width OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5456 of 6000

6E–27 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Non-Emissions related

Dose not request illumination of any lamp

Stores a History DTC on the first trip with a fail

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic test

fails

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

Engine Speed

Engine Load

Engine Coolant Temperature

Vehicle Speed

Intake Throttle Position

MAP

Injector Base Pulse Width

Loop Status

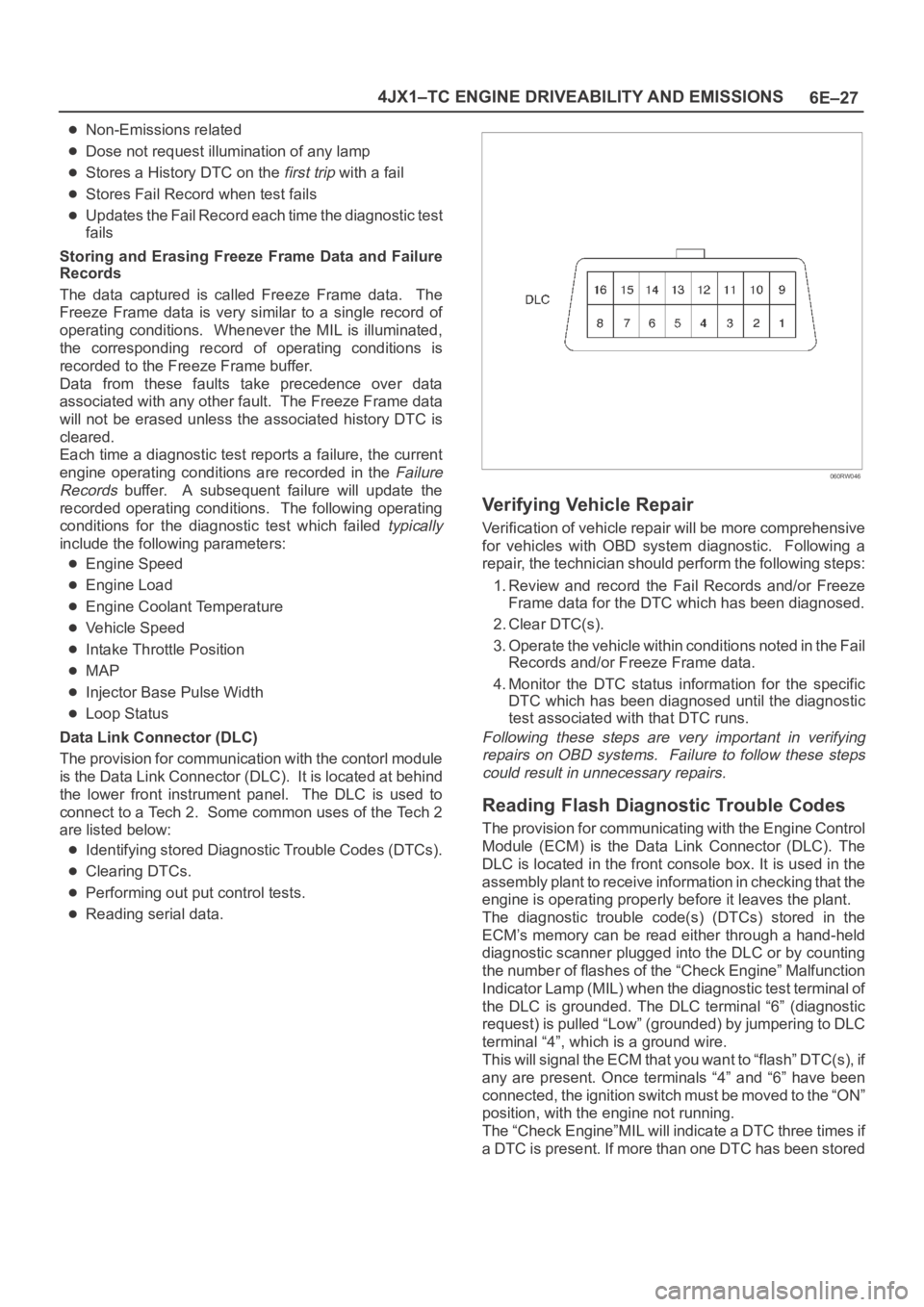

Data Link Connector (DLC)

The provision for communication with the contorl module

is the Data Link Connector (DLC). It is located at behind

the lower front instrument panel. The DLC is used to

connect to a Tech 2. Some common uses of the Tech 2

are listed below:

Identifying stored Diagnostic Trouble Codes (DTCs).

Clearing DTCs.

Performing out put control tests.

Reading serial data.

060RW046

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensive

for vehicles with OBD system diagnostic. Following a

repair, the technician should perform the following steps:

1. Review and record the Fail Records and/or Freeze

Frame data for the DTC which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the Fail

Records and/or Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). The

DLC is located in the front console box. It is used in the

assembly plant to receive information in checking that the

engine is operating properly before it leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-held

diagnostic scanner plugged into the DLC or by counting

the number of flashes of the “Check Engine” Malfunction

Indicator Lamp (MIL) when the diagnostic test terminal of

the DLC is grounded. The DLC terminal “6” (diagnostic

request) is pulled “Low” (grounded) by jumpering to DLC

terminal “4”, which is a ground wire.

This will signal the ECM that you want to “flash” DTC(s), if

any are present. Once terminals “4” and “6” have been

connected, the ignition switch must be moved to the “ON”

position, with the engine not running.

The “Check Engine”MIL will indicate a DTC three times if

a DTC is present. If more than one DTC has been stored

Page 5471 of 6000

6E–42

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

4JX1-TC Engine (Automatic and Manual Transmission)

Te c h 2

Parameter

Data ListUnits

DisplayedTy p i c a l D a t a

Values (IDLE)Typical Data

Va l u e s

(2500 RPM)Refer To

Battery VoltageEngineVo l t s12.5 14.513 15General Description

Ignition StatusEngineOn/OffOnOnGeneral Description

Ignition Relay2EngineOn/OffOnOnGeneral Description

Idle SwitchEngineInactive/

Active——DTC P0510, P1510

Manifold

Absolute

PressureEngineKPa96 106110 150General Description

DTC P0107, P0108

Rail Oil

PressureEngineMPa3.5 54.5 10General Description

DTC P0192, P0193

Desired Rail Oil

PressureEngineMPa4 55 9General Description

DTC P0192, P0193

Fuel

TemperatureEngineC (F)75 8575 85DTC P0182, P0183

Quick Warming

SwitchEngineOn/OffOffOffDTC P0380

Thermo RelayEngineOn/Off——DTC P1655

Actual EGR

PressureEngineKPa58 60M/T 63 66

A/T 95

105

DTC P0405, P0406

Barometric

PressureEngineKPa98 10298 102General Description

Relative EGR

PressureEngineKPa–38 –45M/T –34 –37

A/T 0General Description

Desired EGR

PressureEngineKPa–43 –40M/T 36

A/T 0General Description

Brake SwitchEngineInactive/

Active——DTC P1588

GearEngine————

Vehicle SpeedEngineKm/h00Transmission Diagnosis

Rail Pressure

Control ValveEngine%17 2218 27DTC P1193

EGR StatusEngineDisable/

EnableEnableM/T Enable

A/T DisableGeneral Description

EGR Switching

Va l v eEngineOn/Off——General Description

Throttle Motor

Position SensorEngineVo l t s3.1 3.90.2 0.9DTC P1485, P1486,

P1487

Throttle Motor

PositionEngineSteps

0 1.00 1.0

DTC P1488

Delirered Fuel

QuantityEnginemm 3/st

6 106 12

General Description

Injector StatusEngineDisable/

EnableEnableEnableDTC P0201, P0202,

P0203, P0204, General

Description

Injector Pulse

WidthEnginems0.9 1.250.7 1.1General Description

Injector Start

OffsetEngineCA——General Description

Page 5999 of 6000

7A1–6

TRANSMISSION CONTROL SYSTEM (4L30–E)

Shift Control

The transmission gear is shifted according to the shift

pattern selected by the driver. In shifting gears, the gear

ratio is controlled by the ON/ OFF signal using the shift

solenoid A and the shift solenoid B.

Band Apply Control

The band apply is controlled when in the 3–2 downshift

(engine overrun prevention) and the garage shift (shock

control).

The band apply solenoid is controlled by the signal from

the Pulse Width Modulation (PWM) to regulate the flow of

the oil.

Torque Converter Clutch Control

The clutch ON/OFF is controlled by moving the converter

clutch valve through shifting Torque Converter Clutch

(TCC) solenoid using the ON/OFF signal.

Line Pressure Control

The throttle signal allows the current signal to be sent to

the force motor. After receiving the current signal, the

force motor activates the pressure regulator valve to

regulate the line pressure.

On–Board Diagnostic System

Several malfunction displays can be stored in the

Powertrain Control Module (PCM) memory, and read out

of it afterward.The serial data lines, which are required for the testing of

the final assembly and the coupling to other electronic

modules, can be regulated by this function.

Fail Safe Mechanism

If there is a problem in the transmission system, the PCM

will go into a “backup” mode.

The vehicle can still be driven, but the driver must use the

select lever to shift gears.

Torque Management Control

The transmission control side sends the absolute spark

advance signal to the engine control side while the

transmission is being shifted. This controls the engine

spark timing in compliance with the vehicle running

condition to reduce the shocks caused by the change of

speed.

ATF Warning Control

The oil temperature sensor detects the ATF oil

temperature to control the oil temperature warning, TCC,

and the winter mode.

ABS Control (If equipped)

When the select lever is at “L” or “R” range, a signal is sent

to the ABS controller as one of the ABS control

conditions.