Gas OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4281 of 6000

4D1–20

TRANSFER CASE (STANDARD TYPE)

Removal

1. Remove the speedometer sensor.

2. Remove the plate.

3. Remove the speedometer driven gear bushing and

driven gear.

NOTE: Apply a reference mark to the driven gear bushing

before removal.

4. Remove the front companion flange and the rear

companion flange, using the flange companion holder

5–8840–0133–0 (J–8614–11) to remove the end

nuts.

262RW067

NOTE: Use a universal puller to remove the rear

companion flange.

5. Disconnect the transfer breather hose from the

control box.

6. Remove the control box assembly.

7. Remove the transfer rear cover assembly from the

transfer case assembly.

Installation

1. Apply the recommended liquid gasket (LOCTITE

17430) or its equivalent to the transfer rear cover

fitting faces.

220RS017

2. Install the transfer rear cover assembly to the transfer

case assembly.

3. Perform the following steps before fitting the transfer

rear case:

1. Shift the high–low shift rod to the 4H side.

2. Turn the select rod counterclockwise so that the

select block projection may enter into the

2WD–4WD shift block.

3. The cut–away portion of the select rod head (9)

should align with that of the rear case hole’s

stopper (10).

230RW004

4. Tighten the transfer rear case bolts to the specified

torque.

Torque: 37 Nꞏm (3.8kgꞏm/27 lb ft)

Page 4289 of 6000

4D1–28

TRANSFER CASE (STANDARD TYPE)

Inspection and Repair

Refer to “TRANSFER CASE ASSEMBLY” in this section

for inspection and repair.

Reassembly

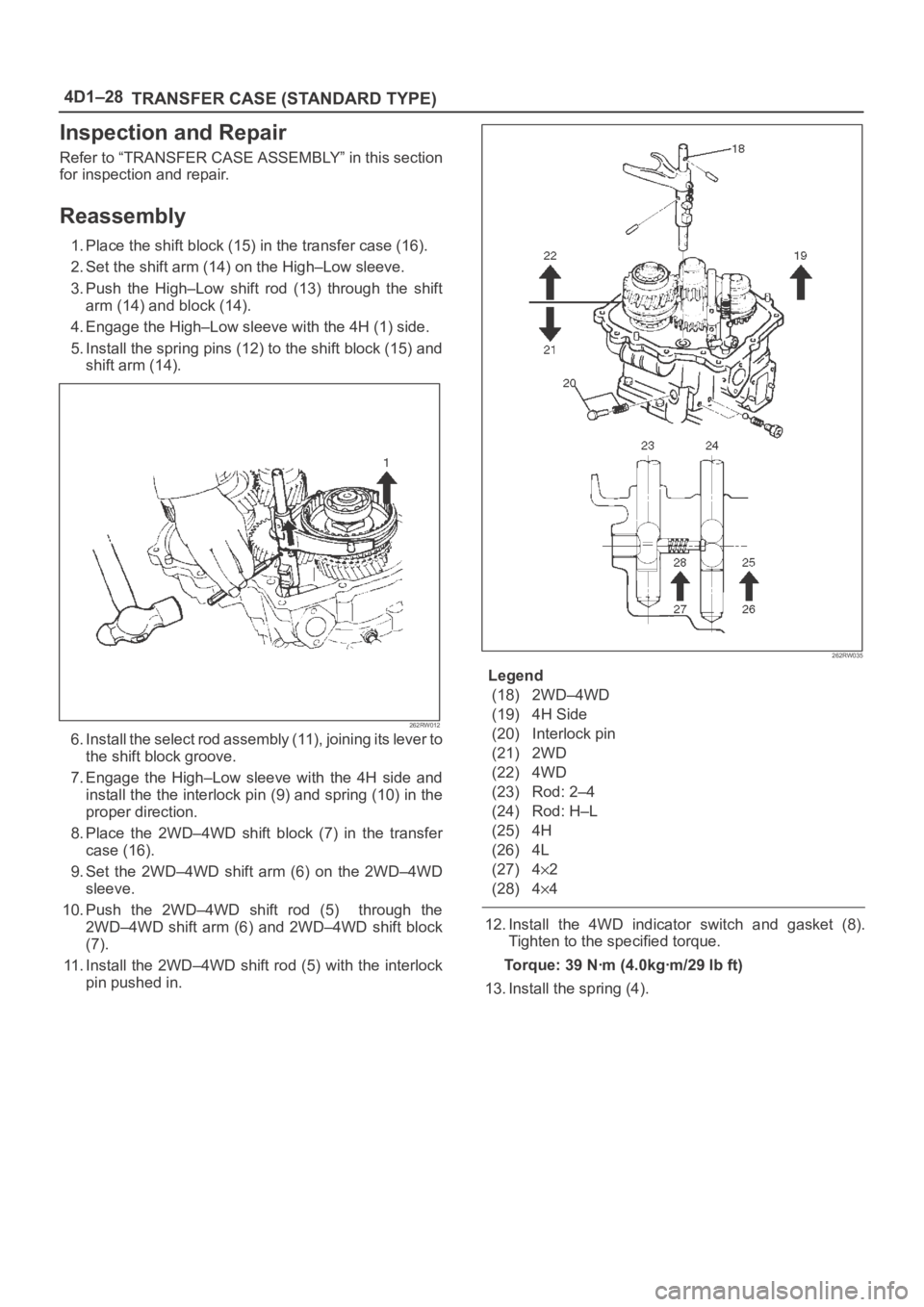

1. Place the shift block (15) in the transfer case (16).

2. Set the shift arm (14) on the High–Low sleeve.

3. Push the High–Low shift rod (13) through the shift

arm (14) and block (14).

4. Engage the High–Low sleeve with the 4H (1) side.

5. Install the spring pins (12) to the shift block (15) and

shift arm (14).

262RW012

6 . I n s t a l l t h e s e l e c t r o d a s s e m b l y ( 11 ) , j o i n i n g i t s l e v e r t o

the shift block groove.

7. Engage the High–Low sleeve with the 4H side and

install the the interlock pin (9) and spring (10) in the

proper direction.

8. Place the 2WD–4WD shift block (7) in the transfer

case (16).

9. Set the 2WD–4WD shift arm (6) on the 2WD–4WD

sleeve.

10. Push the 2WD–4WD shift rod (5) through the

2WD–4WD shift arm (6) and 2WD–4WD shift block

(7).

11. Install the 2WD–4WD shift rod (5) with the interlock

pin pushed in.

262RW035

Legend

(18) 2WD–4WD

(19) 4H Side

(20) Interlock pin

(21) 2WD

(22) 4WD

(23) Rod: 2–4

(24) Rod: H–L

(25) 4H

(26) 4L

(27) 4

2

(28) 4

4

12. Install the 4WD indicator switch and gasket (8).

Tighten to the specified torque.

Torque: 39 Nꞏm (4.0kgꞏm/29 lb ft)

13. Install the spring (4).

Page 4317 of 6000

4D2–10

TRANSFER CASE (TOD)

6. Remove the offset lever set bolt on the right side.

261RW015

7. Remove the offset lever lock spring pin.

NOTE: When removing the spring pin, note the recess

position of the pin.

261RW016

8. Remove the offset lever.

261RW017

9. Remove the sixteen bolts and detach the transfer

cover assembly from the transfer case assembly.

NOTE: When removing the transfer cover assembly, be

careful not to damage the oil seal.

Reassembly

1. Apply liquid gasket (Loctite 598 or equivalent)

uniformly to the mating face that contacts the transfer

case.

261RW023

Page 4501 of 6000

6A–5

ENGINE MECHANICAL

4. Engine Lacks Compression

Condition

Possible causeCorrection

Engine lacks compressionSpark plug loosely fitted or spark

plug gasket defectiveTighten to specified torque or replace

gasket

Valve timing incorrectAdjust

Cylinder head gasket defectiveReplace gasket

Valve incorrectly seatedLap valve

Valve stem seizedReplace valve and valve guide

Valve spring weakened or brokenReplace

Cylinder or piston rings wornOverhaul engine

Piston ring seizedOverhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking speed

is approximately 300 rpm.7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle reaches

the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

Page 4502 of 6000

6A–6

ENGINE MECHANICAL

Rough Engine Idling or Engine Stalling

ConditionPossible causeCorrection

Trouble in fuel injection systemIdle air control valve defectiveReplace

Throttle shutting off incompleteCorrect or replace

Throttle position sensor circuit open

or shortedCorrect or replace

Fuel injector circuits open or shortedCorrect or replace

Fuel injectors damagedReplace

Fuel pump relay defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or poor connectionsCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature Sensor

circuit open or poor connectionsCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Intake Air Temperature sensor circuit

open or poor connectionsCorrect or replace

Intake Air Temperature sensor

defectiveReplace

Knock Sensor (KS) cable broken or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or groundCorrect or replace

KS Module defectiveReplace

Vehicle Speed Sensor circuit open or

shortedCorrect or replace

Vehicle Speed Sensor defectiveReplace

Trouble in emission control systemPowertrain Control Module defectiveReplace

Exhaust Gas Recirculation Valve

circuit open or poor connectionsCorrect or replace

Exhaust Gas Recirculation Valve

faultyReplace

Canister purge valve circuit open or

poor connectionsCorrect or replace

Canister purge valve defectiveReplace

Evaporative Emission Canister

Purge control valve defectiveReplace

Trouble in ignition systemRefer to “Hard Start”

Page 4507 of 6000

6A–11

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine overheatingLevel of Engine Coolant too lowReplenish

Fan clutch defectiveReplace

Incorrect fan installedReplace

Thermostat defectiveReplace

Engine Coolant pump defectiveCorrect or replace

Radiator cloggedClean or replace

Radiator filler cap defectiveReplace

Level of oil in engine crankcase too

low or wrong engine oilChange or replenish

Resistance in exhaust system

increasedClean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrectReplace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shortedCorrect or replace

Cylinder head gasket damagedReplace

Engine overcoolingThermostat defectiveReplace (Use a thermostat set to

open at 82

C (180F))

Engine lacks compression————Refer to Hard Start

OthersTire inflation pressure abnormalAdjust to recommended pressures

Brake dragAdjust

Clutch slippingAdjust or replace

Level of oil in engine crankcase too

highCorrect level of engine oil

Exhaust Gas Recirculation Valve

defectiveReplace

Engine Noisy

Abnormal engine noise often consists of various noises

originating in rotating parts, sliding parts and othermoving parts of the engine. It is, therefore, advisable to

locate the source of noise systematically.

Condition

Possible causeCorrection

Noise from crank journals or from

crank bearings

(Faulty crank journals and crankOil clearance increased due to worn

crank journals or crank bearingsReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

yj

bearings usually make dull noise that

becomes more evident when

accelerating)Crankshaft out of roundReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crank bearing seizedCrank bearing seized. Replace crank

bearings and crankshaft or regrind

crankshaft and install the undersize

bearing

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with defectivebearing by listening for abnormal noise that stops when

spark plug is shorted out.

Page 4510 of 6000

6A–14

ENGINE MECHANICAL

Condition CorrectionPossible cause

Trouble in emission control systemHeated Oxygen Sensor circuit openCorrect or replace

Heated Oxygen Sensor defectiveReplace

Signal vacuum hose loosely fitted or

defectiveCorrect or replace

EGR Valve circuit open or shortedCorrect or replace

Exhaust Gas Recirculation Valve

defectiveReplace

ECT Sensor circuit open or shortedCorrect or replace

Canister Purge Valve circuit open or

shortedCorrect or replace

Canister Purge Valve defectiveReplace

ECT Sensor defectiveReplace

Positive Crankcase Ventilation

(PCV) valve and hose cloggedCorrect or replace

Evaporator systemRefer to Section 6E

Trouble in ignition system————Refer to “Engine Lacks Power”

Trouble in cylinder head partsCarbon deposits in combustion

chamberRemove carbon

Carbon deposit on valve, valve seat

and valve guideRemove carbon

Engine Oil Consumption Excessive

ConditionPossible causeCorrection

Oil leakingOil pan drain plug looseRetighten or replace gasket

Crankcase fixing bolts loosenedRetighten

Oil pan setting bolts loosenedRetighten

Oil pan gasket brokenReplace gasket

Front cover retaining bolts loose or

gasket brokenRetighten or replace gasket

Head cover fixing bolts loose or

gasket brokenRetighten or replace gasket

Oil cooler adapter crackedReplace

Oil cooler center bolt looseRetighten

Oil cooler O–ring brokenReplace

Oil cooler piping loose or brokenRetighten or replace

Oil filter adapter crackedReplace

Oil filter attaching bolt loose or rubber

gasket brokenRetighten or replace oil filter

Oil cooler brokenReplace

Crankshaft front or rear oil seal

defectiveReplace oil seal

Oil pressure unit loose or brokenRetighten or replace

Blow–by gas hose brokenReplace hose

Positive Crankcase Ventilation Valve

cloggedClean

Engine/Transmission coupling failedReplace oil seal

Page 4511 of 6000

6A–15

ENGINE MECHANICAL

Condition CorrectionPossible cause

Oil leaking into combustion

chambers due topoor seal in valve

Valve stem oil seal defectiveReplace

chambers due to oor seal in valve

systemValve stem or valve guide wornReplace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in cylinder

t

Cylinders and pistons worn

excessivelyReplace cylinder body assembly and

pistons

partsPiston ring gaps incorrectly

positionedCorrect

Piston rings set with wrong side upCorrect

Piston ring stickingReplace cylinder body assembly and

pistons

Piston ring and ring groove wornReplace pistons and others

Return ports in oil rings cloggedClean piston and replace rings

Positive Crankcase Ventilation

System malfunctioningPositive Crankcase Ventilation Valve

cloggedClean

OthersImproper oil viscosityUse oil of recommended S.A.E.

viscosity

Continuous high speed driving

and/or severe usage such as trailer

towingContinuous high speed operation

and/or severe usage will normally

cause increased oil consumption

Fuel Consumption Excessive

ConditionPossible causeCorrection

Trouble in fuel systemMixture too rich or too lean due to

trouble in fuel injection systemRefer to “Abnormal Combustion”

Fuel cut function does not workRefer to “Abnormal Combustion”

Trouble in ignition systemMisfiring or abnormal combustion

due to trouble in ignition systemRefer to “Hard Start” or “Abnormal

Combustion”

OthersEngine idle speed too highReset Idle Air Control Valve

Returning of accelerator control

sluggishCorrect

Fuel system leakageCorrect or replace

Clutch slippingCorrect

Brake dragCorrect

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Excessive Exhaust Gas

Recirculation flow due to trouble in

Exhaust Gas Recirculation systemRefer to “Abnormal Combustion”

Page 4512 of 6000

6A–16

ENGINE MECHANICAL

Lubrication Problems

ConditionPossible causeCorrection

Oil pressure too lowWrong oil in useReplace with correct engine oil

Relief valve stickingReplace

Oil pump not operating properlyCorrect or replace

Oil pump strainer cloggedClean or replace strainer

Oil pump wornReplace

Oil pressure gauge defectiveCorrect or replace

Crankshaft bearing or connecting

rod bearing wornReplace

Oil contaminationWrong oil in useReplace with correct engine oil

Oil filter cloggedReplace oil filter

Cylinder head gasket damageReplace gasket

Burned gases leakingReplace piston and piston rings or

cylinder body assembly

Oil not reaching valve systemOil passage in cylinder head or

cylinder body cloggedClean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the

specified standard.

c. Refer to the “Maintenance and Lubrication” section

of this manual.

2. Check the engine oil level.

The level should fall somewhere between the “ADD”

and the “FULL” marks on the oil level dipstick.

If the oil level does not reach the “ADD” mark on the

oil level dipstick, engine oil must be added.3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal

operating temperature (About 80

C).

6. Measure the oil pressure.

Oil pressure should be:

392–550 kPa (56.9–80.4 psi) at 3000 rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

Page 4517 of 6000

6A–21

ENGINE MECHANICAL

Cylinder Head Cover RH

Removal

1. Disconnect battery ground cable.

2. Remove battery from the vehicle.

3. Drain engine coolant from faucet bottom of radiator.

4. Remove engine cover from the dowels on the

common chamber.

F06RW018

5. Remove air cleaner duct assembly (3) and air cleaner

element (4).

130RW001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

NOTE: Disconnect the mass air flow (MAF) sensor

connector, intake air temperature (IAT) sensor connector,

and positive crankcase ventilation (PCV) hose before

hand the air cleaner duct assembly is removed.

6. Disconnect following wiring connectors and bonding

cable:

Exhaust Gas Recirculation (EGR) valve

Fuel injectors for right bank

Ignition coils for right bank

Bonding cable

Othres as necessitated

7. Disconnect radiator upper and lower hoses.

8. Remove engine harness from the cylinder head

cover.

9. Remove the upper fan guide.

10. Remove cooling fan and clutch assembly.

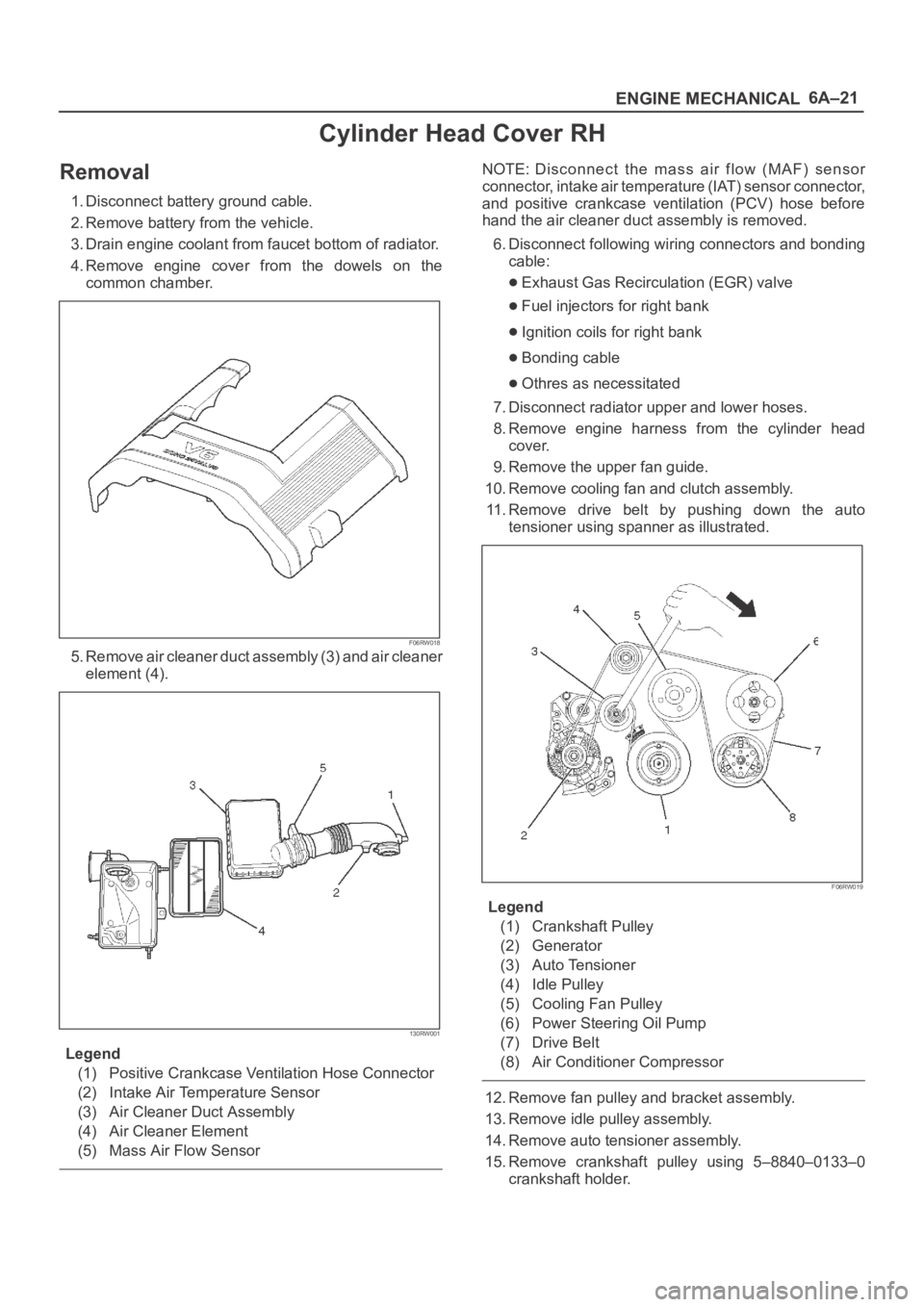

11. Remove drive belt by pushing down the auto

tensioner using spanner as illustrated.

F06RW019

Legend

(1) Crankshaft Pulley

(2) Generator

(3) Auto Tensioner

(4) Idle Pulley

(5) Cooling Fan Pulley

(6) Power Steering Oil Pump

(7) Drive Belt

(8) Air Conditioner Compressor

12. Remove fan pulley and bracket assembly.

13. Remove idle pulley assembly.

14. Remove auto tensioner assembly.

15. Remove crankshaft pulley using 5–8840–0133–0

crankshaft holder.