Seat OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3549 of 6000

RESTRAINT CONTROL SYSTEM 9J1–62

DTC 46 Driver Pretensioner Loop Short To Ignition

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

Ignition switch “OFF.”

Connect scan tool data link connector. follow directions as

given in the scan tool operator’s manual.

2. Ignition switch “ON.”

3. Read driver belt sense LO .

Is driver belt sense LO more than 3.5 volts?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly yellow 2–pin

connector at the base of the driver seat, leave passenger

pretensioner assembly connected.

3. Connect SRS driver /passenger load tool 5–8840–2421–0 and

appropriate adapter to driver pretensioner assembly harness

connector.

4. Ignition switch “ON.”

Is DTC 46 current?

Go to Step 4

Ignition switch

“OFF”

Replace driver

pretensioner

assembly

Go to Step 6

41. Ignition switch “OFF.”

2. Disconnect SDM.

3. Disconnect SRS driver /passenger load tool.

4. Measure resistance on SDM harness connector “21” to

terminal “12” (ignition).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Step 5

Replace SRS

harness or repair

chassis harness

Go to Step 6

5Measure resistance on SDM harness connector from terminal

“22” to terminal “12” (ignition).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Chart A

Replace SRS

harness or repair

chassis harness

Go to Step 6

61. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 6

Page 3550 of 6000

9J1–63

RESTRAINT CONTROL SYSTEM

DTC 52 Pretensioner Deployment Event Commanded

D09RW014

Circuit Description:

The SDM contains a sensing device which converts

vehicle velocity changes to an electrical signal. The

electrical signal generated is processed by the SDM and

then compared to a value stored in memory. When the

generated signal exceeds the stored value, the SDM will

cause current to flow through the pretensioner assembly

deploying the pretensioners and causing DTC 52 to set.

DTC Will Set When:

The SDM detects a frontal crash, up to 30 degrees off the

centerline of the vehicle, of sufficient force to warrant

deployment of the air bags and pretensioner seat belt.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp records

“Crash Data”, and sets a diagnostic trouble code.

DTC Will Clear When:

The SDM is replaced.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If pretensioner assembly (s) has not deployed, DTC

52 may have falsely set.

3. If DTC 52 has set with no signs of frontal impact, the

diagnostic trouble code has falsely set.

Page 3569 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

8A LIGHTING SYSTEM

8B WIPER / WASHER SYSTEM

8C ENTERTAINMENT

8D WIRING SYSTEM

8E METER AND GAUGE

8F BODY STRUCTURE

8G SEATS

8H SECURITY AND LOCKS

8I SUN ROOF/CONVERTIBLE TOP

8J EXTERIOR / INTERIOR TRIM

HOME

8A

8B

8C

8D

8E

8F

8G

8H

8I

8J

Page 3570 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

9A SEAT BELT SYSTEM

9J SUPPLEMENTAL RESTRAINT SYSTEM

9J1 RESTRAINT CONTROL SYSTEM

HOME

9A

9J

9J1

Page 3780 of 6000

Installation

1. Place the clutch coil assembly (1) on the front head

with the terminals positioned at the "marked" location.

2. Place the J-33024 clutch coil installer over the

internal opening of the clutch coil housing and align

installer with the compressor front head.

3. Center the J-8433-1 puller crossbar in the counter-

sunk center hole of the J-33024 clutch coil installer.

Install the J-33026 through bolts and washers

through the crossbar slots and thread them into the

holding fixture J-33026 to full fixture thickness.

4. Turn the center forcing screw of J-8433-1 puller

crossbar to force the clutch coil onto the front head.

Be sure clutch coil and J-33024 installer stay "in-

line" during installation.

5. When coil is fully seated on the front head, use a

1/8 in diameter drift punch (2) and stake the front

head at three places 120 degrees apart, to ensure

clutch coil (3) remains in position.

Stake size should be only one-half the area of the

punch tip and be only approximately 0.28–0.35

mm (.010–.015 in) deep.

Legend

(1) Stake Front Head 0.28–0.35 mm Deep

(0.10–015 in)

(2) Clutch Coil Housing

(3) Front Head Surface

6. Install rotor and bearing assembly and the clutch

plate and hub assembly as described previously.

J-8433-3

J-8433-1

J-33024

1

901RW007

2

3

871RW004

1

23

871RW005

Page 3782 of 6000

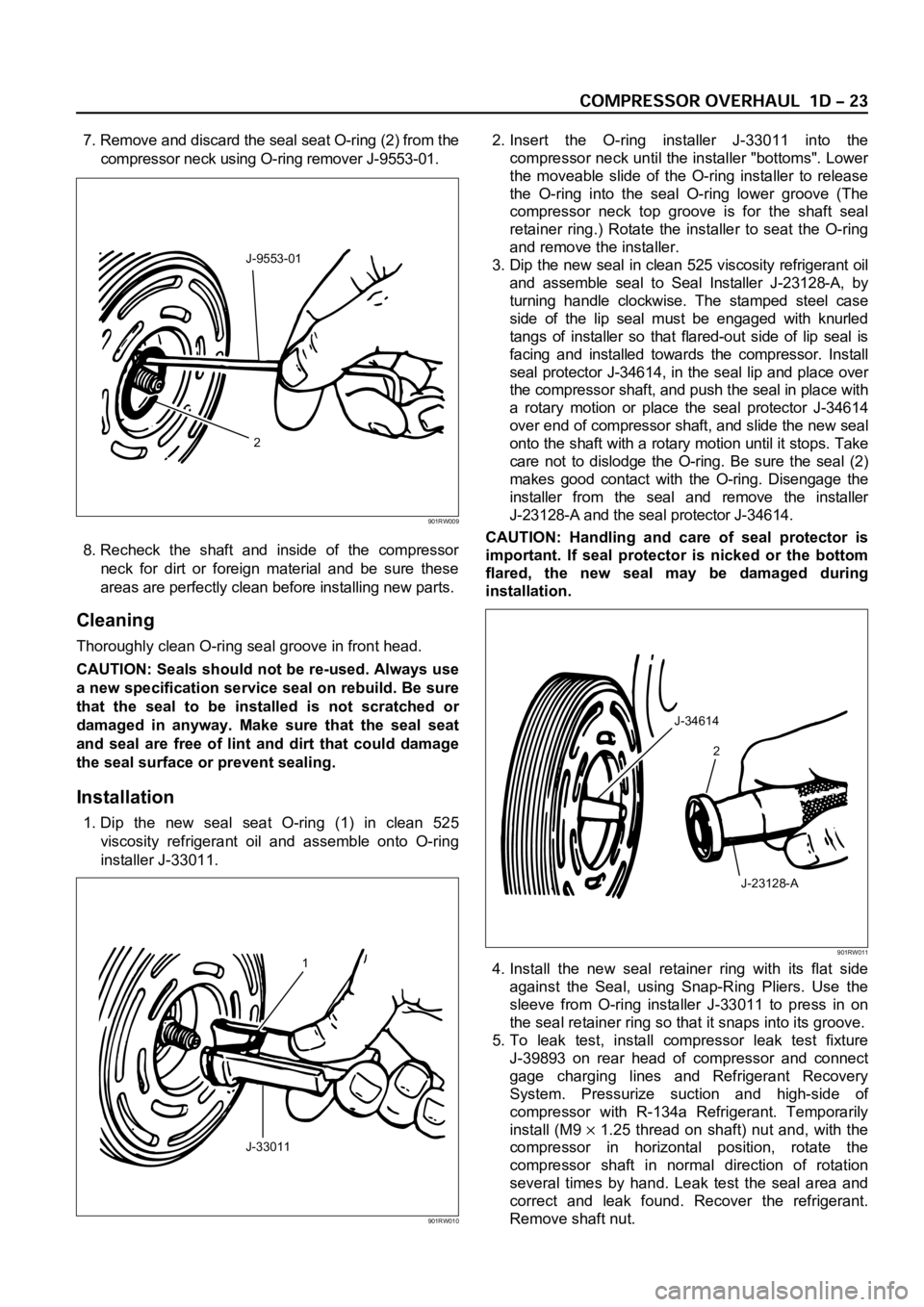

7. Remove and discard the seal seat O-ring (2) from the

compressor neck using O-ring remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck for dirt or foreign material and be sure these

areas are perfectly clean before installing new parts.

Cleaning

Thoroughly clean O-ring seal groove in front head.

CAUTION: Seals should not be re-used. Always use

a new specification service seal on rebuild. Be sure

that the seal to be installed is not scratched or

damaged in anyway. Make sure that the seal seat

and seal are free of lint and dirt that could damage

the seal surface or prevent sealing.

Installation

1. Dip the new seal seat O-ring (1) in clean 525

viscosity refrigerant oil and assemble onto O-ring

installer J-33011.2. Insert the O-ring installer J-33011 into the

compressor neck until the installer "bottoms". Lower

the moveable slide of the O-ring installer to release

the O-ring into the seal O-ring lower groove (The

compressor neck top groove is for the shaft seal

retainer ring.) Rotate the installer to seat the O-ring

and remove the installer.

3. Dip the new seal in clean 525 viscosity refrigerant oil

and assemble seal to Seal Installer J-23128-A, by

turning handle clockwise. The stamped steel case

side of the lip seal must be engaged with knurled

tangs of installer so that flared-out side of lip seal is

facing and installed towards the compressor. Install

seal protector J-34614, in the seal lip and place over

the compressor shaft, and push the seal in place with

a rotary motion or place the seal protector J-34614

over end of compressor shaft, and slide the new seal

onto the shaft with a rotary motion until it stops. Take

care not to dislodge the O-ring. Be sure the seal (2)

makes good contact with the O-ring. Disengage the

installer from the seal and remove the installer

J-23128-A and the seal protector J-34614.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

4. Install the new seal retainer ring with its flat side

against the Seal, using Snap-Ring Pliers. Use the

sleeve from O-ring installer J-33011 to press in on

the seal retainer ring so that it snaps into its groove.

5. To leak test, install compressor leak test fixture

J-39893 on rear head of compressor and connect

gage charging lines and Refrigerant Recovery

System. Pressurize suction and high-side of

compressor with R-134a Refrigerant. Temporarily

install (M9

1.25 thread on shaft) nut and, with the

compressor in horizontal position, rotate the

compressor shaft in normal direction of rotation

several times by hand. Leak test the seal area and

correct and leak found. Recover the refrigerant.

Remove shaft nut.

2 J-9553-01

901RW009

1

J-33011

901RW010

J-34614

2

J-23128-A

901RW011

Page 3783 of 6000

6. Remove any excess oil resulting from installing the

new seal parts from the shaft and inside the

compressor neck.

7. Install the clutch plate and hub assembly as

described previously.8. Reinstall compressor belt and tighten bracket.

9. Evacuate and charge the refrigerant system.

COMPRESSOR PRESSURE RELIEF VALVE

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Remove old pressure relief valve.

Installation

1. Clean valve seat area on rear head.2. Lubricate O-ring of new pressure relief valve and

O-ring assembly with new 525 viscosity refrigerant

oil. Install new valve and torque in place, 9.0 Nꞏm

(6.1 ft lbs)

3. Evacuate and recharge the system.

4. Leak test system.

COMPRESSOR OIL

Compressor Oil Check

The oil used to lubricate the compressor is circulating

with the refrigerant.

Whenever replacing any component of the system or a

large amount of gas leakage occurs, add oil to maintain

the original amount of oil.

Checking and Adjusting Oil Quantity for

Used Compressor

1. Perform oil return operation. Refer to Oil Return

Operation in this section.

2. Discharge and recover refrigerant and remove the

compressor.

3. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

4. If the amount of oil drained is much less than 90 cc

(3.0 fl. oz.), some refrigerant may have leaked out.

Conduct a leak tests on the connections of each

system, and if necessary, repair or replace faulty

parts.

5. Check the compressor oil contamination. (Refer to

Contamination of Compressor Oil in this section.)

6. Adjust the oil level following the next procedure

below.7. Install the compressor, then evacuate, charge and

perform the oil return operation.

8. Check system operation.

When it is impossible to preform oil return

operation, the compressor oil should be checked in

the following order:

1. Discharge and recover refrigerant and remove the

compressor.

2. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

3. Check the oil for contamination.

4. If more than 90 cc (3.0 fl. oz.) of oil is extracted from

the compressor, supply the same amount of oil to

the compressor to be installed. If the amount of oil

extracted is less than 90 cc (3.0 fl. oz.), recheck the

compressor oil in the following order:

5. Supply 90 cc (3.0 fl. oz.) of oil to the compressor

and install it onto the vehicle.

6. Evacuate and recharge with the proper amount of

refrigerant.

7. Perform the oil return operation.

8. Remove the compressor and recheck the amount of

oil.

9. Adjust the compressor oil, if necessary.

Checking and Adjusting for Compressor

Replacement

The oil is not charged in compressor (service parts). So

it is necessary to charge the proper amount of oil to the

new compressor. (Oil Capacity)

Capacity total in system 150 cc (5.0 fl.oz)

Compressor (Service 150 cc (5.0 fl.oz)

parts) charging amount

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 4090 of 6000

4B2–7 DRIVE LINE CONTROL SYSTEM (TOD)

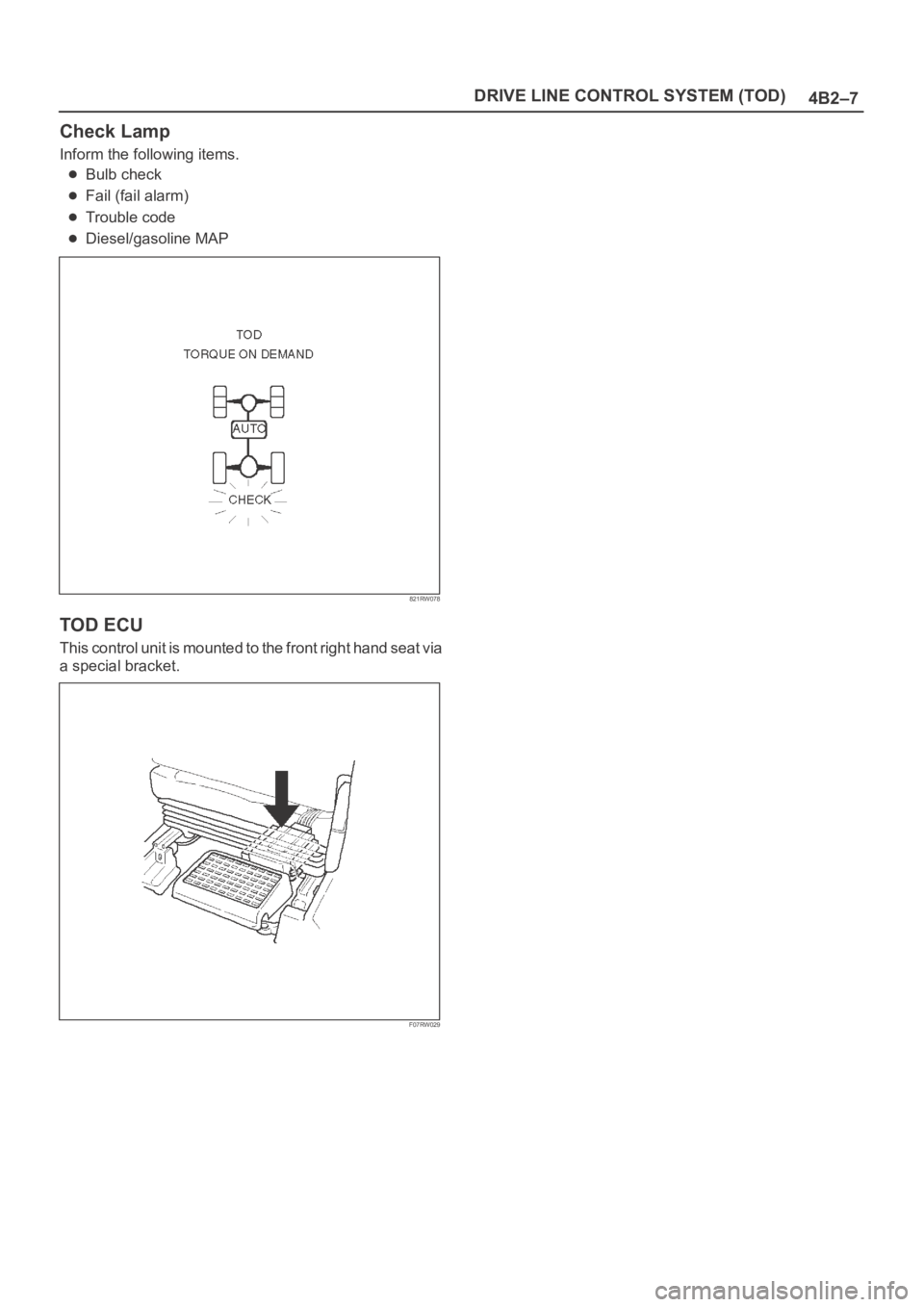

Check Lamp

Inform the following items.

Bulb check

Fail (fail alarm)

Trouble code

Diesel/gasoline MAP

821RW078

TOD ECU

This control unit is mounted to the front right hand seat via

a special bracket.

F07RW029

Page 4217 of 6000

4C–11 DRIVE SHAFT SYSTEM

Reassembly

1. Install wheel pin.

Place the hub on a wood workbench or a block of

wood approx. 6” by 6” to protect the wheel stud

ends and threads.

Insert a wheel stud using a hammer.

Be sure the wheel stud is started squarely and

seats completely.

411RS005

2. Align scribe marks(1) and attach the hub to the disc,

then tighten the bolts to the specified torque.

Torque: 103 Nꞏm (10.5 kgꞏm/76 lb ft)

411RS003

3. Use installer 5–8840–2119–0 and grip

5–8840–0007–0, then install the inner bearing by

driving it into the hub.

411RW006

4. Use installer 5–8840–2118–0 and grip

5–8840–0007–0, then install the outer bearing by

driving it into the hub.

411RW007

Page 4309 of 6000

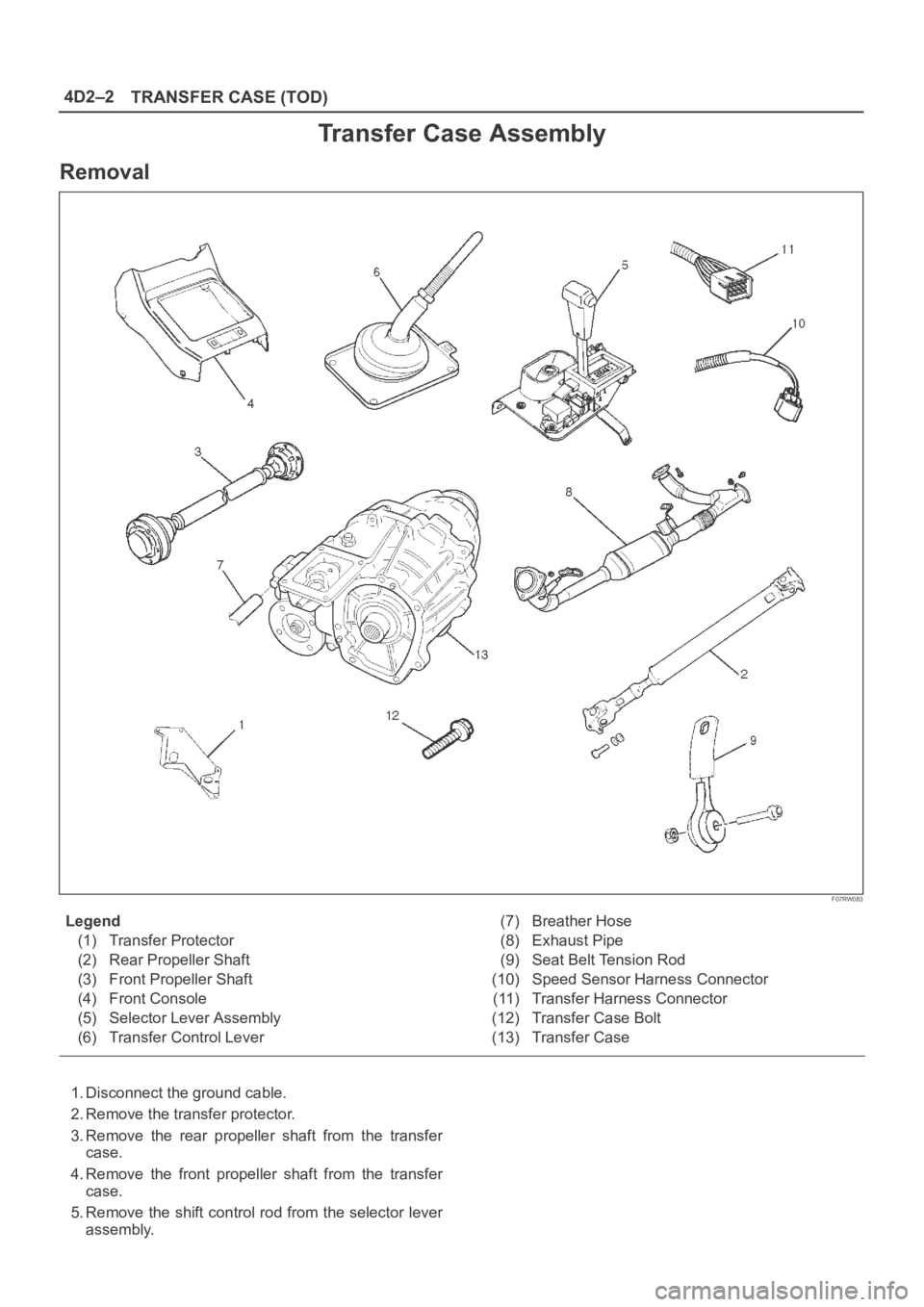

4D2–2

TRANSFER CASE (TOD)

Transfer Case Assembly

Removal

F07RW083

Legend

(1) Transfer Protector

(2) Rear Propeller Shaft

(3) Front Propeller Shaft

(4) Front Console

(5) Selector Lever Assembly

(6) Transfer Control Lever(7) Breather Hose

(8) Exhaust Pipe

(9) Seat Belt Tension Rod

(10) Speed Sensor Harness Connector

(11) Transfer Harness Connector

(12) Transfer Case Bolt

(13) Transfer Case

1. Disconnect the ground cable.

2. Remove the transfer protector.

3. Remove the rear propeller shaft from the transfer

case.

4. Remove the front propeller shaft from the transfer

case.

5. Remove the shift control rod from the selector lever

assembly.