tow OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1813 of 6000

6A – 80 ENGINE MECHANICAL

3. Piston and Connecting Rod Assembly

1) Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins

and each piston ring and piston.

2) Align the front mark (2) of piston and front mark

(3) of connecting rod then assemble them.

3) The N mark of the piston ring is faced toward the

top, check to see that the piston ring end gap is

correctly positioned.

Legend

(1) 1st piston ring end gap

(2) 2nd piston ring end gap

(3) Oil ring end gap4) Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

The front marks must be facing the front of the

engine.

Piston Ring Compressor: 5-8840-9018-0

5) Match the numbered caps with the numbers on

the connecting rods. Align the punched marks

on the connecting rods and caps.

6) Apply engine oil to the threads and seating faces

of the nuts.

7) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°

After tightening the cap nuts, check to see that

the crankshaft rotates smoothly

4. Piston Cooling Oil Pipe

If the piston cooling oil pipe is forcibly assembled,

the end of the oil jet may bend. It could make it

impossible to supply oil to the piston cooling holes,

which will sometimes cause piston seizure.

Sufficient care should be taken to pipe assembly

work.

1) Tighten the bolt and oil jet plug to the specified

torque.

Torque:

M6: 8 Nꞏm (0.8 kgꞏm/6 lb ft)

M8: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

Oiling Jet Plug: 30 Nꞏm (3.1 kgꞏm/22 lb ft)

5. Crank case

1) Refer to “Crank case” in this manual.

6. Apply liquid gasket (TB-1207C or equivalent) to

retainer then install it to rear end of cylinder block

within 5 minutes.

7. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear and

section with 2 bolts.

2) Insert the oil seal into the peripheral section of

the adapter.

3) Insert the sleeve into the adapter and tighten it

with a bolt (M12 x 1.75L = 70) until the adapter

hits the sleeve.

4) Remove the adapter and the sleeve.

5) Check the dimension of the oil seal setting from

rear end of crankshaft.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-0

2

3

1

015RW051

3

1

2

015RW083

Page 1870 of 6000

ENGINE ELECTRICAL 6D – 3

ON-VEHICLE SERVICE

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the rate

of charge reduced if the battery feels hot to the

touch.

Battery charging should be discontinued or the rate

of charge reduced if the battery begins to gas or

spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue

dot or ring, it may be necessary to jiggle or tilt the

battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the same

manner as other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: Failure to carefully follow the jump

starting procedure could result in the following:

1. Serious personal injury, particularly to your

eyes.

2. Property damage from a battery explosion,

battery acid, or an electrical fire.

3. Damage to the electronic components of one or

both vehicles.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode. Remove any rings, watches, or other jewelry

before working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with your

eyes or skin.

Never allow battery fluid to come in contact with fabrics

or painted surfaces.

Battery fluid is a highly corrosive acid.Should battery fluid come in contact with your eyes,

skin, fabric, or a painted surface, immediately and

thoroughly rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the “PARK”

position.

If the vehicle is equipped with a manual

transmission place the shift lever in the “NEUTRAL”

position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the A/C compressor

bracket or the generator mounting bracket) of the

vehicle with the discharged battery.

This ground connection must be at least 450 mm

(18 in) from the battery of the vehicle whose battery

is being charged.

WARNING: Never attach the end of the jumper

cable directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical

accessories have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable from

the vehicle with the discharged battery.

Page 2107 of 6000

6E–214

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

6. Remove the fuel gauge unit.

Cover or plug the fuel tank to prevent dust, dirt, or

debris from entering the tank.

TS22911

Installation Procedure

1. Install the fuel gauge unit.

2. Install the fuel gauge unit retaining screws.

TS22911

3. Connect the wiring connector to the fuel gauge unit.

TS23771

4. Fill the fuel tank with fuel.

Tighten the fuel filler cap.

Check for leaks at the fuel gauge unit gasket.

5. Connect the negative battery cable.

Fuel Injectors

Removal and Installation Procedure

Refer to Engine Fuel in 4JX1 Engine Section.

Fuel Temperature Sensor

Removal Procedure

CAUTION: To reduce the risk of fire and personal

injury, it is necessary to relieve the fuel system

pressure before servicing the fuel system

components.

CAUTION: After relieving the system pressure, a

small amount of fuel may be released when servicing

fuel lines or connections. Reduce the chance of

personal injury by covering the fuel line fittings with

a shop towel before disconnecting the fittings. The

towels will absorb any fuel that may leak out. When

the disconnect is completed, place the towel in an

approved container.

1. Disconnect the negative battery cable.

2. Remove the intercooler assembly.

3. Remove the cylinder head. Refer to engine

mechanical section.

Page 2154 of 6000

INDUCTION 6J – 13

IHI SERVICE NETWORK

For inquiries relating to turbochargers, please contact your ISUZU distributor or the nearest IHI Turbocharger Service

Facility.

HEADQUARTERS

ISHIKAWAJIMA HARIMA HEAVY INDUSTRIES CO., LTD. (IHI)

General Machinery Division

Tokyo Chuo Building 1-6-2 Marunouchi Chiyoda-ku

Tokyo 100-0005 JAPAN

TEL: 81-(3)-3286-2405 to 2407 (3 lines)

FAX: 81-(3)-3286-2430

CHINA

IHI BEIJING OFFICE

Room 705, China World Trade Center, No. 1 Jian Guo Men Wai Avenue

Beijing, People’s R epublic of CHINA

TEL: 86-(1)-505-4997, 0408

FAX: 86-(1)-505-4350

TLX: 210343 IHIPK CN

TA I WA N

IHI TAIPEI OFFICE

Room 1202, Chia Hsin Building, No. 96 Chung Shan

North Road, Section 2, Taipei, TAIWAN

TEL: 886-(2)-542-5520, 5521, 5523

FAX: 886-(2)-542-4362

TLX: 11320 IHICO

THAILAND

IHI BANGKOK OFFICE

8th Floor, Thaniya Building, 62 Silom Road, Bangkok, THAILAND

TEL: 66-(2)-236-3490, 7356, 9099

FAX: 66-(2)-236-7340

TLX: 82375 IHICO TH

MALAYSIA

IHI KUALA LUMPUR OFFICE

Letter Box No. 52, 22nd Floor, UBN Tower,

10 Jin. P. Ramlee 50250 Kuala Lumpur, MALAYSIA

TEL: 60-(3)-232-1255, 1271

FAX: 60-(3)-232-1418

TLX: IHI KLMA 20257

INDONESIA

IHI JAKARTA OFFICE

9th Floor, Skyline Building JI. M.H. Thamrin, No. 9, Jakarta, INDONESIA

TEL: 62-(21)-32-2147, 390-2211

FAX: 62-(21)-32-3273

TLX: 44175 IHIJKT

Page 2164 of 6000

7A–10

AUTOMATIC TRANSMISSION (4L30–E)

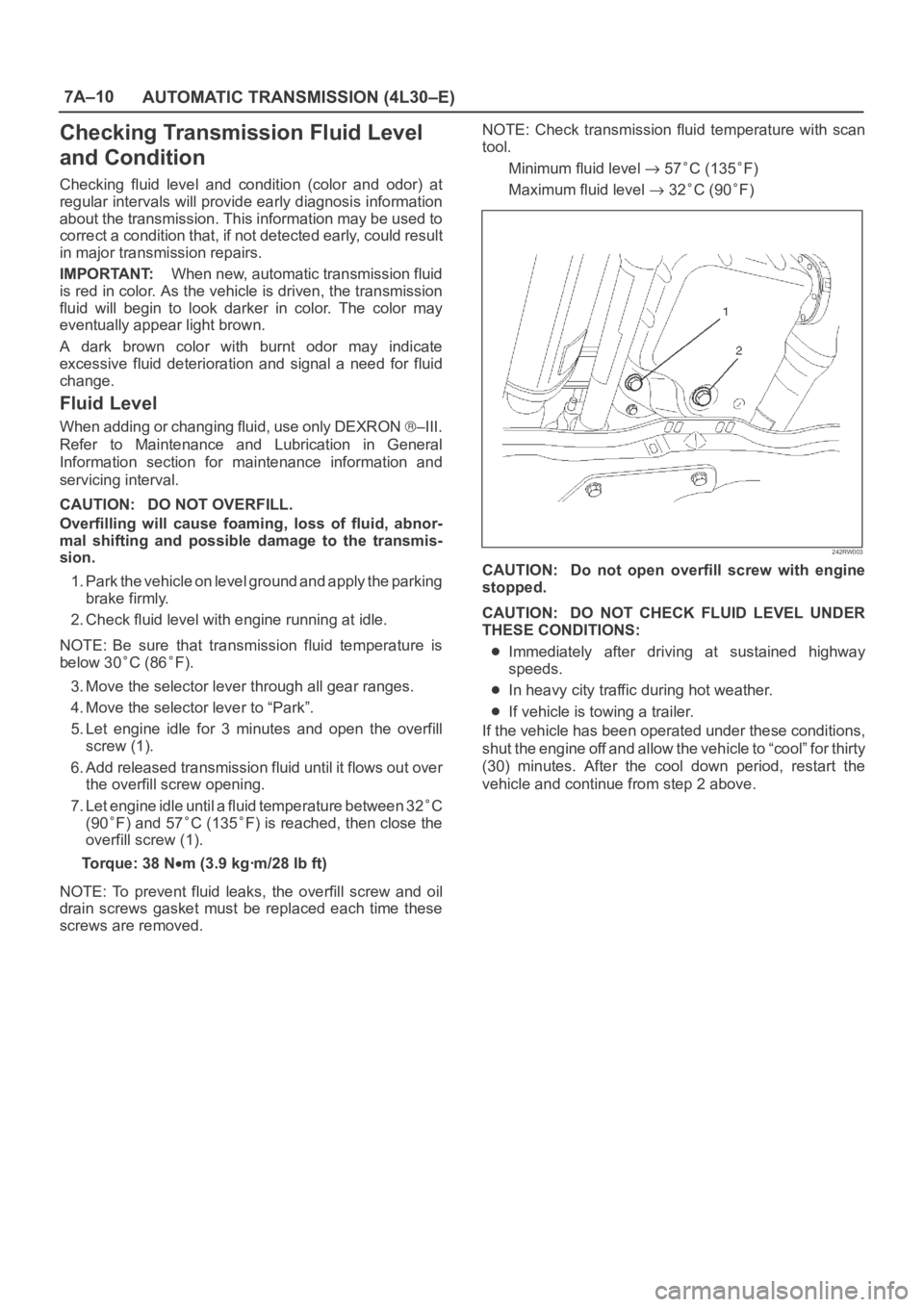

Checking Transmission Fluid Level

and Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis information

about the transmission. This information may be used to

correct a condition that, if not detected early, could result

in major transmission repairs.

IMPORTANT:When new, automatic transmission fluid

is red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON –III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid, abnor-

mal shifting and possible damage to the transmis-

sion.

1. Park the vehicle on level ground and apply the parking

brake firmly.

2. Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30

C (86F).

3. Move the selector lever through all gear ranges.

4. Move the selector lever to “Park”.

5. Let engine idle for 3 minutes and open the overfill

screw (1).

6. Add released transmission fluid until it flows out over

the overfill screw opening.

7. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached, then close the

overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level

57C (135F)

Maximum fluid level

32C (90F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

Immediately after driving at sustained highway

speeds.

In heavy city traffic during hot weather.

If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for thirty

(30) minutes. After the cool down period, restart the

vehicle and continue from step 2 above.

Page 2176 of 6000

7A–22

AUTOMATIC TRANSMISSION (4L30–E)

Chart 16: Possible Causes Of

Transmission Fluid Leaks

Before attempting to correct an oil leak, the actual source

of the leak must be determined. In many cases, the

source of the leak may be difficult to determine due to

“wind flow” around the engine and transmission.

The suspected area should be wiped clean before in-

specting for the source of the leak.Oil leaks around the engine and transmission are gener-

ally carried toward the rear of the vehicle by the air

stream. In determining the source of an leak, the following

two checks should be made:

1. With the engine running, check for external line

pressure leaks.

2. With the engine off, check for oil leaks due to the

raised oil level caused by drainback of converter oil

into the transmission.

Possible Causes Of Fluid Leaks Due To Sealing Malfunction

240RS002

Legend

(1) Electrical Connector (Main Case) Seal

(2) Transmission Vent (Breather)

(3) Speed Sensor O–Ring

(4) Extension (Adapter) Lip Seal

(5) Extension (Adapter) to Main Case Gasket

(6) Oil Drain Plug Gasket

(7) Oil Pan Gasket (Main Case)

(8) Selector Shaft Seal(9) Oil Cooler Connectors (2)

(10) Oil Pan Gasket (Adapter Case)

(11) Converter housing attaching bolts not correctly

torqued

(12) Converter Housing Lip Seal

(13) Line Pressure Tap Plug

(14) Electrical Connector (Adapter Case) Seal

(15) Adapter Case Seal Rings (2)

Page 2181 of 6000

7A–27 AUTOMATIC TRANSMISSION (4L30–E)

Changing Transmission Fluid

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A. Repeated short trips

B. Driving on rough roads

C. Driving on dusty roads

D. Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km.)

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge the

right time for ATF replacement.

The remaining life percentage is calculated from ATF’S

heat history. When it is close to 0%, ATF replacement is

recommended.

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw (2) and drain

fluid.

3. Tighten drain screw (2).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

4. Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON

–III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached.6. Add transmission fluid until it flows out over the overfill

screw opening, then close the overfill screw (1).

To r q u e : 3 8 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

242RW003

Selector Lever

Inspection

1. Make sure that when the shifter control lever is shifted

from “P” to “L”, a “clicking” can be felt at each shift

position. Make sure that the gear corresponds to that

of the position plate indicator.

2. Check to see if the shifter lever can be shifted as

shown in illustration.

C07RW009

Page 2205 of 6000

7A–51 AUTOMATIC TRANSMISSION (4L30–E)

25. Install snap ring (23) in adapter case.

Install 5–8840–0195–0 (J–23327) and

5–8840–2263–0 (J–23327–90) fourth clutch spring

compressor.

Seat snap ring in groove.

Remove compressor.

252RW002

252RW007

26. Install selective washer using petroleum jelly.

27. Install two O–ring seals (24) in main case and adapter

case/main case seal ring (25).28. Install 5–8840–2268–0 (J–38588) guide pins.

Install adapter case and center support assembly to

main case.

242RW007

29. Install thrust washer (26) into adapter case, with

tangs pointing downwards.

30. Preassemble overdrive internal gear (27) and thrust

bearing assembly (28) onto the turbine shaft and

overrun clutch assembly.

NOTE: Install bearing assembly, black side up. Use

petroleum jelly to keep assembly in place.

31. Install overdrive carrier (30) and internal gear

assembly into adapter case.

32. Install fourth clutch plates (29) in the following order:

Steel, Lined, Steel, Steel, Lined, Steel. Steel plates

go in with short tang facing towards valve body

surface.

Page 2206 of 6000

7A–52

AUTOMATIC TRANSMISSION (4L30–E)

33. Install fourth clutch retainer (31) with the notch facing

up and positioned towards valve body surface.

252RW004

34. Overdrive clutch end play measurement

1. Install the 5–8840–2262–0 (J–23085–A)

selective washer gauging tool on the adapter

case flange and against the input shaft.

2. Position the inner shaft of the tool against the

thrust surface of the overrun clutch housing.

3. Tighten thumb screw. Remove the tool.

4. Measure gap. Select appropriate size washer as

shown in the chart.

5. Set selective thrust washer aside.

Selective Thrust Washer

Gap: mm(in)Color

1.53 – 1.63 (0.060 – 0.064)Yellow

1.72 – 1.82 (0.068 – 0.072)Red

1.91 – 2.01 (0.075 – 0.079)Black

2.10 – 2.20 (0.083 – 0.087)Natural

2.29 – 2.39 (0.090 – 0.094)Green

2.48 – 2.58 (0.098 – 0.102)Blue

FOLLOWING THE PROCEDURE SHOULD RE-

SULT IN FINAL END–PLAY FROM 0.1 mm TO 0.8

mm (0.004 in TO 0.03 in)

252RW008

252RW009

35. Install selective washer (32).

NOTE: Use petroleum jelly to hold selective washer in

place.

36. Install gasket (33).

37. Install converter housing and oil pump assembly (34)

to adapter case.

Fit and tighten seven outer 13 mm screws.

To r q u e : 3 9 N

m (4.0 kgꞏm/29 lb ft)

Page 2208 of 6000

7A–54

AUTOMATIC TRANSMISSION (4L30–E)

241RW009

241RW019

43. Main case end play measurement.

1. Attach axial play checking tool on the extension

housing and set indicator to zero on output shaft.

2. Manually push output shaft upwards.

End play: 0.36mm – 0.80mm (0.014 in – 0.031in)

3. Remove axial play checking tool.

4. If end play is not correct, repeat selective washer

selection.

241RS005

44. Inspect servo piston seal ring. Replace if necessary.

Ensure brake band is correctly positioned. Rotate

output shaft if necessary.

Install 5–8840–2274–0 (J–38428) servo piston

fitter in servo bore.

Install apply rod (40), round end toward band, return

spring (41) and piston assembly (42).

45. Install the 5–8840–0501–0 (J–23075) servo spring

compressor with offset to rear of case.

Compress servo piston seal ring, using fitter while

tightening the tool screw.

Install servo piston retaining ring (43).

Remove tool.

Adjust the brake band by tightening the servo

adjusting screw to 4.5 Nꞏm torque. Be certain the

lock nut is loose, then back–off the screw five turns

exactly. Hold piston sleeve with wrench and tighten

lock nut to 18.5 Nꞏm torque. Be certain the adjusting

screw does not turn.