engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1432 of 6000

6E–315 ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the O-ring backup on the fuel injector.

2. Install the new O-ring on the fuel injector.

3. Install the fuel injector on the fuel rail.

055RW009

4. Use new fuel injector retainer clips to retain the fuel

injector to the fuel rail.

5. Coat the end of the fuel injector with engine oil.

6. Install the fuel rail. Refer to

Fuel Rail.

014RW164

7. Install the upper intake manifold. Refer to Common

Chamber in Engine Mechanical.

8. Install the engine cover.

9. Connect the negative battery cable.

Fuel Pressure Regulator

Removal Procedure

CAUTION: To reduce the risk of fire and personal

injury, it is necessary to relieve the fuel system

pressure before servicing the fuel system

components.

CAUTION: After relieving the system pressure, a

small amount of fuel may be released when servicing

fuel lines or connections. Reduce the chance of

personal injury by covering the fuel line fittings with

a shop towel before disconnecting the fittings. The

towels will absorb any fuel that may leak out. When

the disconnect is completed, place the towel in an

approved container.

NOTE: Compressed air must never be used to test or

clean a fuel pressure regulator, as damage to the fuel

pressure regulator may result.

NOTE: To prevent damage to the fuel pressure regulator,

do not immerse the pressure regulator in solvent.

1. Depressurize the fuel system. Refer to

Fuel Pressure

Relief Procedure

.

2. Disconnect the negative battery cable.

3. Remove the fuel pump relay. Refer to

Fuel Pump

Relay

.

4. Remove the pressure regulator hose from the fuel

pressure regulator.

014RW110

Page 1433 of 6000

6E–316

ENGINE DRIVEABILITY AND EMISSIONS

5. Remove the two bolts from the protector that secures

the common chamber.

014RW109

6. Remove the fuel pressure regulator attaching screw.

F06RW043

7. Remove the fuel pressure regulator from the fuel rail.

Disassembly Procedure

1. Remove the O-ring from the fuel pressure regulator.

2. Loosen the swivel nut.

3. Remove the fuel return line from the fuel pressure

regulator.

4. Remove the O-ring from the fuel return line.

The O-ring may be left inside the fuel pressure

regulator instead of on the fuel return line.

F06RW043

Assembly Procedure

1. Install a new O-ring on the fuel return line.

2. Install the fuel return line on the fuel pressure

regulator.

NOTE: Do not over-tighten the swivel nut on the fuel

pressure regulator. The fuel pressure regulator can be

damaged and fuel may leak if the swivel nut is

over-tightened.

3. Tighten the swivel nut.

4. Install a new O-ring on the fuel pressure regulator.

Page 1434 of 6000

6E–317 ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the fuel pressure regulator attaching screw.

Tighten

Tighten the fuel pressure regulator attaching screw

to 3 Nꞏm (26 lb in.).

F06RW043

2. Install the fuel pressure regulator on the fuel rail.

3. Install the two bolts to the protector that secures the

common chamber.

014RW109

4. Install the pressure regulator hose to the fuel

pressure regulator.

014RW110

5. Install the fuel pump relay. Refer to Fuel Pump Relay.

6. Connect the negative battery cable.

7. Crank the engine until it starts. Cranking the engine

may take longer than usual due to trapped air in the

fuel lines.

Fuel Metering System

Fuel Pressure Relief Procedure

CAUTION: To reduce the risk of fire and personal

injury, it is necessary to relieve the fuel system

pressure before servicing the fuel system

components.

CAUTION: After relieving the system pressure, a

small amount of fuel may be released when servicing

fuel lines or connections. Reduce the chance of

personal injury by covering the fuel line fittings with

a shop towel before you disconnect the fittings. The

towels will absorb any fuel that may leak out. When

the disconnect is completed, place the towel in an

approved container.

1. Remove the fuel cap.

Page 1435 of 6000

6E–318

ENGINE DRIVEABILITY AND EMISSIONS

2. Remove the fuel pump relay from the underhood

relay box. Refer to

Fuel Pump Relay.

TS23976R

3. Start the engine and allow it to stall.

4. Crank the engine for 30 seconds.

5. Disconnect the negative battery cable.

Fuel Pump Assembly

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain all the fuel from the tank.

3. Install and tighten the drain plug.

Tighten

Tighten the drain plug to 20 Nꞏm (14 lb ft.).

4. Remove the fuel tank. Refer to

Fuel Tank.

5. Remove the retaining screws from the fuel tank.

6. Remove the fuel pump assembly from the fuel tank.

Cover the fuel pump opening in order to prevent

dust, dirt, or debris from entering the fuel tank.

TS23795

Inspection Procedure

1. Inspect the fuel pump gasket for tears, cracks,

stretching, or rotting. If any of these conditions are

found, replace the fuel pump gasket.

2. Inspect the in-tank fuel filter for tears or evidence of

dirt, debris, or water in the fuel. If any of these

conditions are found, replace the in-tank fuel filter.

Installation Procedure

1. Install the fuel pump assembly.

2. Install the fuel pump assembly retaining screws.

3. Install the fuel tank assembly. Refer to

Fuel Tank.

4. Fill the tank with fuel.

5. Tighten the fuel filler cap.

6. Connect the negative battery cable.

TS23795

Page 1436 of 6000

6E–319 ENGINE DRIVEABILITY AND EMISSIONS

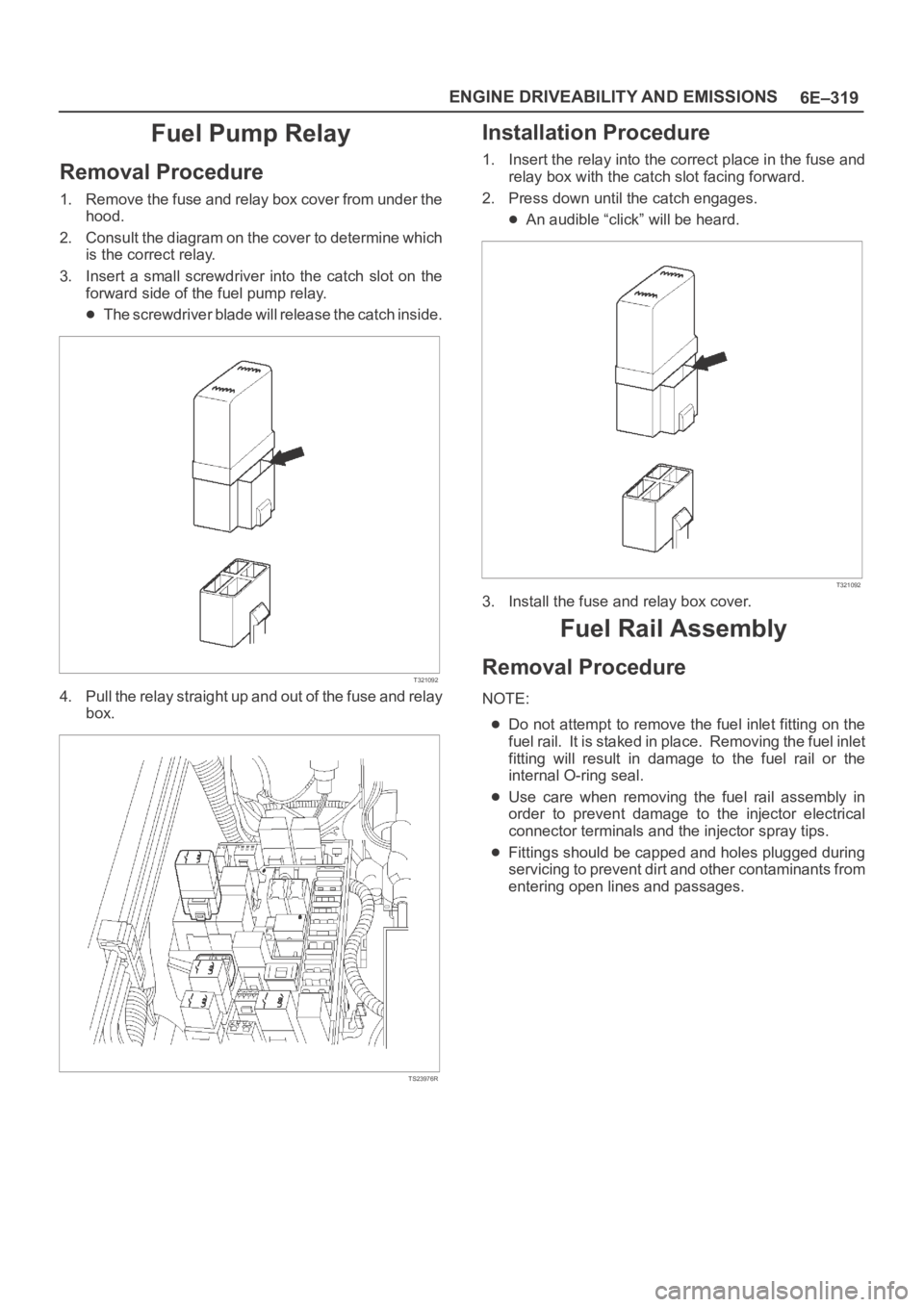

Fuel Pump Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Insert a small screwdriver into the catch slot on the

forward side of the fuel pump relay.

The screwdriver blade will release the catch inside.

T321092

4. Pull the relay straight up and out of the fuse and relay

box.

TS23976R

Installation Procedure

1. Insert the relay into the correct place in the fuse and

relay box with the catch slot facing forward.

2. Press down until the catch engages.

An audible “click” will be heard.

T321092

3. Install the fuse and relay box cover.

Fuel Rail Assembly

Removal Procedure

NOTE:

Do not attempt to remove the fuel inlet fitting on the

fuel rail. It is staked in place. Removing the fuel inlet

fitting will result in damage to the fuel rail or the

internal O-ring seal.

Use care when removing the fuel rail assembly in

order to prevent damage to the injector electrical

connector terminals and the injector spray tips.

Fittings should be capped and holes plugged during

servicing to prevent dirt and other contaminants from

entering open lines and passages.

Page 1437 of 6000

6E–320

ENGINE DRIVEABILITY AND EMISSIONS

IMPORTANT:An eight-digit identification number is

stamped on the side of the fuel rail. Refer to this number

when you service the fuel rail or when a replacement part

is required.

TS24022

Before removal, the fuel rail assembly may be cleaned

with a spray type engine cleaner. Follow the spray

package instructions. Do not immerse the fuel rails in

liquid cleaning solvent.

1. Depressurize the fuel system. Refer to Fuel Pressure

Relief Procedure in this Section.

2. Disconnect the negative battery cable.

3. Remove the engine cover.

4. Disconnect the accelerator pedal cable from throttle

body and cable bracket.

5. Disconnect the connectors from manifold absolute

pressure sensor, solenoid valve, electric vacuum

sensing valve.

6. Disconnect the vacuum hose on canister VSV and

positive crankcase ventilation hose.

7. Remove the common chamber. Refer to the common

chamber in Engine Mechanical.

1. Lift up carefully on the fuel injectors. Do not

separate the fuel injectors from the fuel rail.

2. If an injector becomes separated from the fuel

rail, the infector O-ring seals and the retainer clip

must be replaced.

3. Drain residual fuel into an approved container.

014RW164

8. If removal of the fuel pressure regulator is necessary,

refer to

Fuel Pressure Regulator.

9. If removal of the fuel injectors is necessary, refer to

Fuel Injectors.

Installation Procedure

1. If the fuel injectors were removed, install them. Refer

to

Fuel Injectors.

2. If the fuel pressure regulator was removed, install it.

Refer to

Fuel Pressure Regulator.

3. Install the common chamber. Refer to common

chamber in engine Mechanical.

014RW164

Page 1438 of 6000

6E–321 ENGINE DRIVEABILITY AND EMISSIONS

4. Connect the vacuum hose on Canister VSV and

positive crankcase ventilation hose.

5. Connect the connectors to manifold absolute

pressure sensor, solenoid valve, electric vacuum

sensing valve.

6. Connect the accelerator pedal cable to throttle body

and cable bracket.

7. Install the engine cover.

8. Connect the negative battery cable.

9. Crank the engine until it starts. Cranking the engine

may take longer than usual due to trapped air in the

fuel rail and in the injectors.

Fuel Tank

Removal Procedure

1. Disconnect the negative battery cable.

2. Loosen the fuel filler cap.

3. Drain the fuel from the tank into an approved

container.

4. Install and tighten the drain plug.

Tighten

Tighten the drain plug to 20 Nꞏm (14 lb ft.).

5. Disconnect the fuel filler hose at the fuel tank.

6. Disconnect the air breather hose at the fuel tank.

TS23796

7. Remove the undercover retaining bolts.

8. Remove the undercover.

TS23797

9. Disconnect the wiring connector to the fuel pump.

10. Disconnect the wiring connector to the fuel gauge

unit.

11. Remove the fuel gauge unit connector from the

bracket.

12. Disconnect the EVAP vapor hose.

13. Disconnect the fuel supply hose.

14. Disconnect the fuel return hose.

Plug the hoses to prevent dust from entering the

hoses.

TS23769

Page 1439 of 6000

6E–322

ENGINE DRIVEABILITY AND EMISSIONS

15. Remove the fuel tank retaining bolts on both sides.

16. Remove the fuel tank.

TS23770

Installation Procedure

1. Install the fuel tank.

Place the flanges on the left and right side of the

tank on the bracket.

2. Install the fuel tank retaining bolts.

Tighten

Tighten the fuel tank retaining bolts to 36 Nꞏm (27 lb

ft.).

TS23770

3. Connect the fuel return hose.

4. Connect the fuel supply hose.

5. Connect the EVAP vapor hose.

6. Connect the wiring connector for the fuel gauge unit.

7. Connect the fuel gauge wiring connector to the

bracket.

8. Connect the wiring connector for the fuel pump.

TS23769

9. Install the undercover.

10. Secure the undercover with the retaining bolts.

TS23797

Page 1440 of 6000

6E–323 ENGINE DRIVEABILITY AND EMISSIONS

11. Connect the fuel filler fuse at the tank.

12. Connect the air breather hose at the tank.

TS23796

13. Fill the fuel tank with fuel.

14. Tighten the fuel filler cap.

15. Connect the negative battery cable.

Throttle Body (TB)

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the cooling system. Refer to

Cooling System.

3. Remove the accelerator cable assembly. Refer to

Accelerator Cable in Engine Speed Control System..

4. Disconnect the electrical connectors:

Throttle position (TP) sensor.

Idle air control (IAC) solenoid.

Intake air temperature (IAT) sensor. Refer to

Intake Air Temperature Sensor.

035RW023

5. Disconnect the vacuum hose below the air horn.

6. Remove the intake air duct clamp.

7. Disconnect the intake air duct.

8. Disconnect the coolant lines from the throttle body.

9. Remove the bolts from the common chamber.

10. Remove the throttle body from the common chamber.

11. Remove the gasket from the upper intake manifold.

035RW024

12. Remove the IAC. Refer to Idle Air Control (IAC)

Solenoid

.

13. Remove the TP sensor. Refer to

Throttle Position

(TP) Sensor

.

Inspection Procedure

NOTE: Do not use solvent of any type when you clean the

gasket surfaces on the intake manifold and the throttle

body assembly. The gasket surfaces and the throttle

body assembly may be damaged as a result.

If the throttle body gasket needs to be replaced,

remove any gasket material that may be stuck to the

mating surfaces of the manifold.

Do not leave any scratches in the aluminum casting.

Installation Procedure

1. Install the TP sensor. Refer to Throttle Position (TP)

Sensor

.

2. Install the IAC. Refer to

Idle Air Control (IAC)

Solenoid

.

3. Install the gasket on the common chamber.

4. Install the throttle body on the common chamber.

Page 1441 of 6000

6E–324

ENGINE DRIVEABILITY AND EMISSIONS

5. Secure the gasket and the throttle body with the four

bolts.

The vacuum lines must be properly routed under

the throttle body before tightening the mounting

bolts.

Tighten

Tighten the throttle body mounting bolts to 24 Nꞏm

(17 lb ft.).

035RW024

6. Install the coolant lines.

7. Connect all the vacuum lines.

8. Install the intake air duct.

9. Tighten the intake air duct clamp.

10. Connect all the electrical connectors:

Throttle position (TP) sensor.

Idle air control (IAC) solenoid.

Intake air temperature (IAT) sensor. Refer to

Intake Air Temperature Sensor.

035RW023

11. Install the accelerator cable assembly. Refer to

Accelerator Cable in Engine Speed Control System..

12. Fill the cooling system. Refer to

Cooling System.

13. Install the negative battery cable.

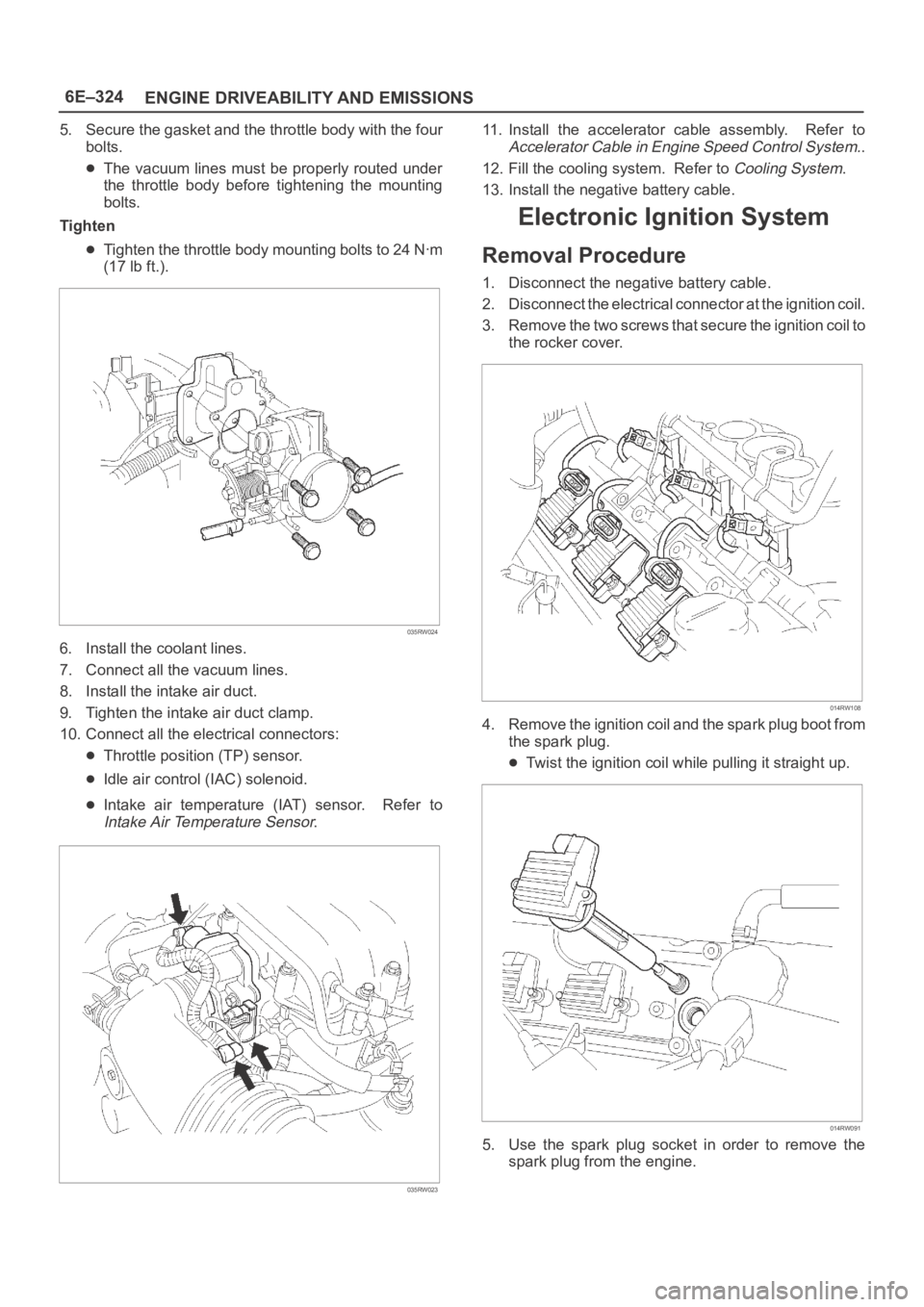

Electronic Ignition System

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector at the ignition coil.

3. Remove the two screws that secure the ignition coil to

the rocker cover.

014RW108

4. Remove the ignition coil and the spark plug boot from

the spark plug.

Twist the ignition coil while pulling it straight up.

014RW091

5. Use the spark plug socket in order to remove the

spark plug from the engine.