battery capacity OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 854 of 6000

5A–44

BRAKE CONTROL SYSTEM

Chart B-3 Power Voltage Drop (DTC 15)

StepActionYe sNo

1Is the battery voltage normal? (Battery capacity check)

Go to Step 2

Charge or

replace battery.

Go to Step 2

21. Turn the key off.

2. Disconnect EHCU connector.

3. Turn the key on.

Is the voltage between EHCU connector terminals 8 and 15,

higher than 10V?Check harness

connector for

suspected

disconnection.

Fault found:

Repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 3

Repair harness or

connector.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-4 CLASS-2 Communication Line Abnormality (DTC 16)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU and PCM connector.

Is there continuity between EHCU connector terminals 25 and

ground?

Go to Step 2

Repair harness or

connector.

Go to Step 3

21. Connect EHCU connector.

2. Clear diagnostic trouble code.

3. Turn the key on.

Is the diagnostic trouble code 16 shown on the displayed?Check the PCM

harness. Refer to

6E section.

Go to Step 3

Replace EHCU.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Page 1082 of 6000

ENGINE ELECTRICAL6D1–3

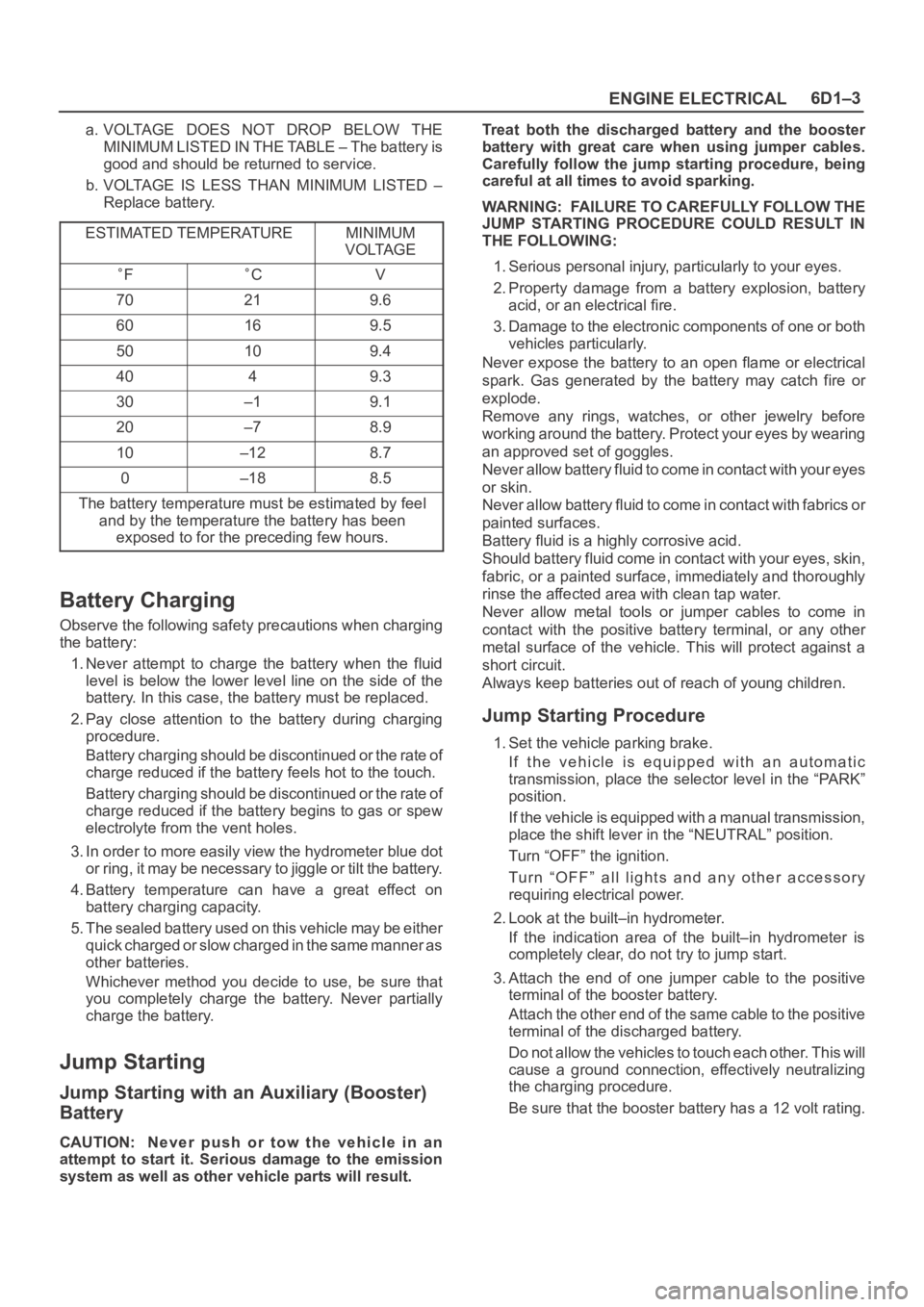

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

Page 1846 of 6000

ENGINE FUEL 6C – 1

ENGINE FUEL

CONTENTS

GENERAL DESCRIPTION

General Description . . . . . . . . . . . . . . . . . . 6C–1

On-Vehicle Service . . . . . . . . . . . . . . . . . . 6C–7

Fuel Filter Assembly . . . . . . . . . . . . . . . . 6C–7

Fuel Filter Cartridge . . . . . . . . . . . . . . . . 6C–7

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . 6C–9

Fuel Pump Pipe . . . . . . . . . . . . . . . . . . . 6C–13High Pressure Oil Pump . . . . . . . . . . . . . 6C–15

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . 6C–20

Fuel Gauge Unit . . . . . . . . . . . . . . . . . . . 6C–21

Fuel Filler Cap . . . . . . . . . . . . . . . . . . . . 6C–21

To realize the compatibility between low exhaust

emission and high engine output, an HEUI

(Hydraulically actuated Electronically controlled Unit

Injector) system, has been introduced. This system is

comprised of a hydraulic system, fuel system, and

electronic control system, using a high-pressure oil

pump in place of the conventional fuel injection pump.

The oil pressurized by means of this pump and by

signals from the ECM (Electronic Control Module)

actuates the fuel injector provided for each cylinder.

Inside of the fuel injector, fuel pressure is increased due

to the high-pressure oil. The ECM detects the driving

state of the vehicle, forms, signals sent by engine and

other part sensors, which determines the optimum fuel

injection amount and timing, thus controlling the fuel

injectors. Thus high engine output, good fuel economy,

and low exhaust emission are realized.When working on the fuel system, there are several

things to keep in mind:

1) Any time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

2) Always keep a dry chemical (Class B) fire

extinguisher near the work area.

3) Replace all pipes with the same pipe and fittings

that were removed.

Clean and inspect “O” rings. Replace where

required.

4) Always relieve the line pressure before servicing

any fuel system components.

5) Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

6) After maintenance work, push priming pump and

send enough fuel to the fuel system before starting

the engine.

NOTE: In comparison with the conventional engine,

the capacity of fuel passage in the 4JX1 engine is

larger. It takes the priming pump more time to fill the

engine with fuel.

Page 1870 of 6000

ENGINE ELECTRICAL 6D – 3

ON-VEHICLE SERVICE

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the rate

of charge reduced if the battery feels hot to the

touch.

Battery charging should be discontinued or the rate

of charge reduced if the battery begins to gas or

spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue

dot or ring, it may be necessary to jiggle or tilt the

battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the same

manner as other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: Failure to carefully follow the jump

starting procedure could result in the following:

1. Serious personal injury, particularly to your

eyes.

2. Property damage from a battery explosion,

battery acid, or an electrical fire.

3. Damage to the electronic components of one or

both vehicles.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode. Remove any rings, watches, or other jewelry

before working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with your

eyes or skin.

Never allow battery fluid to come in contact with fabrics

or painted surfaces.

Battery fluid is a highly corrosive acid.Should battery fluid come in contact with your eyes,

skin, fabric, or a painted surface, immediately and

thoroughly rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the “PARK”

position.

If the vehicle is equipped with a manual

transmission place the shift lever in the “NEUTRAL”

position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the A/C compressor

bracket or the generator mounting bracket) of the

vehicle with the discharged battery.

This ground connection must be at least 450 mm

(18 in) from the battery of the vehicle whose battery

is being charged.

WARNING: Never attach the end of the jumper

cable directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical

accessories have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable from

the vehicle with the discharged battery.

Page 1871 of 6000

6D – 4 ENGINE ELECTRICAL

REMOVAL AND INSTALLATION OF THE

BATTERY

REMOVAL

1. Negative cable

2. Positive cable

3. Retainer screw and rods

4. Retainer

5. Battery

INSTALLATION

To install the battery, follow the removal procedure in

the reverse order, noting the following points:

1. Make sure that the rod is hooked on the body side.

065RW029

MAIN DATA AND SPECIFICATIONS

Model (JIS) 80D26R–MF 75D26R–MF

Voltage (V) 12 12

Cold-Cranking Performance (Amp) 582 490

Reserve Capacity (Min) 133 123

Load Test (Amp) 300 300

Fast Charge Maximum Amperage (Amp) 6.5 6.5

Page 2597 of 6000

The chassis electrical system is a 12–volt system with a

negative ground polarity.

Wire size are appropriate to respective circuits, and

classified by color. (The classification of harnesses by

color is shown on the circuit diagram for ease of harness

identification.)

The wire size is determined by load capacity and the

length of wire required.

The vehicle harnesses are: body harness, chassis

harness, engine room harness, instrument harness,

transmission harness, engine ECGI harness, dome light

harness, door harness, rear body harness, tailgate

harness, SRS harness and battery cables.

The harnesses are protected either by tape or corrugated

tube, depending on harness location.

The circuit for each system consists of the power source,

wire, fuse, relay, switch, load parts and ground, all of

which are shown on the circuit diagram.

In this section, each electrical device is classified by

system.

For major parts shown on the circuit based on the circuit

diagram for each system, a summary, diagnosis of

troubles and inspection procedures are detailed.

Notes for Working on Electrical

Items

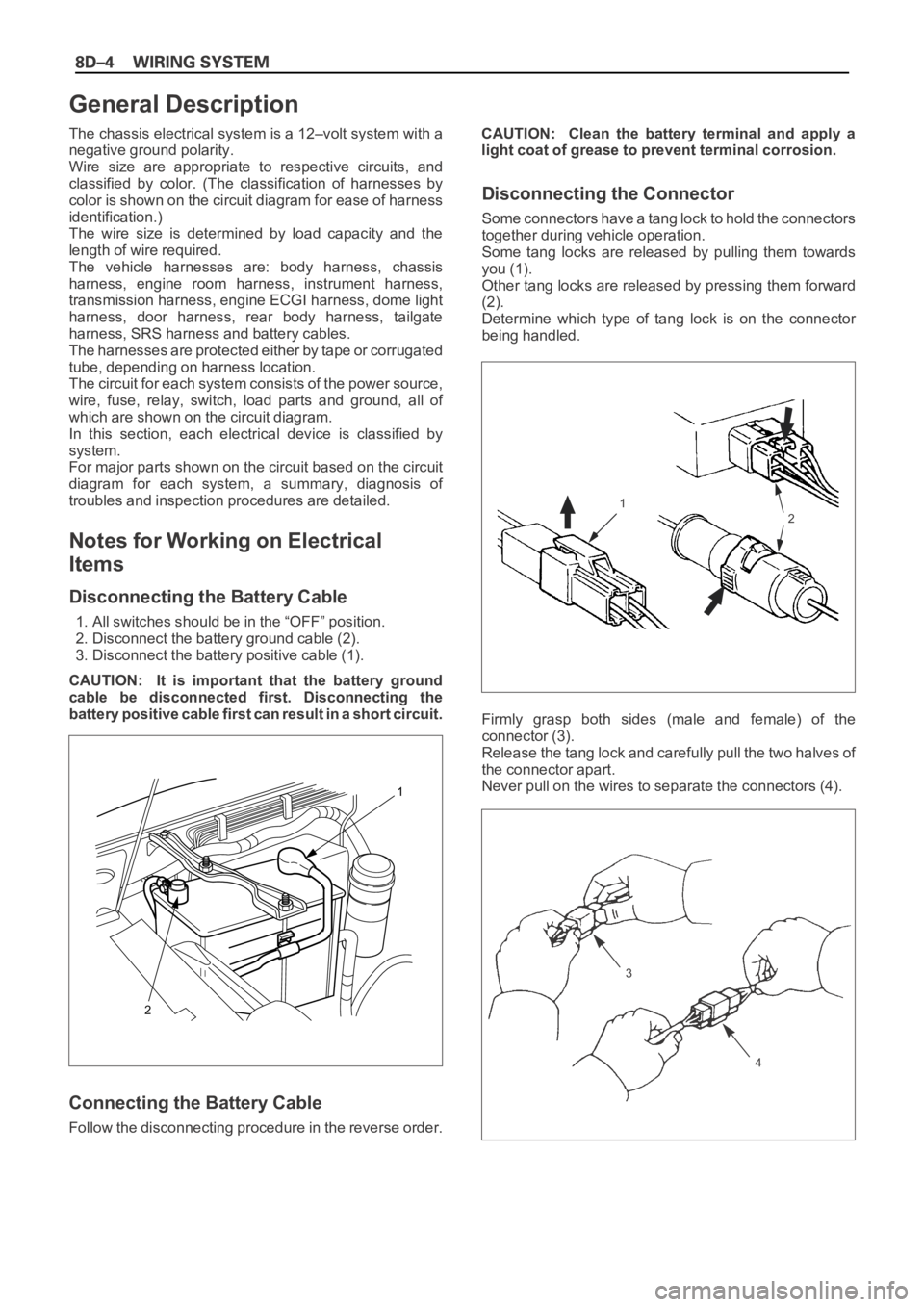

Disconnecting the Battery Cable

1. All switches should be in the “OFF” position.

2. Disconnect the battery ground cable (2).

3. Disconnect the battery positive cable (1).

CAUTION: It is important that the battery ground

cable be disconnected first. Disconnecting the

battery positive cable first can result in a short circuit.

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse order.CAUTION: Clean the battery terminal and apply a

light coat of grease to prevent terminal corrosion.

Disconnecting the Connector

Some connectors have a tang lock to hold the connectors

together during vehicle operation.

Some tang locks are released by pulling them towards

you (1).

Other tang locks are released by pressing them forward

(2).

Determine which type of tang lock is on the connector

being handled.

Firmly grasp both sides (male and female) of the

connector (3).

Release the tang lock and carefully pull the two halves of

the connector apart.

Never pull on the wires to separate the connectors (4).

2

1

General Description

1

2

3

4

Page 2609 of 6000

Circuit Breaker

The circuit breaker is a protective device designed to

open the circuit when a current load is in excess of rated

breaker capacity. If there is a short or other type of

overload condition in the circuit, the excessive current will

open the circuit between the circuit breaker terminals.

The reset knob (1) pops out when the circuit is open. Push

the reset knob in place to restore the circuit after repairing

it.

Relay

Battery and load location may require that a switch be

placed some distance from either component. This

means a longer wire and a higher voltage drop (1).

The installation of a relay between the battery and the

load reduces the voltage drop (2).

Because the switch controls the relay, amperage through

the switch can be reduced.

LOAD

12LOAD

RELAY

D08RW404

1

Page 4394 of 6000

5A–44

BRAKE CONTROL SYSTEM

Chart B-3 Power Voltage Drop (DTC 15)

StepActionYe sNo

1Is the battery voltage normal? (Battery capacity check)

Go to Step 2

Charge or

replace battery.

Go to Step 2

21. Turn the key off.

2. Disconnect EHCU connector.

3. Turn the key on.

Is the voltage between EHCU connector terminals 8 and 15,

higher than 10V?Check harness

connector for

suspected

disconnection.

Fault found:

Repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 3

Repair harness or

connector.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-4 CLASS-2 Communication Line Abnormality (DTC 16)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU and PCM connector.

Is there continuity between EHCU connector terminals 25 and

ground?

Go to Step 2

Repair harness or

connector.

Go to Step 3

21. Connect EHCU connector.

2. Clear diagnostic trouble code.

3. Turn the key on.

Is the diagnostic trouble code 16 shown on the displayed?Check the PCM

harness. Refer to

6E section.

Go to Step 3

Replace EHCU.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Page 4622 of 6000

ENGINE ELECTRICAL6D1–3

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

Page 5382 of 6000

ENGINE FUEL 6C – 1

ENGINE FUEL

CONTENTS

GENERAL DESCRIPTION

General Description . . . . . . . . . . . . . . . . . . 6C–1

On-Vehicle Service . . . . . . . . . . . . . . . . . . 6C–8

Fuel Filter Assembly . . . . . . . . . . . . . . . . 6C–8

Fuel Filter Cartridge . . . . . . . . . . . . . . . . 6C–8

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . 6C–10High Pressure Oil Pump . . . . . . . . . . . . . 6C–14

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . 6C–20

Fuel Gauge Unit . . . . . . . . . . . . . . . . . . . 6C–21

Fuel Filler Cap . . . . . . . . . . . . . . . . . . . . 6C–21

To realize the compatibility between low exhaust

emission and high engine output, an HEUI

(Hydraulically actuated Electronically controlled Unit

Injector) system, has been introduced. This system is

comprised of a hydraulic system, fuel system, and

electronic control system, using a high-pressure oil

pump in place of the conventional fuel injection pump.

The oil pressurized by means of this pump and by

signals from the ECM (Electronic Control Module)

actuates the fuel injector provided for each cylinder.

Inside of the fuel injector, fuel pressure is increased due

to the high-pressure oil. The ECM detects the driving

state of the vehicle, forms, signals sent by engine and

other part sensors, which determines the optimum fuel

injection amount and timing, thus controlling the fuel

injectors. Thus high engine output, good fuel economy,

and low exhaust emission are realized.When working on the fuel system, there are several

things to keep in mind:

1) Any time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

2)Always keep a dry chemical (Class B) fire

extinguisher near the work area.

3) Replace all pipes with the same pipe and fittings

that were removed.

Clean and inspect “O” rings. Replace where

required.

4) Always relieve the line pressure before servicing

any fuel system components.

5) Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

6) After maintenance work, push priming pump and

send enough fuel to the fuel system before starting

the engine.

NOTE: In comparison with the conventional engine,

the capacity of fuel passage in the 4JX1 engine is

larger. It takes the priming pump more time to fill the

engine with fuel.