lock OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4046 of 6000

4B1–1 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (SHIFT ON THE FLY)

CONTENTS

Service Precaution 4B1–1. . . . . . . . . . . . . . . . . . . . . .

Shift on the Fly System (Lever Type) 4B1–2. . . . . . .

Outline of Shift on the Fly System

(Lever Type) 4B1–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift on the Fly Vacuum Piping and Electric

Equipment (For Lever Control Type) 4B1–3. . . . . .

Vacuum Piping Diagram 4B1–3. . . . . . . . . . . . . . . .

Inspection and Repair 4B1–4. . . . . . . . . . . . . . . . . .

Shift on the Fly System (Push Button Type) 4B1–7.

Outline of Shift on the Fly System

(Push Button Type) 4B1–7. . . . . . . . . . . . . . . . . . . . Functions of Indicator Lamp 4B1–11. . . . . . . . . . . . . . .

Diagnosis 4B1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Axle Diagnosis 4B1–30. . . . . . . . . . . . . . . . . . .

Shift on the Fly Vacuum Piping and Electric

Equipment (For Push Button Type) 4B1–32. . . . . . . .

Vacuum Piping Diagram 4B1–32. . . . . . . . . . . . . . . .

Inspection and Repair 4B1–33. . . . . . . . . . . . . . . . . .

4WD Control Unit (For Push Button Type) 4B1–36. .

4WD Control Unit Associated Parts 4B1–36. . . . . .

Removal 4B1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4B1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 4047 of 6000

4B1–2

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Shift on the Fly System (Lever Type)

Outline of Shift on the Fly System

(Lever Type)

The shift on the fly system (Lever type) switches between

2 wheel drive (2WD) and 4 wheel drive (4WD) by driver’s

shifting the transfer control lever on the floor.

This system controls below operations.

1. Connecting front wheels to, and disconnecting them

from, the front axles by vacuum actuator.

2. Indicator on instrument panel.

3. 4WD signal to Electronic Hydraulic Control Unit for

brake system (If anti–lock brake system is equipped).

Page 4052 of 6000

4B1–7 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Shift on the Fly System (Push Button Type)

Outline of Shift on the Fly System (Push Button Type)

The shift on the fly system switches between 2 wheel

drive (2WD) and 4 wheel drive (4WD) electrically by

driver’s pressing the 4WD switch (push button type) on

instrument panel.

This system controls below operations. (Shifting between

“4H” and “4L” must be performed by transfer control lever

on the floor.)

1. Shifting the transfer front output gear (Connecting to,

and disconnecting from, front propeller shaft by motor

actuator).2. Retrial of shifting the transfer front output gear.

3. Connecting front wheels to, and disconnecting them

from, the front axles by vacuum actuator.

4. Indicator on instrument panel.

5. 4WD out signal to other Electronic Hydraulic Control

Unit (If anti–lock brake system is equipped).

System Diagrams

412RW050

Page 4084 of 6000

4B2–1 DRIVE LINE CONTROL SYSTEM (TOD)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (TOD)

CONTENTS

Service Precaution 4B2–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4B2–2. . . . . . . . . . . . . . . . . . . . .

System Components 4B2–4. . . . . . . . . . . . . . . . . . . .

Parts Location 4B2–4. . . . . . . . . . . . . . . . . . . . . . . .

Functions of Indicator Lamp 4B2–8. . . . . . . . . . . . . .

Diagnosis 4B2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 4B2–17. . . . . . . . . . . . . .

Parts Location 4B2–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram 4B2–22. . . . . . . . . . . . . . . . . . . . . . . . . Connector List 4B2–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Failed Pin 4B2–36. . . . . . . . . . . . . . . . . . . . .

Checking Failed TOD Control Unit Pin 4B2–39. . . . .

Diagnostic Trouble Codes 4B2–43. . . . . . . . . . . . . . . .

Diagnosis from Trouble Codes 4B2–44. . . . . . . . . . . .

Trouble Diagnosis Depending on The Status

of TOD Indicator 4B2–74. . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis from Symptom 4B2–114. . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 4085 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–2

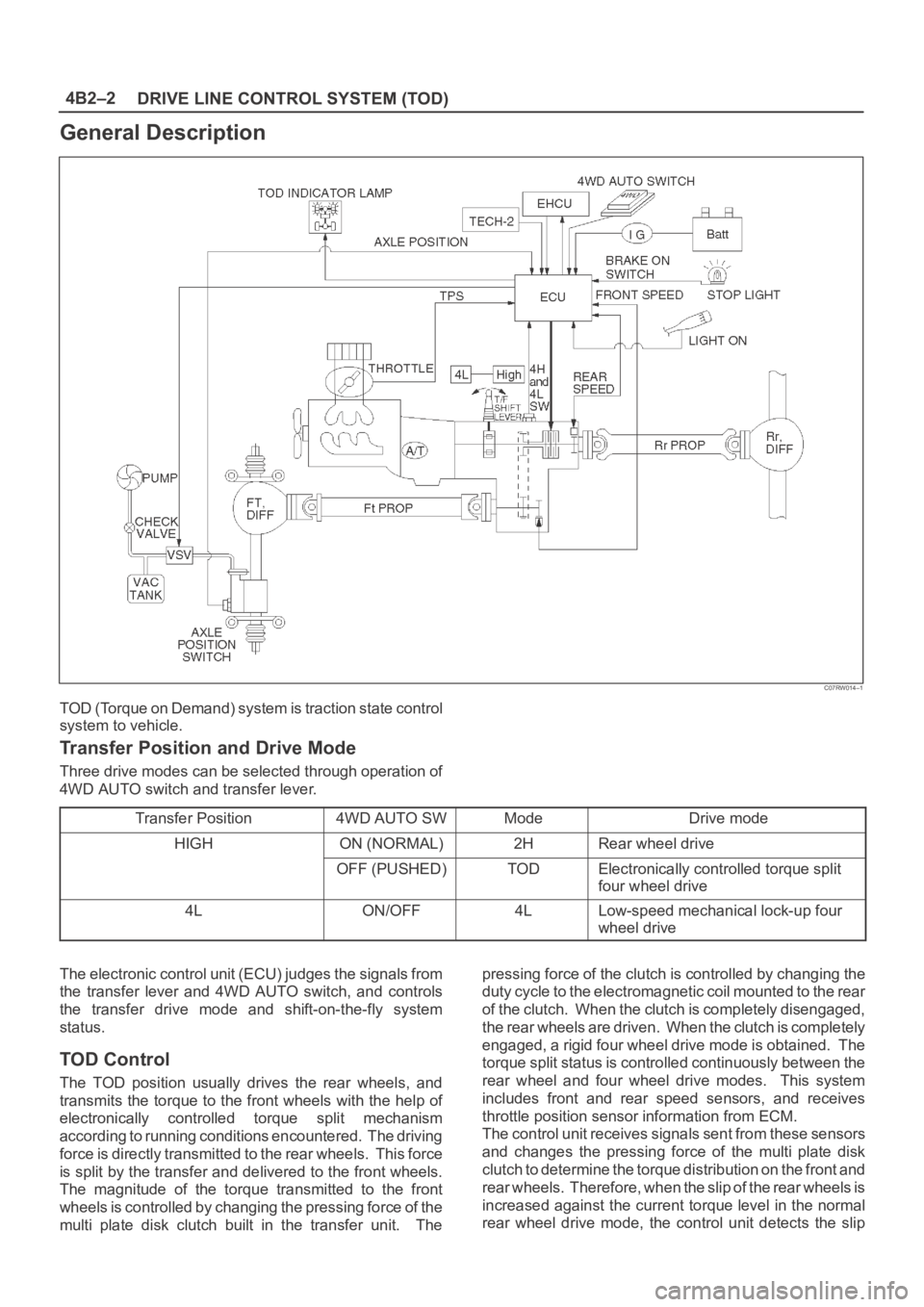

General Description

C07RW014–1

TOD (Torque on Demand) system is traction state control

system to vehicle.

Transfer Position and Drive Mode

Three drive modes can be selected through operation of

4WD AUTO switch and transfer lever.

Transfer Position

4WD AUTO SWModeDrive mode

HIGHON (NORMAL)2HRear wheel drive

OFF (PUSHED)TODElectronically controlled torque split

four wheel drive

4LON/OFF4LLow-speed mechanical lock-up four

wheel drive

The electronic control unit (ECU) judges the signals from

the transfer lever and 4WD AUTO switch, and controls

the transfer drive mode and shift-on-the-fly system

status.

TOD Control

The TOD position usually drives the rear wheels, and

transmits the torque to the front wheels with the help of

electronically controlled torque split mechanism

according to running conditions encountered. The driving

force is directly transmitted to the rear wheels. This force

is split by the transfer and delivered to the front wheels.

The magnitude of the torque transmitted to the front

wheels is controlled by changing the pressing force of the

multi plate disk clutch built in the transfer unit. Thepressing force of the clutch is controlled by changing the

duty cycle to the electromagnetic coil mounted to the rear

of the clutch. When the clutch is completely disengaged,

the rear wheels are driven. When the clutch is completely

engaged, a rigid four wheel drive mode is obtained. The

torque split status is controlled continuously between the

rear wheel and four wheel drive modes. This system

includes front and rear speed sensors, and receives

throttle position sensor information from ECM.

The control unit receives signals sent from these sensors

and changes the pressing force of the multi plate disk

clutch to determine the torque distribution on the front and

rear wheels. Therefore, when the slip of the rear wheels is

increased against the current torque level in the normal

rear wheel drive mode, the control unit detects the slip

Page 4087 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–4

System Components

Parts Location

A07RY00002

Legend

(1) T/F Connector

(2) 4H and 4L Switch

(3) High-Low Planetary Gear Set

(4) Mechanical Lock(5) Multi Plate Disk Clutch Pack

(6) Electromagnetic Coil

(7) Rear Speed Sensor

(8) Front Speed Sensor

Page 4088 of 6000

4B2–5 DRIVE LINE CONTROL SYSTEM (TOD)

Front and Rear Speed Sensors

The sensors are built in the transfer case, detect the

rotation of rotors directly coupled to the propeller shafts.

Thirty rectangular pulses are output per one rotation of

the propeller shaft.

261RW045

Electromagnetic Coil

Receives the duty signals from the TOD control unit and

controls the pressing force of the clutch pressure cam.

261RW044

Multi Plate Disk Clutch Pack

Transmits the torque determined by the clutch pressing

force to the front propeller shaft via the front drive chain.

262RW029

Mechanical Lock Sleeve

Couples the front and rear propeller shaft mechanically

when the transfer shaft is in the 4L position.

262RW028

Page 4200 of 6000

4B2–117 DRIVE LINE CONTROL SYSTEM (TOD)

StepNo Ye s Action

131. Apply the brake and fully turn the steering to the left (or right)

end, and start the creep run.

Does the voltage between terminals 4 and 20 range between 0.1

and 1.0V?Repair the

transfer

assembly.

Go to Step 16The ECU has

failed. Replace

the ECU.

Go to Step 16

141. Shift the transfer lever to the high position and switch the 4WD

AUTO SW to 4WD position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the voltage between terminals 4 and 20 range between 0.1

and 1.0V?

Go to Step 15 Go to Step 10

151. Select the 4WD AUTO SW to the 2WD position.

2. Jack up the right front wheel.

Does the front tire rotate smoothly?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 16

Repair the

transfer

assembly.

Go to Step 16

16Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 16

*NOTE: Before checking this item, run the vehicle more

than 10 meters with the steering wheel in straight position

so that the 4L mechanical lock sleeve can be released

certainly.

Page 4207 of 6000

4C–1 DRIVE SHAFT SYSTEM

DRIVELINE/AXLE

DRIVE SHAFT SYSTEM

CONTENTS

Service Precaution 4C–2. . . . . . . . . . . . . . . . . . . . . .

General Description 4C–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft 4C–4. . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft and Associated Parts 4C–4. . . .

Removal 4C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–5. . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4C–6. . . . . . . . . . . . . . . . . .

Installation 4C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 4C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc (with Shift on the Fly) 4C–9. .

Disassembled View 4C–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–10. . . . . . . . . . . . . . . . . .

Reassembly 4C–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc with Manual Locking Hub 4C–14

Disassembled View 4C–14. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–16. . . . . . . . . . . . . . . . . .

Reassembly 4C–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–20. . . . . . . . . . . . .

Special Tools 4C–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joint 4C–22. . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joints Replacement 4C–22. . . .

Front Axle Drive Shaft 4C–23. . . . . . . . . . . . . . . . . . .

Front Axle Drive Shaft and Associated

Parts 4C–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–25. . . . . . . . . . . . . . . . . .

Bushing Replacement 4C–25. . . . . . . . . . . . . . . . . . Reassembly 4C–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Shift On The Fly System 4C–28. . . . . . . . . . . . . . . . .

Shift On The Fly System and Associated

Parts 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–30. . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–35. . . . . . . . . . .

Special Tools 4C–36. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft 4C–37. . . . . . . . . . . . . . . . . . . . .

General Description 4C–37. . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft and Associated Parts 4C–38

Removal 4C–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly (Except TOD 4

4) 4C–40. . . . . . . . .

Universal Joint Disassembly 4C–41. . . . . . . . . . . .

Inspection and Repair 4C–42. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–45. . . . . . . . . . . . .

Reassembly (Except TOD 4

4) 4C–46. . . . . . . . . .

Main Data and Specifications 4C–47. . . . . . . . . . .

Rear Propeller Shaft 4C–48. . . . . . . . . . . . . . . . . . . . .

General Description 4C–48. . . . . . . . . . . . . . . . . . . . .

Rear Propeller Shaft and Associated Parts 4C–48

Removal 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Universal Joint Disassembly 4C–51. . . . . . . . . . . .

Inspection and Repair 4C–52. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–53. . . . . . . . . . . . .

Reassembly 4C–54. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–55. . . . . . . . . . .

Page 4208 of 6000

4C–2

DRIVE SHAFT SYSTEM

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV) drive

shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint, refer

to Front/Rear Propeller Shaft in this section.