wheel OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4216 of 6000

4C–10

DRIVE SHAFT SYSTEM

8. Remove lock washer and lock screw.

9. Use wrench 5–8840–2117–0, remove hub nut.

411RW005

10. Remove hub and disc assembly.

11. Remove ABS sensor ring (If equipped).

12. Remove outer bearing.

13. Remove oil seal.

14. Remove inner bearing.

15. Remove bolt , if necessary, replace the wheel pin in

the following manner.

Apply a scribe mark(1) to disc to hub.

Clamp the hub and disc assembly in a vise, using

protective pads. Remove the 6 disc–to–hub

retaining bolts.

411RS003

Place hub on a suitable work surface and remove

the studs by using a hammer.

411RS004

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

Hub

Hub bearing oil seal

Knuckle spindle

Disc

Caliper

Shift on the fly system parts (Cap, Hub flange, Shim,

Snap ring)

ABS sensor ring (If equipped)

For inspection and servicing of disc caliper and related

parts, refer to Brakes section.

Page 4217 of 6000

4C–11 DRIVE SHAFT SYSTEM

Reassembly

1. Install wheel pin.

Place the hub on a wood workbench or a block of

wood approx. 6” by 6” to protect the wheel stud

ends and threads.

Insert a wheel stud using a hammer.

Be sure the wheel stud is started squarely and

seats completely.

411RS005

2. Align scribe marks(1) and attach the hub to the disc,

then tighten the bolts to the specified torque.

Torque: 103 Nꞏm (10.5 kgꞏm/76 lb ft)

411RS003

3. Use installer 5–8840–2119–0 and grip

5–8840–0007–0, then install the inner bearing by

driving it into the hub.

411RW006

4. Use installer 5–8840–2118–0 and grip

5–8840–0007–0, then install the outer bearing by

driving it into the hub.

411RW007

Page 4218 of 6000

4C–12

DRIVE SHAFT SYSTEM

5. Apply grease (NLGI No.2 or equivalent) to the lip

portion, then install oil seal by using installer

5–8840–2120–0 and grip 5–8840–0007–0.

411RW008

6. Install ABS sensor ring, then tighten the bolts to the

specified torque.

Torque: 18 Nꞏm (1.8 kgꞏm/13 lb ft)

7. Install hub and disc assembly.

Apply grease in the hub.

Apply wheel bearing type grease NLGI No. 2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23 oz)

Outer bearing: 10 g (0.35 oz)

Inner bearing: 15 g (0.53 oz)

411RS009

Legend

(1) Inner Bearing

(2) Hub

(3) Outer Bearing

8. Install hub nut. Turn the place where there is a

chamfer in the tapped hole to the outer side, then

attach the nut by using front hub nut wrench

5–8840–2117–0.

411RW005

Preload Adjustment

1. Tighten the hub nut to 29 Nꞏm (3.0 kgꞏm/22 lb ft),

then fully loosen the nut.

2. Tighten the hub nut to the value given below,

using a spring scale on the wheel pin.

New bearing and New oil seal

Bearing Preload: 20 – 25 N (2.0–2.5 kg/4.4 –

5.5 lb)

Used bearing and New oil seal

Bearing Preload: 12 – 18 N (1.2–1.8 kg/2.6 –

4.0 lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening the

bearing nut.

411RS011

Page 4219 of 6000

4C–13 DRIVE SHAFT SYSTEM

9. Install lock washer and lock screw in the following

manner.

Turn the side with larger diameter of the tapered

bore to the vehicle outer side, then attach the

washer.

If the bolt holes in the lock plate are not aligned with

the corresponding holes in the nut, reverse the lock

plate.

If the bolt holes are still out of alignment, turn in the

nut just enough to obtain alignment.

Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

10. Apply adhesive (LOCTITE 515 or equivalent) to both

joining flange faces then install hub flange.

11. Install snap ring and shim.

Adjust the clearance between the free wheeling hub

body and the snap ring.

Clearance: 0 mm–0.3 mm (0 in–0.012 in)

Shims Available: 0.2 mm, 0.3 mm, 0.5 mm,

1.0 mm (0.008 in, 0.012 in, 0.020 in, 0.039 in)

411RW002

12. Install hub cap.

13. Tighten the bolts to the specified torque.

Torque: 59 Nꞏm (6.0 kgꞏm/43 lb ft)

Page 4221 of 6000

4C–15 DRIVE SHAFT SYSTEM

3. Remove bolt.

Before removal, shift transfer lever into “2H” position,

set free wheeling hub knob into “FREE” position (1),

and run the vehicle about 50m (160 ft).

411RW010

4. Remove cover assembly.

5. Remove snap ring and shim.

6. Remove body assembly.

7. Remove lock washer and lock screw.

8. Remove hub nut by using wrench 5–8840–2117–0.

411RW005

9. Remove hub and disc assembly.

10. Remove ABS sensor ring (If equipped).

11. Remove outer bearing outer race.

12. Remove oil seal.13. Remove inner bearing outer race.

14. While pushing follower knob against cover, turn clutch

assembly clockwise and then remove clutch

assembly from knob.

411RW011

15. Remove gasket.

16. Remove snap ring.

17. Remove knob.

18. Remove compression spring.

19. Remove follower.

20. Remove retaining spring from clutch assembly by

turning it counterclockwise.

411RW012

21. Remove dedent ball and spring.

22. Remove X–ring.

23. Remove snap ring.

24. Remove inner assembly.

25. Remove snap ring.

26. Remove ring.

27. Remove spacer.

Page 4222 of 6000

4C–16

DRIVE SHAFT SYSTEM

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

Hub

Hub bearing, oil seal

Knuckle spindle

Disc

Caliper

Free wheeling hub parts (Clutch, knob, follower,

inner, ring and spring)

ABS sensor ring (if so equipped)

For inspection and servicing of disc caliper, and relative

parts, refer to Brakes section.

Reassembly

1. Install spacer.

Apply about 1 g wheel bearing grease to both face of

spacer.

2. Install ring.

Apply about 3 g wheel bearing grease to inside face

of ring.

3. Install snap ring

Assembly with grease surplus being left unwiped up

as illustrated.

411RW013

Legend

(1) Inner Assembly

(2) Apply Grease

(3) Body

4. Install inner assembly.

Apply grease to splined portion of body.

5. Install snap ring.6. Install X–ring.

Apply wheel bearing grease to hub lock ring and fit it

in knob paying attention to mounting direction.

NOTE: After fitting, make sure that the hub lock ring is not

twisted.

7. Apply wheel bearing grease to ball and spring and fit

them in knob.

8. Install knob.

1. Apply grease to outer circumference of knob and

inner circumference of cover.

2. Align detent ball (1) to a groove cut in the cover.

411RW014

9. Install snap ring.

Turn the smoother face to knob side.

10. Align the end of retaining spring (1) with clutch spring

groove (2) and fit in the spring.

411RW015

Page 4224 of 6000

4C–18

DRIVE SHAFT SYSTEM

17. Install oil seal by using installer 5–8840–2120–0 and

grip 5–8840–0007–0.

Apply grease (NLGI No.2 or equivalent) to the lip

portion.

411RW008

18. Install ABS sensor ring (if so equipped).

Tighten the bolts to the specified torque.

Torque:18Nꞏm (1.8kgꞏm/13lbft)

19. Install hub and disc assembly.

1. Apply grease in the hub.

2. Apply wheel bearing type grease NLGI No.2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23 oz)

Outer bearing: 10 g (0.35 oz)

Inner bearing: 15 g (0.53 oz)

20. Install hub nut.

1. Turn the place where there is a chamfer in the

tapped hole to the outer side, and attach the nut

by using wrench 5–8840–2117–0.

411RW005

Preload Adjustment

Tighten the hub nut to 29 Nꞏm (3.0 kgꞏm/22 lbꞏft),

then fully loosen the nut.

Tighten the hub nut to the value given below, using

a spring scale on the wheel pin.

Bearing Preload

New bearing and New oil seal:

20-25N (2-2.5 kg/4.4-5.5 lb)

Used bearing and New oil seal:

12-18N (1.2-1.8 kg/2.6-4.0 lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening

the bearing nut.

411RS011

Page 4225 of 6000

4C–19 DRIVE SHAFT SYSTEM

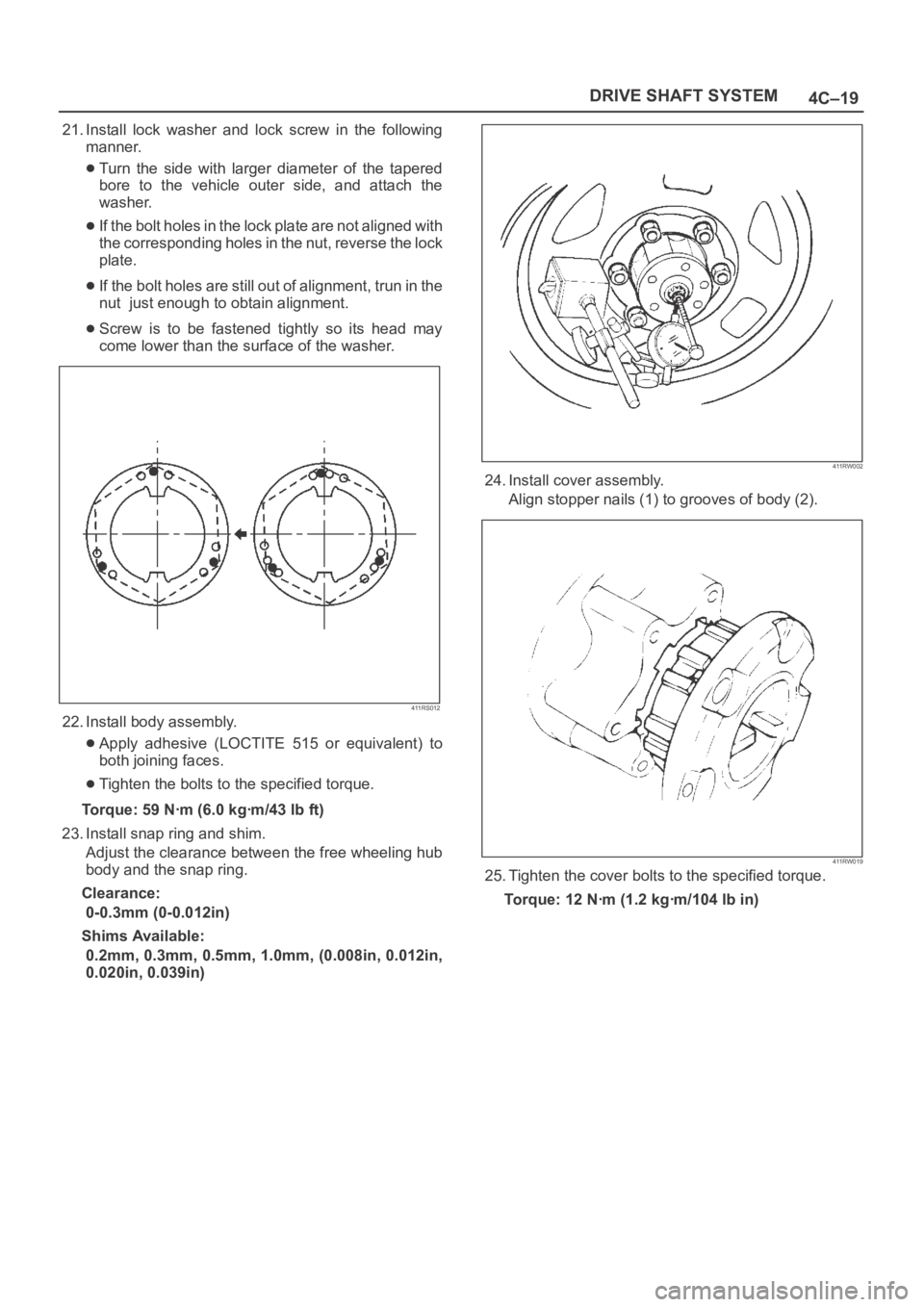

21. Install lock washer and lock screw in the following

manner.

Turn the side with larger diameter of the tapered

bore to the vehicle outer side, and attach the

washer.

If the bolt holes in the lock plate are not aligned with

the corresponding holes in the nut, reverse the lock

plate.

If the bolt holes are still out of alignment, trun in the

nut just enough to obtain alignment.

Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

22. Install body assembly.

Apply adhesive (LOCTITE 515 or equivalent) to

both joining faces.

Tighten the bolts to the specified torque.

Torque:59Nꞏm (6.0kgꞏm/43lbft)

23. Install snap ring and shim.

Adjust the clearance between the free wheeling hub

body and the snap ring.

Clearance:

0-0.3mm (0-0.012in)

Shims Available:

0.2mm, 0.3mm, 0.5mm, 1.0mm, (0.008in, 0.012in,

0.020in, 0.039in)

411RW002

24. Install cover assembly.

Align stopper nails (1) to grooves of body (2).

411RW019

25. Tighten the cover bolts to the specified torque.

Torque:12Nꞏm (1.2kgꞏm/104lbin)

Page 4228 of 6000

4C–22

DRIVE SHAFT SYSTEM

Front Drive Shaft Joint

Front Drive Shaft Joints Replace-

ment

Refer to Front Drive Axle Assembly Replacement in

this section, and refer to Front Hub and Disc in

Suspension section.

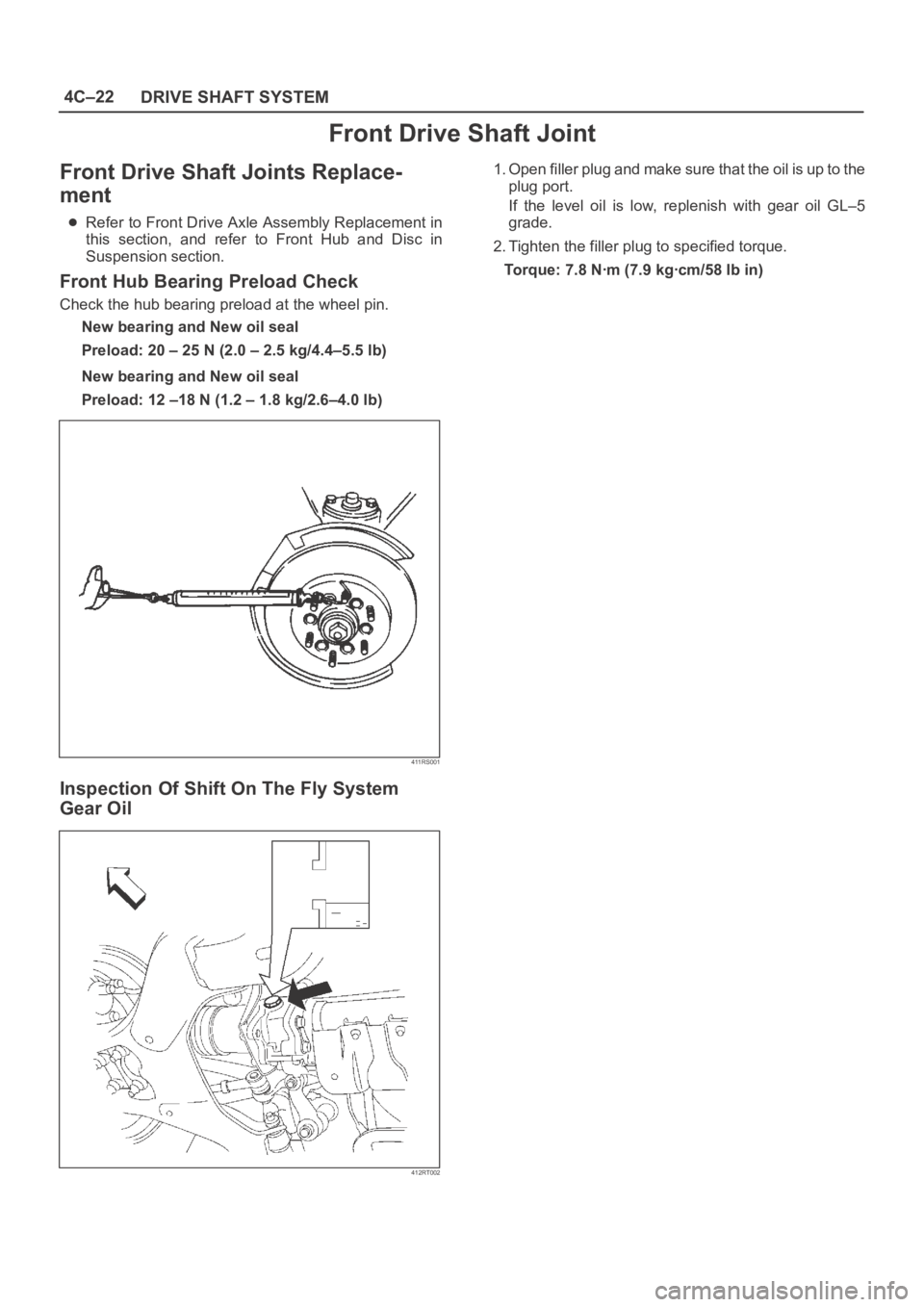

Front Hub Bearing Preload Check

Check the hub bearing preload at the wheel pin.

New bearing and New oil seal

Preload: 20 – 25 N (2.0 – 2.5 kg/4.4–5.5 lb)

New bearing and New oil seal

Preload: 12 –18 N (1.2 – 1.8 kg/2.6–4.0 lb)

411RS001

Inspection Of Shift On The Fly System

Gear Oil

412RT002

1. Open filler plug and make sure that the oil is up to the

plug port.

If the level oil is low, replenish with gear oil GL–5

grade.

2. Tighten the filler plug to specified torque.

Torque: 7.8 Nꞏm (7.9 kgꞏcm/58 lb in)

Page 4268 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–7

A/T, WO/Shift On The Fly, WO/4WD Switch, model

A07RW055

The transfer case is used to provide a means of providing

power flow to the front axle. The transfer case also

provides a means of disconnecting the front axle,

providing better fuel economy and quieter operation when

the vehicle is driven on improved roads where four wheel

drive is not required. In addition, the transfer case

provides an additional gear reduction when placed in low

range, which is useful when difficult off–road conditions

are encountered.

A floor mounted shift lever is used to select the high–low

range. When four wheel drive switch has been turned on,

the four wheel drive indicator light is designed to come on

when the front axle has been engaged.