check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 281 of 6000

1. Perform oil return operation.

2. Discharge and recover the refrigerant and remove

the compressor.

3. Drain the compressor oil and measure the extracted

oil.

4. Check the compressor oil for contamination.

5. Adjust the oil level as required.

6. Evacuate, charge and perform the oil return

operation.

7. Check the system operation.

Contamination of Compressor Oil

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a long

period of time (approximately one season), the oil never

becomes contaminated as long as there is nothing

wrong with the compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

The capacity of the oil has increased.

The oil has changed to red.

Foreign substances, metal powder, etc., are present

in the oil.

If any of these conditions exists, the compressor

oil is contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

Oil Return Operation

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system. When

checking the amount of oil in the system, or replacing

any component of the system, the compressor must be

run in advance for oil return operation. The procedure

is as follows:

1. Open all the doors and the engine hood.

2. Start the engine and air conditioning switch to "ON"

and set the fan control knob at its highest position.

3. Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate the

system.

4. Stop the engine.

Replacement of Component Parts

When replacing the system component parts, supply

the following amount of oil to the component parts to be

installed.

Compressor Leak Testing (External and

Internal)

Bench-Check Procedure

1. Install test plate J-39893 on rear head of compressor.

2. Using Refrigerant Recovery System, attach center

hose of manifold gage set on charging station to a

refrigerant drum standing in an upright drum.

3. Connect charging station high and low pressure

lines to corresponding fittings on test plate J-39893.

Suction port (low-side) of compressor has large

internal opening. Discharge port (high-side) has

smaller internal opening into compressor and

deeper recess.

4. Open low pressure control, high pressure control

and refrigerant control on charging station to allow

refrigerant vapor to flow into compressor.

5. Using a leak detector, check for leaks at pressure

relief valve, rear head switch location, compressor

front and rear head seals, center cylinder seal,

through bolt head gaskets and compressor shaft

seal. After checking, shut off low pressure control

and high-pressure control on charging station.

6. If an external leak is present, perform the necessary

corrective measures and recheck for leaks to make

certain the leak has been connected.

7. Recover the refrigerant.

8. Disconnect both hoses from the test plate J-39893.

9. Add 90 ml (3 oz.) new PAG lubricant to the

compressor assembly. Rotate the complete

compressor assembly (not the crankshaft or drive

plate hub) slowly several turns to distribute oil to all

cylinder and piston areas.

10. Install a M9

1.25 threaded nut on the compressor

crankshaft if the drive plate and clutch assembly are

not installed.

11. Using a box-end wrench or socket and handle,

rotate the compressor crankshaft or clutch drive

plate on the crankshaft several turns to insure

piston assembly to cylinder wall lubrication.

12. Using Refrigerant Recovery System, connect the

charging station high-pressure line to the test plate

J-39893 high-side connector.

13. Using Refrigerant Recovery System, connect the

charging station low-pressure line to the low

pressure port of the test plate J-39893. Oil will drain

out of the compressor suction port if the compressor

is positioned with the suction port downward. (Component parts to be (Amount of Oil)

installed)

Evaporator 50 cc (1.7 fl. oz.)

Condenser 30 cc (1.0 fl. oz.)

Receiver/dryer 30 cc (1.0 fl. oz.)

Refrigerant line (one 10 cc (0.3 fl. oz.)

piece)

(Amount of oil drained (Charging amount of oil

from used compressor) to new compressor)

more than 90 cc same as drained amount

(3.0 fl.oz)

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 470 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently “wow–wows” at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close–fitting parts when possible.

Adjust pinion and ring gear backlash.

Page 506 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently “wow–wows” at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close–fitting parts when possible.

Adjust pinion and ring gear backlash.

Page 537 of 6000

4B1–4

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Inspection and Repair

Va c u u m P i p i n g

C04RW016

1. Pull out the Hose A in figure and install a vacuum

gauge.

2. Plug up Hose B in figure to prevent the leak of

vacuum.

3. Start the engine and measure vacuum 2 or 3 minutes

afterward.

4. Repeat 1) and 2) but with Hose A plugged and Hose B

pulled out.

5. If vacuum measures –400mmHg, or if it shows a

sudden drop immediately after engine stop, inspect

the hose, tank, and pipe for damage.

NOTE: Be careful not to permit the entry of dust and

water during inspection.

6. Pull out Hose D in above illustration.

7. Plug Hose E in above illustration.

8. Make sure that Hose D in above illustration is under

atmospheric pressure.

9. Pull out Hose E and plug Hose D, and make sure that

Hose E is under atmospheric pressure.

10. If Check 8) or 9) has revealed stoppage, check and

see that there is no bend, foreign matter in the hose or

in the filter. If there is trouble, repair or replace.Check Valve

C04RS004

1. Apply vacuum from the orange colored side(1).

Vacuum:–400mmHg

2. Check leakage of vacuum.

3. Make sure that vacuum cannot be applied from the

black colored side(2).

Page 538 of 6000

4B1–5 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

4. If vacuum is not applicable as much as –400mmHg,

and if there is resistance on the intake side, replace

with a new check valve.

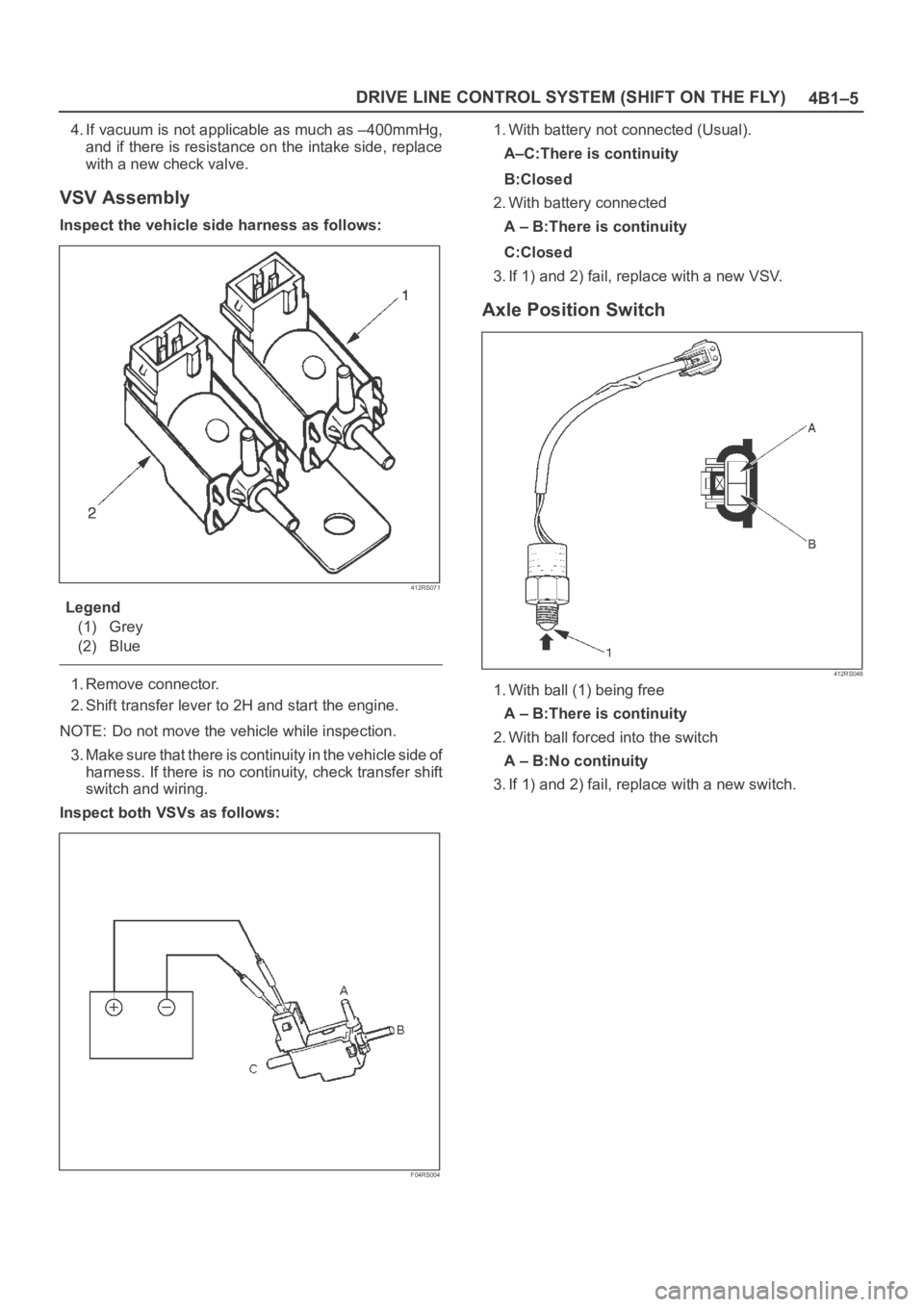

VSV Assembly

Inspect the vehicle side harness as follows:

412RS071

Legend

(1) Grey

(2) Blue

1. Remove connector.

2. Shift transfer lever to 2H and start the engine.

NOTE: Do not move the vehicle while inspection.

3. Make sure that there is continuity in the vehicle side of

harness. If there is no continuity, check transfer shift

switch and wiring.

Inspect both VSVs as follows:

F04RS004

1. With battery not connected (Usual).

A–C:There is continuity

B:Closed

2. With battery connected

A – B:There is continuity

C:Closed

3. If 1) and 2) fail, replace with a new VSV.

Axle Position Switch

412RS048

1. With ball (1) being free

A – B:There is continuity

2. With ball forced into the switch

A – B:No continuity

3. If 1) and 2) fail, replace with a new switch.

Page 544 of 6000

4B1–11 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

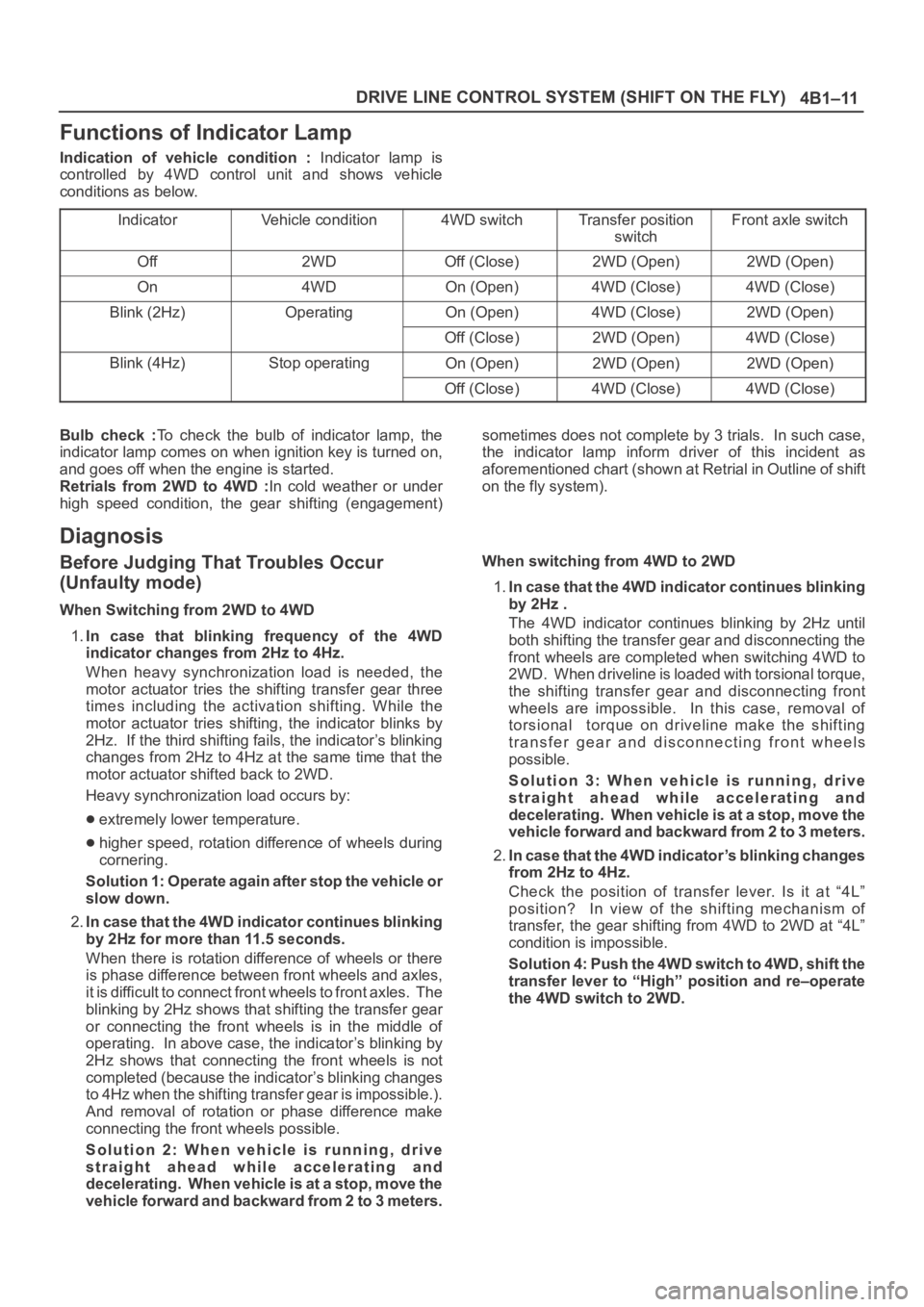

Functions of Indicator Lamp

Indication of vehicle condition : Indicator lamp is

controlled by 4WD control unit and shows vehicle

conditions as below.

Indicator

Vehicle condition4WD switchTransfer position

switchFront axle switch

Off2WDOff (Close)2WD (Open)2WD (Open)

On4WDOn (Open)4WD (Close)4WD (Close)

Blink (2Hz)OperatingOn (Open)4WD (Close)2WD (Open)

Off (Close)2WD (Open)4WD (Close)

Blink (4Hz)Stop operatingOn (Open)2WD (Open)2WD (Open)

Off (Close)4WD (Close)4WD (Close)

Bulb check :To check the bulb of indicator lamp, the

indicator lamp comes on when ignition key is turned on,

and goes off when the engine is started.

Retrials from 2WD to 4WD :In cold weather or under

high speed condition, the gear shifting (engagement)sometimes does not complete by 3 trials. In such case,

the indicator lamp inform driver of this incident as

aforementioned chart (shown at Retrial in Outline of shift

on the fly system).

Diagnosis

Before Judging That Troubles Occur

(Unfaulty mode)

When Switching from 2WD to 4WD

1.In case that blinking frequency of the 4WD

indicator changes from 2Hz to 4Hz.

When heavy synchronization load is needed, the

motor actuator tries the shifting transfer gear three

times including the activation shifting. While the

motor actuator tries shifting, the indicator blinks by

2Hz. If the third shifting fails, the indicator’s blinking

changes from 2Hz to 4Hz at the same time that the

motor actuator shifted back to 2WD.

Heavy synchronization load occurs by:

extremely lower temperature.

higher speed, rotation difference of wheels during

cornering.

Solution 1: Operate again after stop the vehicle or

slow down.

2.In case that the 4WD indicator continues blinking

by 2Hz for more than 11.5 seconds.

When there is rotation difference of wheels or there

is phase difference between front wheels and axles,

it is difficult to connect front wheels to front axles. The

blinking by 2Hz shows that shifting the transfer gear

or connecting the front wheels is in the middle of

operating. In above case, the indicator’s blinking by

2Hz shows that connecting the front wheels is not

completed (because the indicator’s blinking changes

to 4Hz when the shifting transfer gear is impossible.).

And removal of rotation or phase difference make

connecting the front wheels possible.

Solution 2: When vehicle is running, drive

straight ahead while accelerating and

decelerating. When vehicle is at a stop, move the

vehicle forward and backward from 2 to 3 meters.When switching from 4WD to 2WD

1.In case that the 4WD indicator continues blinking

by 2Hz .

The 4WD indicator continues blinking by 2Hz until

both shifting the transfer gear and disconnecting the

front wheels are completed when switching 4WD to

2WD. When driveline is loaded with torsional torque,

the shifting transfer gear and disconnecting front

wheels are impossible. In this case, removal of

torsional torque on driveline make the shifting

transfer gear and disconnecting front wheels

possible.

Solution 3: When vehicle is running, drive

straight ahead while accelerating and

decelerating. When vehicle is at a stop, move the

vehicle forward and backward from 2 to 3 meters.

2.In case that the 4WD indicator’s blinking changes

from 2Hz to 4Hz.

Check the position of transfer lever. Is it at “4L”

position? In view of the shifting mechanism of

transfer, the gear shifting from 4WD to 2WD at “4L”

condition is impossible.

Solution 4: Push the 4WD switch to 4WD, shift the

transfer lever to “High” position and re–operate

the 4WD switch to 2WD.

Page 558 of 6000

4B1–25 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

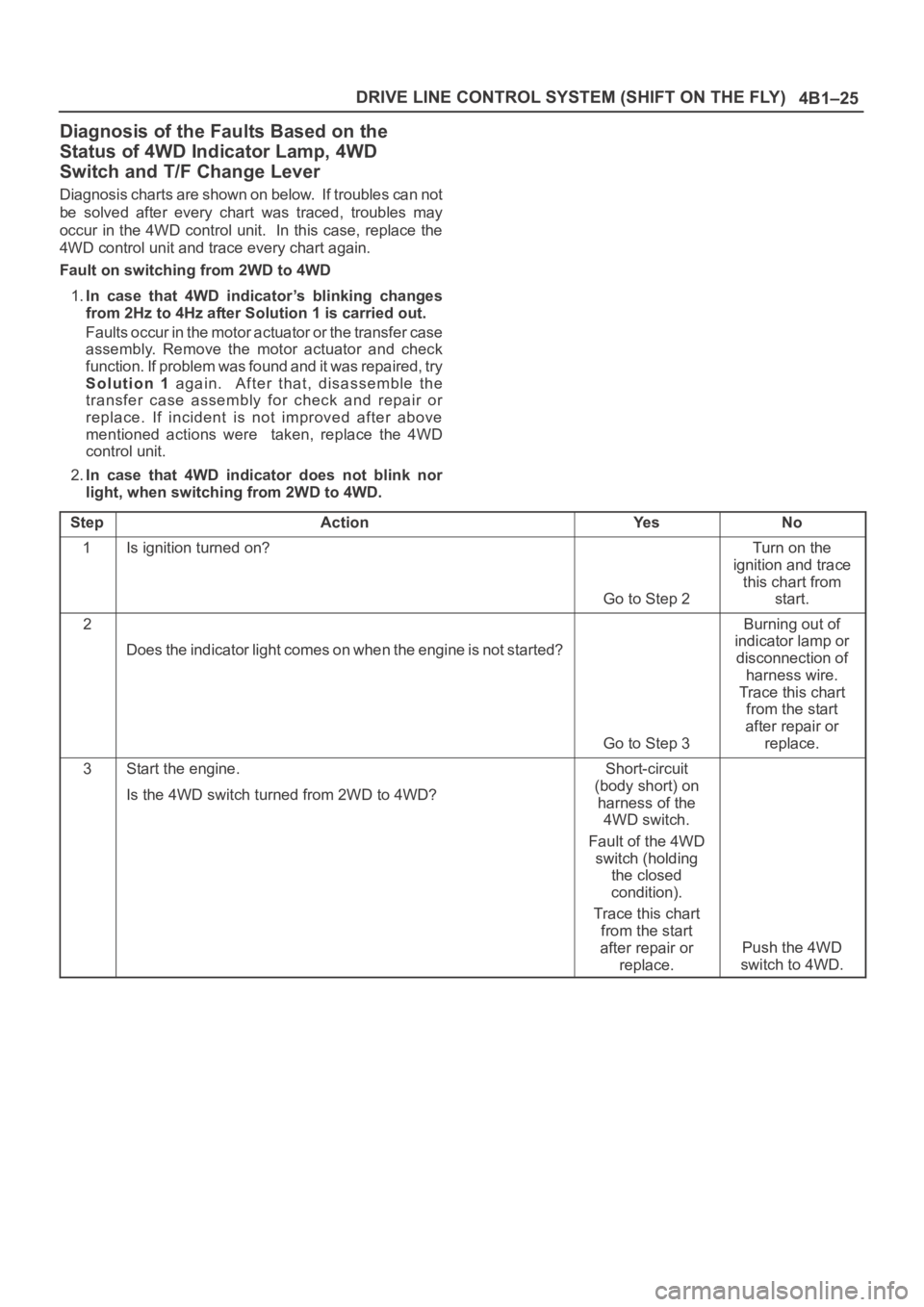

Diagnosis of the Faults Based on the

Status of 4WD Indicator Lamp, 4WD

Switch and T/F Change Lever

Diagnosis charts are shown on below. If troubles can not

be solved after every chart was traced, troubles may

occur in the 4WD control unit. In this case, replace the

4WD control unit and trace every chart again.

Fault on switching from 2WD to 4WD

1.In case that 4WD indicator’s blinking changes

from 2Hz to 4Hz after Solution 1 is carried out.

Faults occur in the motor actuator or the transfer case

assembly. Remove the motor actuator and check

function. If problem was found and it was repaired, try

Solution 1 again. After that, disassemble the

transfer case assembly for check and repair or

replace. If incident is not improved after above

mentioned actions were taken, replace the 4WD

control unit.

2.In case that 4WD indicator does not blink nor

light, when switching from 2WD to 4WD.

Step

ActionYe sNo

1Is ignition turned on?

Go to Step 2

Turn on the

ignition and trace

this chart from

start.

2

Does the indicator light comes on when the engine is not started?

Go to Step 3

Burning out of

indicator lamp or

disconnection of

harness wire.

Trace this chart

from the start

after repair or

replace.

3Start the engine.

Is the 4WD switch turned from 2WD to 4WD?Short-circuit

(body short) on

harness of the

4WD switch.

Fault of the 4WD

switch (holding

the closed

condition).

Trace this chart

from the start

after repair or

replace.

Push the 4WD

switch to 4WD.

Page 566 of 6000

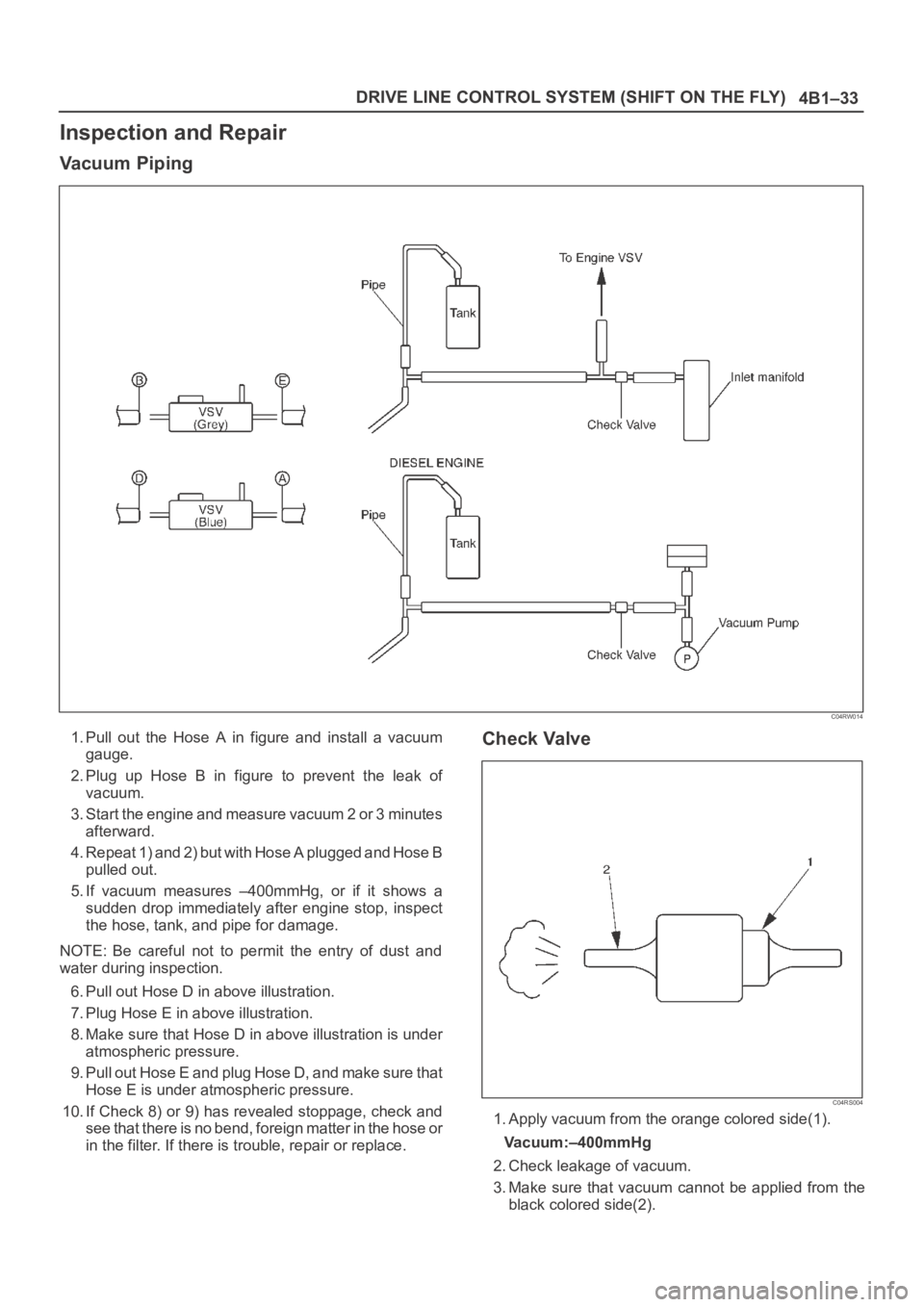

4B1–33 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Inspection and Repair

Va c u u m P i p i n g

C04RW014

1. Pull out the Hose A in figure and install a vacuum

gauge.

2. Plug up Hose B in figure to prevent the leak of

vacuum.

3. Start the engine and measure vacuum 2 or 3 minutes

afterward.

4. Repeat 1) and 2) but with Hose A plugged and Hose B

pulled out.

5. If vacuum measures –400mmHg, or if it shows a

sudden drop immediately after engine stop, inspect

the hose, tank, and pipe for damage.

NOTE: Be careful not to permit the entry of dust and

water during inspection.

6. Pull out Hose D in above illustration.

7. Plug Hose E in above illustration.

8. Make sure that Hose D in above illustration is under

atmospheric pressure.

9. Pull out Hose E and plug Hose D, and make sure that

Hose E is under atmospheric pressure.

10. If Check 8) or 9) has revealed stoppage, check and

see that there is no bend, foreign matter in the hose or

in the filter. If there is trouble, repair or replace.Check Valve

C04RS004

1. Apply vacuum from the orange colored side(1).

Vacuum:–400mmHg

2. Check leakage of vacuum.

3. Make sure that vacuum cannot be applied from the

black colored side(2).

Page 567 of 6000

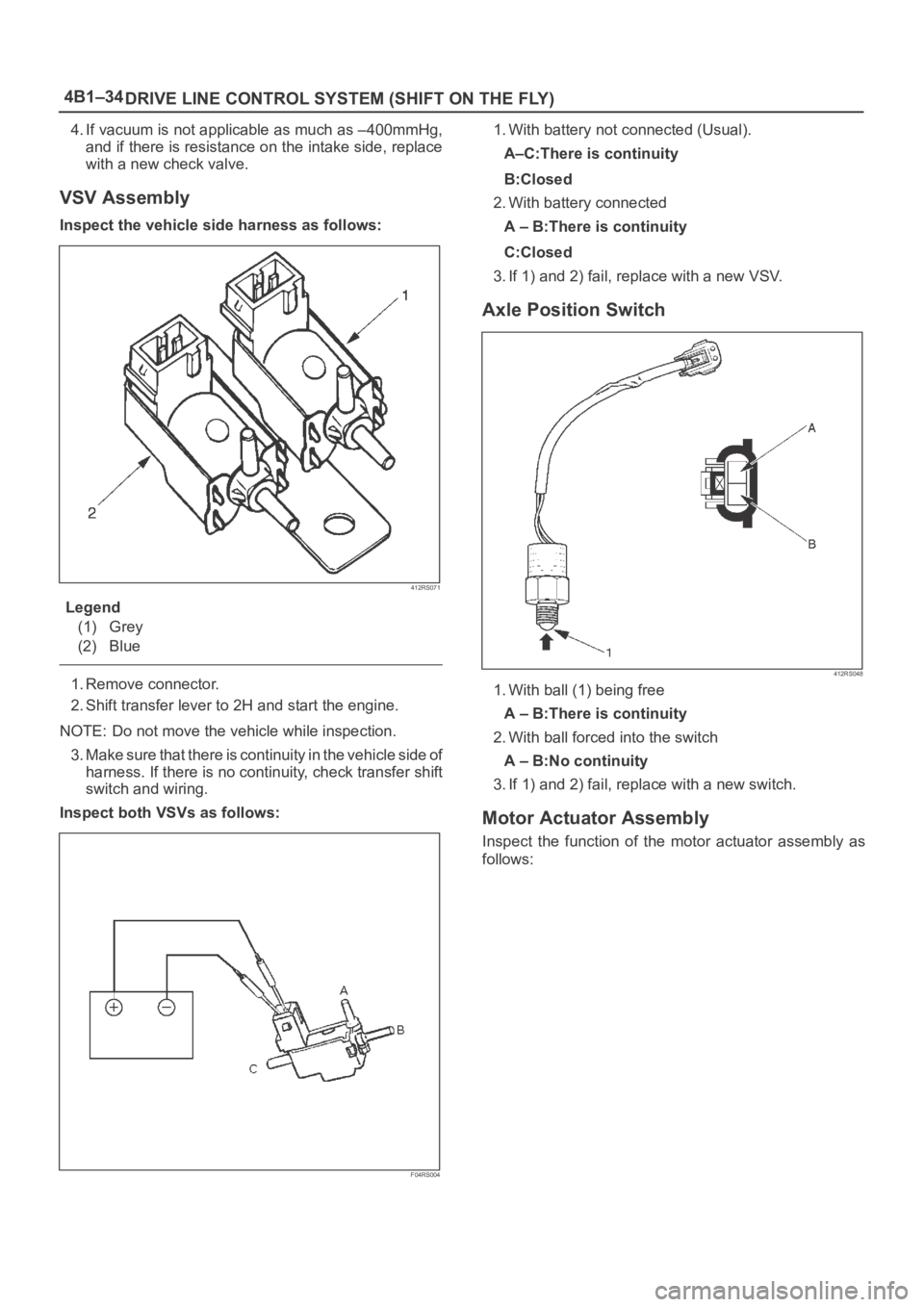

4B1–34

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

4. If vacuum is not applicable as much as –400mmHg,

and if there is resistance on the intake side, replace

with a new check valve.

VSV Assembly

Inspect the vehicle side harness as follows:

412RS071

Legend

(1) Grey

(2) Blue

1. Remove connector.

2. Shift transfer lever to 2H and start the engine.

NOTE: Do not move the vehicle while inspection.

3. Make sure that there is continuity in the vehicle side of

harness. If there is no continuity, check transfer shift

switch and wiring.

Inspect both VSVs as follows:

F04RS004

1. With battery not connected (Usual).

A–C:There is continuity

B:Closed

2. With battery connected

A – B:There is continuity

C:Closed

3. If 1) and 2) fail, replace with a new VSV.

Axle Position Switch

412RS048

1. With ball (1) being free

A – B:There is continuity

2. With ball forced into the switch

A – B:No continuity

3. If 1) and 2) fail, replace with a new switch.

Motor Actuator Assembly

Inspect the function of the motor actuator assembly as

follows:

Page 582 of 6000

4B2–11 DRIVE LINE CONTROL SYSTEM (TOD)

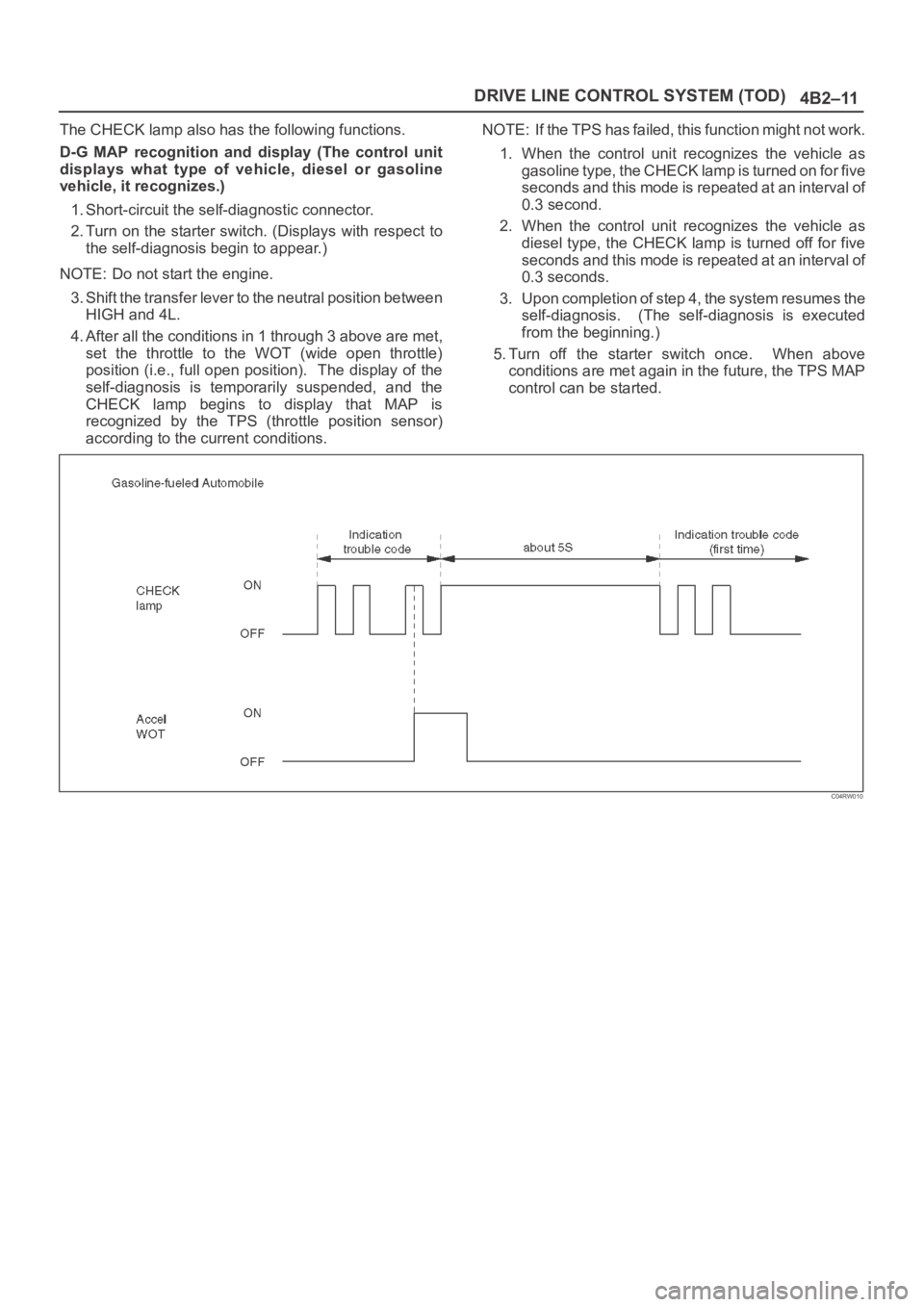

The CHECK lamp also has the following functions.

D-G MAP recognition and display (The control unit

displays what type of vehicle, diesel or gasoline

vehicle, it recognizes.)

1. Short-circuit the self-diagnostic connector.

2. Turn on the starter switch. (Displays with respect to

the self-diagnosis begin to appear.)

NOTE: Do not start the engine.

3. Shift the transfer lever to the neutral position between

HIGH and 4L.

4. After all the conditions in 1 through 3 above are met,

set the throttle to the WOT (wide open throttle)

position (i.e., full open position). The display of the

self-diagnosis is temporarily suspended, and the

CHECK lamp begins to display that MAP is

recognized by the TPS (throttle position sensor)

according to the current conditions.NOTE: If the TPS has failed, this function might not work.

1. When the control unit recognizes the vehicle as

gasoline type, the CHECK lamp is turned on for five

seconds and this mode is repeated at an interval of

0.3 second.

2. When the control unit recognizes the vehicle as

diesel type, the CHECK lamp is turned off for five

seconds and this mode is repeated at an interval of

0.3 seconds.

3. Upon completion of step 4, the system resumes the

self-diagnosis. (The self-diagnosis is executed

from the beginning.)

5. Turn off the starter switch once. When above

conditions are met again in the future, the TPS MAP

control can be started.

C04RW010