coolant capacity OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1057 of 6000

6B–4

ENGINE COOLING

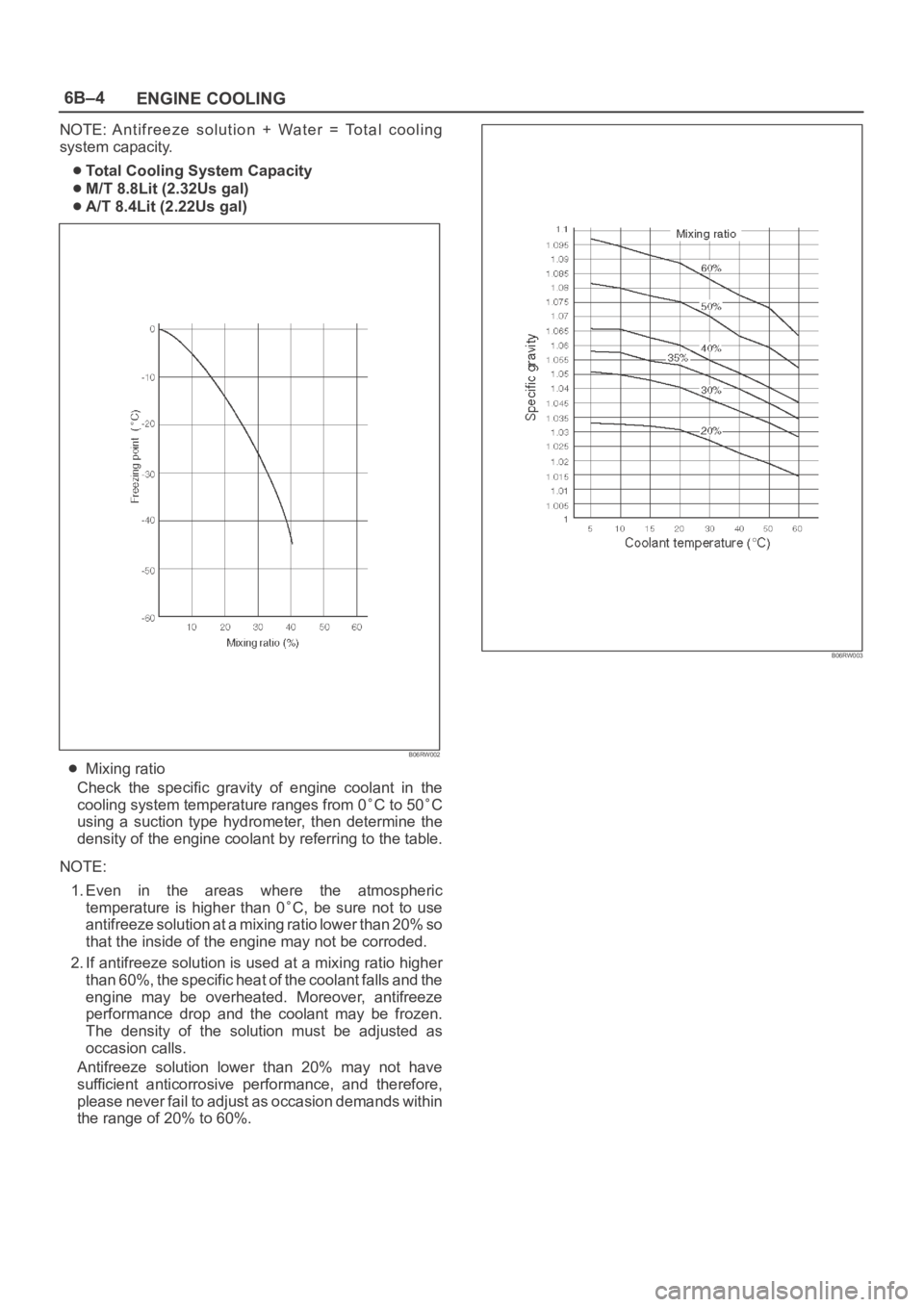

NOTE: Antifreeze solution + Water = Total cooling

system capacity.

Total Cooling System Capacity

M/T 8.8Lit (2.32Us gal)

A/T 8.4Lit (2.22Us gal)

B06RW002

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system temperature ranges from 0

C to 50C

using a suction type hydrometer, then determine the

density of the engine coolant by referring to the table.

NOTE:

1. Even in the areas where the atmospheric

temperature is higher than 0

C, be sure not to use

antifreeze solution at a mixing ratio lower than 20% so

that the inside of the engine may not be corroded.

2. If antifreeze solution is used at a mixing ratio higher

than 60%, the specific heat of the coolant falls and the

engine may be overheated. Moreover, antifreeze

performance drop and the coolant may be frozen.

The density of the solution must be adjusted as

occasion calls.

Antifreeze solution lower than 20% may not have

sufficient anticorrosive performance, and therefore,

please never fail to adjust as occasion demands within

the range of 20% to 60%.

B06RW003

Page 1066 of 6000

ENGINE COOLING6B–13

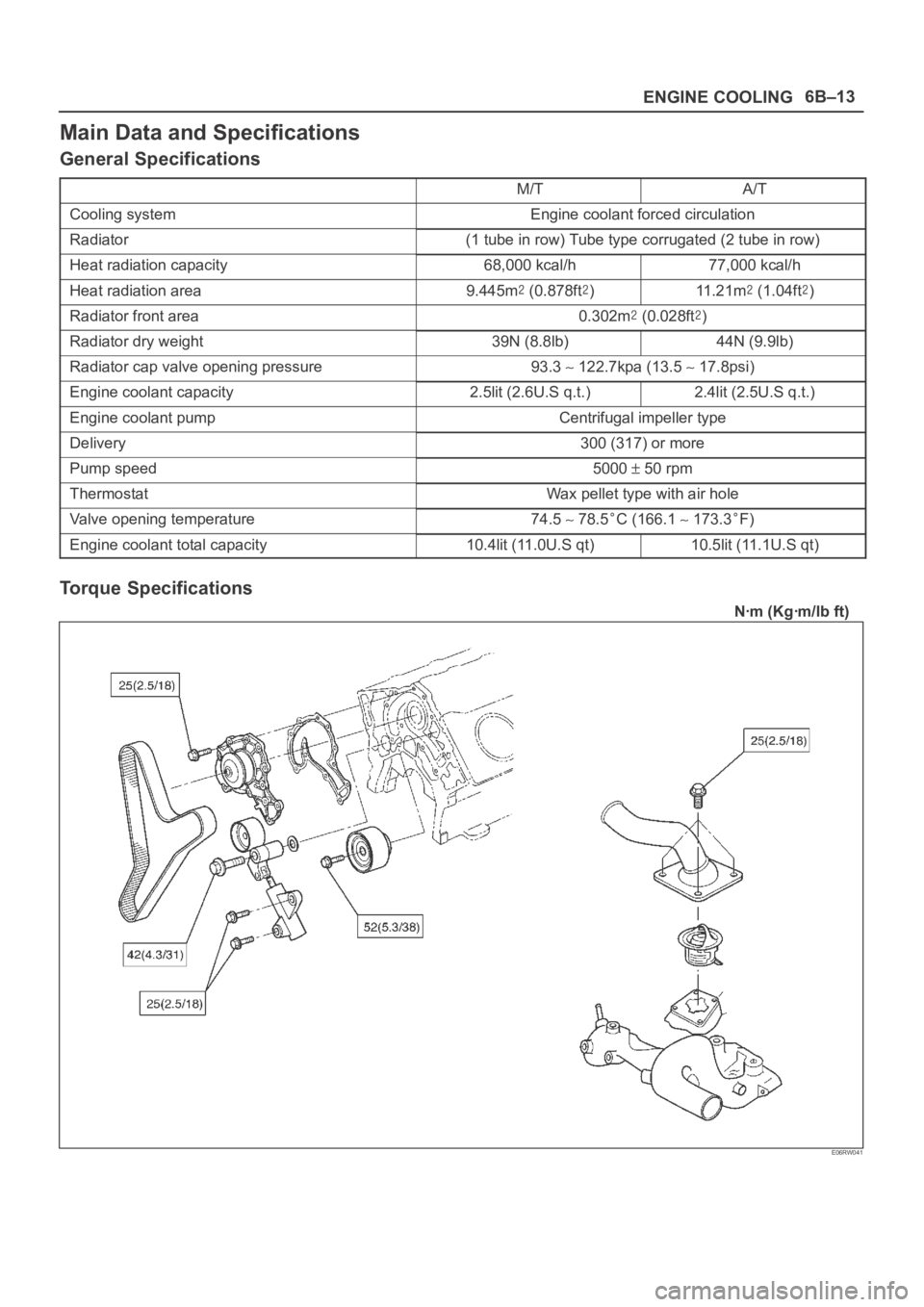

Main Data and Specifications

General Specifications

M/TA/T

Cooling systemEngine coolant forced circulation

Radiator(1 tube in row) Tube type corrugated (2 tube in row)

Heat radiation capacity68,000 kcal/h77,000 kcal/h

Heat radiation area9.445m (0.878ft)11 . 2 1 m (1.04ft)

Radiator front area0.302m (0.028ft)

Radiator dry weight39N (8.8lb)44N (9.9lb)

Radiator cap valve opening pressure93.3 122.7kpa (13.5 17.8psi)

Engine coolant capacity2.5lit (2.6U.S q.t.)2.4lit (2.5U.S q.t.)

Engine coolant pumpCentrifugal impeller type

Delivery300 (317) or more

Pump speed5000 50 rpm

ThermostatWax pellet type with air hole

Valve opening temperature74.5 78.5C (166.1 173.3F)

Engine coolant total capacity10.4lit (11.0U.S qt)10.5lit (11.1U.S qt)

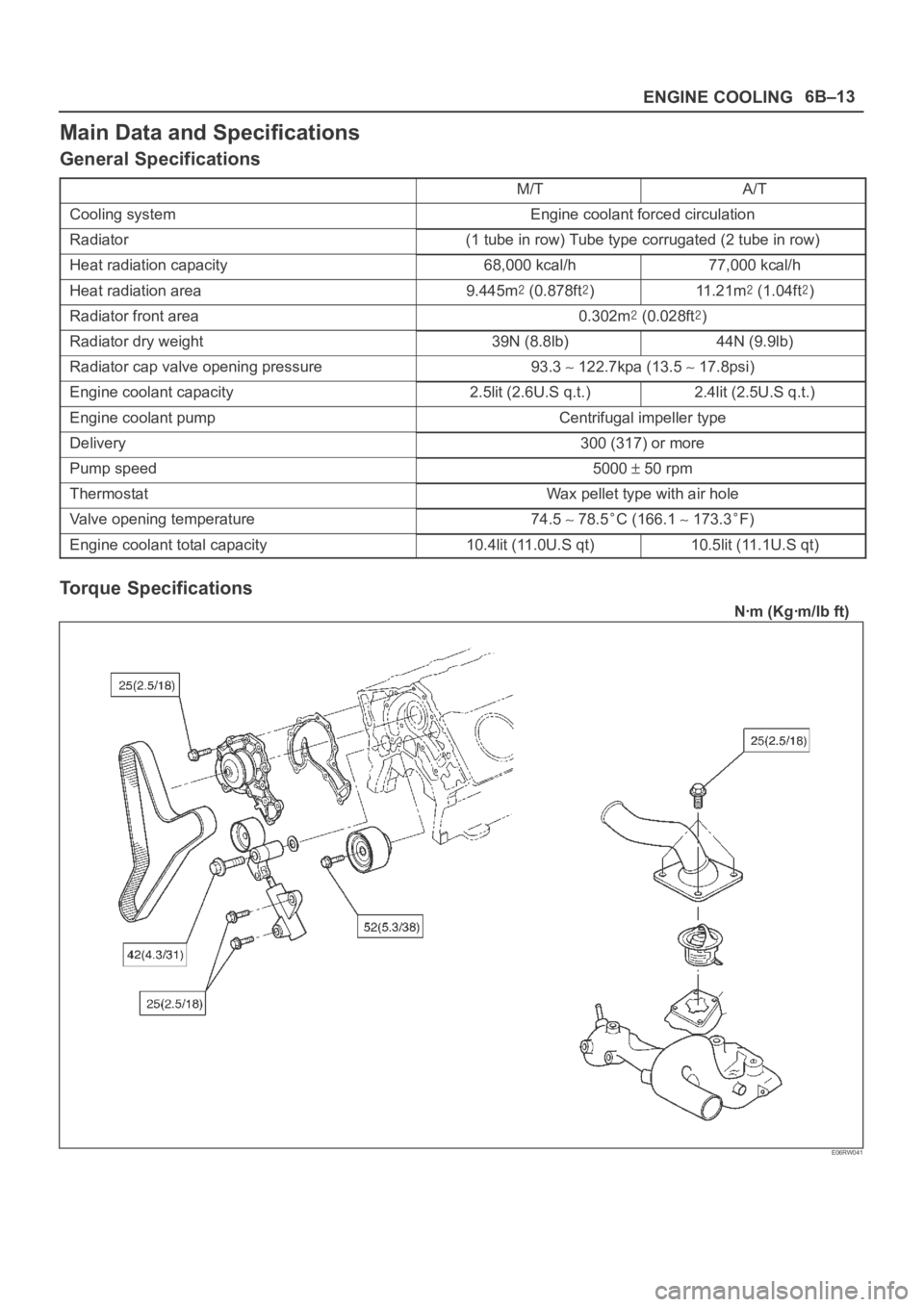

Torque Specifications

Nꞏm (Kgꞏm/lb ft)

E06RW041

Page 1736 of 6000

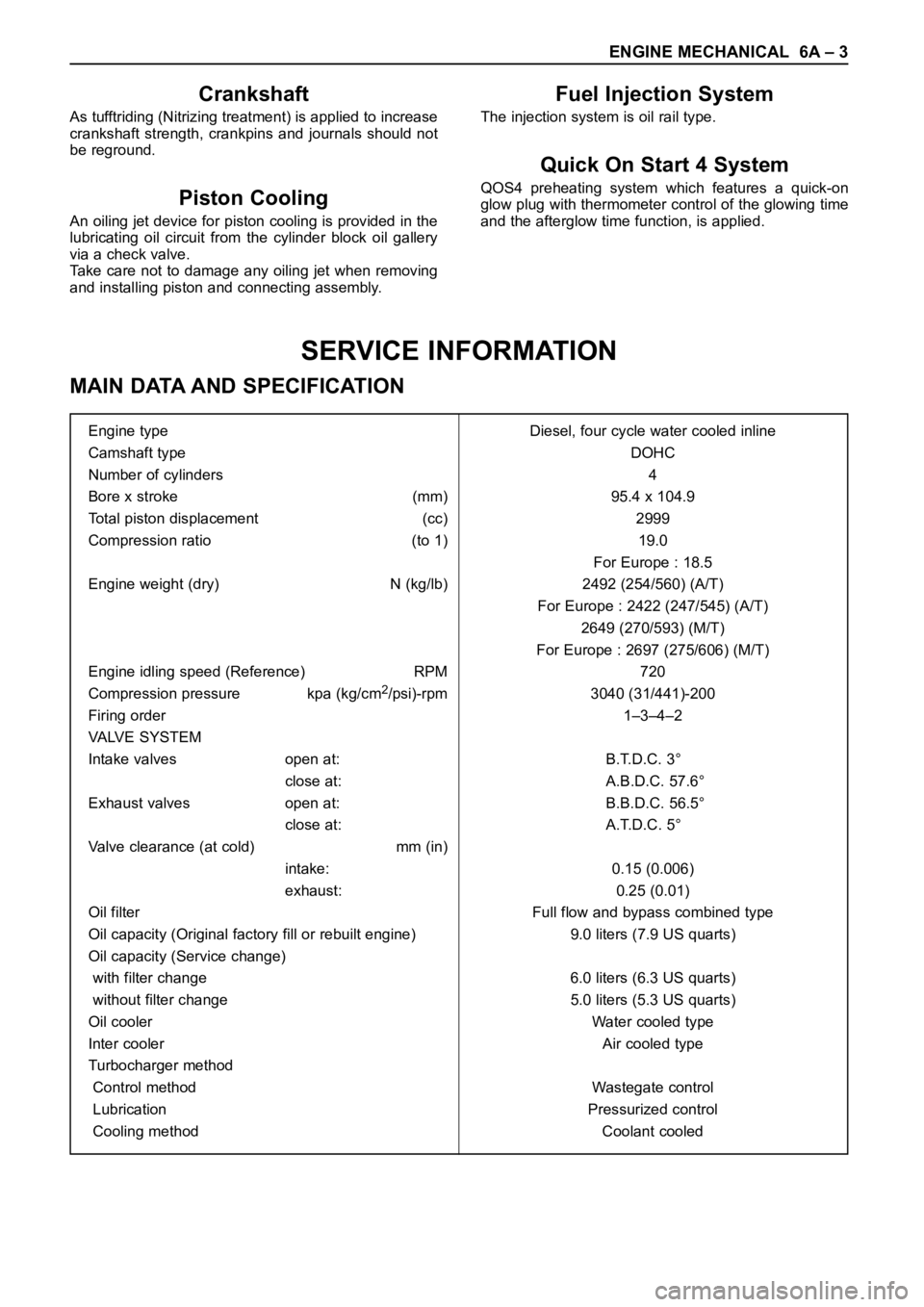

ENGINE MECHANICAL 6A – 3

SERVICE INFORMATION

MAIN DATA AND SPECIFICATION

Engine type Diesel, four cycle water cooled inline

Camshaft type DOHC

Number of cylinders 4

Bore x stroke (mm) 95.4 x 104.9

Total piston displacement (cc) 2999

Compression ratio (to 1) 19.0

For Europe : 18.5

Engine weight (dry) N (kg/lb) 2492 (254/560) (A/T)

For Europe : 2422 (247/545) (A/T)

2649 (270/593) (M/T)

For Europe : 2697 (275/606) (M/T)

Engine idling speed (Reference) RPM 720

Compression pressure kpa (kg/cm

2/psi)-rpm 3040 (31/441)-200

Firing order 1–3–4–2

VALVE SYSTEM

Intake valves open at: B.T.D.C. 3°

close at: A.B.D.C. 57.6°

Exhaust valves open at: B.B.D.C. 56.5°

close at: A.T.D.C. 5°

Valve clearance (at cold) mm (in)

intake: 0.15 (0.006)

exhaust: 0.25 (0.01)

Oil filter Full flow and bypass combined type

Oil capacity (Original factory fill or rebuilt engine) 9.0 liters (7.9 US quarts)

Oil capacity (Service change)

with filter change 6.0 liters (6.3 US quarts)

without filter change 5.0 liters (5.3 US quarts)

Oil cooler Water cooled type

Inter cooler Air cooled type

Turbocharger method

Control method Wastegate control

Lubrication Pressurized control

Cooling method Coolant cooled

Crankshaft

As tufftriding (Nitrizing treatment) is applied to increase

crankshaft strength, crankpins and journals should not

be reground.

Piston Cooling

An oiling jet device for piston cooling is provided in the

lubricating oil circuit from the cylinder block oil gallery

via a check valve.

Take care not to damage any oiling jet when removing

and installing piston and connecting assembly.

Fuel Injection System

The injection system is oil rail type.

Quick On Start 4 System

QOS4 preheating system which features a quick-on

glow plug with thermometer control of the glowing time

and the afterglow time function, is applied.

Page 1737 of 6000

6A – 4 ENGINE MECHANICAL

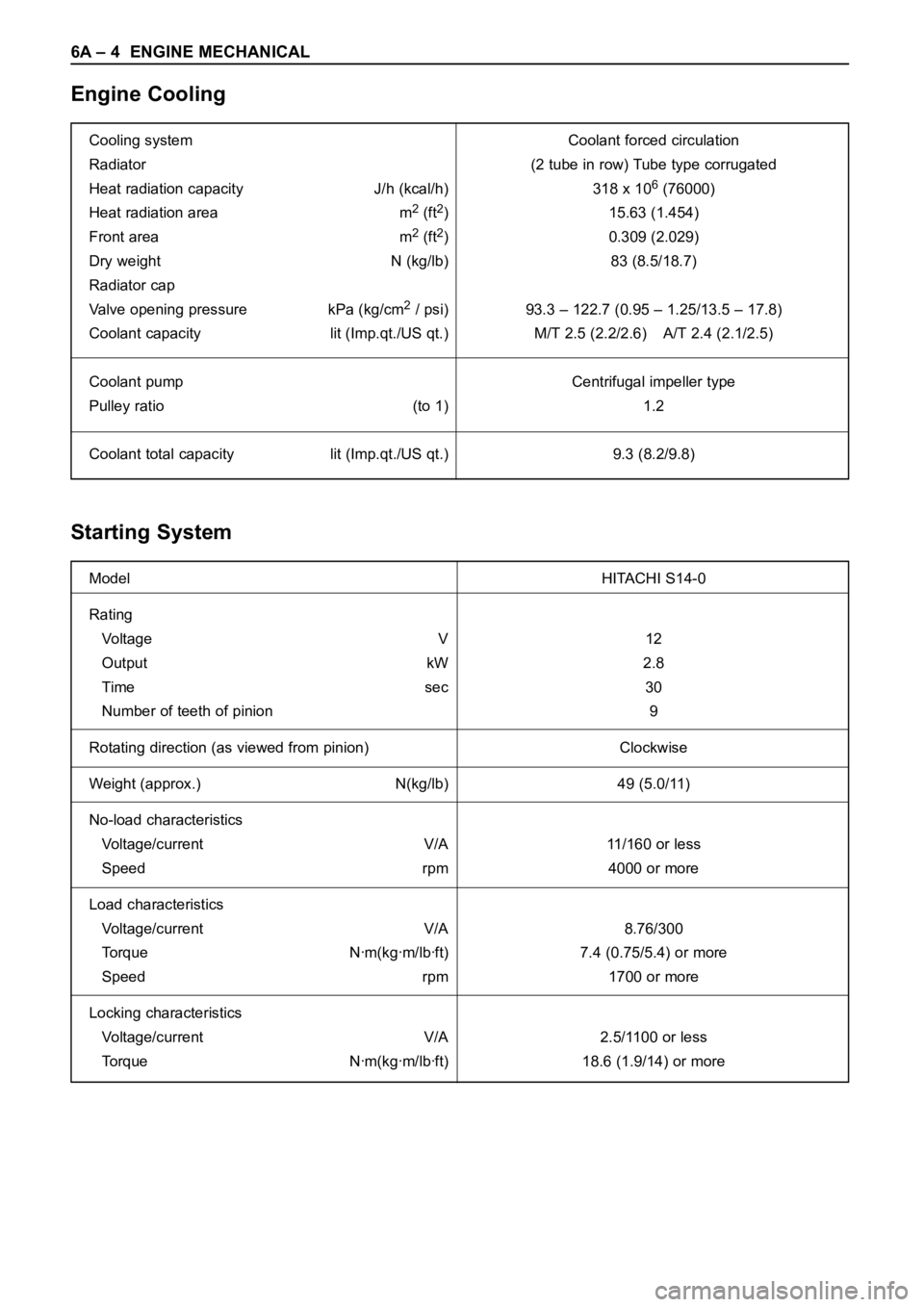

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2/ psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio (to 1) 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Vo l t a ge V 1 2

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 1837 of 6000

6B – 4 ENGINE COOLING

ANTI-FREEZE SOLUTION

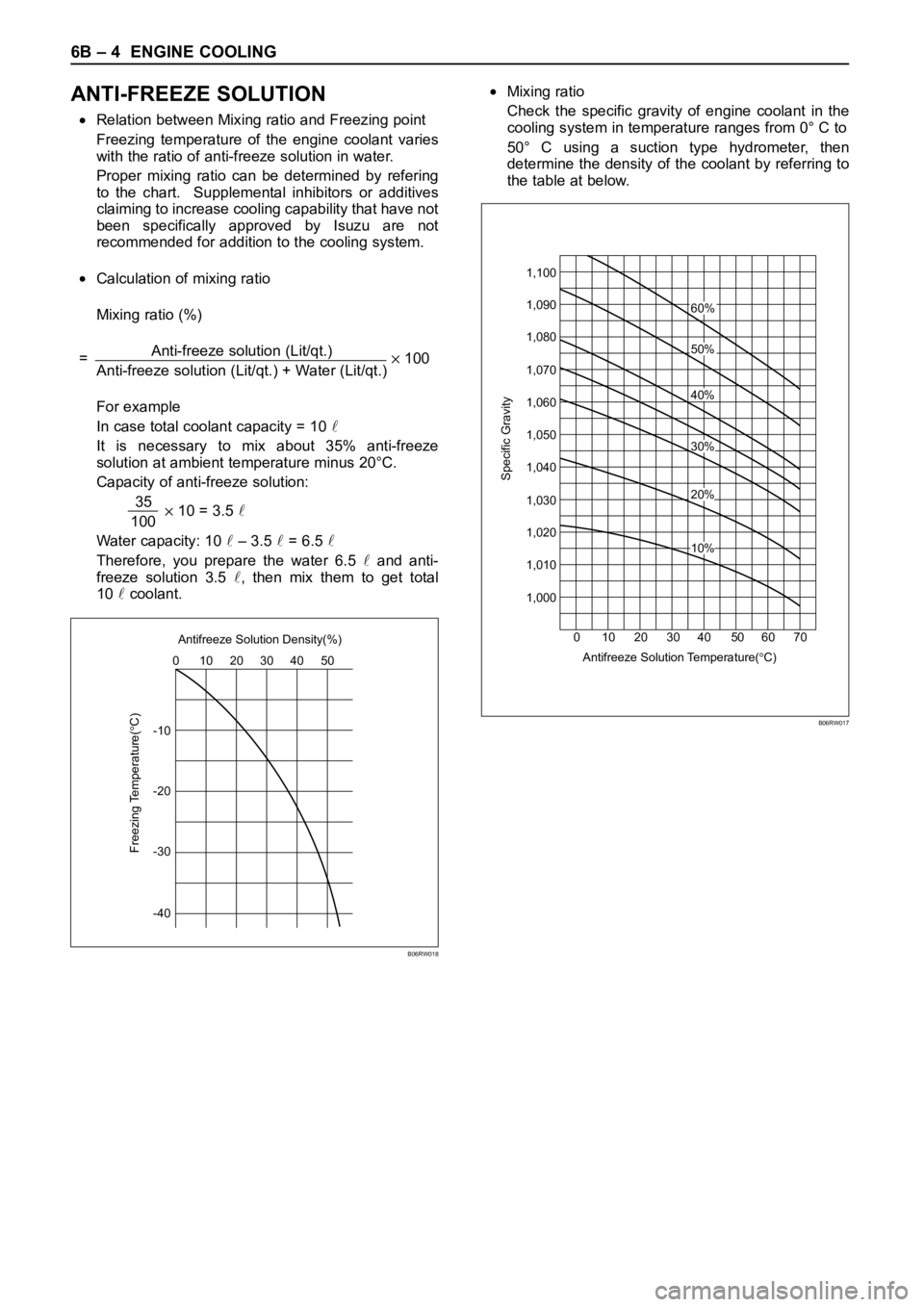

Relation between Mixing ratio and Freezing point

Freezing temperature of the engine coolant varies

with the ratio of anti-freeze solution in water.

Proper mixing ratio can be determined by refering

to the chart. Supplemental inhibitors or additives

claiming to increase cooling capability that have not

been specifically approved by Isuzu are not

recommended for addition to the cooling system.

Calculation of mixing ratio

Mixing ratio (%)

=Anti-freeze solution (Lit/qt.)

100

Anti-freeze solution (Lit/qt.) + Water (Lit/qt.)

For example

In case total coolant capacity = 10

It is necessary to mix about 35% anti-freeze

solution at ambient temperature minus 20°C.

Capacity of anti-freeze solution:

35

10 = 3.5 100

Water capacity: 10

– 3.5 = 6.5

Therefore, you prepare the water 6.5 and anti-

freeze solution 3.5

, then mix them to get total

10

coolant.

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system in temperature ranges from 0° C to

50° C using a suction type hydrometer, then

determine the density of the coolant by referring to

the table at below.

-1010 0

Freezing Temperature(

C)

20 30 Antifreeze Solution Density(%)

40 50

-20

-30

-40

B06RW018

1,100

20 10 30 4060%

50%

40%

20%

10%

30%

Antifreeze Solution Temperature(

C) 50 60 70 0

Specific Gravity

1,090

1,080

1,070

1,060

1,050

1,040

1,030

1,020

1,010

1,000

B06RW017

Page 1839 of 6000

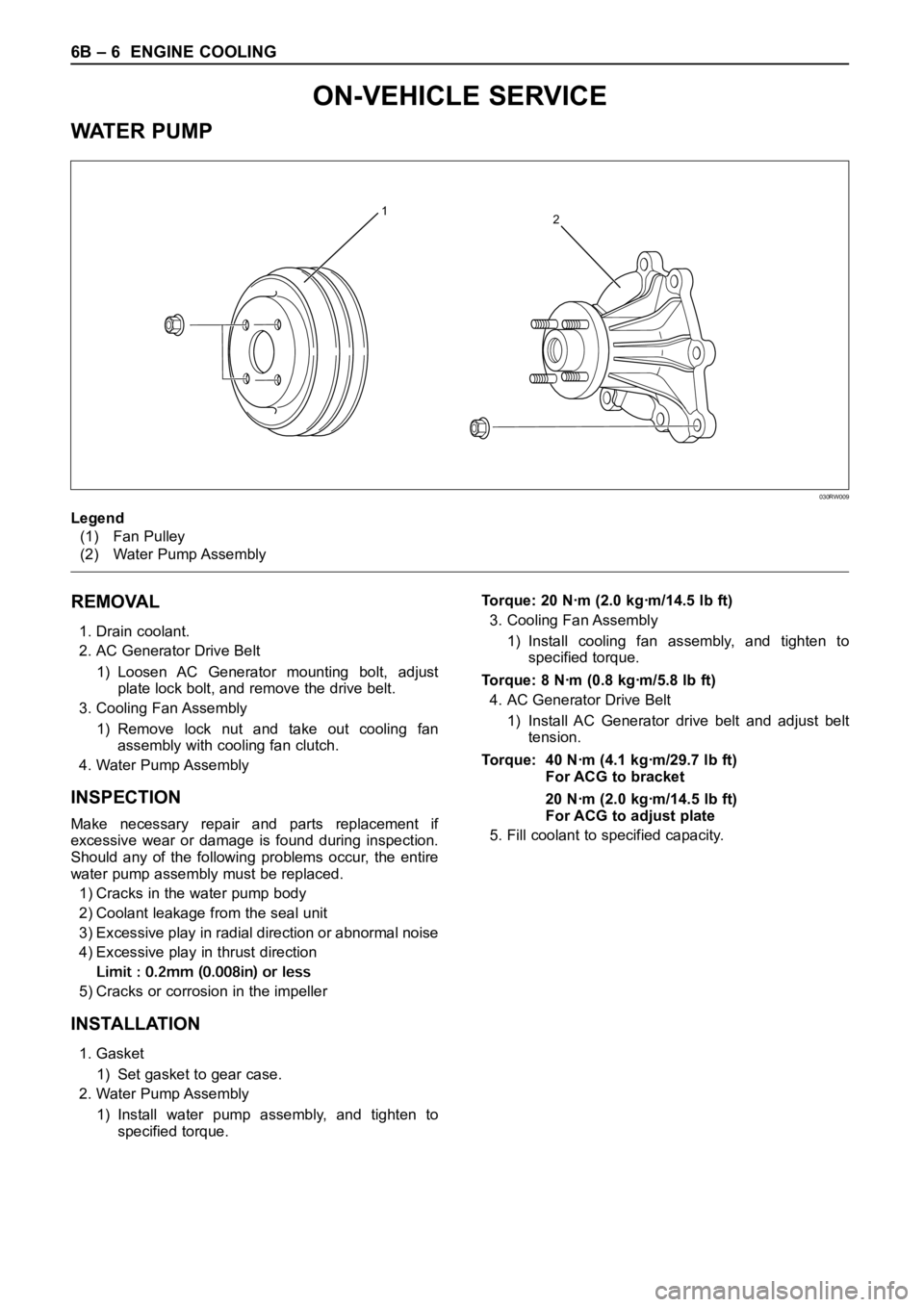

6B – 6 ENGINE COOLING

REMOVAL

1. Drain coolant.

2. AC Generator Drive Belt

1) Loosen AC Generator mounting bolt, adjust

plate lock bolt, and remove the drive belt.

3. Cooling Fan Assembly

1) Remove lock nut and take out cooling fan

assembly with cooling fan clutch.

4. Water Pump Assembly

INSPECTION

Make necessary repair and parts replacement if

excessive wear or damage is found during inspection.

Should any of the following problems occur, the entire

water pump assembly must be replaced.

1) Cracks in the water pump body

2) Coolant leakage from the seal unit

3) Excessive play in radial direction or abnormal noise

4) Excessive play in thrust direction

5) Cracks or corrosion in the impeller

INSTALLATION

1. Gasket

1) Set gasket to gear case.

2. Water Pump Assembly

1) Install water pump assembly, and tighten to

specified torque.Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

3. Cooling Fan Assembly

1) Install cooling fan assembly, and tighten to

specified torque.

Torque: 8 Nꞏm (0.8 kgꞏm/5.8 lb ft)

4. AC Generator Drive Belt

1) Install AC Generator drive belt and adjust belt

tension.

Torque: 40 Nꞏm (4.1 kgꞏm/29.7 lb ft)

For ACG to bracket

20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

For ACG to adjust plate

5. Fill coolant to specified capacity.

12

Legend

(1) Fan Pulley

(2) Water Pump Assembly

030RW009

ON-VEHICLE SERVICE

WAT E R P U M P

Page 2134 of 6000

ENGINE LUBRICATION 6G – 3

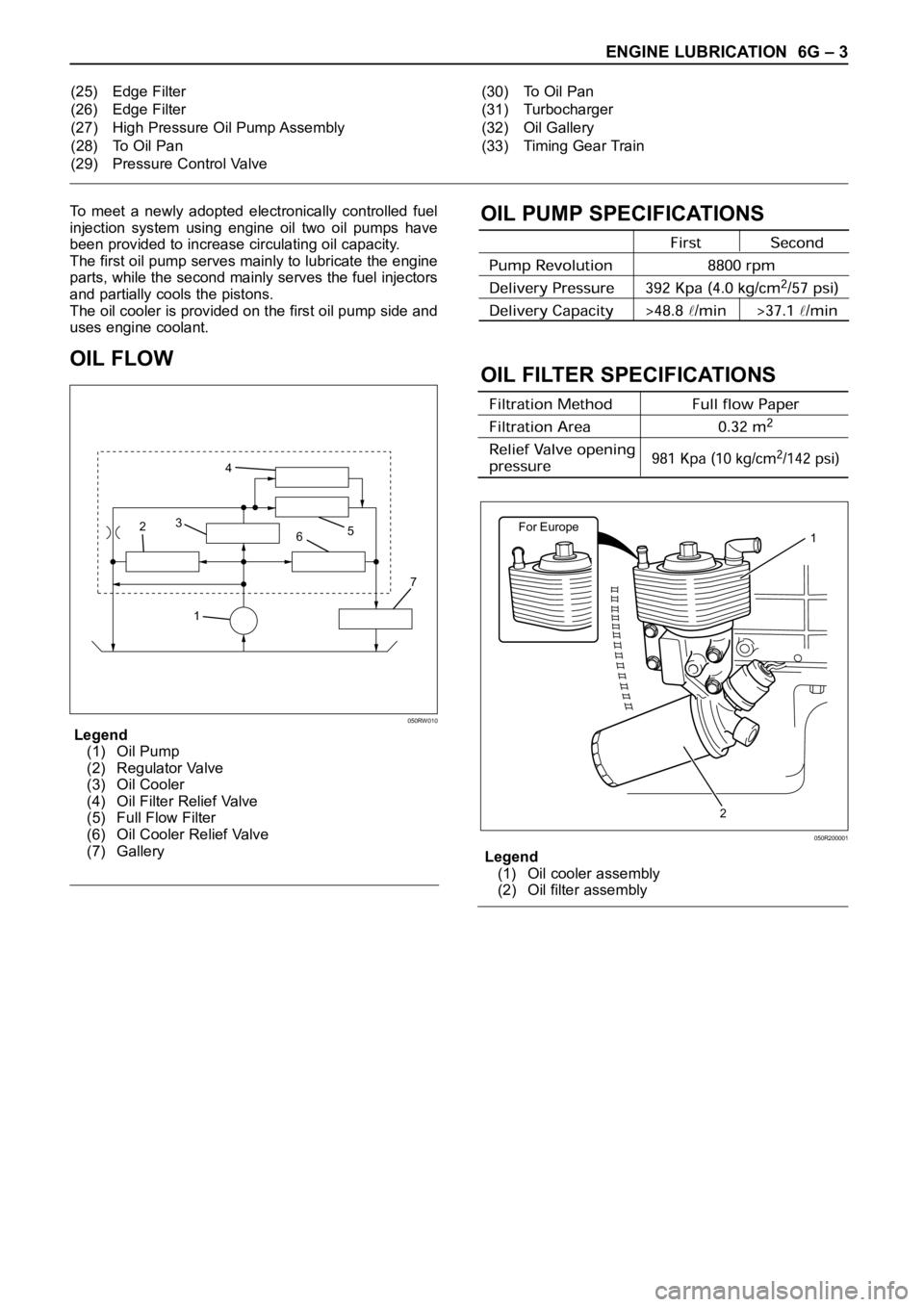

To meet a newly adopted electronically controlled fuel

injection system using engine oil two oil pumps have

been provided to increase circulating oil capacity.

The first oil pump serves mainly to lubricate the engine

parts, while the second mainly serves the fuel injectors

and partially cools the pistons.

The oil cooler is provided on the first oil pump side and

uses engine coolant.

OIL FLOW

Legend

(1) Oil Pump

(2) Regulator Valve

(3) Oil Cooler

(4) Oil Filter Relief Valve

(5) Full Flow Filter

(6) Oil Cooler Relief Valve

(7) Gallery

OIL PUMP SPECIFICATIONS

OIL FILTER SPECIFICATIONS

Legend

(1) Oil cooler assembly

(2) Oil filter assembly (25) Edge Filter

(26) Edge Filter

(27) High Pressure Oil Pump Assembly

(28) To Oil Pan

(29) Pressure Control Valve(30) To Oil Pan

(31) Turbocharger

(32) Oil Gallery

(33) Timing Gear Train

17 65 4

3

2

050RW010

For Europe1

2

050R200001

Page 4597 of 6000

6B–4

ENGINE COOLING

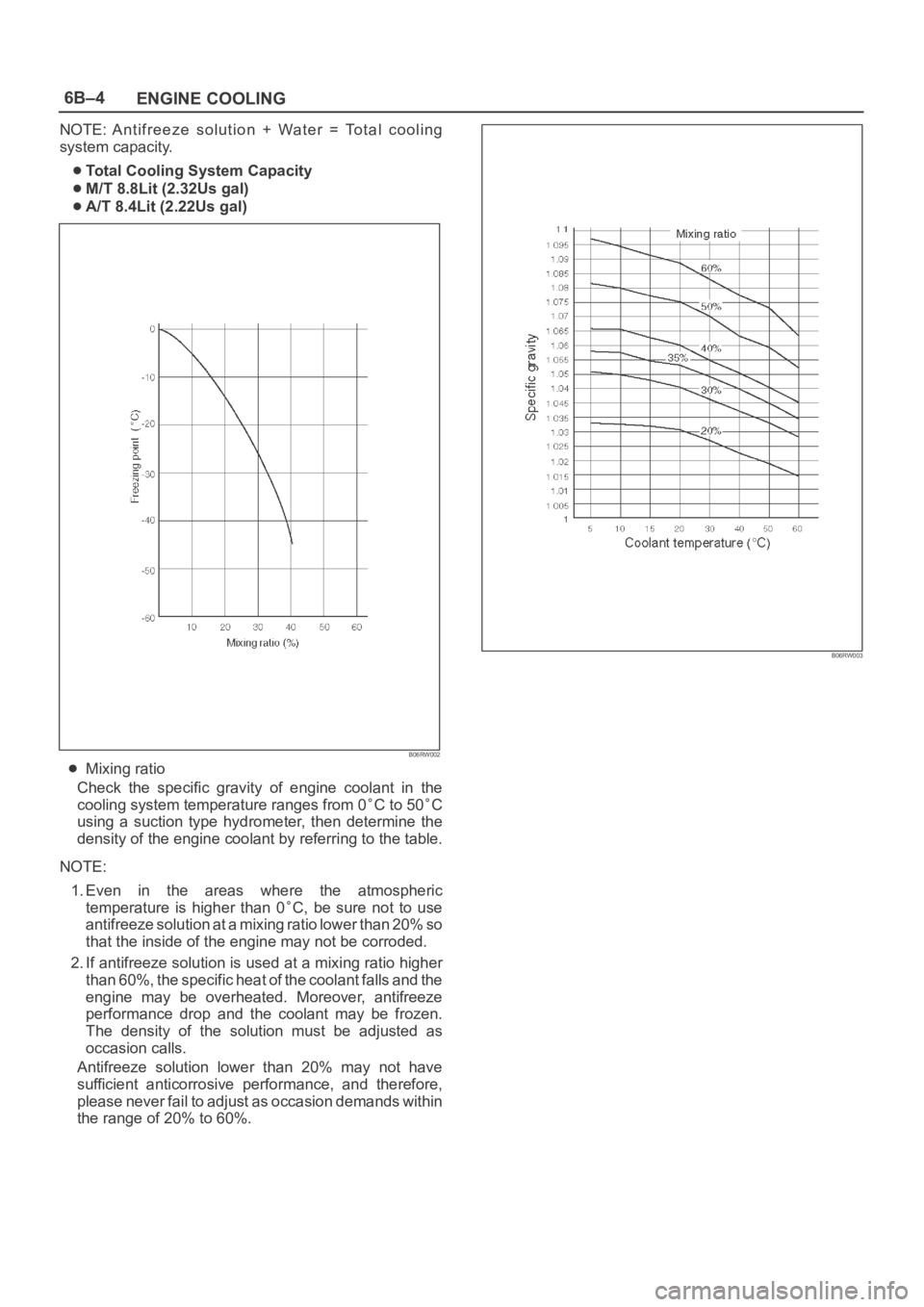

NOTE: Antifreeze solution + Water = Total cooling

system capacity.

Total Cooling System Capacity

M/T 8.8Lit (2.32Us gal)

A/T 8.4Lit (2.22Us gal)

B06RW002

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system temperature ranges from 0

C to 50C

using a suction type hydrometer, then determine the

density of the engine coolant by referring to the table.

NOTE:

1. Even in the areas where the atmospheric

temperature is higher than 0

C, be sure not to use

antifreeze solution at a mixing ratio lower than 20% so

that the inside of the engine may not be corroded.

2. If antifreeze solution is used at a mixing ratio higher

than 60%, the specific heat of the coolant falls and the

engine may be overheated. Moreover, antifreeze

performance drop and the coolant may be frozen.

The density of the solution must be adjusted as

occasion calls.

Antifreeze solution lower than 20% may not have

sufficient anticorrosive performance, and therefore,

please never fail to adjust as occasion demands within

the range of 20% to 60%.

B06RW003

Page 4606 of 6000

ENGINE COOLING6B–13

Main Data and Specifications

General Specifications

M/TA/T

Cooling systemEngine coolant forced circulation

Radiator(1 tube in row) Tube type corrugated (2 tube in row)

Heat radiation capacity68,000 kcal/h77,000 kcal/h

Heat radiation area9.445m (0.878ft)11 . 2 1 m (1.04ft)

Radiator front area0.302m (0.028ft)

Radiator dry weight39N (8.8lb)44N (9.9lb)

Radiator cap valve opening pressure93.3 122.7kpa (13.5 17.8psi)

Engine coolant capacity2.5lit (2.6U.S q.t.)2.4lit (2.5U.S q.t.)

Engine coolant pumpCentrifugal impeller type

Delivery300 (317) or more

Pump speed5000 50 rpm

ThermostatWax pellet type with air hole

Valve opening temperature74.5 78.5C (166.1 173.3F)

Engine coolant total capacity10.4lit (11.0U.S qt)10.5lit (11.1U.S qt)

Torque Specifications

Nꞏm (Kgꞏm/lb ft)

E06RW041

Page 5276 of 6000

ENGINE MECHANICAL 6A – 3

SERVICE INFORMATION

MAIN DATA AND SPECIFICATION

Engine type Diesel, four cycle water cooled inline

Camshaft type DOHC

Number of cylinders 4

Bore x stroke (mm) 95.4 x 104.9

Total piston displacement (cc) 2999

Compression ratio (to 1) 19.0

Engine weight (dry) N (kg/lb) 2492 (254/560) (A/T)

2649 (270/593) (M/T)

Engine idling speed (Reference) RPM 720

Compression pressure kpa (kg/cm

2/psi)-rpm 3000 (31/440)-200

Firing order 1–3–4–2

VALVE SYSTEM

Intake valves open at: B.T.D.C. 3°

close at: A.B.D.C. 57.6°

Exhaust valves open at: B.B.D.C. 56.5°

close at: A.T.D.C. 5°

Valve clearance at cold mm (in)

intake: 0.15 (0.006)

exhaust: 0.25 (0.01)

Oil filter Full flow and bypass combined type

Oil capacity (Original factory fill or rebuilt engine) 9.0 liters (7.9 US quarts)

Oil capacity (Service change)

with filter change 6.0 liters (6.3 US quarts)

without filter change 5.0 liters (5.3 US quarts)

Oil cooler Water cooled type

Inter cooler Air cooled type

Turbocharger method

Control method Wastegate control

Lubrication Pressurized control

Cooling method Coolant cooled