery feels hot to the

touch.

Battery charging should be discontinued or the rate

of charge reduced if the battery begins to gas or

spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue

dot or ring, it may be necessary to jiggle or tilt the

battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the same

manner as other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: Failure to carefully follow the jump

starting procedure could result in the following:

1. Serious personal injury, particularly to your

eyes.

2. Property damage from a battery explosion,

battery acid, or an electrical fire.

3. Damage to the electronic components of one or

both vehicles.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode. Remove any rings, watches, or other jewelry

before working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with your

eyes or skin.

Never allow battery fluid to come in contact with fabrics

or painted surfaces.

Battery fluid is a highly corrosive acid.Should battery fluid come in contact with your eyes,

skin, fabric, or a painted surface, immediately and

thoroughly rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the “PARK”

position.

If the vehicle is equipped with a manual

transmission place the shift lever in the “NEUTRAL”

position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the A/C compressor

bracket or the generator mounting bracket) of the

vehicle with the discharged battery.

This ground connection must be at least 450 mm

(18 in) from the battery of the vehicle whose battery

is being charged.

WARNING: Never attach the end of the jumper

cable directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical

accessories have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable from

the vehicle with the discharged battery.

Page 1938 of 6000

6E–45 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

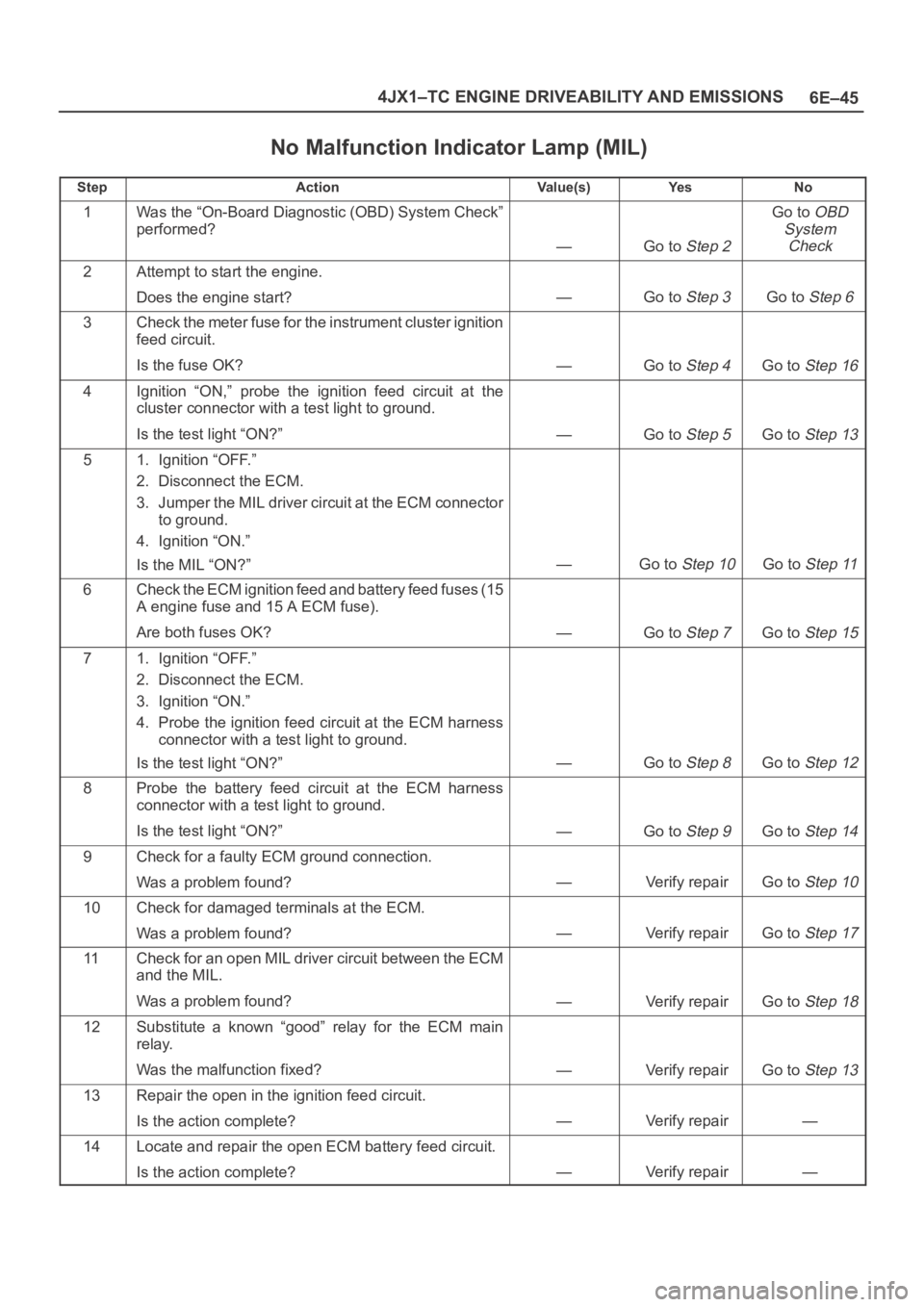

No Malfunction Indicator Lamp (MIL)

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Step 6

3Check the meter fuse for the instrument cluster ignition

feed circuit.

Is the fuse OK?

—Go to Step 4Go to Step 16

4Ignition “ON,” probe the ignition feed circuit at the

cluster connector with a test light to ground.

Is the test light “ON?”

—Go to Step 5Go to Step 13

51. Ignition “OFF.”

2. Disconnect the ECM.

3. Jumper the MIL driver circuit at the ECM connector

to ground.

4. Ignition “ON.”

Is the MIL “ON?”

—Go to Step 10Go to Step 11

6Check the ECM ignition feed and battery feed fuses (15

A engine fuse and 15 A ECM fuse).

Are both fuses OK?

—Go to Step 7Go to Step 15

71. Ignition “OFF.”

2. Disconnect the ECM.

3. Ignition “ON.”

4. Probe the ignition feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 8Go to Step 12

8Probe the battery feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 9Go to Step 14

9Check for a faulty ECM ground connection.

Was a problem found?

—Verify repairGo to Step 10

10Check for damaged terminals at the ECM.

Was a problem found?

—Verify repairGo to Step 17

11Check for an open MIL driver circuit between the ECM

and the MIL.

Was a problem found?

—Verify repairGo to Step 18

12Substitute a known “good” relay for the ECM main

relay.

Was the malfunction fixed?

—Verify repairGo to Step 13

13Repair the open in the ignition feed circuit.

Is the action complete?

—Verify repair—

14Locate and repair the open ECM battery feed circuit.

Is the action complete?

—Verify repair—

Page 2272 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–27

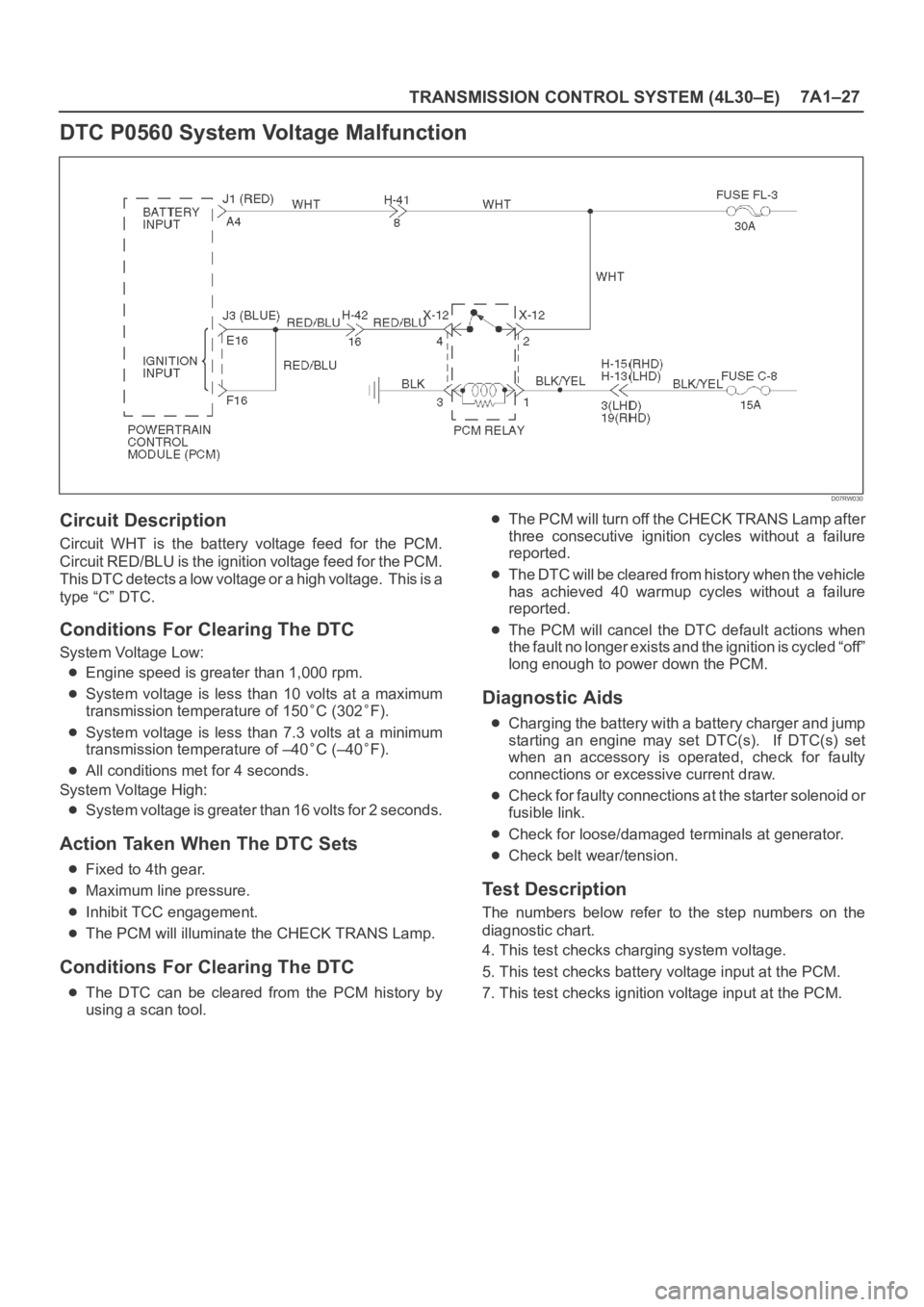

DTC P0560 System Voltage Malfunction

D07RW030

Circuit Description

Circuit WHT is the battery voltage feed for the PCM.

Circuit RED/BLU is the ignition voltage feed for the PCM.

This DTC detects a low voltage or a high voltage. This is a

type “C” DTC.

Conditions For Clearing The DTC

System Voltage Low:

Engine speed is greater than 1,000 rpm.

System voltage is less than 10 volts at a maximum

transmission temperature of 150

C (302F).

System voltage is less than 7.3 volts at a minimum

transmission temperature of –40

C (–40F).

All conditions met for 4 seconds.

System Voltage High:

System voltage is greater than 16 volts for 2 seconds.

Action Taken When The DTC Sets

Fixed to 4th gear.

Maximum line pressure.

Inhibit TCC engagement.

The PCM will illuminate the CHECK TRANS Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The PCM will turn off the CHECK TRANS Lamp after

three consecutive ignition cycles without a failure

reported.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Charging the battery with a battery charger and jump

starting an engine may set DTC(s). If DTC(s) set

when an accessory is operated, check for faulty

connections or excessive current draw.

Check for faulty connections at the starter solenoid or

fusible link.

Check for loose/damaged terminals at generator.

Check belt wear/tension.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart.

4. This test checks charging system voltage.

5. This test checks battery voltage input at the PCM.

7. This test checks ignition voltage input at the PCM.

Page 3451 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–14

10. Place a power source near the shorted end of the

SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps minimum. A

vehicle battery is suggested.

11. Connect the driver air bag assembly to the pigtail

adapter on the SRS deployment harness.

Deployment harness shall remain shorted and not be

connected to a power source until the air bag is to be

deployed. The driver air bag assembly will

immediately deploy the air bag when a power source

is connected to it.

NOTE: Ensure that the pigtail adapter is firmly seated into

the driver air bag assembly connector. Failure to fully

seat the connectors may leave the shorting bar located in

the driver air bag assembly connector functioning

(shorted) and may result in nondeployment of the driver

air bag assembly.

12. Verify that the area around the driver air bag

assembly is clear of all people and loose or flammable

objects.

13. Verify that the driver air bag assembly is resting with

its trim cover facing up.

14. Notify all people in the immediate area that you intend

to deploy the driver air bag. The deployment will be

accompanied by a substantial noise which may

startle the uninformed.

15. Separate the two banana plugs on the SRS

deployment harness.

NOTE: When the air bag deploys, the driver air bag

assembly may jump about 3 m (ten feet) vertically. This

is a normal reaction of the driver air bag to the force of the

rapid gas expansion inside the air bag.

NOTE: When the air bag deploys, the rapid gas

expansion will create a substantial noise. Notify all

people in the immediate area that you intend to deploy the

driver air bag.

WARNING: DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO A

POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT HARNESS TO

THE POWER SOURCE SHOULD ALWAYS BE THE

LAST STEP IN THE AIR BAG ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO FOLLOW

PROCEDURES IN THE ORDER LISTED MAY RESULT

IN PERSONAL INJURY.

16. Connect the SRS deployment harness wires to the

power source to immediately deploy the driver air

bag. Recommended application: 12 volts minimum, 2

amps minimum. A vehicle battery is suggested.

17. Disconnect the SRS deployment harness from the

power source.

18. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other.19. In the unlikely event that the driver air bag assembly

did not deploy after following these procedures,

proceed immediately with Steps 24 through 26. If the

driver air bag assembly did deploy, proceed with

Steps 20 through 23.

20. Put on a pair of shop gloves and safety glasses to

protect your hands and eyes from possible irritation

and heat when handling the deployed driver air bag

assembly. After the air bag assembly has been

deployed, the surface of the air bag may contain a

powdery residue. This solid particulate consists

primarily of by products of the chemical reaction,

Potassium Chloride and copper metal dust.

Compounds of Potassium Borate, Strontium

Chloride, Copper Chloride, and Ammonium Chloride

may be found in amounts of about 1 % (each) of the

total particulate.

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDING A DEPLOYED AIR BAG

ASSEMBLY. AFTER DEPLOYMENT, THE METAL

SURFACES OF THE AIR BAG ASSEMBLY WILL BE

VERY HOT. ALLOW THE INFLATOR MODULE TO

COOL BEFORE HANDLING ANY METAL PORTION

OF IT. DO NOT PLACE THE DEPLOYED AIR BAG

ASSEMBLY NEAR ANY FLAMMABLE OBJECTS.

FAILURE TO FOLLOW PROCEDURES MAY RESULT

IN FIRE OR PERSONAL INJURY.

AFTER A DRIVER AIR BAG ASSEMBLY HAS BEEN

DEPLOYED, THE METAL CANISTER AND

SURROUNDING AREAS OF THE DRIVER AIR BAG

ASSEMBLY WILL BE VERY HOT. DO NOT TOUCH

THE METAL AREAS OF THE DRIVER AIR BAG

ASSEMBLY FOR ABOUT TEN MINUTES AFTER

DEPLOYMENT. IF THE DEPLOYED DRIVER AIR BAG

ASSEMBLY MUST BE MOVED BEFORE IT IS COOL,

WEAR GLOVES AND HANDLE BY THE AIR BAG OR

TRIM COVER.

21. Disconnect the pigtail adapter from the driver air bag

assembly as soon after deployment as possible. This

will prevent damage to the pigtail adapter or SRS

deployment harness due to possible contact with the

hot driver air bag assembly canister. The pigtail

adapter can be reused. They should, however, be

inspected for damage after each deployment and

replaced if necessary.

22. Dispose of the deployed driver air bag assembly

through normal refuse channels after it has cooled for

at least 30 minutes.

23. Wash your hands with mild soap and water afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the driver air bag assembly did not

deploy after following these procedures.

24. Ensure that the SRS deployment harness has been

disconnected from the power source and that its two

banana plugs have been shorted together by fully

seating one banana plug into the other.

25. Disconnect the pigtail adapter from the driver air bag

assembly.

WARNING: W H E N S T O R I N G A L I V E A I R B A G

ASSEMBLY OR WHEN LEAVING A LIVE INFLATOR

MODULE UNATTENDED ON A BENCH OR OTHER

Page 4355 of 6000

5A–5 BRAKE CONTROL SYSTEM

FR

Front Right

GEN

Generator

MV

Millivolts

RL

Rear Left

RR

Rear RightRPS

Revolution per Second

VDC

Vo l t s D C

VA C

Vo l t s A C

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS malfunction can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

Box Wrench

Brake Fluid

Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure toobserve these precautions may result in Anti-lock Brake

System damage.

If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

EHCU of the Anti-lock Brake System are not

separately serviceable and must be replaced as

assemblies. Do not disassemble any component

which is designated as non-serviceable in this

Section.

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(40A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

Improperly formed or damaged terminals.

Page 4500 of 6000

6A–4

ENGINE MECHANICAL

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble — Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5–8840–0607–0, start the engine,

a n d c h e c k i f a s p a r k i s g e n e r a t e d in t h e s p a r k p l u g t e s t e r.

Before starting the engine, make sure that the spark plugtester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the igniton coil is

broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to “Electronic Fuel Injection”

section

Page 4612 of 6000

6C–5

ENGINE FUEL

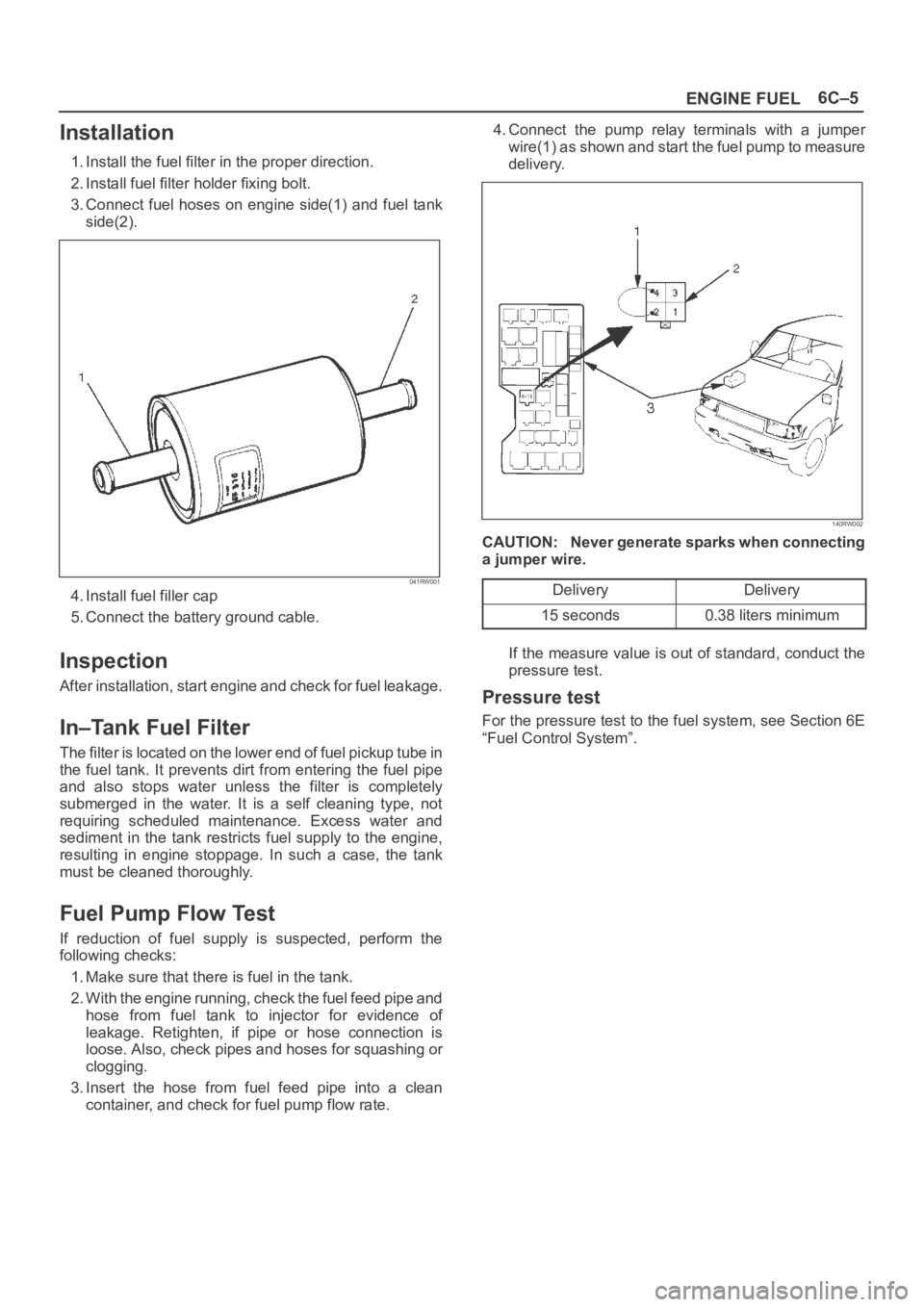

Installation

1. Install the fuel filter in the proper direction.

2. Install fuel filter holder fixing bolt.

3. Connect fuel hoses on engine side(1) and fuel tank

side(2).

041RW001

4. Install fuel filler cap

5. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube in

the fuel tank. It prevents dirt from entering the fuel pipe

and also stops water unless the filter is completely

submerged in the water. It is a self cleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks:

1. Make sure that there is fuel in the tank.

2. With the engine running, check the fuel feed pipe and

hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, check pipes and hoses for squashing or

clogging.

3. Insert the hose from fuel feed pipe into a clean

container, and check for fuel pump flow rate.4. Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to measure

delivery.

140RW002

CAUTION: Never generate sparks when connecting

a jumper wire.

Delivery

Delivery

15 seconds0.38 liters minimum

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

“Fuel Control System”.

Page 4620 of 6000

ENGINE ELECTRICAL6D1–1

ENGINE

ENGINE ELECTRICAL

CONTENTS

Service Precaution 6D1–1. . . . . . . . . . . . . . . . . . . . . .

Battery 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D1–2. . . . . . . . . . . . . . . . . . . .

Diagnosis 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charging 6D1–3. . . . . . . . . . . . . . . . . . . . . . Jump Starting 6D1–3. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Removal 6D1–4. . . . . . . . . . . . . . . . . . . . . .

Battery Installation 6D1–4. . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D1–5. . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 4622 of 6000

ENGINE ELECTRICAL6D1–3

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

Page 4623 of 6000

6D1–4

ENGINE ELECTRICAL

4. Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the air conditioning

compressor bracket or the generator mounting

bracket) of the vehicle with the discharged battery.

The ground connection must be at least 450 mm (18

in.) from the battery of the vehicle whose battery is

being charged.

WARNING: NEVER ATTACH THE END OF THE

JUMPER CABLE DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories

have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in reverse order.

Be sure to first disconnect the negative cable from the

vehicle with the discharged battery.

Battery Removal

061RS002

1. Remove negative cable (1).

2. Remove positive cable (2).

3. Remove retainer screw and rods (3).

4. Remove retainer (4).

5. Remove battery (5).

Battery Installation

1. Install battery (5).

2. Install retainer (4).

3. Instal retainer screw and rods (3).

NOTE: Make sure that the rod is hooked on the body

side.

4. Install positive cable (2).

5. Install negative cable (1).