air condition OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

00 SERVICE INFORMATION

1A HEATING AND VENTILATION

1B AIR CONDITIONING

1D COMPRESSOR OVERHAUL

HOME

00

1D

1B

1A

Page 201 of 6000

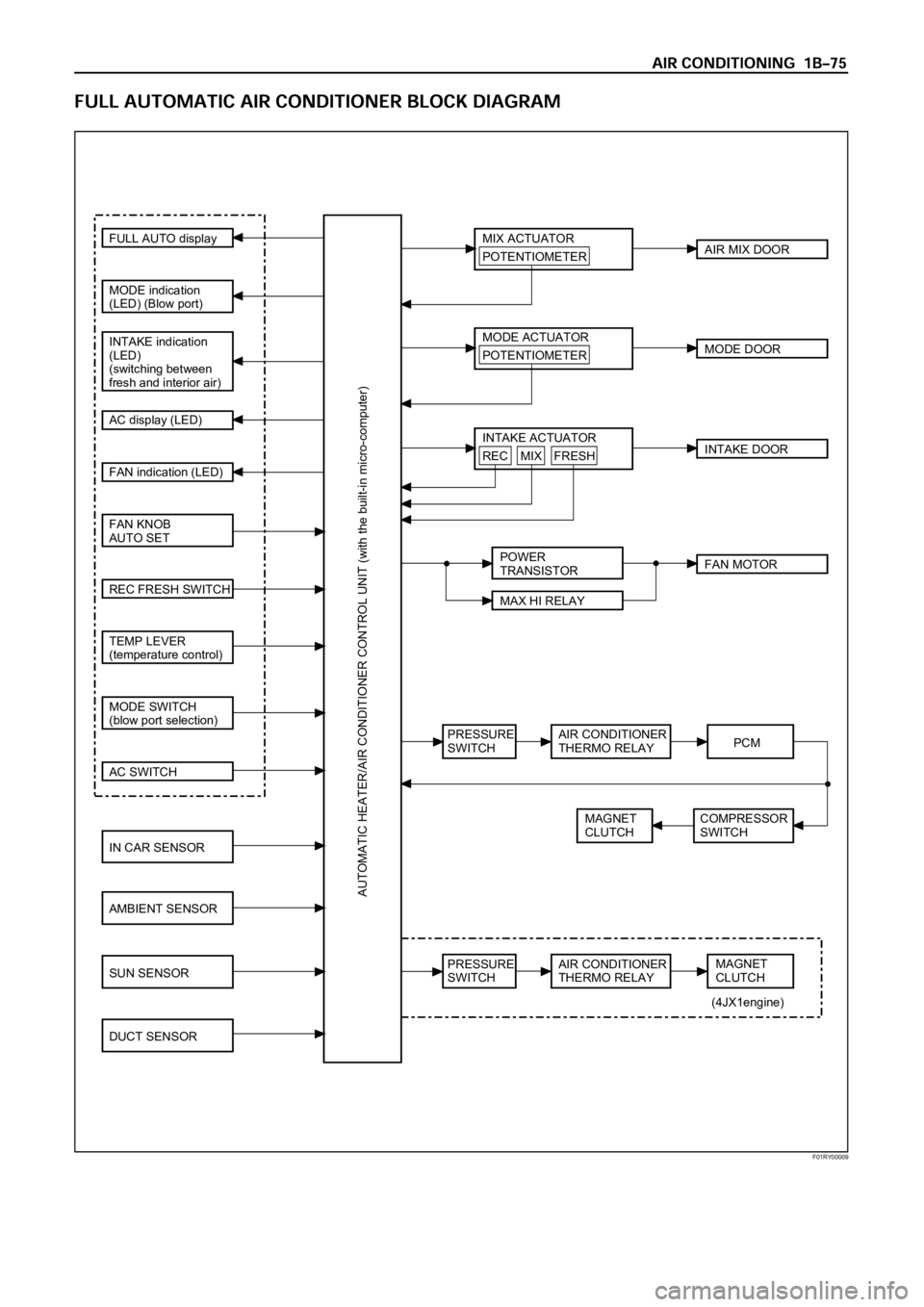

FULL AUTO display

INTAKE indication

(LED)

(switching between

fresh and interior air)

MODE indication

(LED) (Blow port)

AC display (LED)

FAN indication (LED)

FAN KNOB

AUTO SET

REC FRESH SWITCH

TEMP LEVER

(temperature control)

MODE SWITCH

(blow port selection)

AC SWITCH

IN CAR SENSOR

AMBIENT SENSOR

SUN SENSOR

DUCT SENSOR

MIX ACTUATOR

POTENTIOMETER

MODE ACTUATOR

POTENTIOMETER

AIR MIX DOOR

MODE DOOR

INTAKE ACTUATOR

RECINTAKE DOOR

FAN MOTORPOWER

TRANSISTOR

AUTOMATIC HEATER/AIR CONDITIONER CONTROL UNIT (with the built-in micro-computer)

MAX HI RELAY

PRESSURE

SWITCHAIR CONDITIONER

THERMO RELAY

COMPRESSOR

SWITCH MAGNET

CLUTCH

PCM

PRESSURE

SWITCHAIR CONDITIONER

THERMO RELAYMAGNET

CLUTCH

(4JX1engine)

MIX FRESH

F01RY00009

Page 212 of 6000

12

43

860RW026

C01RX016

M

N 3

2

7

6

8

98 43

65 21

7

Potentiometer

ConnectionPosition

Detection

Block Automatic Heater / Air

Conditioner Control Unit

Controller

Sliding Contact

Full Heate PositionTerminal PlateFull Cool PositionDriver

Cool Side Heat Side

C01RX005

Full cool

Full cool0 0 0.5 1.0

50 100%

Aperture of air mix doorVoltage ratio VM/VDD

Full heat Full heat

VDD

VM +

–

Page 214 of 6000

0 50

140 104 68 32

Air mix door aperture

Full cool

Heater

side Restriction on the

aperture enabied

in the VENT modeAir conditioning

ON mode Full heatSet temperature

signal

Mix

actuator

Potentio

meter

Air mix door

In car sensor

Ambient sensor

Sun sensor

Control unitAir conditioning

switch

Set up temperature

signal

Air conditioning

OFF mode

Total signal Cooler

side

C01RY00011

Page 215 of 6000

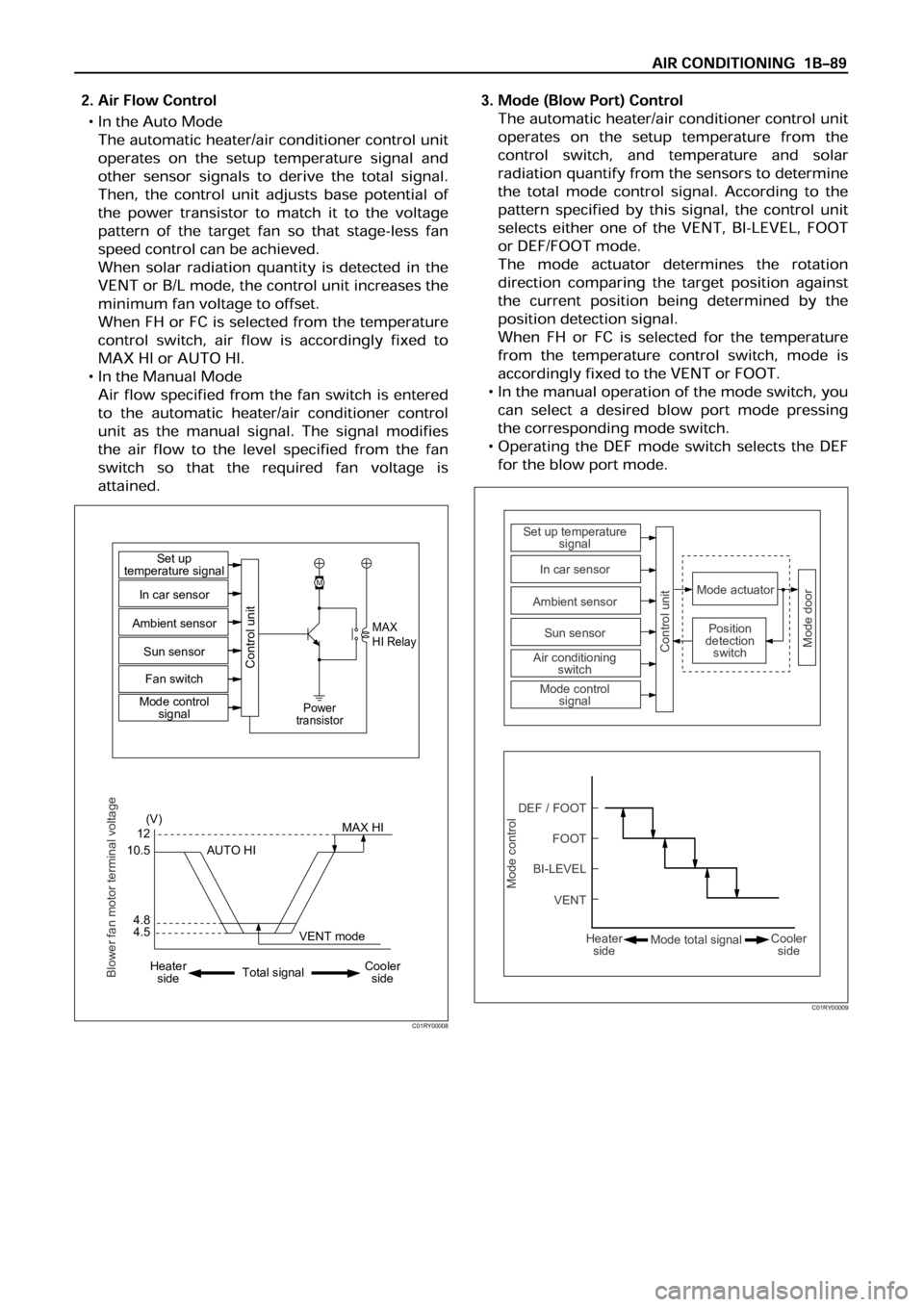

4.512

(V)

M

MAX

HI Relay

Power

transistor

4.8 10.5MAX HI Set up

temperature signal

Control unit

In car sensor

Ambient sensor

Sun sensor

Mode control

signal Fan switch

AUTO HI

Heater

sideCooler

side Total signalVENT mode

Blower fan motor terminal voltage

C01RY00008

Mode control

DEF / FOOTSet up temperature

signal

Mode actuator

Mode doorPosition

detection

switch

Control unit

In car sensor

Sun sensor

Air conditioning

switch

Mode control

signal Ambient sensor

FOOT

BI-LEVEL

VENT

Heater

sideCooler

side Mode total signal

C01RY00009

Page 216 of 6000

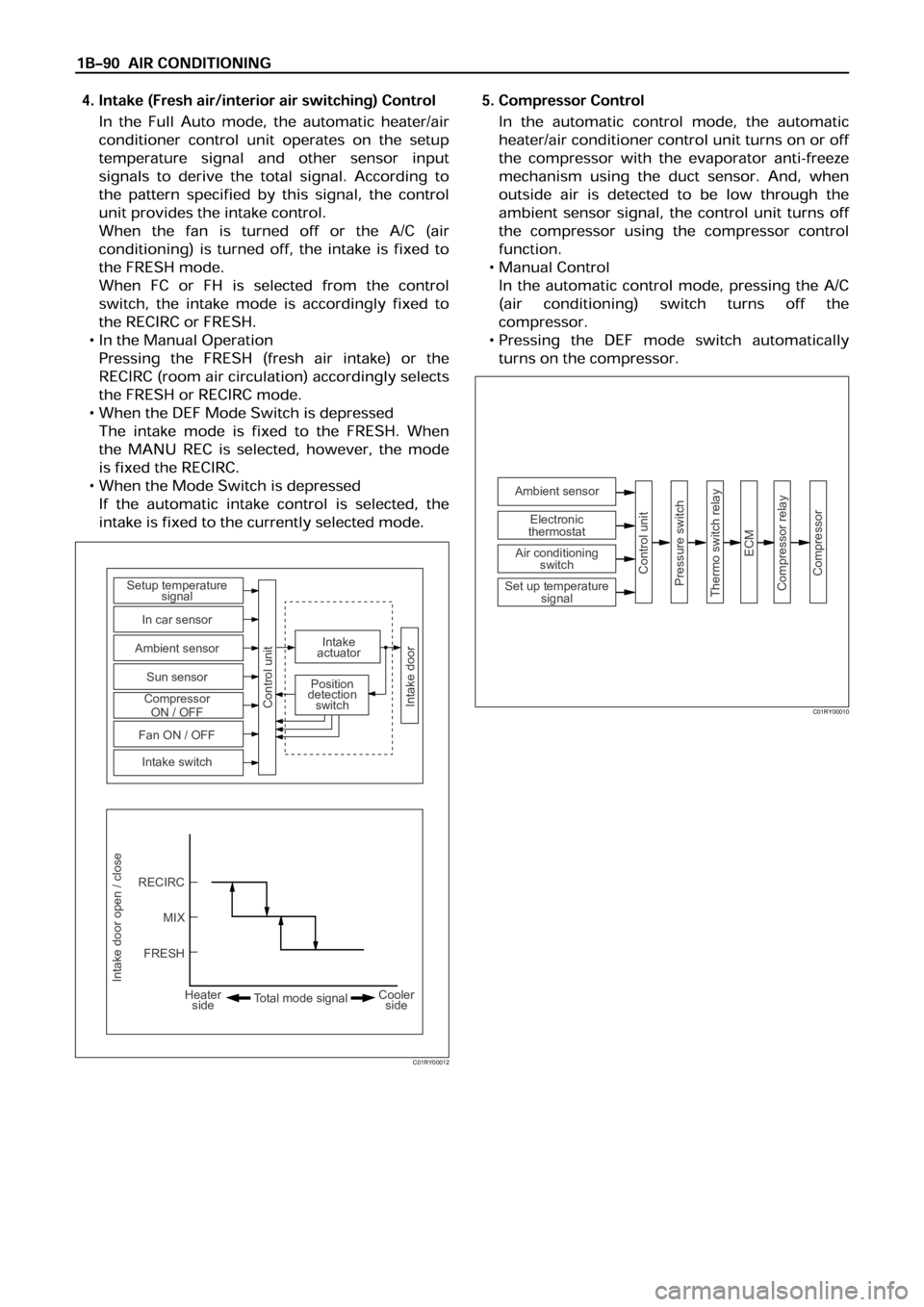

Intake door open / close

RECIRC Setup temperature

signal

Intake

actuator

Position

detection

switch

In car sensor

Ambient sensor

Sun sensor

Compressor

ON / OFF

Fan ON / OFF

Intake switch

Control unit

Intake door

MIX

FRESH

Heater

sideCooler

side Total mode signal

C01RY00012

Ambient sensor

Control unit

Pressure switch

Thermo switch relay

ECM

Compressor relay

Compressor

Electronic

thermostat

Air conditioning

switch

Set up temperature

signal

C01RY00010

Page 218 of 6000

Occurrence of a trouble

Refer to the check list for

the inspection.Locate the failed location.

Check the failed part.

Correction

Correction

Correction

Troubleshooting by the

self-diagnosis function.Reference the "Check

Procedure by Failed

Location" for the inspection.

Reference the "Check

Procedure by Failed

Location" for the inspection.Correction

Check the cooling / heating

cycles.

End OK OK OK OKNG

NG

NG

NG

NG OK

Check if the automatic

heater / air conditioner

control unit indicator LED

is turned on.Check the power supply and

circuit on the automatic

heater / air conditioner control

unit.

Troubleshooting not relying

on the self-diagnosis

function(troubleshooting

by failure type).

F01RX009

Page 219 of 6000

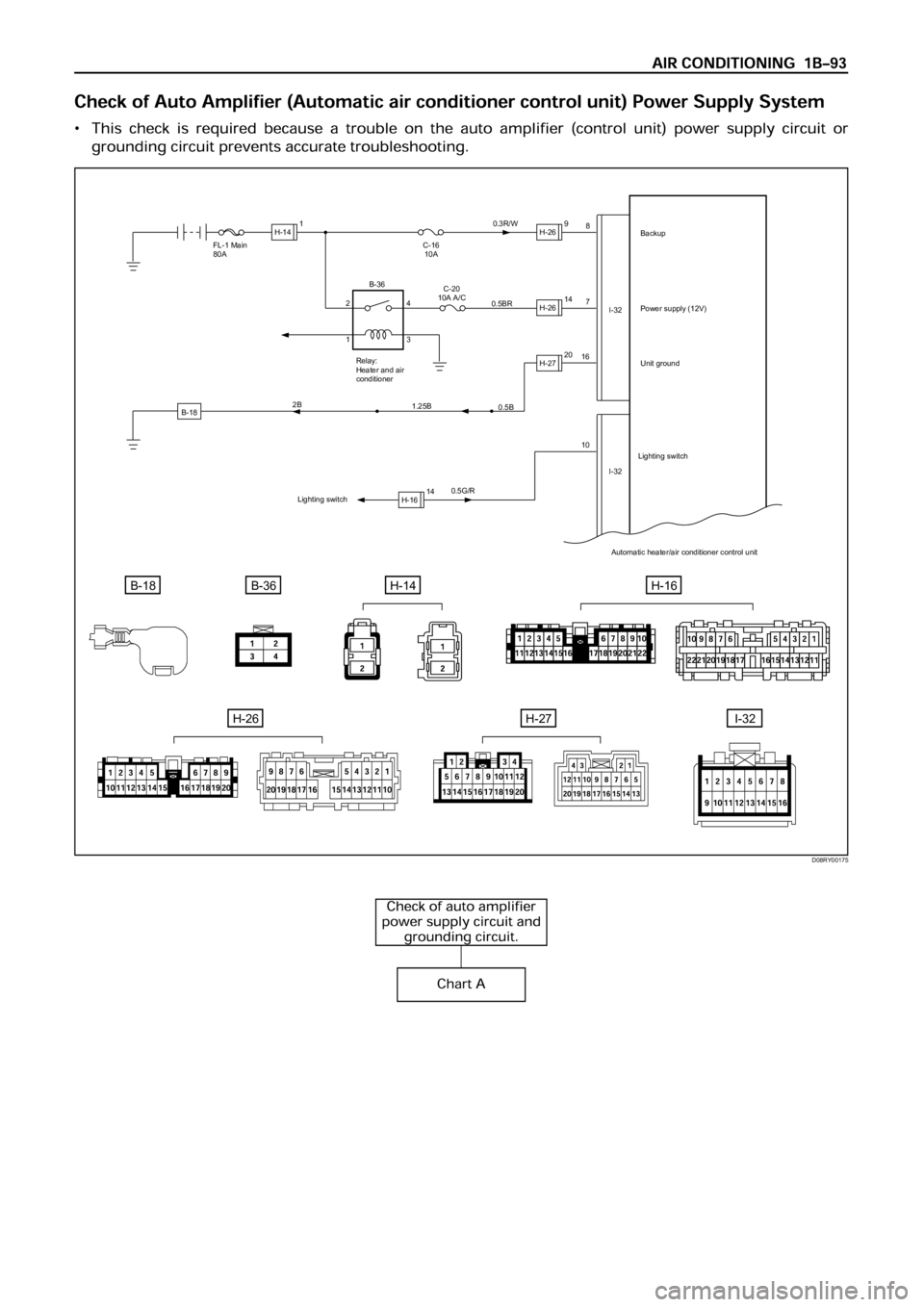

B-18

FL-1 Main

80A

0.5G/R16

107 8

I-32

I-32 C-16

10A0.3R/W

0.5BRBackup

Power supply (12V)

Unit ground

Automatic heater/air conditioner control unit

B-18B-36H-14

C-20

10A A/C

Relay:

Heater and air

conditioner

0.5B

1.25B 2B

Lighting switchLighting switch

H-141H-269

H-2614

H-2720

H-1614 2

14

3 B-36

H-16

H-26H-27I-32

D08RY00175

Page 247 of 6000

C-25

0.5 BR

C-25

X-5X-5

X-5X-5

2 1

4 3

0.5 P/G FL-1 MAIN

80A

C-20

10A A/C

0.5 G/W 0.5 G/O

C-25E-27H-16

Pressure

switch

Relay:

Air conditioning

thermostat

Automatic heater/air conditioner

control unitRelay:

Air conditioning

0.5 BR

1

2

I-3214

Fan “ON”

I-32X-5

E-271

Magnet

clutch

B-36

B-36

H-1616

D08RY00183

Page 281 of 6000

1. Perform oil return operation.

2. Discharge and recover the refrigerant and remove

the compressor.

3. Drain the compressor oil and measure the extracted

oil.

4. Check the compressor oil for contamination.

5. Adjust the oil level as required.

6. Evacuate, charge and perform the oil return

operation.

7. Check the system operation.

Contamination of Compressor Oil

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a long

period of time (approximately one season), the oil never

becomes contaminated as long as there is nothing

wrong with the compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

The capacity of the oil has increased.

The oil has changed to red.

Foreign substances, metal powder, etc., are present

in the oil.

If any of these conditions exists, the compressor

oil is contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

Oil Return Operation

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system. When

checking the amount of oil in the system, or replacing

any component of the system, the compressor must be

run in advance for oil return operation. The procedure

is as follows:

1. Open all the doors and the engine hood.

2. Start the engine and air conditioning switch to "ON"

and set the fan control knob at its highest position.

3. Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate the

system.

4. Stop the engine.

Replacement of Component Parts

When replacing the system component parts, supply

the following amount of oil to the component parts to be

installed.

Compressor Leak Testing (External and

Internal)

Bench-Check Procedure

1. Install test plate J-39893 on rear head of compressor.

2. Using Refrigerant Recovery System, attach center

hose of manifold gage set on charging station to a

refrigerant drum standing in an upright drum.

3. Connect charging station high and low pressure

lines to corresponding fittings on test plate J-39893.

Suction port (low-side) of compressor has large

internal opening. Discharge port (high-side) has

smaller internal opening into compressor and

deeper recess.

4. Open low pressure control, high pressure control

and refrigerant control on charging station to allow

refrigerant vapor to flow into compressor.

5. Using a leak detector, check for leaks at pressure

relief valve, rear head switch location, compressor

front and rear head seals, center cylinder seal,

through bolt head gaskets and compressor shaft

seal. After checking, shut off low pressure control

and high-pressure control on charging station.

6. If an external leak is present, perform the necessary

corrective measures and recheck for leaks to make

certain the leak has been connected.

7. Recover the refrigerant.

8. Disconnect both hoses from the test plate J-39893.

9. Add 90 ml (3 oz.) new PAG lubricant to the

compressor assembly. Rotate the complete

compressor assembly (not the crankshaft or drive

plate hub) slowly several turns to distribute oil to all

cylinder and piston areas.

10. Install a M9

1.25 threaded nut on the compressor

crankshaft if the drive plate and clutch assembly are

not installed.

11. Using a box-end wrench or socket and handle,

rotate the compressor crankshaft or clutch drive

plate on the crankshaft several turns to insure

piston assembly to cylinder wall lubrication.

12. Using Refrigerant Recovery System, connect the

charging station high-pressure line to the test plate

J-39893 high-side connector.

13. Using Refrigerant Recovery System, connect the

charging station low-pressure line to the low

pressure port of the test plate J-39893. Oil will drain

out of the compressor suction port if the compressor

is positioned with the suction port downward. (Component parts to be (Amount of Oil)

installed)

Evaporator 50 cc (1.7 fl. oz.)

Condenser 30 cc (1.0 fl. oz.)

Receiver/dryer 30 cc (1.0 fl. oz.)

Refrigerant line (one 10 cc (0.3 fl. oz.)

piece)

(Amount of oil drained (Charging amount of oil

from used compressor) to new compressor)

more than 90 cc same as drained amount

(3.0 fl.oz)

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)