timing belt OPEL FRONTERA 1998 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1778 of 6000

ENGINE MECHANICAL 6A – 45

Cylinder head gasket and piston projection mm

CAUTION:

The projection of each piston should be 0.333

mm or more and less than 0.483 mm.

Maximum difference in projection between

pistons should be less than 0.1 mm.

If the piston projection is without standard,

reassemble the engine all over again.

3. Install cylinder head assembly, tighten bolts by

angular tightening method.

To r q u e :

1st step; 49 Nꞏm (4.9 kgꞏm/35.4 lb ft)

2nd step; 60°

3rd step; 60°

CAUTION: The cylinder head bolts cannot be

reused.

4. Install camshaft carrier assembly.

Refer to “Camshaft” in this manual.

5. Install oil rail and injector assembly.

Refer to “Oil rail and injector” in this manual.

6. Install injector harness to connect harness

connector.

Note: Apply liquid gasket (TB 1207B or equivalent) to

the rubber seal of the camshaft end, injector harness

gasket area and No. 1 camshaft bracket. Refer to the

Cylinder head cover.

7. Install cylinder head cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

8. Install glow plug to tighten specified torque.

Torque: 15 Nꞏm (1.5 kgꞏm/11 lb ft) and connectglow plug harness.

9. Install intake manifold.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

10. Install fuel return pipe.

11. Install fuel pipe in between fuel pump and intake

manifold.

12. Install water pipe in between cylinder head and

water pump.

Tighten flange bolt to the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

13. Install front plate.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

14. Install camshaft pulley, tighten with angular

tightening method.

1st step 40 Nꞏm (4.0 kgꞏm/29 lb ft)

2nd step 60°

NOTE: Apply engine oil to camshaft pulley bolt.

15. Align timing mark oil pump pulley and camshaft

pulley to front plate then put the timing belt and

tighten tensioner bolt.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for M8

50 Nꞏm (5.1 kgꞏm/37 lb ft)

16. Install CMP sensor bracket.

17. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

18. Fill with about 300 cc of engine oil from the high

pressure oil pipe installing port of oil rail using an oil

filler.

If assembled without filling the oil rail with oil, the

time for engine start will be longer.

19. Immediately install high pressure oil pipe to tighten

with specified torque.

Torque: 80 Nꞏm (8 kgꞏm/57.9 lb ft)

20. Install cylinder head noise insulator cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

Grade A Grade B Grade C

011RW042

Grade Piston projectionGasket

thickness

A more 0.333 to less 0.383 1.35

B more 0.383 to less 0.433 1.40

C more 0.433 to less 0.483 1.45

Page 1785 of 6000

6A – 52 ENGINE MECHANICAL

TIMING GEAR

REMOVAL

1. Loosen fixing bolt for generator and remove

generator assembly.

2. Remove fixing nuts, then remove cooling fan

assembly and fan pulley.

3. Remove crankshaft damper pulley.

4. Belt cover

1) Disconnect harness connector of CMP

(camshaft position) sensor.

2) Remove CMP sensor.

3) Remove belt cover.

5. Loosen belt tensioner to remove timing belt.

6. Remove camshaft pulley.

7. Remove high pressure oil pump pulley.

8. Remove front plate.

9. Remove vacuum pump.

10. Remove power steering pump.

11. Remove gear cover assembly.

12. Idle gear A.

1) Set two bolts to sub gear of idle gear A and turn

it to align the tooth of idle gear A then lock them

by bolt as show in the illustration.

2) Remove idle gear A fixing bolts.

3) Remove idle gear A.Legend

(1) Sub-Gear

(2) Main Gear

(3) Bar

(4) Locking Bolt

2

3

4

5 8

7

6 91

020RW028

Legend

(1) Idle Gear A

(2) High Pressure Oil Pump Gear

(3) Vacuum Pump Gear

(4) Power Steering Pump Gear(5) Balance Gear LH

(6) Idle Gear C

(7) Crankshaft Gear

(8) Balance Gear RH

(9) Idle Gear B

4 1

2

3

014RW177

Page 1791 of 6000

6A – 58 ENGINE MECHANICAL

14. Camshaft pulley

1) Align TDC mark with crankshaft pulley and gear

case cover.

2) Set camshaft stopper on the end of intake and

exhaust camshaft.

Camshaft Stopper: 5-8840-2592-0

3) Install key to camshaft and install camshaft

pulley.

4) Apply engine oil to camshaft pulley fixing bolt

and tighten bolt with angular tightening method.

First step: 40 Nꞏm (4.0 kgꞏm / 29 lb ft)

Second step: 60° to 90°

15. Timing belt

1) Install tensioner and tighten the bolt temporarily.

2) Align timing mark with camshaft pulley timing

mark and timing gear case timing mark.

3) Set No.1 cylinder TDC position.4) Install the timing belt in the following order

camshaft pulley, oil pump pulley, tensioner.

NOTE:

1) It is recommended for easy installation that the belt

be secured with a double clip after it is installed to

each pulley.

2) The “ISUZU” mark should be read from the front of

the engine when installing the timing belt.

5) Install the belt tensioner.

6) Conform not phase difference each pulley.

7) Tension the timing belt with two turns of the

crankshaft.

8) Tighten the tensioner bolt in order A to B to the

specified torque.

Torque: Bolt A 5 Nꞏm (0.5 kgꞏm/3.6 lb ft)

Bolt B 2 Nꞏm (0.2 kgꞏm/1.4 lb ft)

Legend

(1) Align Mark

(2) Camshaft Pulley

(3) Timing Belt

(4) Oil Pump Pulley

(5) Bolt B

(6) Tensioner Assy

(7) Tensioner Bolt A

(8) Tensioner Spring

16. CMP sensor bracket

1) Install CMP sensor bracket and tighten bolt to

the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

17. Timing belt cover

1) Install timing belt cover and tighten bolt to the

specified torque.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

2) Tighten CMP sensor to the specified torque.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

012RW036

012RW099

1

2

3

8

67

4 5

F06RW055

Page 1793 of 6000

6A – 60 ENGINE MECHANICAL

VALVE STEM SEAL, VALVE SPRING AND ADJUSTER

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove the air duct from between air cleaner and

turbocharger.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Disconnect PCV hose.

7. Disconnect EGR vacuum hose.

8. Disconnect harness connectors around the cylinder

head such as the injector, CMP sensor, MAP

sensor, EGR sensor, EVRV, IAT sensor, A/C

compressor, TP stepping motor, TP sensor and fuel

temperature sensor etc.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out drivebelt.

12. Remove heat protector, remove exhaust valve

assembly.

13. Remove water cooling hose and lubrication pipe for

turbocharger.

14. Remove turbocharger assembly.

15. Remove hose between thermostat and radiator.

16. Remove noise insulator cover of cylinder head.

NOTE: Do not damage injector harness.

17. Remove high pressure oil pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner then remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove engine coolant pipe between cylinder

head and water pump.

1

2

3

4

5

6

9

10

7

8

011RW031

Legend

(1) Adjuster

(2) Tappet

(3) Split Collar

(4) Spring Seat Upper

(5) Valve Spring(6) Spring Seat Lower

(7) Valve Stem Seal

(8) Valve Guide

(9) Valve Seat

(10) Valve

Page 1799 of 6000

6A – 66 ENGINE MECHANICAL

INSTALLATION

1. Valve stem seal

1) Use the special tool to install the stem seal to the

valve guide.

Stem Seal Installer: 5-8840-2033-0

2. Valve spring.

1) Install the lower valve seat spring, valve spring,

then the upper valve spring seat.

2) Use valve spring compressor to compress the

spring then install the split collar.

Valve spring compressor: 5-8840-2441-0

NOTE: Make sure the split collar installs completely.

3. Install cylinder head assembly.

Refer to “Cylinder Head” in this manual.

4. Install the camshaft carrier with camshaft.

Refer to “Camshaft” in this manual.

5. Install oil rail assembly.

Refer to “Oil rail and injector” in this manual.

6. Install injector assembly.

Refer to “Oil rail and injector” in this manual.

7. Install the injector harness assembly.

Refer to “Injector” in this manual.

8. Reconnect harness connecter to oil pressure

sensor and oil temperature sensor on the oil rail.

9. Reconnect Injector harness connecter to injector.

Refer to “Injector” in this manual.

10. Install cylinder head cover with gasket.

Refer to “Cylinder Head Cover” in this manual.

11. Install glow plug with specified torque.

Torque: 15 Nꞏm (1.5 kgꞏm / 10.8 lb ft)

12. Install the intake manifold assembly.

Refer to “Intake Manifold” in this manual.

13. Install the fuel pipe.14. Install the water pipe between the cylinder head

and water pump.

Torque: 20 Nꞏm (2.0 kꞏm / 14.5 lb ft)

15. Install the front plate.

16. Install the camshaft pulley.

Refer to “Timing Gear” in this manual.

17. Install timing belt and set the tensioner.

Refer to “Timing Belt” in this manual.

18. Install CMP sensor bracket.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

19. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

20. Fill the oil rail with engine oil then immediately

install the high pressure oil pipe with the specified

torque.

Torque: 80 Nꞏm (8.1 kgꞏm / 57.9 lb ft)

21. Install the noise insulator cover.

22. Reconnect hose between thermostat and radiator.

23. Install turbocharger assembly.

Refer to “Turbocharger” in this manual.

24. Install water hose and oil pipe for turbocharger.

Refer to “Turbocharger” in this manual.

25. Install the valve assembly and install heat protector.

26. Install generator and set the fan belts.

27. Install A/C compressor bracket, compressor

assembly and set drive belt.

28. Reconnect harness connector around cylinder

head.

29. Reconnect vacuum hose to EGR valve.

30. Reconnect PCV hose.

31. Install oil level gauge guide assembly.

32. Install intercooler assembly.

Refer to “Intercooler” in this manual.

33. Install the air duct assembly.

34. Fill engine coolant.

35. Connect battery ground cable.

014RW042

Page 1805 of 6000

6A – 72 ENGINE MECHANICAL

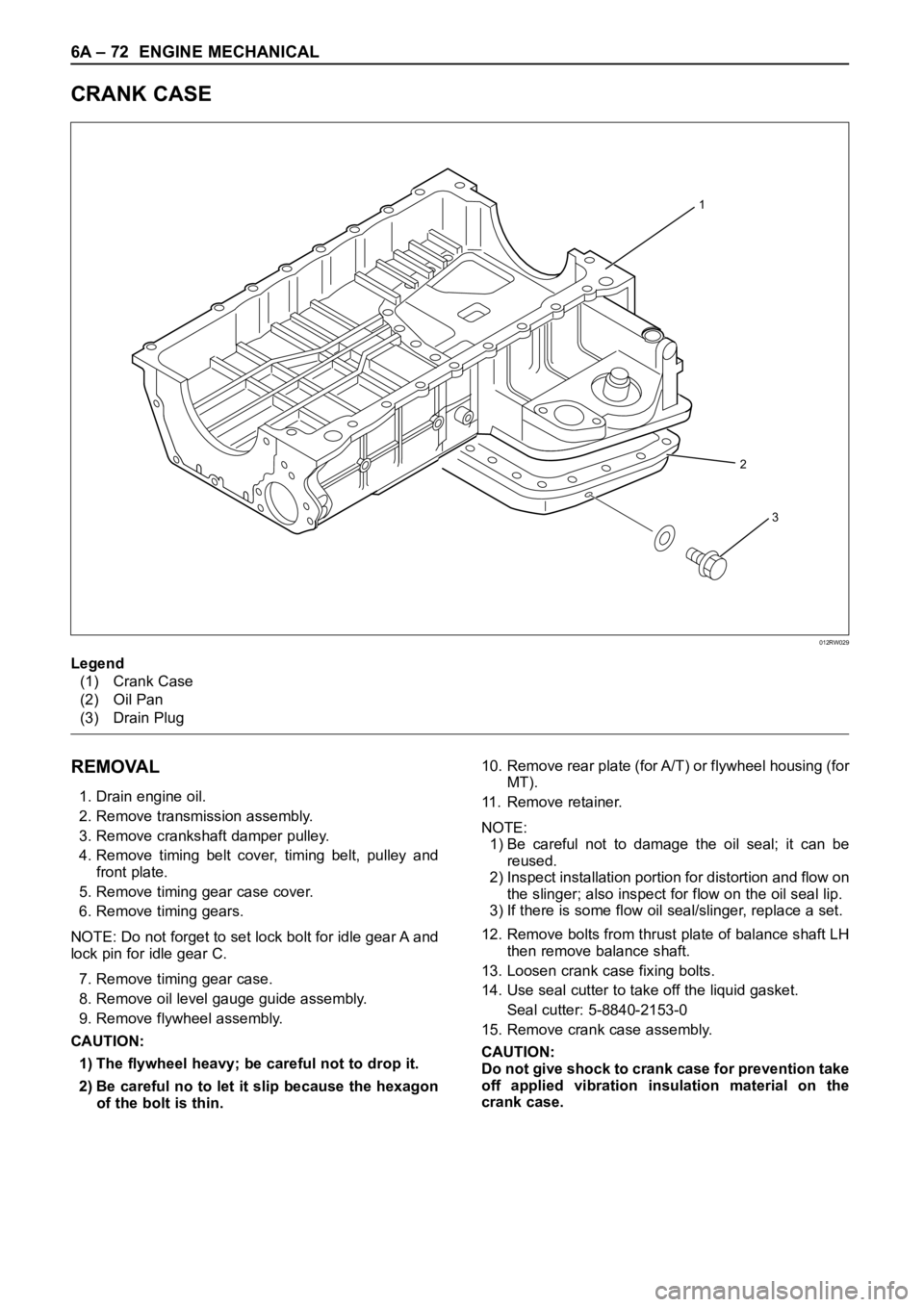

CRANK CASE

REMOVAL

1. Drain engine oil.

2. Remove transmission assembly.

3. Remove crankshaft damper pulley.

4. Remove timing belt cover, timing belt, pulley and

front plate.

5. Remove timing gear case cover.

6. Remove timing gears.

NOTE: Do not forget to set lock bolt for idle gear A and

lock pin for idle gear C.

7. Remove timing gear case.

8. Remove oil level gauge guide assembly.

9. Remove flywheel assembly.

CAUTION:

1) The flywheel heavy; be careful not to drop it.

2) Be careful no to let it slip because the hexagon

of the bolt is thin.10. Remove rear plate (for A/T) or flywheel housing (for

MT).

11. Remove retainer.

NOTE:

1) Be careful not to damage the oil seal; it can be

reused.

2) Inspect installation portion for distortion and flow on

the slinger; also inspect for flow on the oil seal lip.

3) If there is some flow oil seal/slinger, replace a set.

12. Remove bolts from thrust plate of balance shaft LH

then remove balance shaft.

13. Loosen crank case fixing bolts.

14. Use seal cutter to take off the liquid gasket.

Seal cutter: 5-8840-2153-0

15. Remove crank case assembly.

CAUTION:

Do not give shock to crank case for prevention take

off applied vibration insulation material on the

crank case.

1

2

3

012RW029

Legend

(1) Crank Case

(2) Oil Pan

(3) Drain Plug

Page 1806 of 6000

ENGINE MECHANICAL 6A – 73

INSTALLATION

1. Install relief valve (if it was removed).

Torque: 30 Nꞏm (3.1 kgꞏm / 22 lb ft)

2. Insert O-ring to strainer, install strainer and tighten

to specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

3. Apply liquid gasket (TB1207B or equivalent) to

surface of oil pan and tighten bolt to the specified

torque.

Torque: 19 Nꞏm (1.9 kgꞏm / 13.7 lb ft)

4. Apply engine oil to the balance shaft and insert it

into crank case.

NOTE:

Do not damage bearing when inserting the balance

shaft.

Make sure it rotates smoothly.

5. Tighten thrust plate of balance shaft LH.

Torque: 25 Nꞏm (2.5 kgꞏm / 18 lb ft)

6. Set O-ring port of oil gallery on the cylinder block.

7. Apply liquid gasket (TB1207C or equivalent) to

crankcase fixing surface then tighten bolts to the

specified torque.

Torque: 25 Nꞏm (2.5 kgꞏm / 18 lb ft)

NOTE: Make sure there is no oil, dust or scratches on

the surface coated with liquid gasket and mount within

five minutes of gasket application.8. Install retainer with oil seal.

9. Install rear plate (A/T) or flywheel housing (MT),

tighten bolt to the specified torque.

Torque: 97 Nꞏm 9.9 kgꞏm / 72 lb ft)

10. Install flywheel assembly with applied engine oil to

the bolt, tighten the bolt using angular tightening

method.

1st step: 59 Nꞏm (6.0 kgꞏm / 43 lb ft)

2nd step: 60° to 90°

11. Install oil level gauge guide assembly.

12. Install timing gear case.

Torque: 20 Nꞏm (2.5 kgꞏm / 14.5 lb ft)

13. Install timing gears

Refer to “Timing Gear” in this manual.

14. Remove lock bolt from idle gear A and remove lock

pin from idle gear C.

15. Install timing gear case cover.

Torque: 20 Nꞏm (2.5 kgꞏm / 14.5 lb ft)

16. Install oil pump pulley.

Torque: 10 Nꞏm (1.0 kgꞏm / 7.2 lb ft)

17. Install camshaft pulley tighten bolt with angular

tightening method.

To r q u e :

1st step: 40 Nꞏm (4.0 kgꞏm / 29 lb ft)

2nd step: 75°

18. Install timing belt and belt tensioner.

Refer to “Timing Gear” in this manual.

19. Install crankshaft damper pulley.

Torque: 220 Nꞏm (22 kgꞏm / 159 lb ft)

20. Fill engine oil.

2

2~2.5mm

2~2.5mm

Apply liquid gasket around inside

of the bolt hole

Bolt hole

Inside

Outside

F06HX00001

2

2~2.5mm

2~2.5mm

Apply liquid gasket around inside

of the bolt hole

Bolt hole

Inside

Outside

F06HX00001

Page 1860 of 6000

ENGINE FUEL 6C – 15

HIGH PRESSURE OIL PUMP

REMOVAL

1. Disconnect battery ground cable.

2. Remove air cleaner cover and air duct

3. Intercooler assembly

Refer to “Intercooler” in this manual.

4. Remove high pressure oil pipe

5. Timing belt cover

Disconnect CMP sensor cable.

Remove CMP sensor bracket.

6. Tensioner

7. Timing Belt

8. Remove high pressure oil pump timing pulley

9. Remove crankshaft damper pulley

10. Remove timing gear case cover

11. Remove idle gear A

Before removing idle gear A, set two bolts to the

sub gear of idle gear A and turn it to align the teeth

of idle gear A main gear.

Then lock them by bolts as shown in the illustration.Legend

(1) Idle gear A sub gear

(2) Idle gear A main gear

(3) Bar

(4) Lock bolt

1

2

43

Legend

(1) O-Ring

(2) High Pressure Oil Pump Assembly

(3) Nut

(4) O-Ring

040RW007

4 1

2

3

014RW177

Page 1863 of 6000

6C – 18 ENGINE FUEL

4. Remove lock bolt of idle gear A.

5. Install timing gear case cover.

Refer to “Timing gear” in this manual.

6. Install front plate.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

7. Install timing pulley of high pressure oil pump.

Torque: 10 Nꞏm (1.0 kgꞏm/7.2 lb ft)

8. Install timing belt and tighten timing belt tensioner

assembly.

Refer to “Cylinder head” in this manual.

Legend

(1) Align Mark

(2) Camshaft Pulley

(3) Timing Belt

(4) High Pressure Oil Pump Pulley

(5) Bolt

(6) Tensioner Assembly

(7) Tensioner Bolt

(8) Tensioner Spring

9. Install CMP sensor bracket.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

10. Connect CMP sensor cable.

11. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

12. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

13. Immediately install high pressure oil pipe and

tighten to specified torque.

NOTE:

1) Use new O-ring.

2) Clean O-ring groove and fitting surface of parts.

3) Apply engine oil to O-ring.

Torque: 80 Nꞏm (8.1 kgꞏm/57.9 lb ft)14. Install the crankshaft damper pulley with specified

torque.

Torque: 220 Nꞏm (22 kgꞏm/159 lb ft)

15. Install the intercooler assembly.

Refer to “Intercooler” in this manual.

16. Install air cleaner cover and air duct.

1

2

3

8

67

4 5

F06RW055

Page 1943 of 6000

6E–50

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

StepNo Ye s Va l u e ( s ) Action

10Refer to Engine Mechanical Diagnosis to diagnose the

following conditions:

Faulty camshaft drive belts

Leaking or sticky valves or rings

Excessive valve deposits

Weak valve springs

Incorrect valve timing

Leaking head gasket

Is the action complete?

—Verify repairGo to Step 11

11Observe the “Engine Speed” data display on the Tech 2

while cranking the engine.

Is the engine RPM indicated? (If the Tech 2 is normally

powered from the cigarette lighter socket, and if the

Tech 2 display goes blank while cranking the engine, it

will be necessary to power the Tech 2 directly from the

vehicle battery.)

—Go to Step 12Go to Step 17

121. At the ECM (female) side of the connector

mentioned in step, connect a test light between the

ignition + terminal and one of the injector driver

circuits at the same connector.

2. Ignition “ON.”

3. Observe the test light, and repeat the test for each

injector driver circuit by oscilloscope.

Did the test light stay on when checking any of the 4

injector driver circuits?

—Go to Step 13Go to Step 15

131. Ignition “OFF,” disconnect the ECM.

2. Ignition “ON,” observe the test light.

Is the test light “ON?”

—Go to Step 14Go to Step 16

14Locate and repair the short to ground in the injector

driver circuit.

Is the action complete?

—Verify repair—

15Check for an open injector driver circuit.

Was a problem found?

—Verify repairGo to Step 16

16Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

171. Raise the vehicle and disconnect the CKP sensor

harness.

2. Ignition “ON.”

3. With a test light to ground, probe the harness

ignition feed terminal.

Did the light illuminate?

—Go to Step 19Go to Step 18

18Check the ignition feed wire between the sensor and

the ECM for a short to ground or open circuit.

Is the action complete?

—Verify repair—