fuel pressure OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5007 of 6000

6E–350

ENGINE DRIVEABILITY AND EMISSIONS

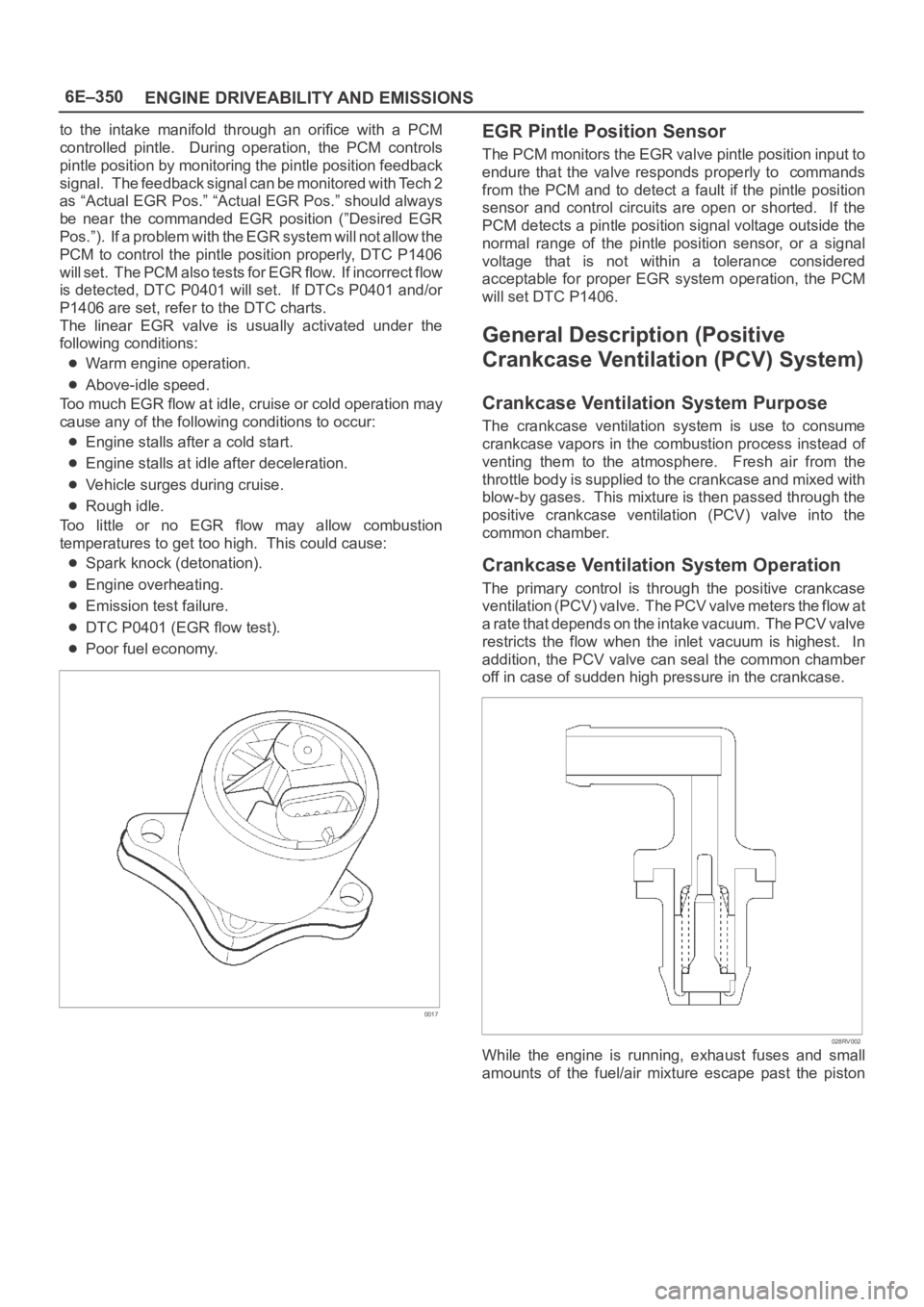

to the intake manifold through an orifice with a PCM

controlled pintle. During operation, the PCM controls

pintle position by monitoring the pintle position feedback

signal. The feedback signal can be monitored with Tech 2

as “Actual EGR Pos.” “Actual EGR Pos.” should always

be near the commanded EGR position (”Desired EGR

Pos.”). If a problem with the EGR system will not allow the

PCM to control the pintle position properly, DTC P1406

will set. The PCM also tests for EGR flow. If incorrect flow

is detected, DTC P0401 will set. If DTCs P0401 and/or

P1406 are set, refer to the DTC charts.

The linear EGR valve is usually activated under the

following conditions:

Warm engine operation.

Above-idle speed.

Too much EGR flow at idle, cruise or cold operation may

cause any of the following conditions to occur:

Engine stalls after a cold start.

Engine stalls at idle after deceleration.

Vehicle surges during cruise.

Rough idle.

Too little or no EGR flow may allow combustion

temperatures to get too high. This could cause:

Spark knock (detonation).

Engine overheating.

Emission test failure.

DTC P0401 (EGR flow test).

Poor fuel economy.

0017

EGR Pintle Position Sensor

The PCM monitors the EGR valve pintle position input to

endure that the valve responds properly to commands

from the PCM and to detect a fault if the pintle position

sensor and control circuits are open or shorted. If the

PCM detects a pintle position signal voltage outside the

normal range of the pintle position sensor, or a signal

voltage that is not within a tolerance considered

acceptable for proper EGR system operation, the PCM

will set DTC P1406.

General Description (Positive

Crankcase Ventilation (PCV) System)

Crankcase Ventilation System Purpose

The crankcase ventilation system is use to consume

crankcase vapors in the combustion process instead of

venting them to the atmosphere. Fresh air from the

throttle body is supplied to the crankcase and mixed with

blow-by gases. This mixture is then passed through the

positive crankcase ventilation (PCV) valve into the

common chamber.

Crankcase Ventilation System Operation

The primary control is through the positive crankcase

v e n t i l a t i o n ( P C V ) v a l v e . T h e PCV valve meters the flow at

a rate that depends on the intake vacuum. The PCV valve

restricts the flow when the inlet vacuum is highest. In

addition, the PCV valve can seal the common chamber

off in case of sudden high pressure in the crankcase.

028RV002

While the engine is running, exhaust fuses and small

amounts of the fuel/air mixture escape past the piston

Page 5286 of 6000

ENGINE MECHANICAL 6A – 13

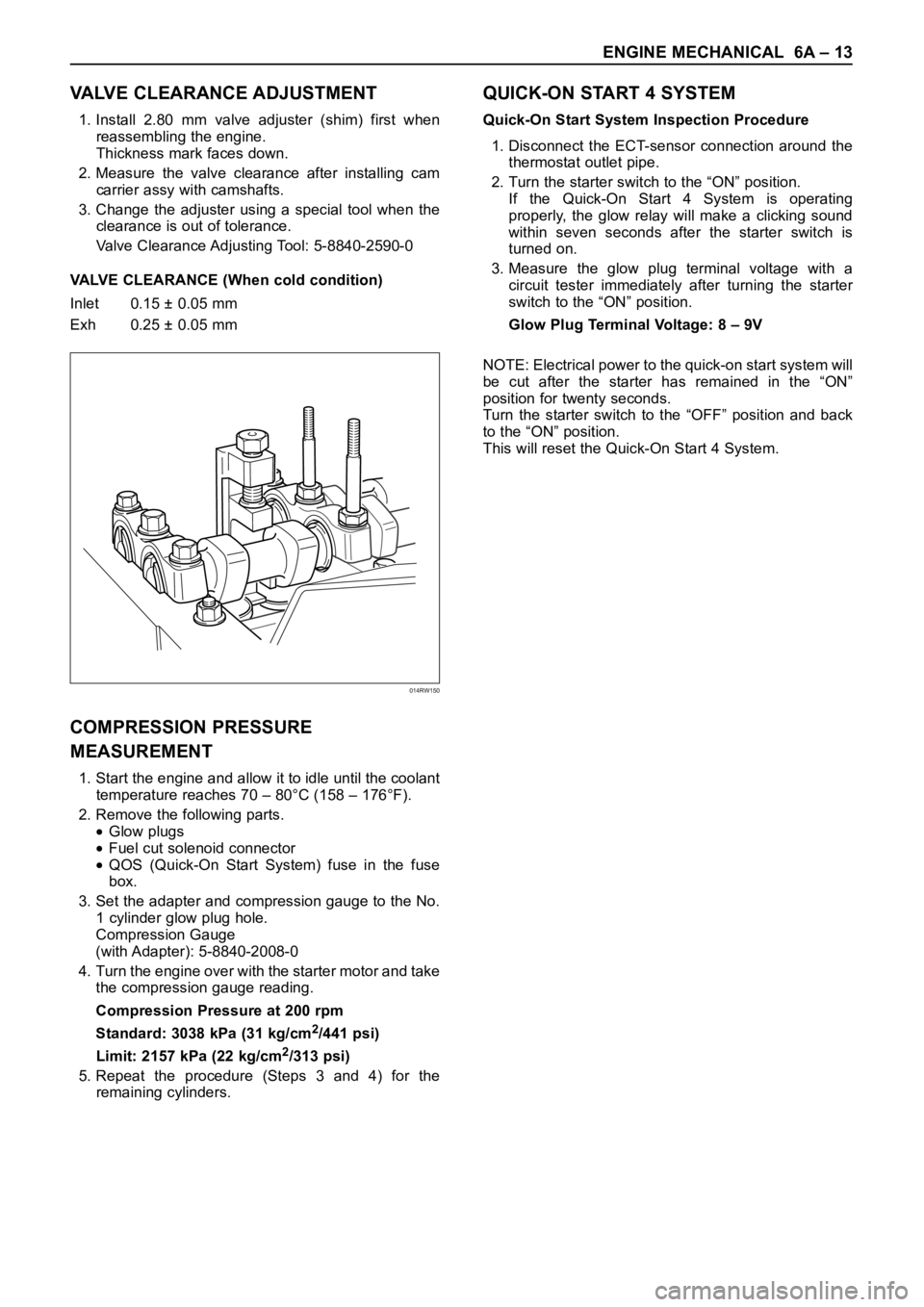

VALVE CLEARANCE ADJUSTMENT

1. Install 2.80 mm valve adjuster (shim) first when

reassembling the engine.

Thickness mark faces down.

2. Measure the valve clearance after installing cam

carrier assy with camshafts.

3. Change the adjuster using a special tool when the

clearance is out of tolerance.

Valve Clearance Adjusting Tool: 5-8840-2590-0

VALVE CLEARANCE (When cold condition)

Inlet 0.15 ± 0.05 mm

Exh 0.25 ± 0.05 mm

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80°C (158 – 176°F).

2. Remove the following parts.

Glow plugs

Fuel cut solenoid connector

QOS (Quick-On Start System) fuse in the fuse

box.

3. Set the adapter and compression gauge to the No.

1 cylinder glow plug hole.

Compression Gauge

(with Adapter): 5-8840-2008-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure at 200 rpm

Standard: 3038 kPa (31 kg/cm

2/441 psi)

Limit: 2157 kPa (22 kg/cm

2/313 psi)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

QUICK-ON START 4 SYSTEM

Quick-On Start System Inspection Procedure

1. Disconnect the ECT-sensor connection around the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start 4 System is operating

properly, the glow relay will make a clicking sound

within seven seconds after the starter switch is

turned on.

3. Measure the glow plug terminal voltage with a

circuit tester immediately after turning the starter

switch to the “ON” position.

Glow Plug Terminal Voltage: 8 – 9V

NOTE: Electrical power to the quick-on start system will

be cut after the starter has remained in the “ON”

position for twenty seconds.

Turn the starter switch to the “OFF” position and back

to the “ON” position.

This will reset the Quick-On Start 4 System.

014RW150

Page 5306 of 6000

ENGINE MECHANICAL 6A – 33

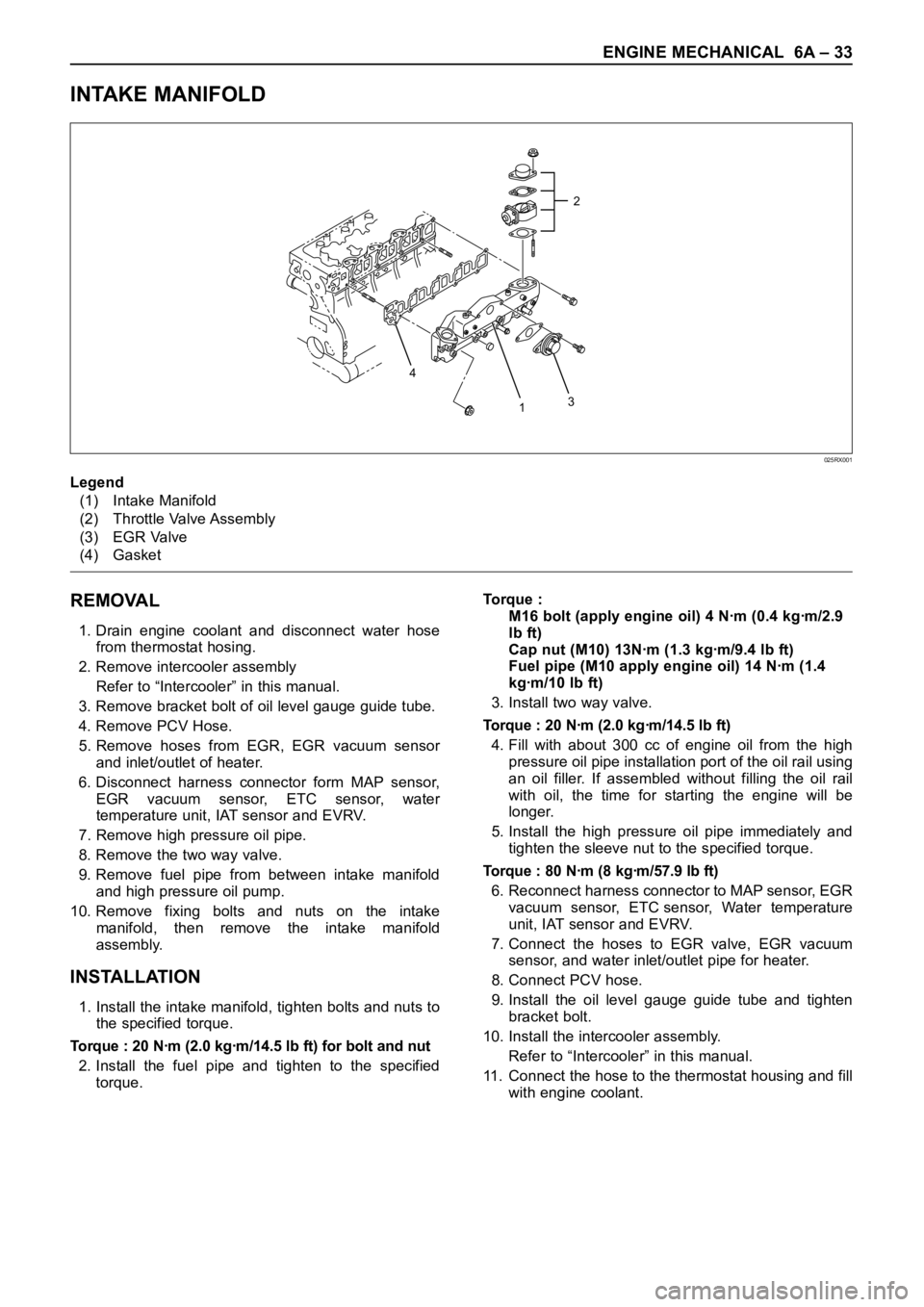

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and disconnect water hose

from thermostat hosing.

2. Remove intercooler assembly

Refer to “Intercooler” in this manual.

3. Remove bracket bolt of oil level gauge guide tube.

4. Remove PCV Hose.

5. Remove hoses from EGR, EGR vacuum sensor

and inlet/outlet of heater.

6. Disconnect harness connector form MAP sensor,

EGR vacuum sensor, ETC sensor, water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove the two way valve.

9. Remove fuel pipe from between intake manifold

and high pressure oil pump.

10. Remove fixing bolts and nuts on the intake

manifold, then remove the intake manifold

assembly.

INSTALLATION

1. Install the intake manifold, tighten bolts and nuts to

the specified torque.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for bolt and nut

2. Install the fuel pipe and tighten to the specified

torque.To r q u e :

M16 bolt (apply engine oil) 4 Nꞏm (0.4 kgꞏm/2.9

lb ft)

Cap nut (M10) 13Nꞏm (1.3 kgꞏm/9.4 lb ft)

Fuel pipe (M10 apply engine oil) 14 Nꞏm (1.4

kgꞏm/10 lb ft)

3. Install two way valve.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler. If assembled without filling the oil rail

with oil, the time for starting the engine will be

longer.

5. Install the high pressure oil pipe immediately and

tighten the sleeve nut to the specified torque.

Torque : 80 Nꞏm (8 kgꞏm/57.9 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water temperature

unit, IAT sensor and EVRV.

7. Connect the hoses to EGR valve, EGR vacuum

sensor, and water inlet/outlet pipe for heater.

8. Connect PCV hose.

9. Install the oil level gauge guide tube and tighten

bracket bolt.

10. Install the intercooler assembly.

Refer to “Intercooler” in this manual.

11. Connect the hose to the thermostat housing and fill

with engine coolant.

2

3

4

1

025RX001

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

Page 5313 of 6000

6A – 40 ENGINE MECHANICAL

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove air cleaner and air duct.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Remove PCV hose.

7. Remove EGR vacuum hose.

8. Disconnect harness connector around the cylinder

head.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out fan belt.

12. Remove heat protector and remove valve

assembly.

13. Remove water hose and oil pipe from turbocharger.

14. Remove turbocharger assembly.

15. Remove water hose between thermostat and

radiator.

16. Remove cylinder head noise insulator cover.

NOTE: Do not make damage to the harness.

17. Remove high pressure pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner and remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove water pipe between cylinder head and

water pump.

24. Remove fuel pipe between fuel pump and intake

manifold.

25. Remove fuel return pipe.

26. Remove intake manifold assembly.

27. Disconnect glow plug wiring and remove glow plug.

28. Remove cylinder head cover.

29. Drain oil from oil rail.

30. Disconnect injector harness connector.

31. Disconnect harness connector from oil pressure

sensor and oil temperature sensor on the oil rail.

32. Disconnect injector harness assembly.

33. Remove injector clamp.

34. Remove injector spacer.

35. Remove injector assembly.

36. Remove oil rail assembly.

37. Remove camshaft carrier.

38. Remove cylinder head assembly.

39. Remove cylinder gasket.

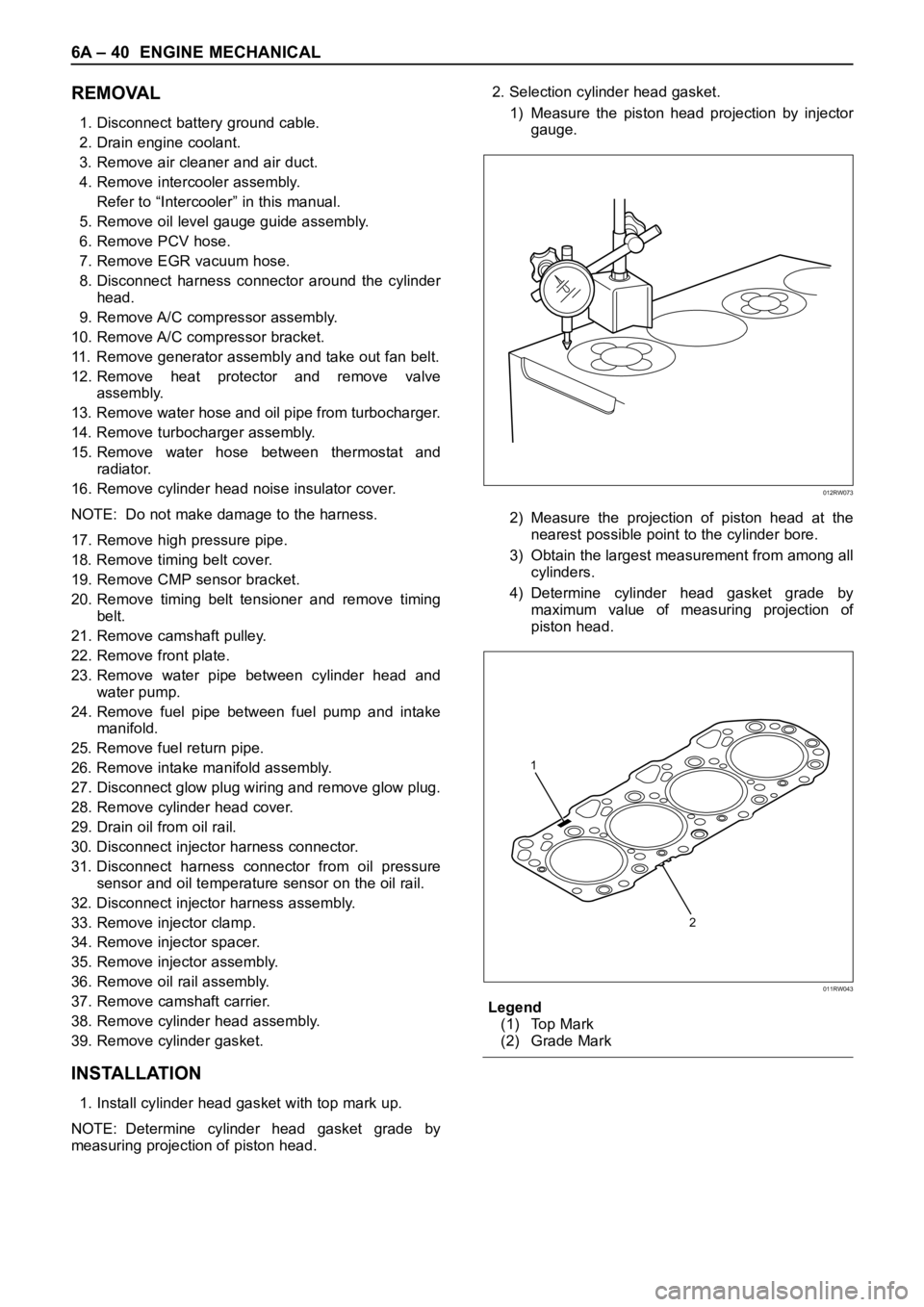

INSTALLATION

1. Install cylinder head gasket with top mark up.

NOTE: Determine cylinder head gasket grade by

measuring projection of piston head.2. Selection cylinder head gasket.

1) Measure the piston head projection by injector

gauge.

2) Measure the projection of piston head at the

nearest possible point to the cylinder bore.

3) Obtain the largest measurement from among all

cylinders.

4) Determine cylinder head gasket grade by

maximum value of measuring projection of

piston head.

Legend

(1) Top Mark

(2) Grade Mark

012RW073

2 1

011RW043

Page 5314 of 6000

ENGINE MECHANICAL 6A – 41

Cylinder head gasket and piston projection mm

CAUTION:

The projection of each piston should be 0.333

mm or more and less than 0.483 mm.

Maximum difference in projection between

pistons should be less than 0.1 mm.

If the piston projection is without standard,

reassemble the engine all over again.

3. Install cylinder head assembly, tighten bolts by

angular tightening method.

To r q u e :

1st step; 49 Nꞏm (4.9 kgꞏm/35.4 lb ft)

2nd step; 60°

3rd step; 60°

4. Install camshaft carrier assembly.

Refer to “Camshaft” in this manual.

5. Install oil rail and injector assembly.

Refer to “Oil rail and injector” in this manual.

6. Install injector harness to connect harness

connector.

Note: Apply liquid gasket (TB 1207B or equivalent) to

the rubber seal of the camshaft end, injector harness

gasket area and No. 1 camshaft bracket. Refer to the

Cylinder head cover.

7. Install cylinder head cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

8. Install glow plug to tighten specified torque.

Torque: 15 Nꞏm (1.5 kgꞏm/11 lb ft) and connect

glow plug harness.

9. Install intake manifold.Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

10. Install fuel return pipe.

11. Install fuel pipe in between fuel pump and intake

manifold.

12. Install water pipe in between cylinder head and

water pump.

Tighten flange bolt to the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

13. Install front plate.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

14. Install camshaft pulley, tighten with angular

tightening method.

1st step 40 Nꞏm (4.0 kgꞏm/29 lb ft)

2nd step 60°

NOTE: Apply engine oil to camshaft pulley bolt.

15. Align timing mark oil pump pulley and camshaft

pulley to front plate then put the timing belt and

tighten tensioner bolt.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for M8

50 Nꞏm (5.1 kgꞏm/37 lb ft)

16. Install CMP sensor bracket.

17. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

18. Fill with about 300 cc of engine oil from the high

pressure oil pipe installing port of oil rail using an oil

filler.

If assembled without filling the oil rail with oil, the

time for engine start will be longer.

19. Immediately install high pressure oil pipe to tighten

with specified torque.

Torque: 80 Nꞏm (8 kgꞏm/57.9 lb ft)

20. Install cylinder head noise insulator cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

Grade A Grade B Grade C

011RW042

Grade Piston projectionGasket

thickness

A more 0.333 to less 0.383 1.35

B more 0.383 to less 0.433 1.40

C more 0.433 to less 0.483 1.45

Page 5329 of 6000

6A – 56 ENGINE MECHANICAL

VALVE STEM SEAL, VALVE SPRING AND ADJUSTER

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove the air duct from between air cleaner and

turbocharger.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Disconnect PCV hose.

7. Disconnect EGR vacuum hose.

8. Disconnect harness connectors around the cylinder

head such as the injector, CMP sensor, MAP

sensor, EGR sensor, EVRV, IAT sensor, A/C

compressor, TP stepping motor, TP sensor and fuel

temperature sensor etc.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out drivebelt.

12. Remove heat protector, remove exhaust valve

assembly.

13. Remove water cooling hose and lubrication pipe for

turbocharger.

14. Remove turbocharger assembly.

15. Remove hose between thermostat and radiator.

16. Remove noise insulator cover of cylinder head.

NOTE: Do not damage injector harness.

17. Remove high pressure oil pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner then remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove engine coolant pipe between cylinder

head and water pump.

1

2

3

4

5

6

9

10

7

8

011RW031

Legend

(1) Adjuster

(2) Tappet

(3) Split Collar

(4) Spring Seat Upper

(5) Valve Spring(6) Spring Seat Lower

(7) Valve Stem Seal

(8) Valve Guide

(9) Valve Seat

(10) Valve

Page 5330 of 6000

ENGINE MECHANICAL 6A – 57

24. Remove fuel pipe between fuel pump and intake

manifold.

25. Remove fuel return pipe from rear of cylinder head.

26. Remove intake manifold assembly.

27. Disconnect glow plug harness and remove glow

plug.

28. Remove cylinder head cover.

29. Remove injector harness connector.

30. Disconnect harness connector from oil pressure

sensor and oil temperature sensor on the oil rail.

31. Remove injector harness assembly.

32. Remove injector clamp.

33. Remove injector is fixed bolts.

34. Remove injector assembly.

35. Remove oil rail.

36. Remove camshaft carrier assembly with camshaft.

37. Remove cylinder head assembly.

38. Disassemble valve spring according to the following

method.

1) Use valve spring compressor then remove split

collars.

2) Valve spring compressor: 5-8840-2441-0

NOTE: Put removed valve spring in order of cylinder

number.

39. Valve stem seal.

1) Use a screwdriver or pliers to remove valve

stem seal.

NOTE: Do not reuse removed valve stem seal.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs and part

replacements if excessive wear or damage is

discovered during inspection.

Va l v e s p r i n g

CAUTION: Visually inspect the valve springs and

replace them if damage or abnormal wear is

evident.

1. Free height

1) Measure the free height of the springs. The

springs must be replaced if the height is below

the specified limit.

Standard: 45.85 mm (1.8051in)

Limit: 43.9 mm (1.7283 in)

2. Squareness

1) Measure the valve spring squareness with a

steel square.

2) Replace the valve springs if the measured value

exceeds the specified limit.

Limit: 1.6 mm (0.063 in)

014rw042

014rs004

014rs005

Page 5335 of 6000

6A – 62 ENGINE MECHANICAL

INSTALLATION

1. Valve stem seal

1) Use the special tool to install the stem seal to the

valve guide.

Stem Seal Installer: 5-8840-2033-0

2. Valve spring.

1) Install the lower valve seat spring, valve spring,

then the upper valve spring seat.

2) Use valve spring compressor to compress the

spring then install the split collar.

Valve spring compressor: 5-8840-2441-0

NOTE: Make sure the split collar installs completely.

3. Install cylinder head assembly.

Refer to “Cylinder Head” in this manual.

4. Install the camshaft carrier with camshaft.

Refer to “Camshaft” in this manual.

5. Install oil rail assembly.

Refer to “Oil rail and injector” in this manual.

6. Install injector assembly.

Refer to “Oil rail and injector” in this manual.

7. Install the injector harness assembly.

Refer to “Injector” in this manual.

8. Reconnect harness connecter to oil pressure

sensor and oil temperature sensor on the oil rail.

9. Reconnect Injector harness connecter to injector.

Refer to “Injector” in this manual.

10. Install cylinder head cover with gasket.

Refer to “Cylinder Head Cover” in this manual.

11. Install glow plug with specified torque.

Torque: 15 Nꞏm (1.5 kgꞏm / 10.8 lb ft)

12. Install the intake manifold assembly.

Refer to “Intake Manifold” in this manual.

13. Install the fuel pipe.14. Install the water pipe between the cylinder head

and water pump.

Torque: 20 Nꞏm (2.0 kꞏm / 14.5 lb ft)

15. Install the front plate.

16. Install the camshaft pulley.

Refer to “Timing Gear” in this manual.

17. Install timing belt and set the tensioner.

Refer to “Timing Belt” in this manual.

18. Install CMP sensor bracket.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

19. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

20. Fill the oil rail with engine oil then immediately

install the high pressure oil pipe with the specified

torque.

Torque: 80 Nꞏm (8.1 kgꞏm / 57.9 lb ft)

21. Install the noise insulator cover.

22. Reconnect hose between thermostat and radiator.

23. Install turbocharger assembly.

Refer to “Turbocharger” in this manual.

24. Install water hose and oil pipe for turbocharger.

Refer to “Turbocharger” in this manual.

25. Install the valve assembly and install heat protector.

26. Install generator and set the fan belts.

27. Install A/C compressor bracket, compressor

assembly and set drive belt.

28. Reconnect harness connector around cylinder

head.

29. Reconnect vacuum hose to EGR valve.

30. Reconnect PCV hose.

31. Install oil level gauge guide assembly.

32. Install intercooler assembly.

Refer to “Intercooler” in this manual.

33. Install the air duct assembly.

34. Fill engine coolant.

35. Connect battery ground cable.

014RW042

Page 5338 of 6000

ENGINE MECHANICAL 6A – 65

OIL RAIL AND INJECTOR

REMOVAL

Prior to removal, be sure to confirm and record the

group code of the injector installed using Tech2.

1. Disconnect battery ground cable.

2. Remove air cleaner cover and air duct.

3. Remove intercooler.

Refer to “Intercooler” in this manual.

4. Remove PCV hose and pipe.

5. Remove cylinder head noise insulator cover.

6. Remove high pressure oil pipe.

CAUTION:

1) Sleeve nut should be loosened with cloth tied

around it to prevent oil from spurting due to the

remaining pressure.

2) The high pressure pipe should be disconnected

with a cloth tied around the intake manifold

glow plug to prevent oil from flowing out of the

oil rail.7. Loosen eye bolt of fuel pipe at fuel pump side.

NOTE: Cloth should be put around the loosened eye

bolt to prevent fuel from flowing out.

8. Remove fuel return hose at chassis side.

9. Remove PCV hose to cylinder head cover.

10. Remove cylinder head cover.

11. Drain the oil from oil rail assembly.

12. Record the identification marking of injector for

each cylinder which is indicated on the upper

portion of injector.

There are nine kinds of identification marking

available, one alphabet letter and one numeral

letter.

In case three kinds of markings are given, one

alphabet letter (sometimes printed) and one

numeral letter, top priority is given to the one

alphabet letter and one numeral letter.

1

6

27

3

5

4

012RW102-1

Legend

(1) Injector Clamp

(2) Injector Assembly

(3) Oil Rail Assembly(4) Camshaft Bracket

(5) Camshaft

(6) O-Ring

7) Drain Plug

Page 5340 of 6000

ENGINE MECHANICAL 6A – 67

12. Immediately install high pressure oil pipe and

tighten to specified torque.

Torque: 80 Nꞏm (8.1 kgꞏm / 57.9 lb ft)

13. Install cylinder head noise insulator cover.

Refer to “Cylinder Head” in this manual.

14. Install intercooler assembly.

Refer to “Intercooler” in this manual.

15. Install air cleaner cover and air duct.

16. Use TECH2 to rewrite injector data to ECM.

For rewriting method refer to section “Data

Programming in Case of ECM Change” of 6E 4JX1

engine driveability and emissions in this manual.

NOTE:

1) On completion of servicing, bleed air from the

engine inside fuel passage by means of the priming

pump. (The priming pump should be operated more

times than in the case of conventional engines.)

2) As air is in the oil rail, it takes more time to start the

engine. Rough idling may occur while the air is

being bled completely after starting the engine, but

it does not indicate trouble.

The air will be bled and normal engine status will be

reached while the vehicle is driven for about 5 km

or engine is operated for about 5 minutes at 1500 to

2000 rpm.

3) The injector spare part will be provided for group

number B1, B2 and B3 only.