wheel OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4304 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–43

Main Data and Specifications

General Specifications

Ty p eW/Shift On The Fly System model

Synchronized type gears shifting between the 2 and 4 wheel drive mode.

Constant mesh type gears shifting between “low” and “high”.

WO/Shift On The Fly System model

Constant mesh type gears shifting between the 2 and 4 wheel drive mode,

and between “low” and “high”.

Control methodW/4WD Switch model

Electric control with the button switch on the instrument panel for gear

shifting between the 2 and 4 wheel drive mode.

Remote control with the gear shift lever on the floor for gear shifting

between “low and high” .

WO/4WD Switch model

Remote control with the gear shift lever on the floor for gear shifting.

Gear ratioHigh; 1.000

Low; 2.050

Oil capacity1.45 lit. (1.53 U.S. quart)

Type of lubricantEngine oil

Refer to chart in Section 0

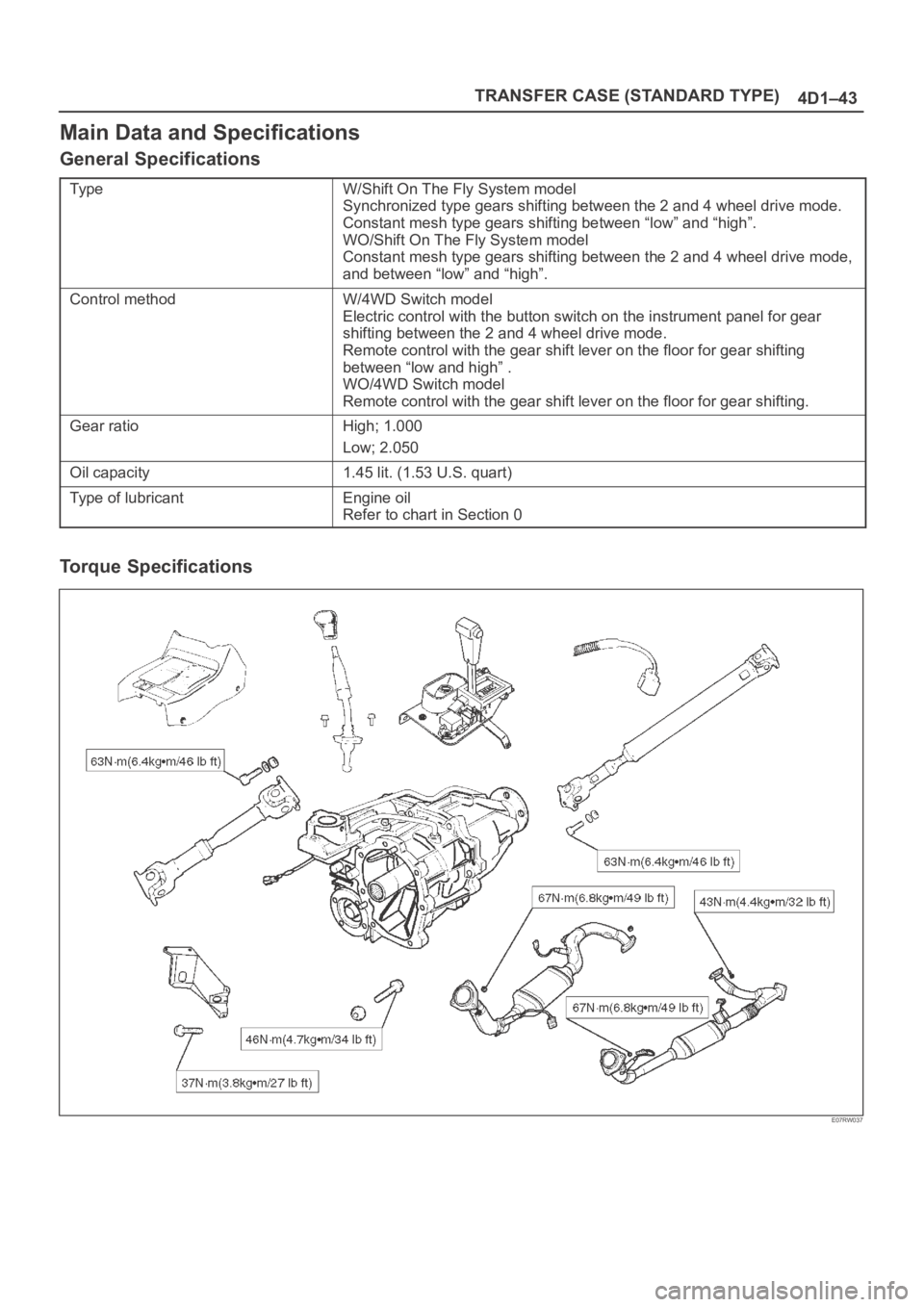

Torque Specifications

E07RW037

Page 4319 of 6000

4D2–12

TRANSFER CASE (TOD)

Transfer Cover Assembly

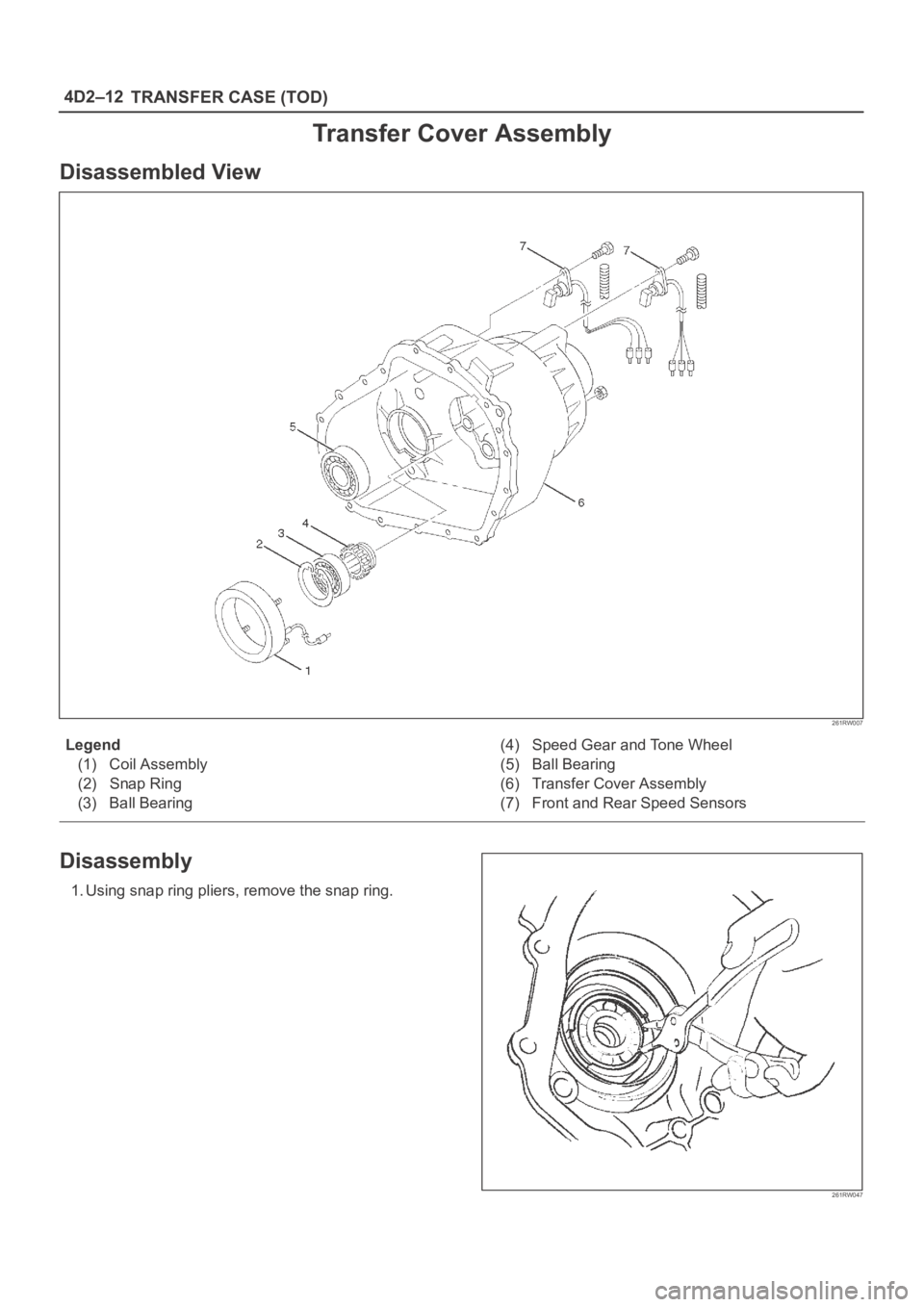

Disassembled View

261RW007

Legend

(1) Coil Assembly

(2) Snap Ring

(3) Ball Bearing(4) Speed Gear and Tone Wheel

(5) Ball Bearing

(6) Transfer Cover Assembly

(7) Front and Rear Speed Sensors

Disassembly

1. Using snap ring pliers, remove the snap ring.

261RW047

Page 4320 of 6000

4D2–13 TRANSFER CASE (TOD)

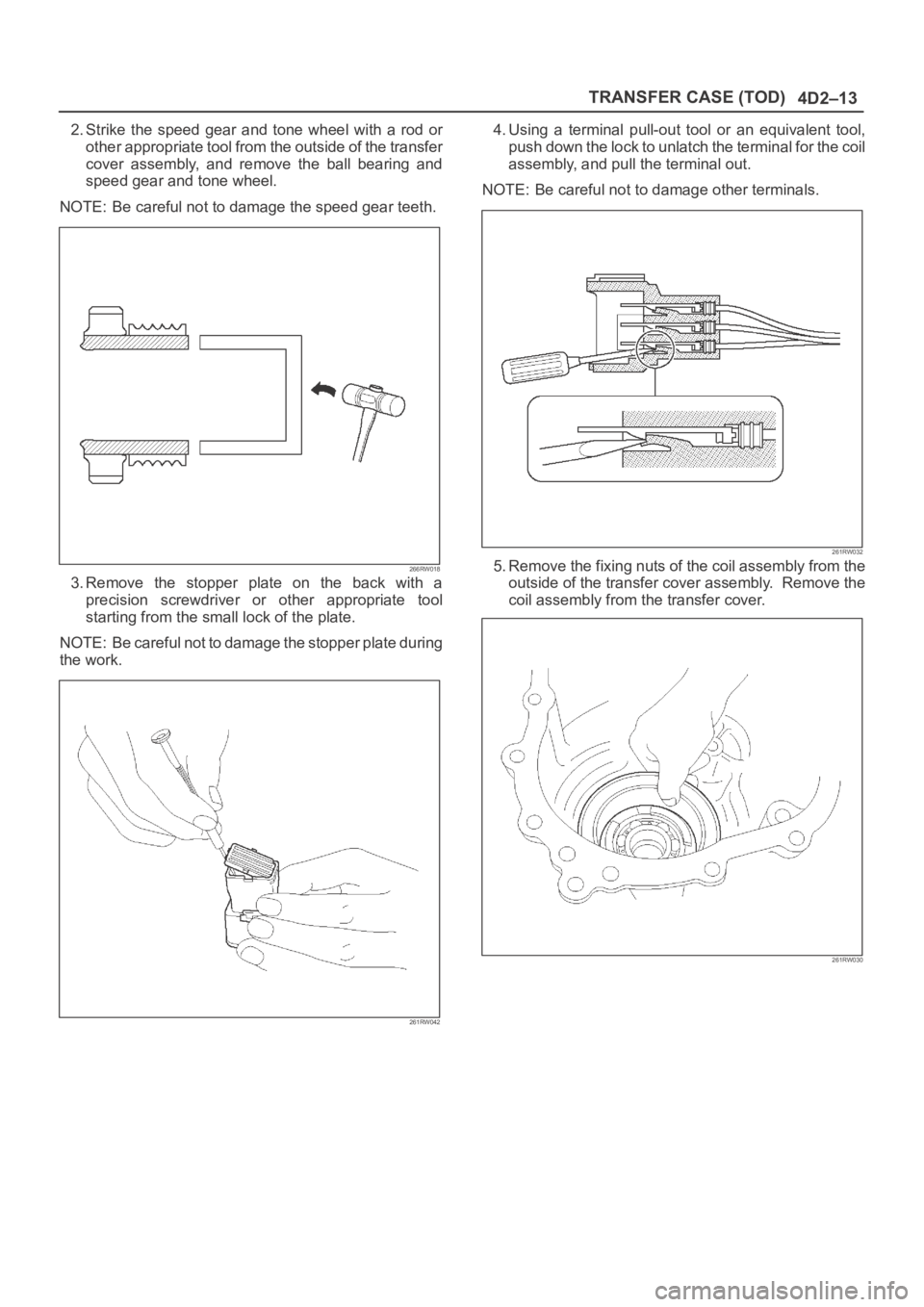

2. Strike the speed gear and tone wheel with a rod or

other appropriate tool from the outside of the transfer

cover assembly, and remove the ball bearing and

speed gear and tone wheel.

NOTE: Be careful not to damage the speed gear teeth.

266RW018

3. Remove the stopper plate on the back with a

precision screwdriver or other appropriate tool

starting from the small lock of the plate.

NOTE: Be careful not to damage the stopper plate during

the work.

261RW042

4. Using a terminal pull-out tool or an equivalent tool,

push down the lock to unlatch the terminal for the coil

assembly, and pull the terminal out.

NOTE: Be careful not to damage other terminals.

261RW032

5. Remove the fixing nuts of the coil assembly from the

outside of the transfer cover assembly. Remove the

coil assembly from the transfer cover.

261RW030

Page 4322 of 6000

4D2–15 TRANSFER CASE (TOD)

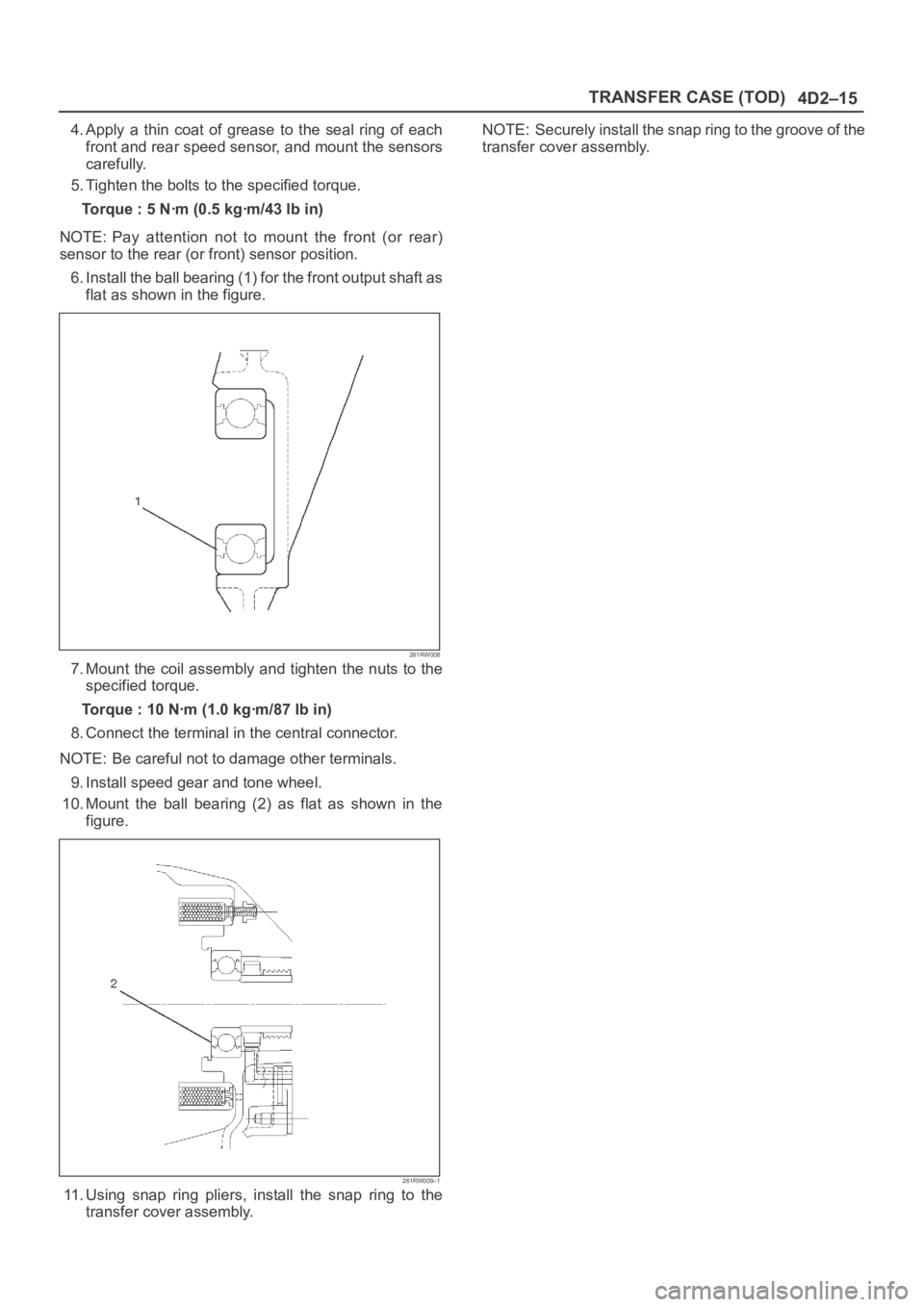

4. Apply a thin coat of grease to the seal ring of each

front and rear speed sensor, and mount the sensors

carefully.

5. Tighten the bolts to the specified torque.

Torque : 5 Nꞏm (0.5 kgꞏm/43 lb in)

NOTE: Pay attention not to mount the front (or rear)

sensor to the rear (or front) sensor position.

6. Install the ball bearing (1) for the front output shaft as

flat as shown in the figure.

261RW008

7. Mount the coil assembly and tighten the nuts to the

specified torque.

Torque : 10 Nꞏm (1.0 kgꞏm/87 lb in)

8. Connect the terminal in the central connector.

NOTE: Be careful not to damage other terminals.

9. Install speed gear and tone wheel.

10. Mount the ball bearing (2) as flat as shown in the

figure.

261RW009–1

11. Using snap ring pliers, install the snap ring to the

transfer cover assembly.NOTE: Securely install the snap ring to the groove of the

transfer cover assembly.

Page 4325 of 6000

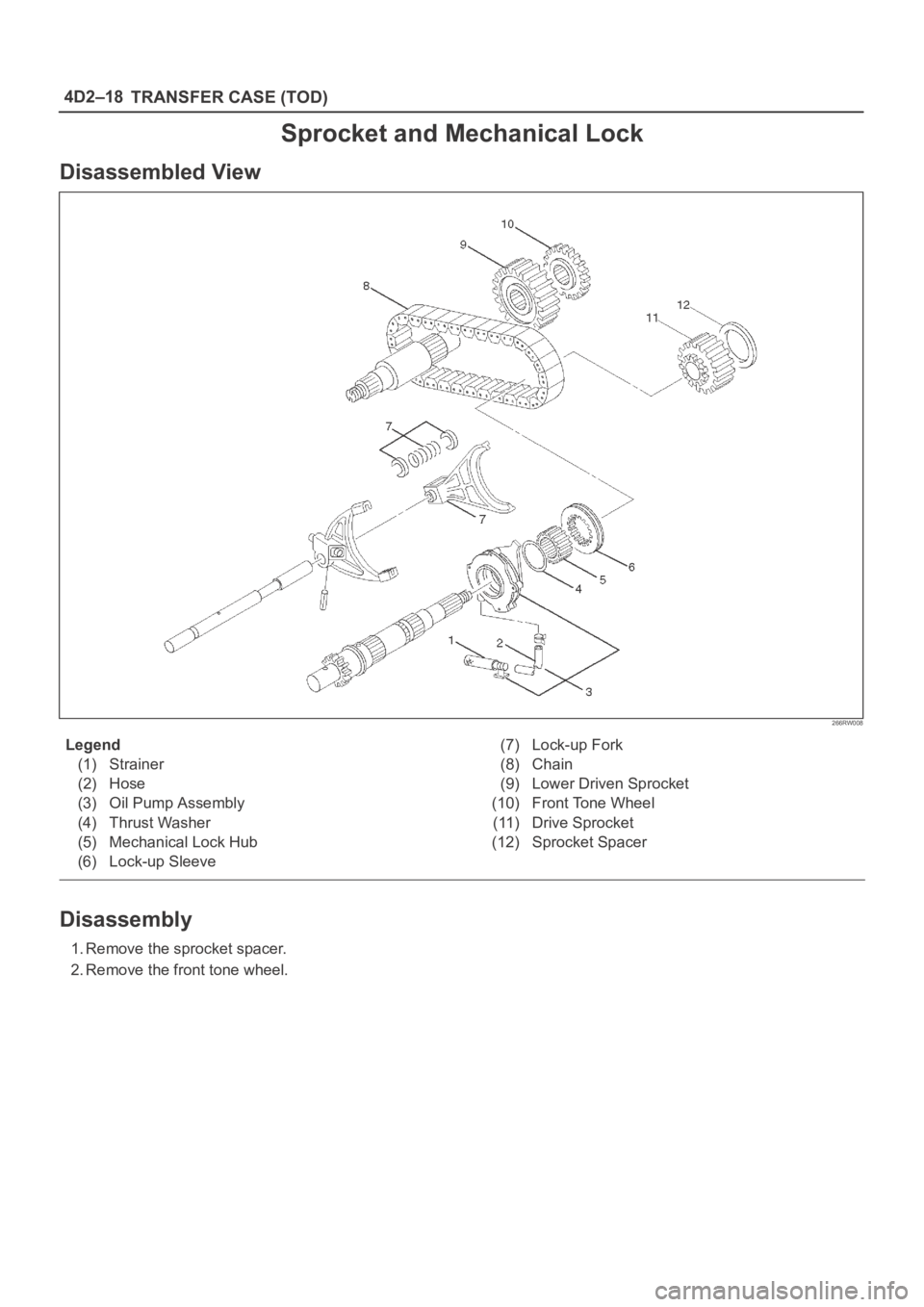

4D2–18

TRANSFER CASE (TOD)

Sprocket and Mechanical Lock

Disassembled View

266RW008

Legend

(1) Strainer

(2) Hose

(3) Oil Pump Assembly

(4) Thrust Washer

(5) Mechanical Lock Hub

(6) Lock-up Sleeve(7) Lock-up Fork

(8) Chain

(9) Lower Driven Sprocket

(10) Front Tone Wheel

(11) Drive Sprocket

(12) Sprocket Spacer

Disassembly

1. Remove the sprocket spacer.

2. Remove the front tone wheel.

Page 4344 of 6000

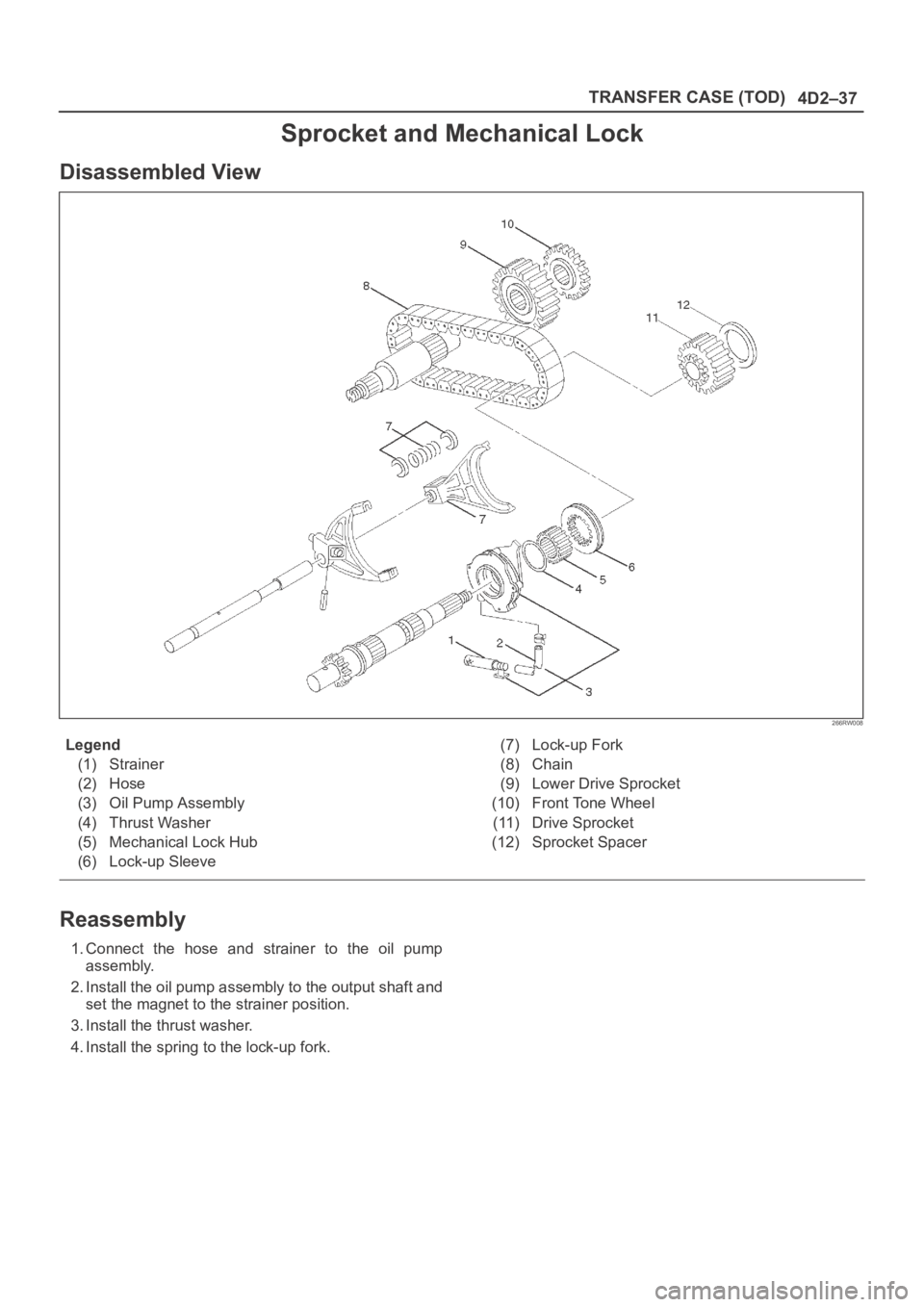

4D2–37 TRANSFER CASE (TOD)

Sprocket and Mechanical Lock

Disassembled View

266RW008

Legend

(1) Strainer

(2) Hose

(3) Oil Pump Assembly

(4) Thrust Washer

(5) Mechanical Lock Hub

(6) Lock-up Sleeve(7) Lock-up Fork

(8) Chain

(9) Lower Drive Sprocket

(10) Front Tone Wheel

(11) Drive Sprocket

(12) Sprocket Spacer

Reassembly

1. Connect the hose and strainer to the oil pump

assembly.

2. Install the oil pump assembly to the output shaft and

set the magnet to the strainer position.

3. Install the thrust washer.

4. Install the spring to the lock-up fork.

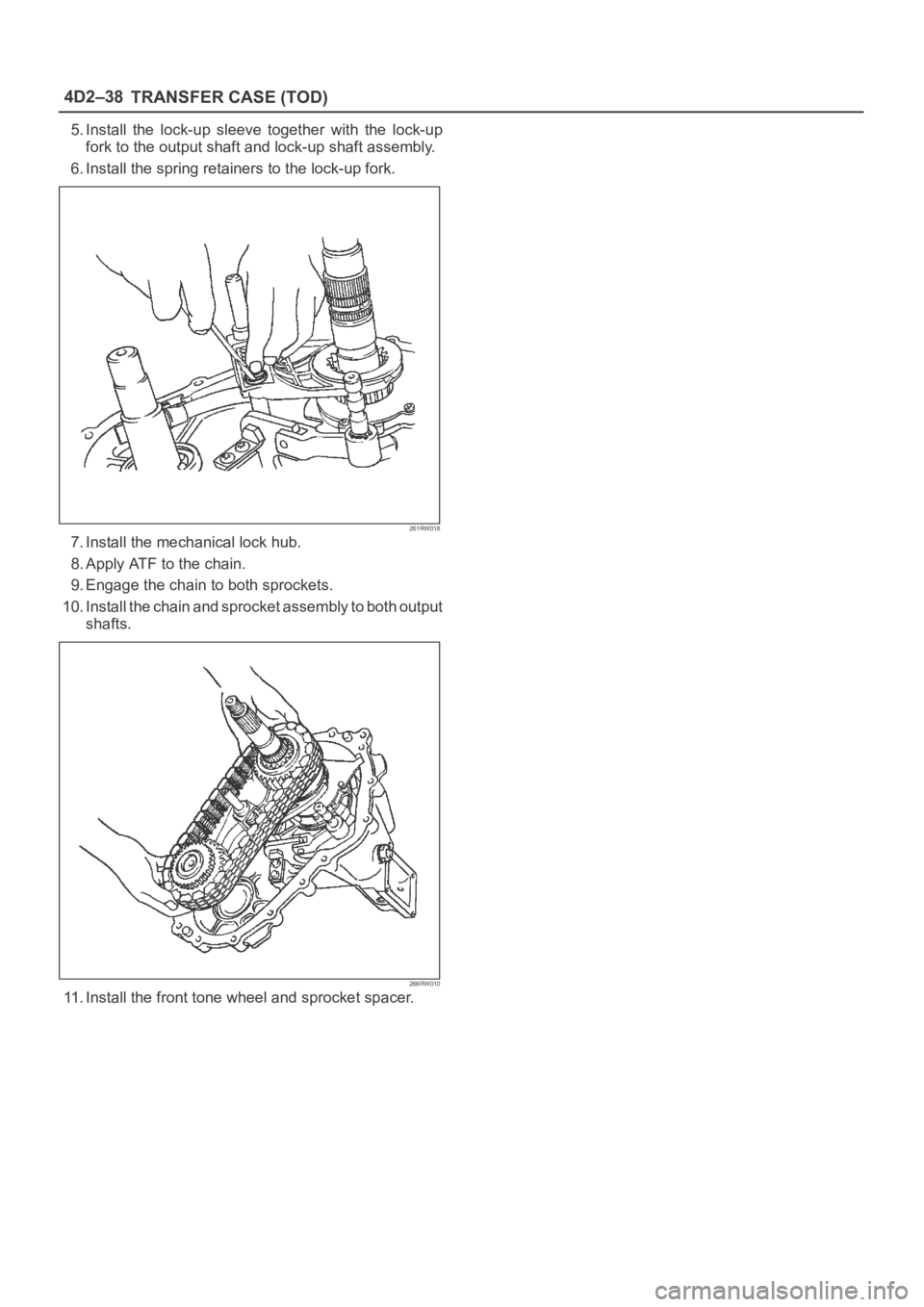

Page 4345 of 6000

4D2–38

TRANSFER CASE (TOD)

5. Install the lock-up sleeve together with the lock-up

fork to the output shaft and lock-up shaft assembly.

6. Install the spring retainers to the lock-up fork.

261RW018

7. Install the mechanical lock hub.

8. Apply ATF to the chain.

9. Engage the chain to both sprockets.

10. Install the chain and sprocket assembly to both output

shafts.

266RW010

11. Install the front tone wheel and sprocket spacer.

Page 4348 of 6000

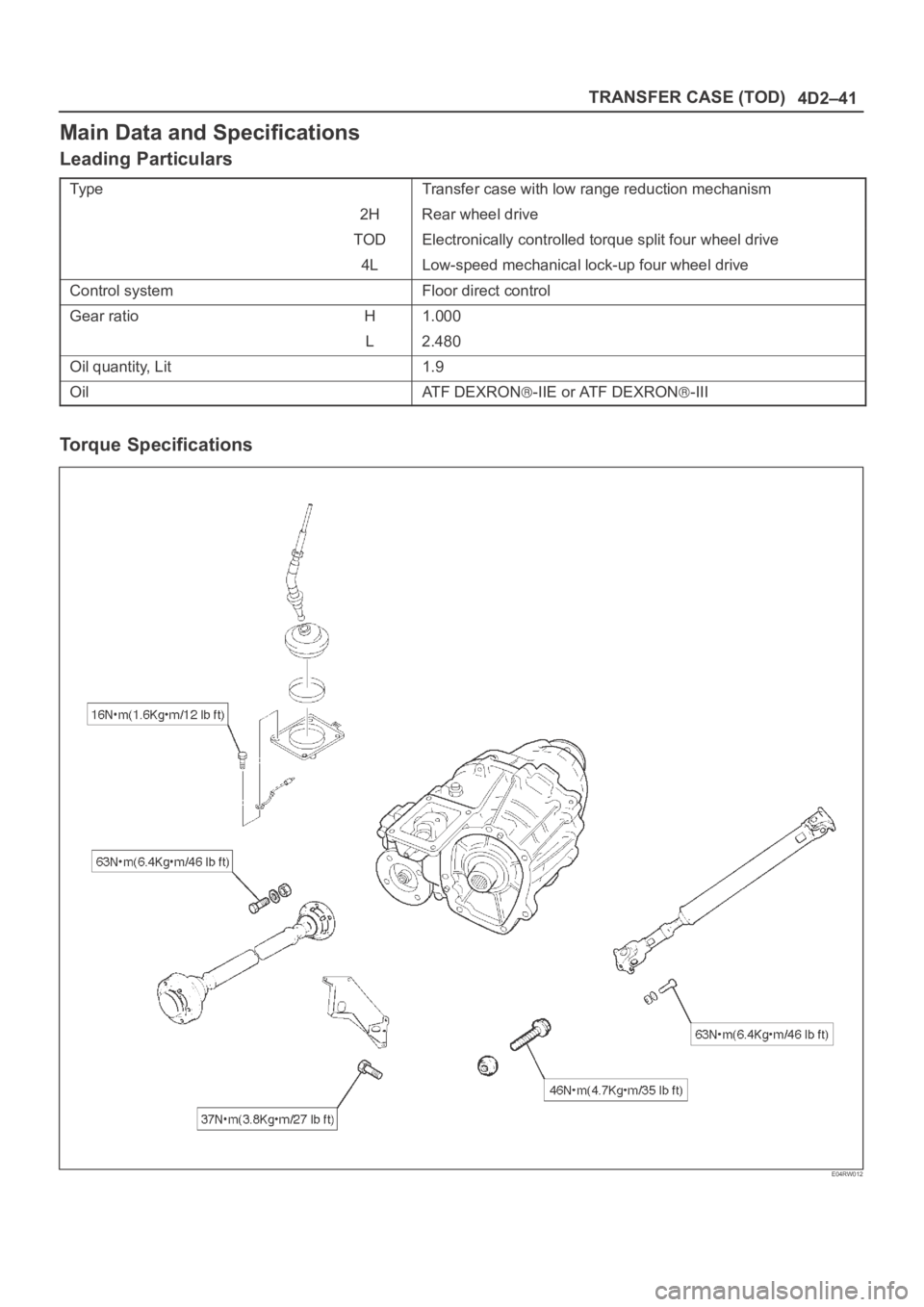

4D2–41 TRANSFER CASE (TOD)

Main Data and Specifications

Leading Particulars

Ty p eTransfer case with low range reduction mechanism

2H Rear wheel drive

TOD Electronically controlled torque split four wheel drive

4L Low-speed mechanical lock-up four wheel drive

Control systemFloor direct control

Gear ratioH1.000

L2.480

Oil quantity, Lit1.9

OilAT F D E X R O N-IIE or ATF DEXRON-III

Torque Specifications

E04RW012

Page 4351 of 6000

5A–1 BRAKE CONTROL SYSTEM

BRAKES

CONTENTS

Brake Control System 5A. . . . . . . . . . . . . . . . . . . .

Anti–lock Brake System 5B. . . . . . . . . . . . . . . . . . Power–Assisted Brake System 5C. . . . . . . . . . . .

Parking Brakes 5D. . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE CONTROL SYSTEM

CONTENTS

Service Precaution 5A–2. . . . . . . . . . . . . . . . . . . . . .

General Description 5A–3. . . . . . . . . . . . . . . . . . . . .

System Components 5A–3. . . . . . . . . . . . . . . . . . .

Electronic Hydraulic Control Unit (EHCU) 5A–3.

ABS Warning Light 5A–4. . . . . . . . . . . . . . . . . . . .

Wheel Speed Sensor 5A–4. . . . . . . . . . . . . . . . . .

G-Sensor 5A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal and Anti-lock Braking 5A–4. . . . . . . . . . .

Brake Pedal Travel 5A–4. . . . . . . . . . . . . . . . . . . .

Acronyms and Abbreviations 5A–4. . . . . . . . . . . .

General Diagnosis 5A–5. . . . . . . . . . . . . . . . . . . . . . .

General Information 5A–5. . . . . . . . . . . . . . . . . . . .

ABS Service Precautions 5A–5. . . . . . . . . . . . . . .

Computer System Service Precautions 5A–5. . .

General Service Precautions 5A–5. . . . . . . . . . . .

Note on Intermittents 5A–5. . . . . . . . . . . . . . . . . . .

Test Driving ABS Complaint Vehicles 5A–6. . . . .

“ABS” Warning Light 5A–6. . . . . . . . . . . . . . . . . . .

Normal Operation 5A–6. . . . . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 5A–6. . . . . . . . . . . .

Basic Inspection Procedure 5A–7. . . . . . . . . . . . .

Tech 2 Scan Tool 5A–8. . . . . . . . . . . . . . . . . . . . . .

Getting Started 5A–9. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure 5A–10. . . . . . . . . . . . . . . . . . .

Data List 5A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EHCU Connector Pin-out Checks 5A–12. . . . . . . .

Circuit Diagram (LHD model / 6VD1 and

4JG2) 5A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram (LHD model / 4JG2) 5A–14. . . . .

Circuit Diagram (LHD model / 4JG2) 5A–15. . . . .

Circuit Diagram (LHD model / 6VD1) 5A–16. . . . .

Circuit Diagram (LHD model / 6VD1) 5A–17. . . . .

Connector List (LHD model) 5A–18. . . . . . . . . . . .

Part Location (LHD model) 5A–20. . . . . . . . . . . . . .

Circuit Diagram (RHD model / 6VD1 and

4JG2) 5A–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram (RHD model / 4JG2) 5A–22. . . . .

Circuit Diagram (RHD model / 4JG2) 5A–23. . . . .

Circuit Diagram (RHD model / 6VD1) 5A–24. . . . .

Circuit Diagram (RHD model / 6VD1) 5A–25. . . . .

Circuit Diagram (RHD model / 6VE1 and

4JX1) 5A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Circuit Diagram (RHD model / 4JX1) 5A–27. . . . .

Circuit Diagram (RHD model / 4JX1) 5A–28. . . . .

Circuit Diagram (RHD model / 6VE1) 5A–29. . . . .

Circuit Diagram (RHD model / 6VE1) 5A–30. . . . .

Connector List (RHD model) 5A–31. . . . . . . . . . . .

Part Location (RHD model) 5A–34. . . . . . . . . . . . .

Symptom Diagnosis 5A–35. . . . . . . . . . . . . . . . . . . . .

Chart A–1 ABS Works Frequently But

Vehicle Does Not Decelerate 5A–35. . . . . . . . . . .

Chart TA-1 ABS Works Frequently But

Vehicle Does Not Decelerate (Use

TECH 2) 5A–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart A-2 Uneven Braking Occurs While

ABS Works 5A–36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart A-3, TA-3 The Wheels Are Locked 5A–36.

Chart A-4 Brake Pedal Feed Is Abnormal 5A–37.

Chart A-5, TA-5 Braking Sound (From

EHCU) Is Heard While Not Braking 5A–38. . . . . .

Diagnostic Trouble Codes 5A–39. . . . . . . . . . . . . . . .

Diagnosis By “ABS” Warning Light

Illumination Pattern 5A–40. . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Codes (DTCs) 5A–40. . . . . . .

Chart B-1 With the key in the ON position

(Before starting the engine). Warning light

(W/L) is not activated. 5A–43. . . . . . . . . . . . . . . . .

Chart B-2 EHCU Abnormality (DTC 14) 5A–43. . .

Chart B-3 Power Voltage Drop (DTC 15) 5A–44. .

Chart B-4 CLASS-2 Communication Line

Abnormality (DTC 16) 5A–44. . . . . . . . . . . . . . . . .

Chart B-5 G-Sensor Circuit (DTC 21) 5A–45. . . . .

Chart B-6 Abnormal Transmission Input

(DTC 23) 5A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-7 Transfer Monitor (DTC 24) 5A–47. . . . .

Chart B-8 EHCU Pump Motor And Motor

Relay Circuit (DTC 32) 5A–47. . . . . . . . . . . . . . . . .

Chart B-9 EHCU Pump Valve And Valve

Relay Circuit (DTC 35) 5A–47. . . . . . . . . . . . . . . . .

Chart B-10 FL Isolation Solenoid Valve

Abnormality (DTC 41) 5A–48. . . . . . . . . . . . . . . . .

Chart B-11 FL Dump Solenoid Valve

Abnormality (DTC 42) 5A–48. . . . . . . . . . . . . . . . .

Chart B-12 FR Isolation Solenoid Valve

Abnormality (DTC 43) 5A–48. . . . . . . . . . . . . . . . .

Chart B-13 FR Dump Solenoid Valve

Abnormality (DTC 44) 5A–49. . . . . . . . . . . . . . . . .

Chart B-14 Rear Isolation Solenoid Valve

Abnormality (DTC 45) 5A–49. . . . . . . . . . . . . . . . .

Chart B-15 Rear Dump Solenoid Valve

Abnormality (DTC 46) 5A–49. . . . . . . . . . . . . . . . .

Page 4353 of 6000

5A–3 BRAKE CONTROL SYSTEM

General Description

The Anti-lock Brake System (ABS) works on all four

wheels. A combination of wheel speed sensor and

Electronic Hydraulic Control Unit (EHCU) can determine

when a wheel is about to stop turning and adjust brake

pressure to maintain best braking.This system helps the driver maintain greater control of

the vehicle under heavy braking conditions.

C05RW027

Legend

(1) With P&B Valve Model

(2) With LSPV Model

(3) Electronic Hydraulic Control Unit (EHCU)

(4) Front Wheel Speed Sensor

(5) Rear Wheel Speed Sensor(6) G-Sensor

(7) Proportioning and Bypass (P&B) Valve

(8) Load Sensing Proportioning Valve (LSPV)

(9) Electronic Line

(10) Hydraulic Line

System Components

Electronic Hydraulic Control Unit (EHCU), four Wheel

Speed Sensors, Warning Light, and G-sensor.

Electronic Hydraulic Control Unit (EHCU)

T h e E H C U c o n s i s t s o f A B S c o n t r o l c i r c u i t s , f a u l t d e t e c t o r,

and a fail-safe. It drives the hydraulic unit according to the

signal from each sensor, cancelling ABS to return to