roof OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 12 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

8A LIGHTING SYSTEM

8B WIPER / WASHER SYSTEM

8C ENTERTAINMENT

8D WIRING SYSTEM

8E METER AND GAUGE

8F BODY STRUCTURE

8G SEATS

8H SECURITY AND LOCKS

8I SUN ROOF/CONVERTIBLE TOP

8J EXTERIOR / INTERIOR TRIM

HOME

8A

8B

8C

8D

8E

8F

8G

8H

8I

8J

Page 577 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–6

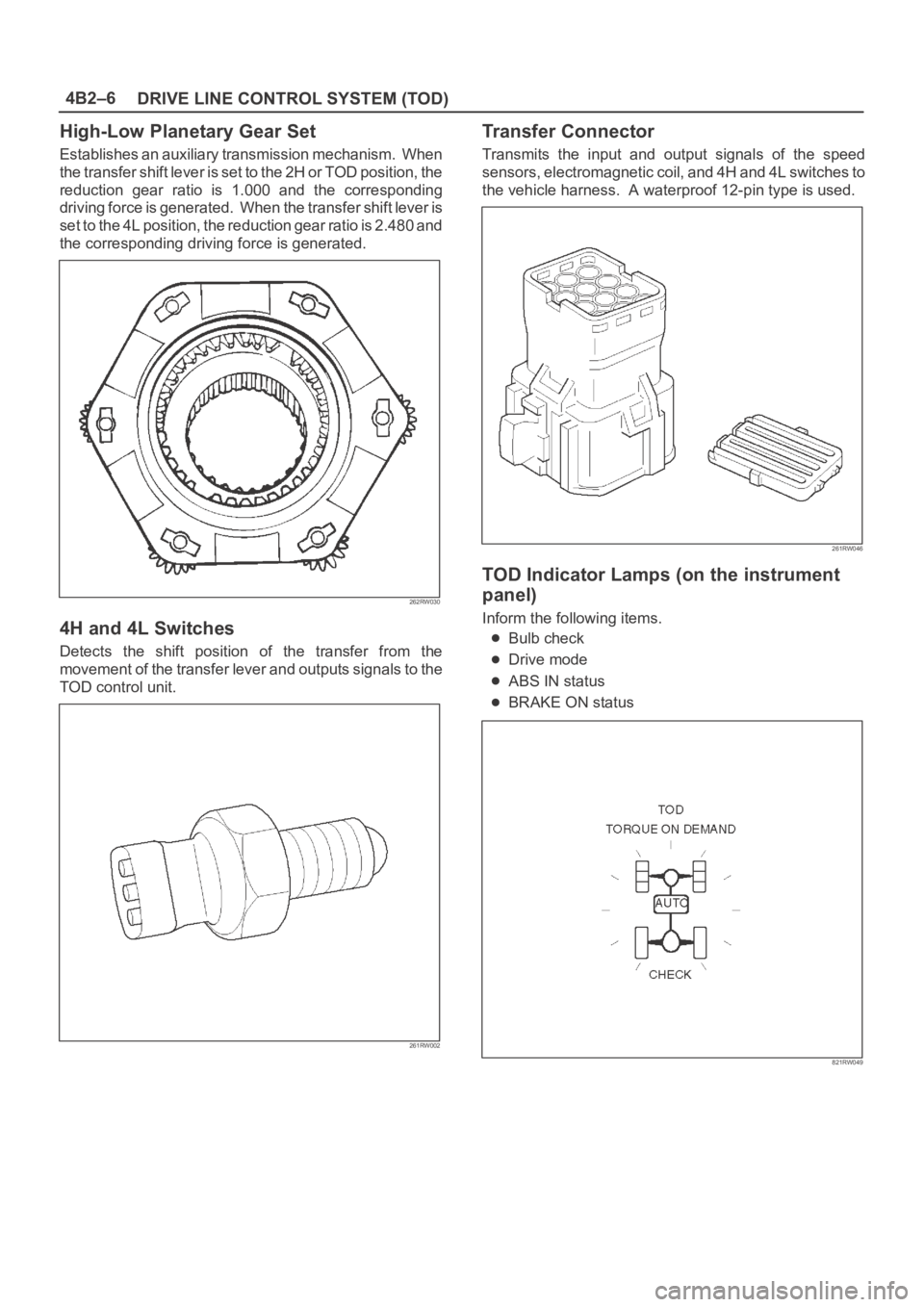

High-Low Planetary Gear Set

Establishes an auxiliary transmission mechanism. When

the transfer shift lever is set to the 2H or TOD position, the

reduction gear ratio is 1.000 and the corresponding

driving force is generated. When the transfer shift lever is

set to the 4L position, the reduction gear ratio is 2.480 and

the corresponding driving force is generated.

262RW030

4H and 4L Switches

Detects the shift position of the transfer from the

movement of the transfer lever and outputs signals to the

TOD control unit.

261RW002

Transfer Connector

Transmits the input and output signals of the speed

sensors, electromagnetic coil, and 4H and 4L switches to

the vehicle harness. A waterproof 12-pin type is used.

261RW046

TOD Indicator Lamps (on the instrument

panel)

Inform the following items.

Bulb check

Drive mode

ABS IN status

BRAKE ON status

821RW049

Page 959 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 1046 of 6000

6A–90

ENGINE MECHANICAL

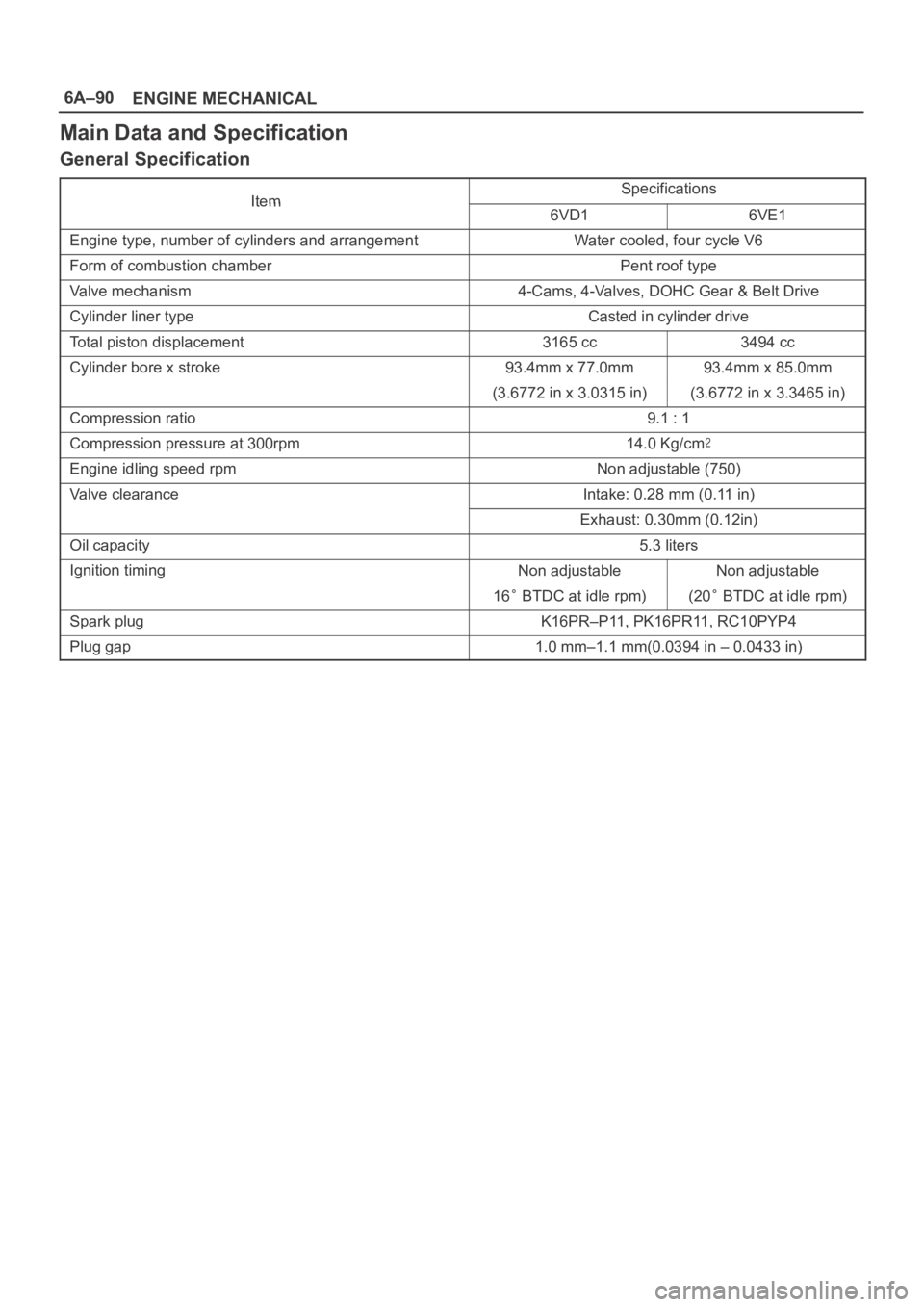

Main Data and Specification

General Specification

ItemSpecificationsItem6VD16VE1

Engine type, number of cylinders and arrangementWater cooled, four cycle V6

Form of combustion chamberPent roof type

Valve mechanism4-Cams, 4-Valves, DOHC Gear & Belt Drive

Cylinder liner typeCasted in cylinder drive

Total piston displacement3165 cc3494 cc

Cylinder bore x stroke93.4mm x 77.0mm93.4mm x 85.0mm

(3.6772 in x 3.0315 in)(3.6772 in x 3.3465 in)

Compression ratio9.1 : 1

Compression pressure at 300rpm14.0 Kg/cm

Engine idling speed rpmNon adjustable (750)

Valve clearanceIntake: 0.28 mm (0.11 in)

Exhaust: 0.30mm (0.12in)

Oil capacity5.3 liters

Ignition timingNon adjustableNon adjustable

16 BTDC at idle rpm)(20 BTDC at idle rpm)

Spark plugK16PR–P11, PK16PR11, RC10PYP4

Plug gap1.0 mm–1.1 mm(0.0394 in – 0.0433 in)

Page 2540 of 6000

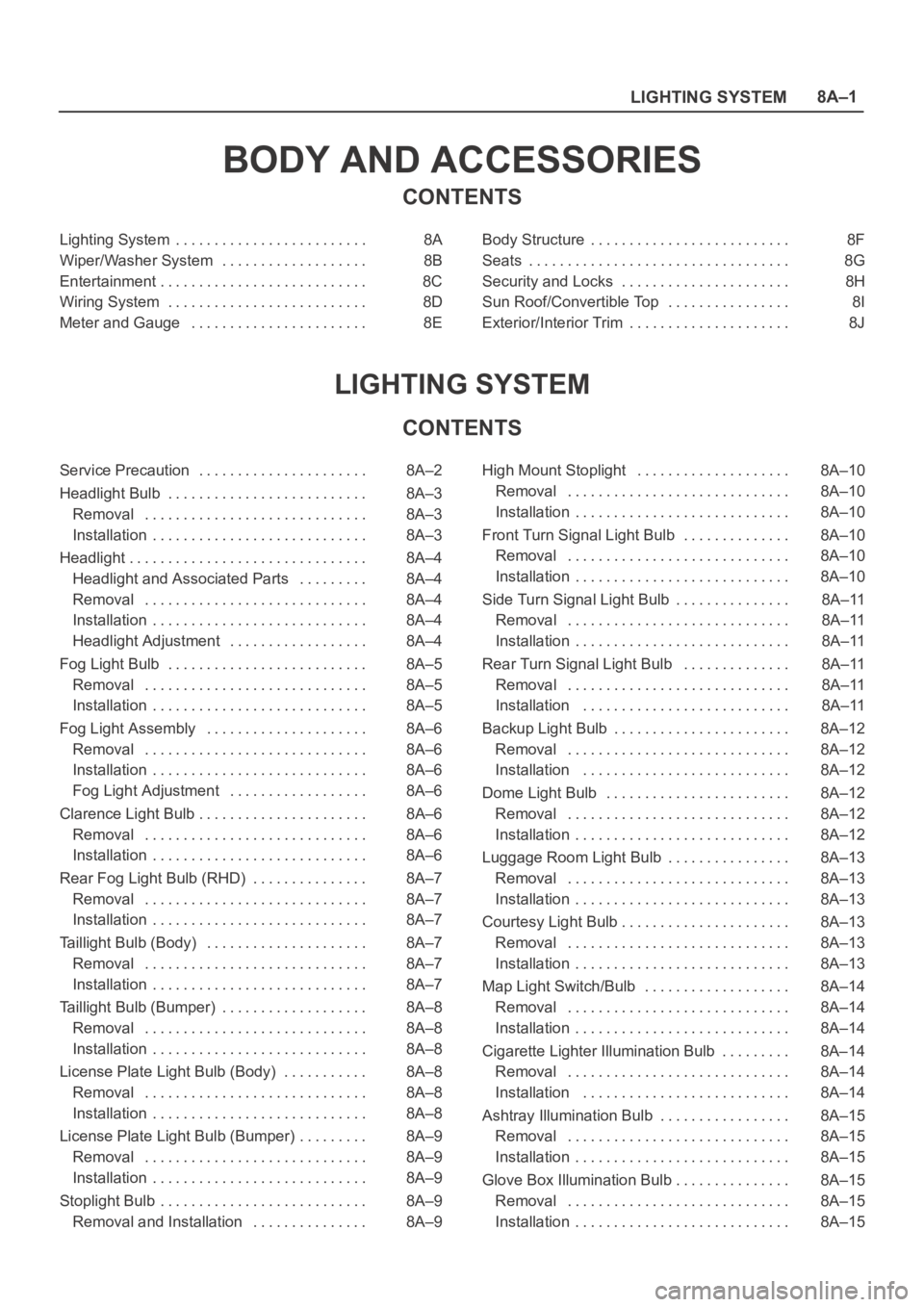

LIGHTING SYSTEM8A–1

BODY AND ACCESSORIES

CONTENTS

Lighting System 8A. . . . . . . . . . . . . . . . . . . . . . . . .

Wiper/Washer System 8B. . . . . . . . . . . . . . . . . . .

Entertainment 8C. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring System 8D. . . . . . . . . . . . . . . . . . . . . . . . . .

Meter and Gauge 8E. . . . . . . . . . . . . . . . . . . . . . . Body Structure 8F. . . . . . . . . . . . . . . . . . . . . . . . . .

Seats 8G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security and Locks 8H. . . . . . . . . . . . . . . . . . . . . .

Sun Roof/Convertible Top 8I. . . . . . . . . . . . . . . .

Exterior/Interior Trim 8J. . . . . . . . . . . . . . . . . . . . .

LIGHTING SYSTEM

CONTENTS

Service Precaution 8A–2. . . . . . . . . . . . . . . . . . . . . .

Headlight Bulb 8A–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight 8A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight and Associated Parts 8A–4. . . . . . . . .

Removal 8A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight Adjustment 8A–4. . . . . . . . . . . . . . . . . .

Fog Light Bulb 8A–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fog Light Assembly 8A–6. . . . . . . . . . . . . . . . . . . . .

Removal 8A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fog Light Adjustment 8A–6. . . . . . . . . . . . . . . . . .

Clarence Light Bulb 8A–6. . . . . . . . . . . . . . . . . . . . . .

Removal 8A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Fog Light Bulb (RHD) 8A–7. . . . . . . . . . . . . . .

Removal 8A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Taillight Bulb (Body) 8A–7. . . . . . . . . . . . . . . . . . . . .

Removal 8A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Taillight Bulb (Bumper) 8A–8. . . . . . . . . . . . . . . . . . .

Removal 8A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

License Plate Light Bulb (Body) 8A–8. . . . . . . . . . .

Removal 8A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

License Plate Light Bulb (Bumper) 8A–9. . . . . . . . .

Removal 8A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stoplight Bulb 8A–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 8A–9. . . . . . . . . . . . . . . High Mount Stoplight 8A–10. . . . . . . . . . . . . . . . . . . .

Removal 8A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Turn Signal Light Bulb 8A–10. . . . . . . . . . . . . .

Removal 8A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Turn Signal Light Bulb 8A–11. . . . . . . . . . . . . . .

Removal 8A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Turn Signal Light Bulb 8A–11. . . . . . . . . . . . . .

Removal 8A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup Light Bulb 8A–12. . . . . . . . . . . . . . . . . . . . . . .

Removal 8A–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–12

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Dome Light Bulb 8A–12. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Luggage Room Light Bulb 8A–13. . . . . . . . . . . . . . . .

Removal 8A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Courtesy Light Bulb 8A–13. . . . . . . . . . . . . . . . . . . . . .

Removal 8A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Map Light Switch/Bulb 8A–14. . . . . . . . . . . . . . . . . . .

Removal 8A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigarette Lighter Illumination Bulb 8A–14. . . . . . . . .

Removal 8A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray Illumination Bulb 8A–15. . . . . . . . . . . . . . . . .

Removal 8A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glove Box Illumination Bulb 8A–15. . . . . . . . . . . . . . .

Removal 8A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2553 of 6000

8A–14LIGHTING SYSTEM

Map Light Switch/Bulb

Removal

1. Disconnect the battery ground cable.

2. Pull the map light body downward to release the lock.

3. Disconnect the connectors of the map light and the

sun roof switch.

4. Remove the map light switch.

5. Turn the socket counterclockwise to remove it.

6. Pull out the bulb from the socket.

805RS008

Installation

To install, follow the removal steps in the reverse order.

Cigarette Lighter Illumination Bulb

Removal

1. Disconnect the battery ground cable.

2. Remove eight screws to remove the instrument

cluster panel(2).

3. Turn the socket counterclockwise to remove it then

pull out the bulb(1).

826RS013

Installation

To install, follow the removal steps in the reverse order.

Page 2599 of 6000

Waterproof Connector Inspection

It is not possible to insert the test probes (2) into the

connector wire side of a waterproof connector.

Use one side of a connector (1) with its wires cut to make

the test. Connect the test connector to the connector to

be tested (3). Connect the test probes to the cut wires to

check the connector continuity.

Connector Pin Removal – Connector

Housing Tang Lock Type

1. Insert a slender shaft (1) into the connector housing

open end (5).

2. Push the tang lock (2) up (in the direction of the arrow

in the illustration).

Pull the wire (3) with pin (4) free from the wire side of

the connector.

Connector Pin Removal – Pin Tang Lock

Ty p e

1. Insert a slender shaft (1) into the connector housing

open end (5).

2. Push the tang lock (2) flat (toward the wire (3) side of

the connector.

Pull the wire with pin (4) free from the wire side of the

connector.

Connector Pin Insertion

1. Check that the tang lock (1) is fully up.

2. Insert the pin (3) from the connector wire (2) side.

Push the pin in until the tang lock closes firmly.

3. Gently pull on the wires to make sure that the

connector pin is firmly set in place.

1

3

21

2

3

5

4

1

2

3

4 51

2

3

Page 2775 of 6000

A

B

D

E

VANITY

MIRROR

-LH

1H-2114

H-16

(W/SUN ROOF) 0.5

B0.5

B

0.5

B 0.5

G/R

0.5

G/R

0.5

G/R0.85

G/R

0.85

G/R

0.3

R/G0.3

R/G 0.85

G/R

0.3

R/G 0.85

G/R

0.3

R/G 0.85

G/R

0.3

R/G 0.85

G/R

4

H-214H-21

CIGARE-

TTE

LIGHTER

1

2

2.0

B2.0

B

B-2

BODY-LH

HAZARD

SW

3

1I-11

I-11FOG

LIGHT

SW

6

2I-5

I-5RR

DEFOGGER

SW

6

2I-17I-20

I-20 I-17

AUDIO

11

3I-15

I-15

1L-4

2 L-4

VANITY

MIRROR

-RH

1L-6

2 L-6

D08RW656

Page 3009 of 6000

D08RW 730

BODY-LH BODY-LH TAIL RELAY

(4)

(W/O SUNROOF) STARTER SW

(ACC)AMBIENT TEMPERATURE

SENSOR

0.5

B

2.0

B 2.0

B 2.0

B 0.5

P/G0.5

G/R0.5

G/R

0.5

O/G0.5

O/G3.0

L/B

0.5

P/G 0.5

P/L0.5

P/L

0.5

P/G 0.5

P/L0.85

B

4

H-21 4 6

H-21 H-21H-21

H-7

C-9L-5

5

8

H-212

3

H-78

2

C-91L-5

4 L-53

L-51 1

H-213

L-5

B-2 B-2

MULTI METER

C-11 10A

AUDIO(ACC), MIRROR

Page 3015 of 6000

D08RW 730

BODY-LH BODY-LH TAIL RELAY

(4)

(W/O SUNROOF) STARTER SW

(ACC)AMBIENT TEMPERATURE

SENSOR

0.5

B

2.0

B 2.0

B 2.0

B 0.5

P/G0.5

G/R0.5

G/R

0.5

O/G0.5

O/G3.0

L/B

0.5

P/G 0.5

P/L0.5

P/L

0.5

P/G 0.5

P/L0.85

B

4

H-21 4 6

H-21 H-21H-21

H-7

C-9L-5

5

8

H-212

3

H-78

2

C-91L-5

4 L-53

L-51 1

H-213

L-5

B-2 B-2

MULTI METER

C-11 10A

AUDIO(ACC), MIRROR