width OPEL FRONTERA 1998 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2264 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–19

C07RT006

Class 2 data is also pulse width modulated. Each bit of

information can have one of two lengths: long or short. On

the other hand, UART data bits come in only one length

(short). The pulse width modulation of Class 2 data allows

better utilization of the data line.

The message carried on Class 2 data streams are also

prioritized. This means that if two devices try to

communication on the data line at the same time, only the

higher priority message will continue. The device with the

lower priority message must wait.

NOTE: The Class 2 data wire is always terminal 2 of the

new 16–terminal Data Link Connector (DLC).

16 – Terminal Data Link Connector (DLC)

OBD II standardizes Data Link Connector (DLC)

configurations. The DLC, formerly referred to as the

ALDL, will be a 16–terminal connector found on the lower

left side of the driver’s side instrument panel. All

manufacturers must conform to this 16–terminal

standard.

821RW262

Page 2312 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–67

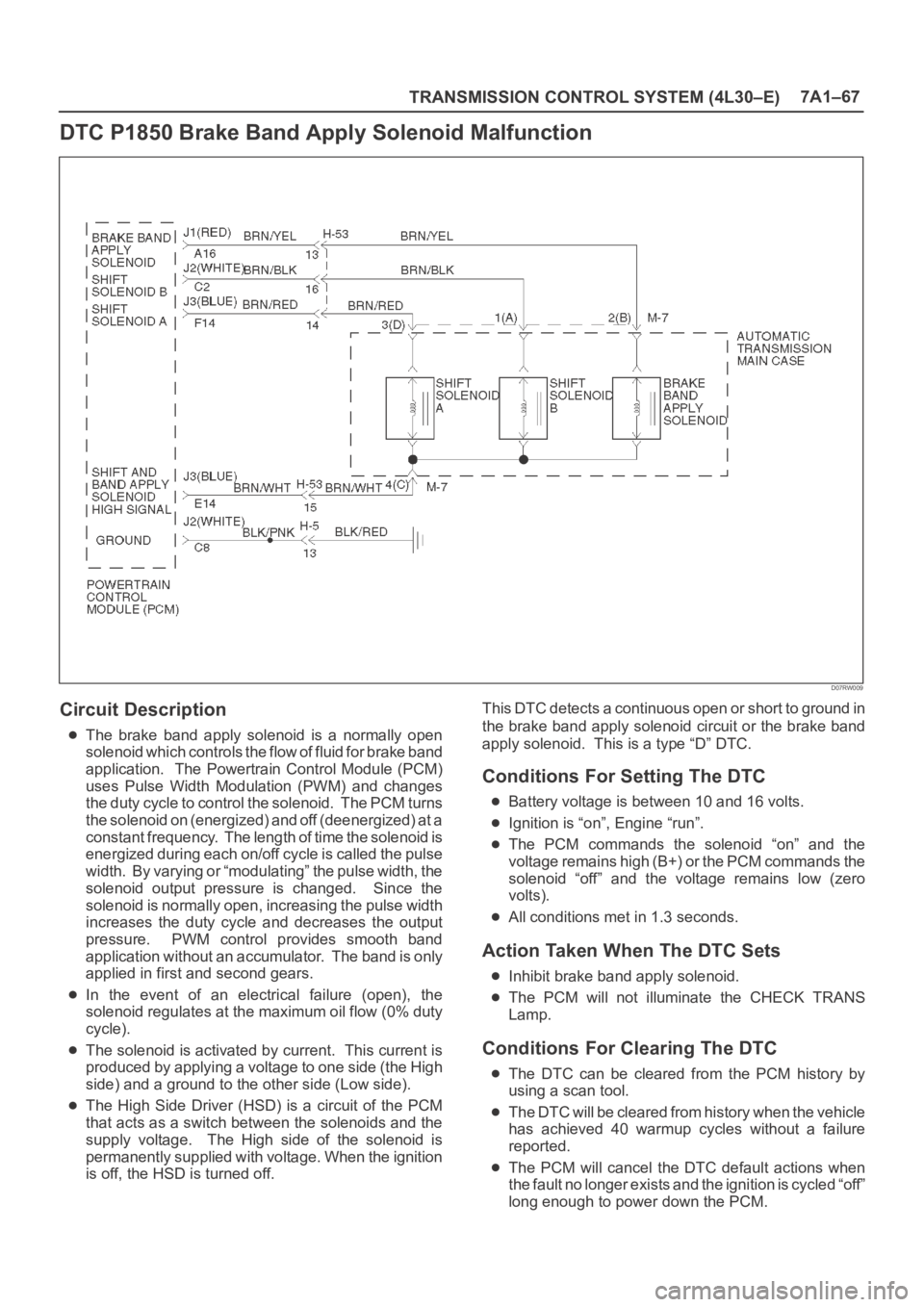

DTC P1850 Brake Band Apply Solenoid Malfunction

D07RW009

Circuit Description

The brake band apply solenoid is a normally open

solenoid which controls the flow of fluid for brake band

application. The Powertrain Control Module (PCM)

uses Pulse Width Modulation (PWM) and changes

the duty cycle to control the solenoid. The PCM turns

the solenoid on (energized) and off (deenergized) at a

constant frequency. The length of time the solenoid is

energized during each on/off cycle is called the pulse

width. By varying or “modulating” the pulse width, the

solenoid output pressure is changed. Since the

solenoid is normally open, increasing the pulse width

increases the duty cycle and decreases the output

pressure. PWM control provides smooth band

application without an accumulator. The band is only

applied in first and second gears.

In the event of an electrical failure (open), the

solenoid regulates at the maximum oil flow (0% duty

cycle).

The solenoid is activated by current. This current is

produced by applying a voltage to one side (the High

side) and a ground to the other side (Low side).

The High Side Driver (HSD) is a circuit of the PCM

that acts as a switch between the solenoids and the

supply voltage. The High side of the solenoid is

permanently supplied with voltage. When the ignition

is off, the HSD is turned off.This DTC detects a continuous open or short to ground in

the brake band apply solenoid circuit or the brake band

apply solenoid. This is a type “D” DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

Ignition is “on”, Engine “run”.

The PCM commands the solenoid “on” and the

voltage remains high (B+) or the PCM commands the

solenoid “off” and the voltage remains low (zero

volts).

All conditions met in 1.3 seconds.

Action Taken When The DTC Sets

Inhibit brake band apply solenoid.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Page 2601 of 6000

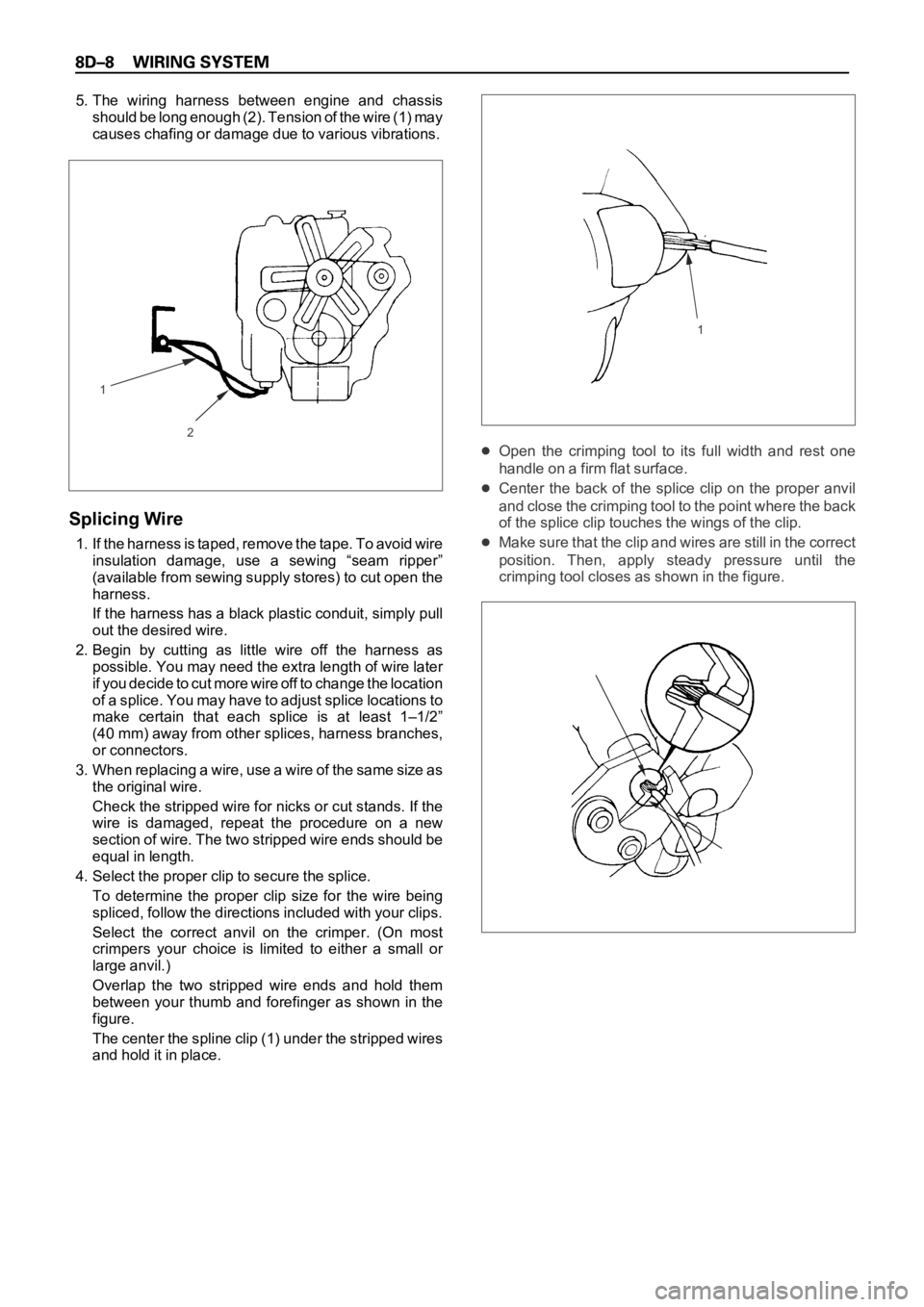

5. The wiring harness between engine and chassis

should be long enough (2). Tension of the wire (1) may

causes chafing or damage due to various vibrations.

Splicing Wire

1. If the harness is taped, remove the tape. To avoid wire

insulation damage, use a sewing “seam ripper”

(available from sewing supply stores) to cut open the

harness.

If the harness has a black plastic conduit, simply pull

out the desired wire.

2. Begin by cutting as little wire off the harness as

possible. You may need the extra length of wire later

if you decide to cut more wire off to change the location

of a splice. You may have to adjust splice locations to

make certain that each splice is at least 1–1/2”

(40 mm) away from other splices, harness branches,

or connectors.

3 . W h e n r e p l a c i n g a w i r e , u s e a w i r e o f t h e s a m e s i z e a s

the original wire.

Check the stripped wire for nicks or cut stands. If the

wire is damaged, repeat the procedure on a new

section of wire. The two stripped wire ends should be

equal in length.

4. Select the proper clip to secure the splice.

To determine the proper clip size for the wire being

spliced, follow the directions included with your clips.

Select the correct anvil on the crimper. (On most

crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them

between your thumb and forefinger as shown in the

figure.

The center the spline clip (1) under the stripped wires

and hold it in place.

Open the crimping tool to its full width and rest one

handle on a firm flat surface.

Center the back of the splice clip on the proper anvil

and close the crimping tool to the point where the back

of the splice clip touches the wings of the clip.

Make sure that the clip and wires are still in the correct

position. Then, apply steady pressure until the

crimping tool closes as shown in the figure.

2

11

Page 4237 of 6000

4C–31 DRIVE SHAFT SYSTEM

Sleeve Condition

Check and see that there is no wear, damage, or cracking

in the sleeve.

NOTE: Close inspection of the groove and inner gear are

required because those are important parts.

Sleeve Function

412RW011Operate the sleeve with the inner shaft combined with the

clutch gear. If roughness is felt, replace the sleeve.

NOTE: Gear oil should be applied to the contact surface

of gear.

Check the width of sleeve center groove.

Limit: 7.1 mm (0.28 in) max.

412RW022

Clutch Gear Condition

Check and see that there is no wear, damage, cracking,

or any other abnormality in the clutch gear.

Clutch Gear Function

412RW010If there is an abnormality such as roughness when

operated in combination with sleeve, replace the clutch

gear.

NOTE: When inspecting, gear oil should be applied to the

contact surface of gear.

Clutch Gear Journal Diameter

Make sure of the size illustrated.

Limit: 36.98 mm (1.456 in) min.

412RW009

Page 4499 of 6000

6A–3

ENGINE MECHANICAL

General Description

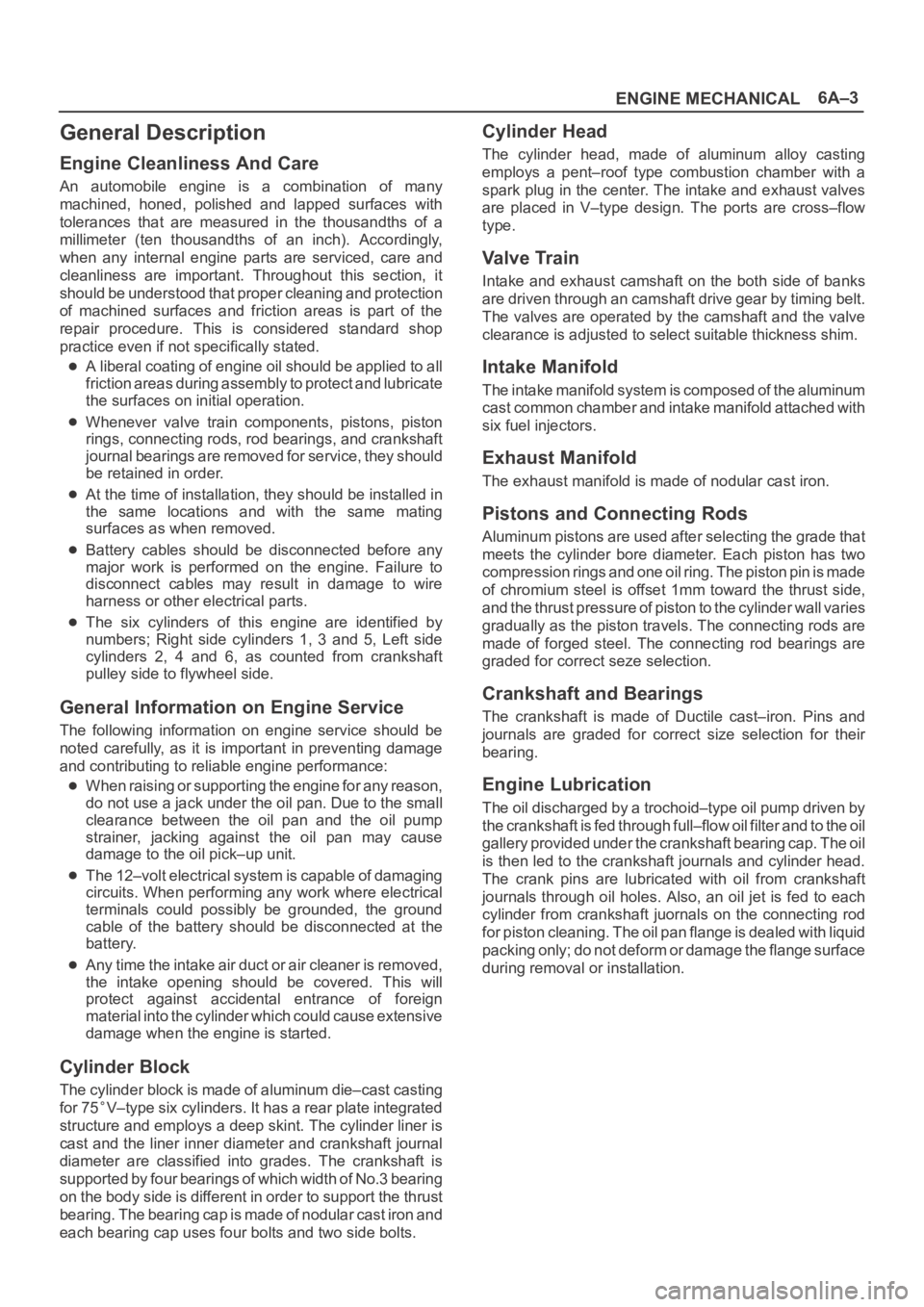

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 4555 of 6000

6A–59

ENGINE MECHANICAL

Limit: 39.47 mm (1.5539 in)

Exhaust

Standard: 39.30 mm (1.5472 in)

Limit: 39.45 mm (1.5531 in)

014RW047

2. Measure the valve seat contact width. Make the

necessary corrections if the seat contact surface is

damaged or rough or if the contact width wear

exceeds the limit.

Valve seat contact width

Standard: 1.1 mm (0.0433 in)

Limit: 1.7 mm (0.0669 in)

014RS011

Contact Surface Angle on Valve Seat on

Va l v e

1. Measure contact surface angle on valve seat.2. If the measured value exceeds the limit, replace

valve, valve guide and valve seat as a set.

Valve contact surface angle: 45

014RS012

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert

surface.

2. Use a valve cutter to minimize scratches and other

rough areas. This will bring the contact width back to

the standard value. Remove only the scratches and

rough areas. Do not cut away too much. Take care not

to cut away unblemished areas of the valve seat

surface.

Valve seat angle degree: 90

014RW059

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5.Turn the valve while lapping it to fit the valve seat

insert.

Page 4556 of 6000

6A–60

ENGINE MECHANICAL

6. Check that the valve contact width is correct.

7. Check that the valve seat insert surface is in contact

with the entire circumference of the valve.

014RS014

Valve Seat Insert Replacement

1. Arc weld the rod at several points. Be careful not to

damage the aluminum section.

2. Allow the rod to cool for a few minutes. This will cause

the valve seat to shrink.

3. Strike the rod and pull it out.

014RS015

4. Carefully clean the valve seat press–fit section on the

cylinder head side.

5. Heat the press–fit section with steam or some other

means to cause expansion. Cool the valve seat with

dry ice or some other means.

6. Insert the press–fit section into the valve seat

horizontally.

Standard fitting interference: 0.14 mm–0.09 mm

(0.0055 in–0.0035 in)7. After insertion, use a seat grinder to grind finish the

seating face. Carefully note the seating angle, the

contact width, and the depression.

8. Lap the valve and the seat.

Reassembly

1. Install valve guide (1) to cylinder head. Apply engine

oil to the outside of the valve guide. Using valve guide

replacer 5–8840–2442–0, drive in a new valve guide

from the camshaft side.

2. Install oil controller (3) and spring lower seat (2).

Using oil controller replacer 5–8840–0623–0, drive in

a new oil controller.

014RW058

3. Install valve to valve guide. Before install valve guide

apply engine oil to the outside of the valve stem.

4. Install valve spring to cylinder head. Attach the valve

spring to the lower spring seat. The painted area of

the valve spring should be facing downward.

014RS020

Page 4567 of 6000

6A–71

ENGINE MECHANICAL

NOTE: Do not apply engine oil to the crank case side

bolts.

Main bearing cap bolts.

Torque: 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

Oil gallery fixing bolts.

Torque:

1st step: 29 Nꞏm (3.0 Kgꞏm/21 lb ft)

2nd step 55

65

Crank case side bolts

Torque : 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

NOTE: Do not allow the crankshaft to rotate.

015RS006

10. Remove the main bearing caps in the sequence

shown in the illustration.

015RS004

11. Measure the plastigage width and determine the oil

clearance. If the oil clearance exceeds the specified

limit, replace the main bearings as a set and/or

replace the crankshaft.

Standard : 0.019 mm–0.043 mm

(0.0007 in–0.0017 in)Limit : 0.08 mm (0.0031 in)

015RS008

12. Clean the plastigage from the bearings and the

crankshaft.

Remove the crankshaft and the bearings.

Crankshaft (12) Inspection

Inspect the surface of the crankshaft journal and crank

pins for excessive wear and damage. Inspect the oil seal

fitting surfaces for excessive wear and damage. Inspect

the oil ports for obstructions.

Inspection and Repair

1. Carefully set the crankshaft on the V–blocks. Slowly

rotate the crankshaft and measure the runout. If the

crankshaft runout exceeds the specified limit, the

crankshaft must be replaced.

Runout : 0.04 mm (0.0016 in)

015RS007

Page 4572 of 6000

6A–76

ENGINE MECHANICAL

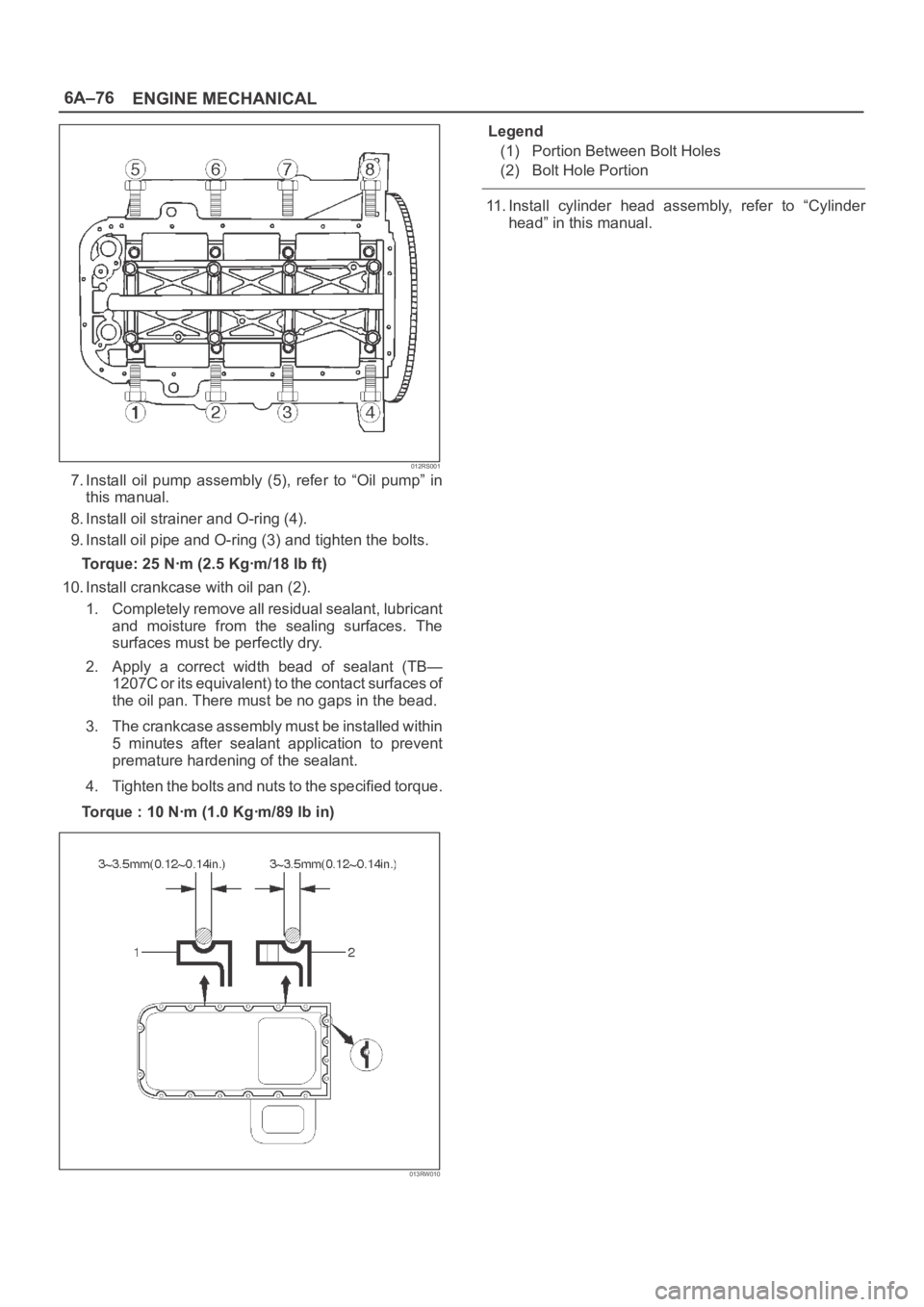

012RS001

7. Install oil pump assembly (5), refer to “Oil pump” in

this manual.

8. Install oil strainer and O-ring (4).

9. Install oil pipe and O-ring (3) and tighten the bolts.

Torque: 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

10. Install crankcase with oil pan (2).

1. Completely remove all residual sealant, lubricant

and moisture from the sealing surfaces. The

surfaces must be perfectly dry.

2. Apply a correct width bead of sealant (TB—

1207C or its equivalent) to the contact surfaces of

the oil pan. There must be no gaps in the bead.

3. The crankcase assembly must be installed within

5 minutes after sealant application to prevent

premature hardening of the sealant.

4. Tighten the bolts and nuts to the specified torque.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

013RW010

Legend

(1) Portion Between Bolt Holes

(2) Bolt Hole Portion

11. Install cylinder head assembly, refer to “Cylinder

head” in this manual.

Page 4578 of 6000

6A–82

ENGINE MECHANICAL

4. Reinstall the rod caps (12) to their original

positions.

Tighten the rod cap nuts.

Torque: 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

NOTE: Do not allow the crankshaft to rotate.

5. Remove the rod caps.

6. Measure the width of the plastigage and

determine the oil clearance. If the oil clearance

exceeds the limit, replace the rod bearing as a

set.

Standard : 0.019 mm–0.043 mm

(0.0007 in–0.0017 in)

Limit : 0.08 mm (0.003 in)

015RS008

7. Clean the plastigage from the bearings and the

crankshaft pins.

Con–rod Bearing Selection

Select and install the new connecting rod bearings,

paying close attention to the connecting rod big end

diameter size mark (1).

NOTE: Take care not to confuse the alignment mark (2)

and the size mark (1) during the installation procedure.

015RS034

1 Size MarkBig end Bore

DiameterCrankshaft Pin

DiameterConnecting Rod

Bearing Thickness

(Reference)Color of

Size

MarkOil Clearance

(Reference)

A56.994-57.000

(2.2439-2.2441)1.512-1.516

(0.0595-0.0597)Ye l l o w0.025-0.054

(0.0010-0.0021)

B56.988-56.994

(2.2436-2.2439)53.922-53.937

(2.1229-2.1235)1.508-1.512

(0.0594-0.0595)Green0.027-0.056

(0.0011-0.0022)

C56.982-56.988

(2.2434-2.2436)1.504-1.508

(0.0592-0.0594)Pink0.029-0.058

(0.0011-0.0023)

Reassembly

1. Install connecting rod

2. Install piston3. Install piston pinApply a thin coat of engine oil to the piston pin. Try to

insert the piston pin into the piston pin hole with

normal finger pressure.

NOTE: When changing piston / connecting rod

combinations, do not change the piston / piston pin

combination and do not reuse the old piston pin.