flat tire OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 439 of 6000

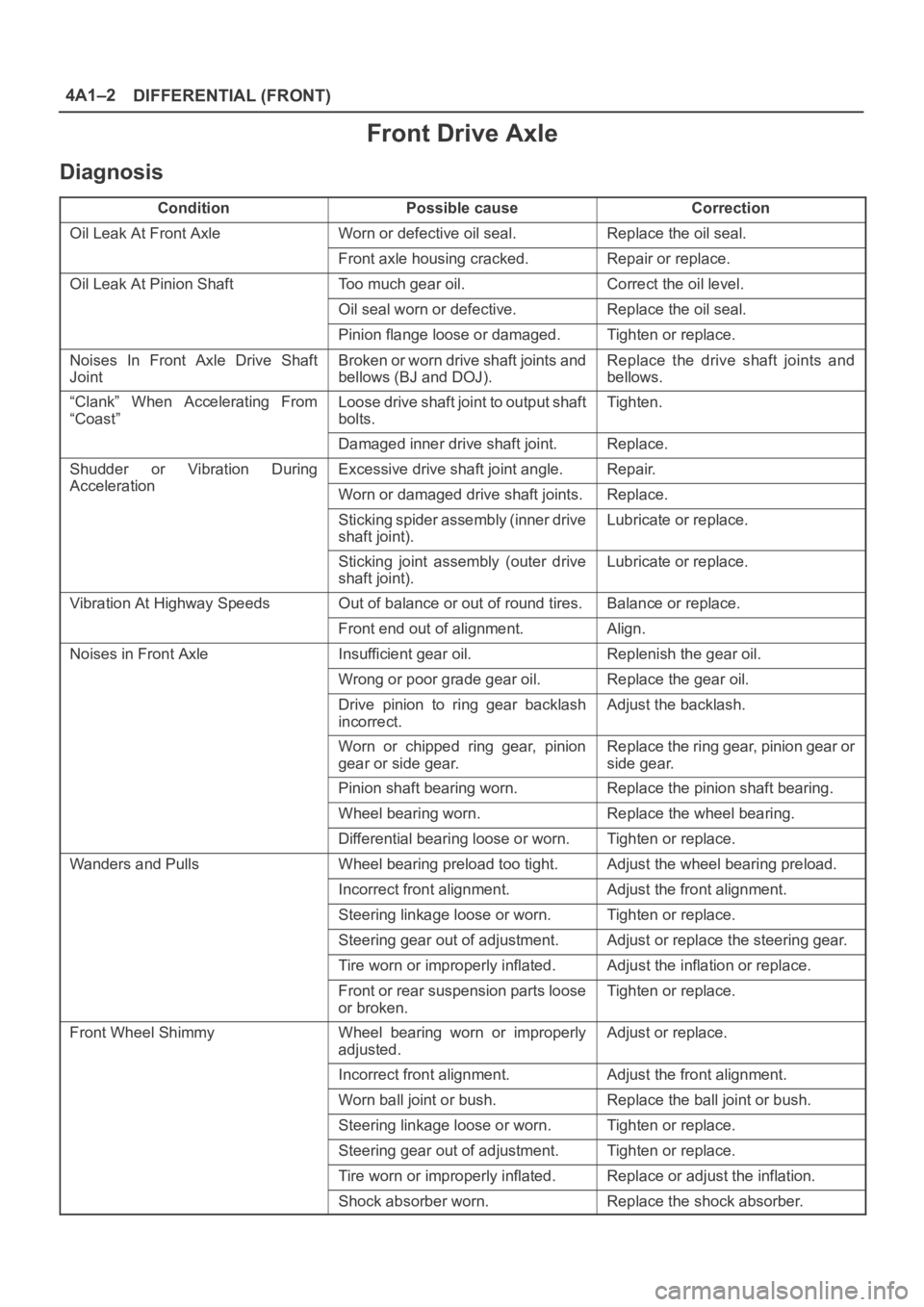

DIFFERENTIAL (FRONT) 4A1–2

Front Drive Axle

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 470 of 6000

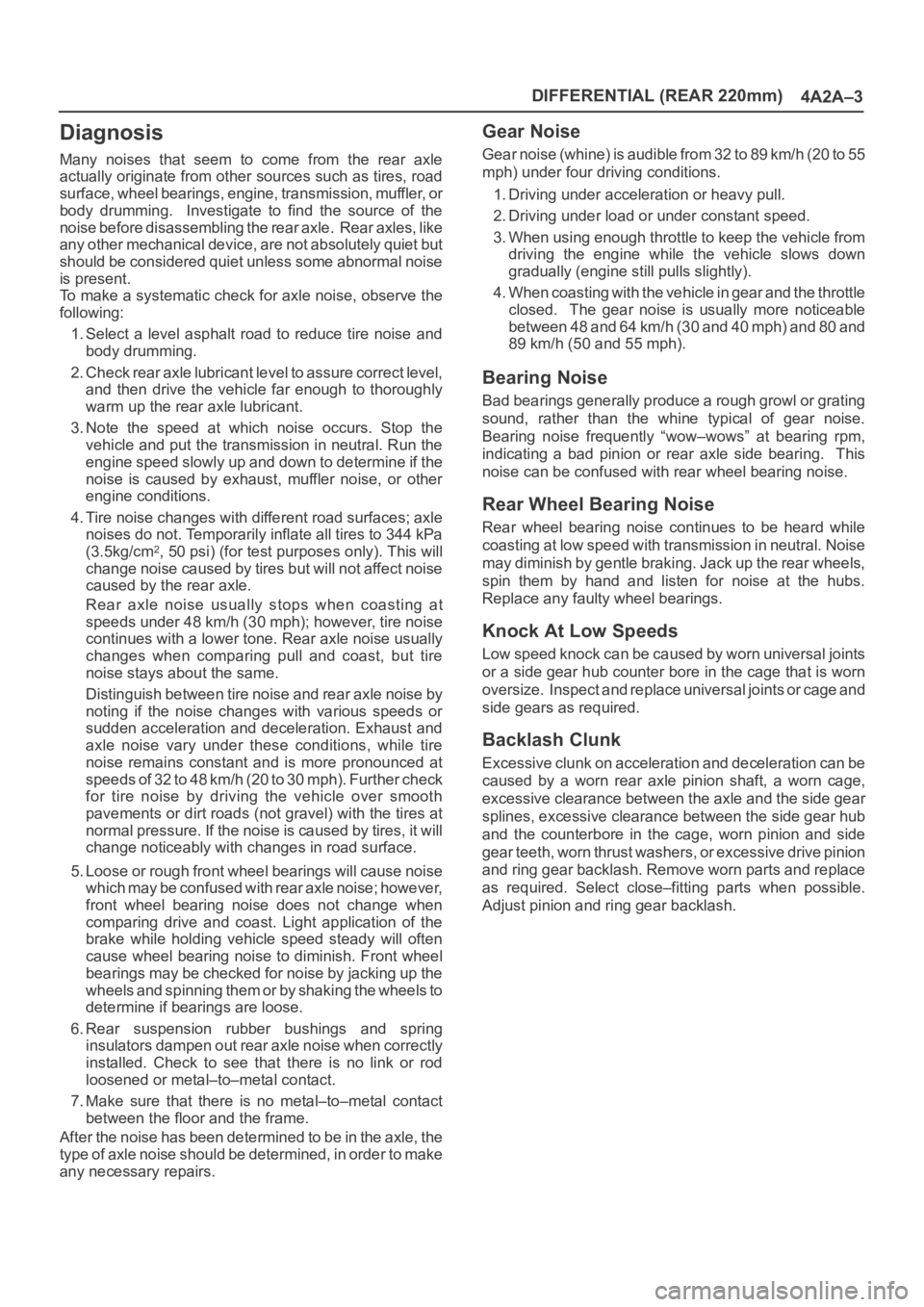

DIFFERENTIAL (REAR 220mm)

4A2A–3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently “wow–wows” at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close–fitting parts when possible.

Adjust pinion and ring gear backlash.

Page 506 of 6000

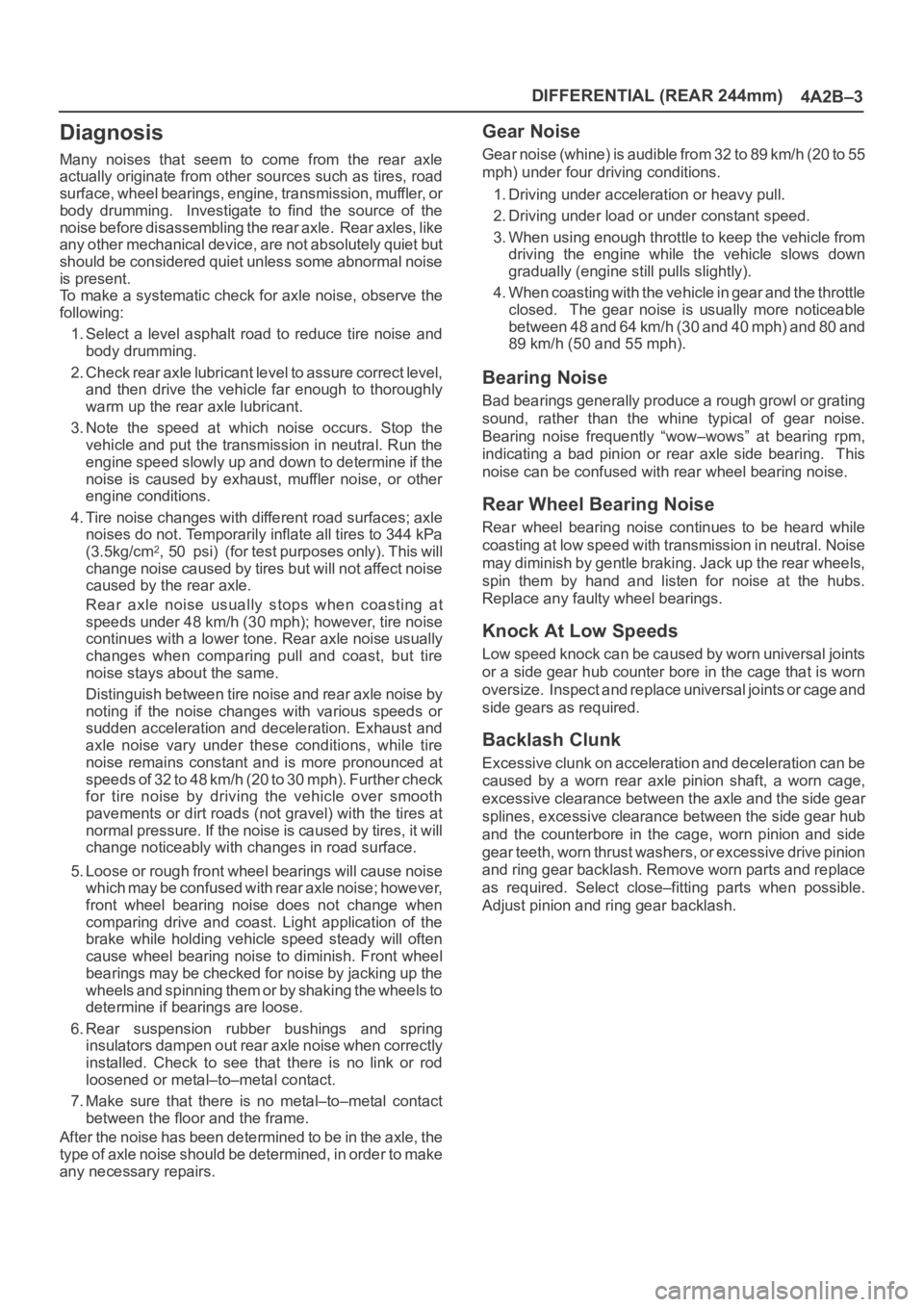

DIFFERENTIAL (REAR 244mm)

4A2B–3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently “wow–wows” at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close–fitting parts when possible.

Adjust pinion and ring gear backlash.

Page 669 of 6000

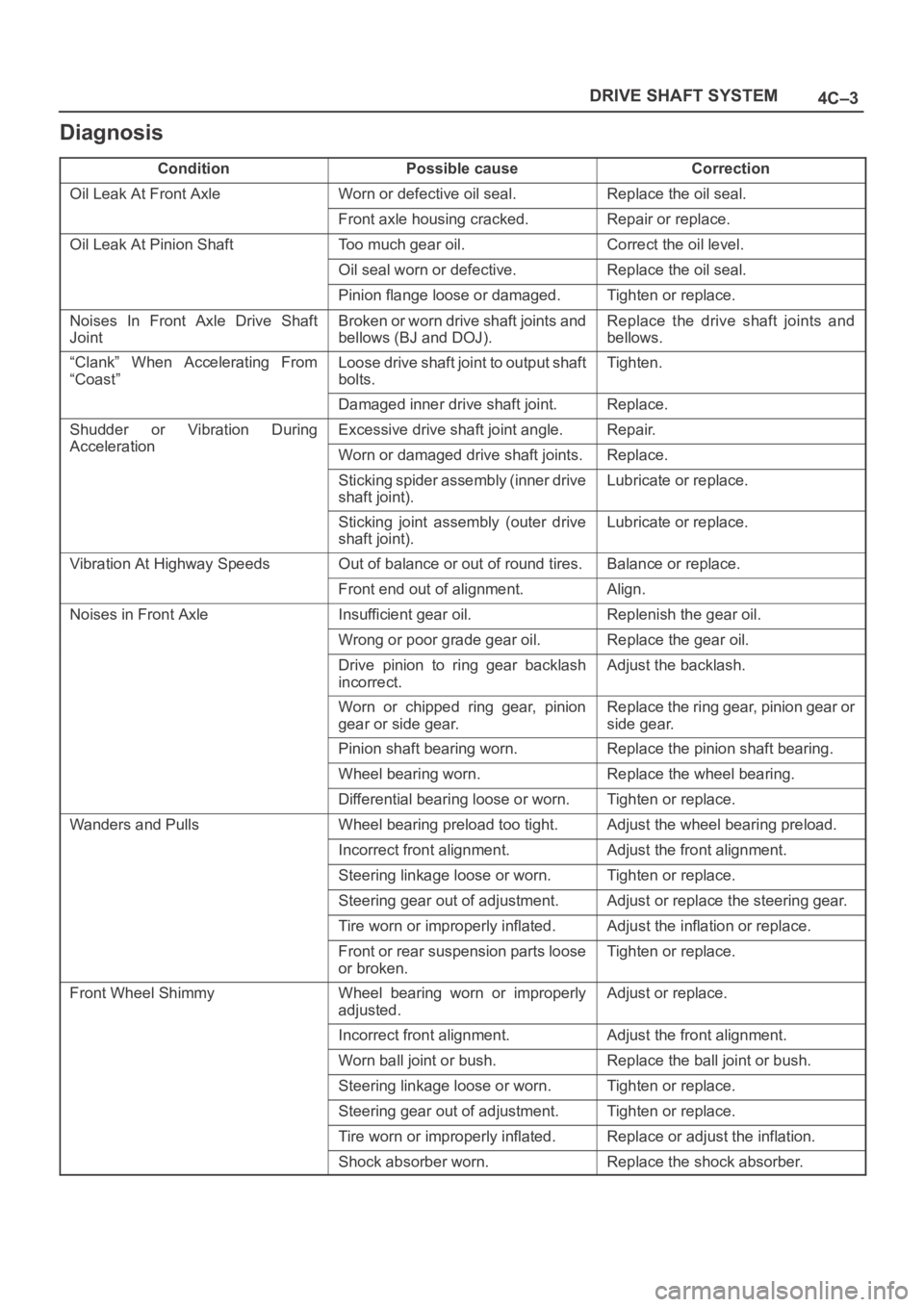

4C–3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 967 of 6000

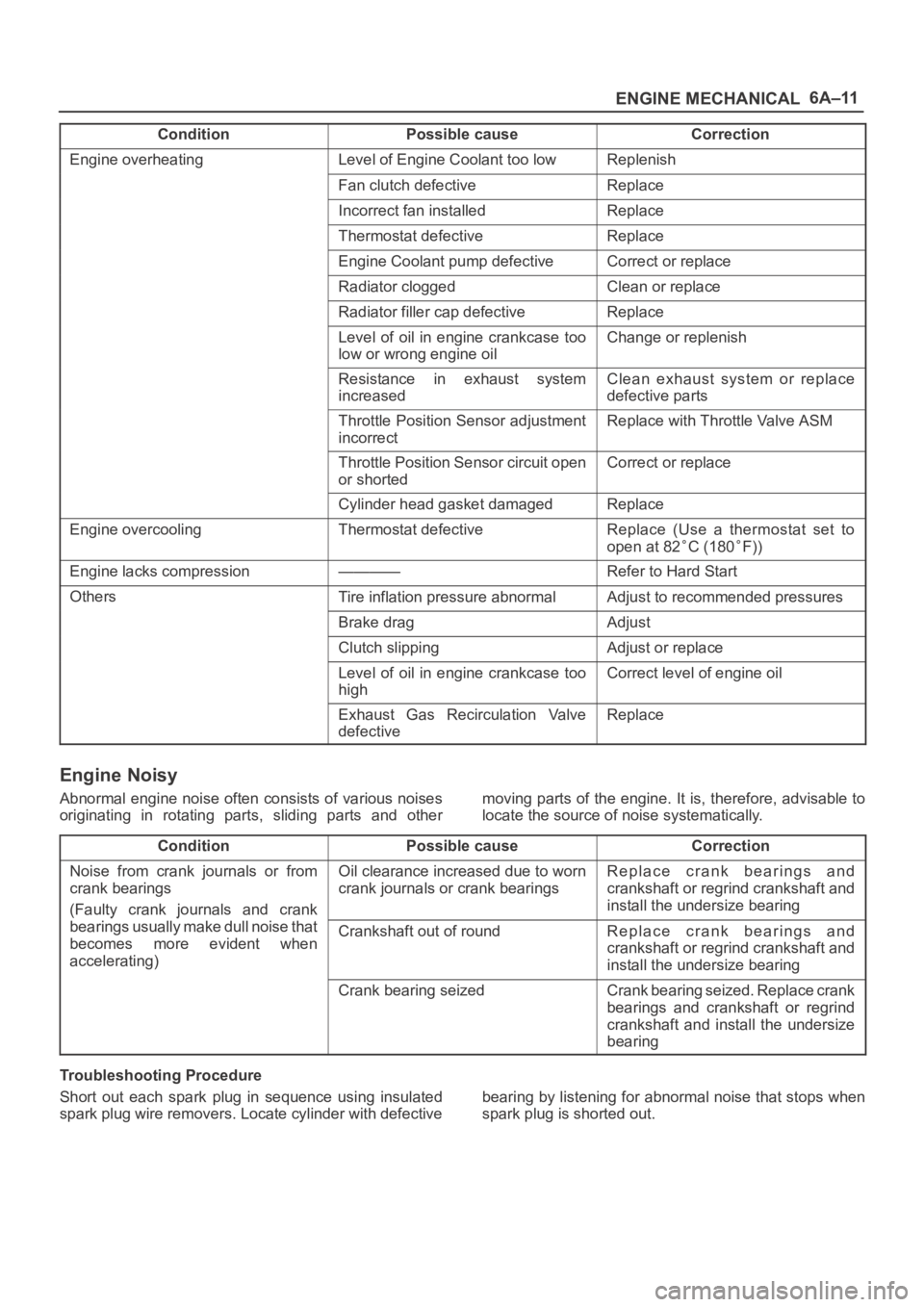

6A–11

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine overheatingLevel of Engine Coolant too lowReplenish

Fan clutch defectiveReplace

Incorrect fan installedReplace

Thermostat defectiveReplace

Engine Coolant pump defectiveCorrect or replace

Radiator cloggedClean or replace

Radiator filler cap defectiveReplace

Level of oil in engine crankcase too

low or wrong engine oilChange or replenish

Resistance in exhaust system

increasedClean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrectReplace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shortedCorrect or replace

Cylinder head gasket damagedReplace

Engine overcoolingThermostat defectiveReplace (Use a thermostat set to

open at 82

C (180F))

Engine lacks compression————Refer to Hard Start

OthersTire inflation pressure abnormalAdjust to recommended pressures

Brake dragAdjust

Clutch slippingAdjust or replace

Level of oil in engine crankcase too

highCorrect level of engine oil

Exhaust Gas Recirculation Valve

defectiveReplace

Engine Noisy

Abnormal engine noise often consists of various noises

originating in rotating parts, sliding parts and othermoving parts of the engine. It is, therefore, advisable to

locate the source of noise systematically.

Condition

Possible causeCorrection

Noise from crank journals or from

crank bearings

(Faulty crank journals and crankOil clearance increased due to worn

crank journals or crank bearingsReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

yj

bearings usually make dull noise that

becomes more evident when

accelerating)Crankshaft out of roundReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crank bearing seizedCrank bearing seized. Replace crank

bearings and crankshaft or regrind

crankshaft and install the undersize

bearing

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with defectivebearing by listening for abnormal noise that stops when

spark plug is shorted out.

Page 2520 of 6000

CLUTCH7C–11

1. Use a straight edge and a feeler gauge to measure

the pressure plate friction surface flatness in four

directions.

2. If any of the measured values exceeds the specified

limit, the pressure plate must be replaced.

Pressure Plate Warpage

Limit: 0.3 mm (0.012 in)

Clutch Cover

201RS004

1. Visually check the entire clutch cover for excessive

wear, cracking, and other damage.

2. The clutch cover must be replaced if any of these

conditions are present.

Clutch Set Force

201RS005

1. Invert the pressure plate assembly.2. Place a new driven plate over the pressure plate. A

metal sheet with “A” thickness of 8.3 mm (0.327 in)

may be used in place of the driven plate.

3. Compress the pressure plate assembly until the

distance “B” becomes 12 mm (0.472 in).

4. Note the pressure gauge reading.

5. If the measured value is less than the specified limit,

the pressure plate assembly must be replaced.

Clutch Set Force

Standard: 7208 N ( 1621 lb)

Limit: 6468 N (1454 lb)

Diaphragm Spring Finger Height

201RW009

Legend

(1) Release Side

1. Place a new driven plate or a 8.3 mm (0.327 in)

spacer beneath the pressure plate.

2. Fully compress the pressure plate and diaphragm

spring.

3. There are two ways to do this.

4. Use a bench press to press down on the assembly

from the top.

5. Tighten the fixing bolts.

NOTE: Preload on diaphragm spring finger must be 49 –

98 N (11 – 22 lb) in direction of release, when clutch cover

assembly is bolted to the flywheel.

6. Measure the spring height from base to spring tip “A”.

If the measured value exceeds the specified limit, the

pressure plate assembly must be replaced.

Diaphragm Spring Finger Height

Standard: 49.9 mm – 51.9 mm (1.965 in –

2.043 in)

Page 2543 of 6000

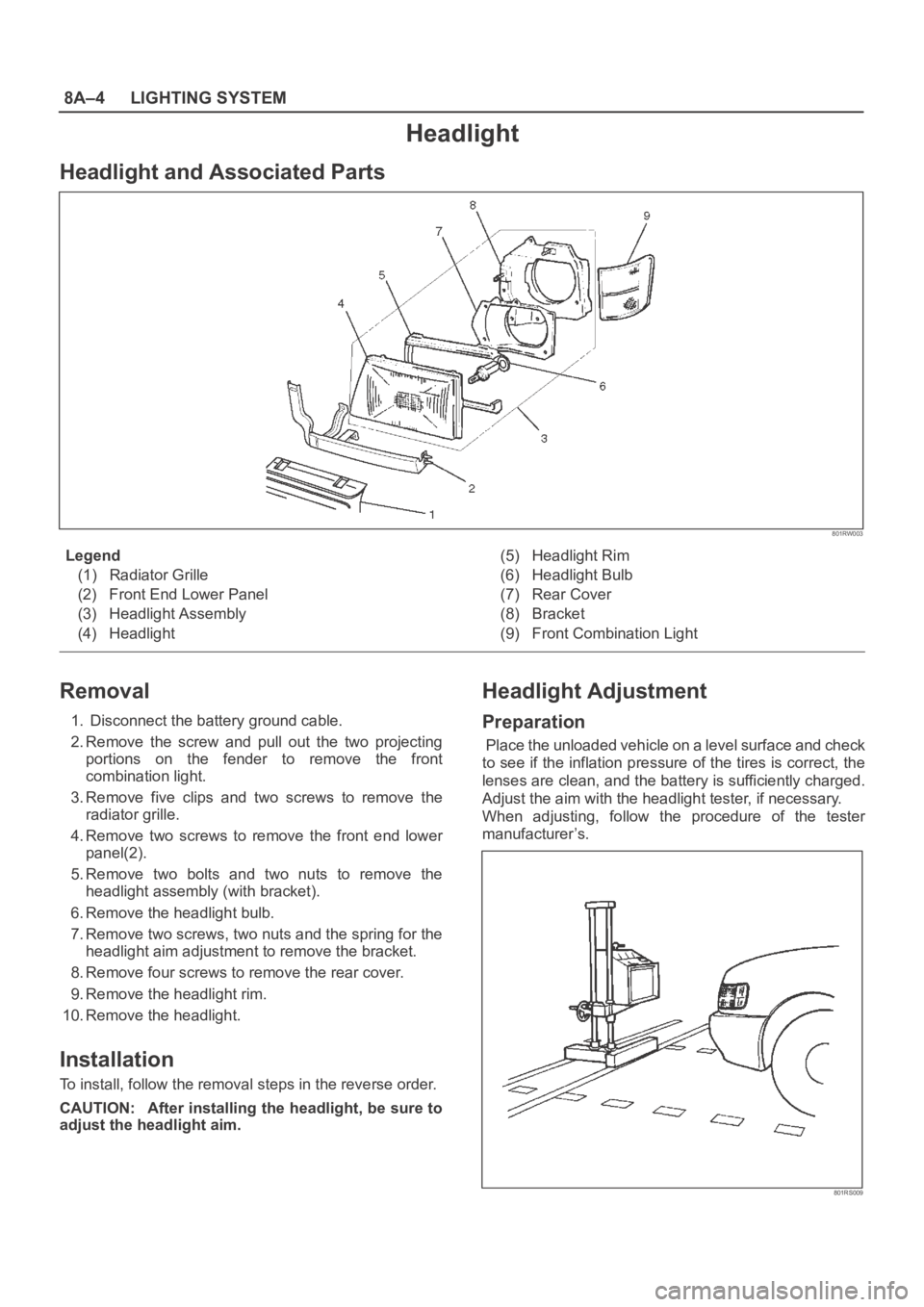

8A–4LIGHTING SYSTEM

Headlight

Headlight and Associated Parts

801RW003

Legend

(1) Radiator Grille

(2) Front End Lower Panel

(3) Headlight Assembly

(4) Headlight(5) Headlight Rim

(6) Headlight Bulb

(7) Rear Cover

(8) Bracket

(9) Front Combination Light

Removal

1. Disconnect the battery ground cable.

2. Remove the screw and pull out the two projecting

portions on the fender to remove the front

combination light.

3. Remove five clips and two screws to remove the

radiator grille.

4. Remove two screws to remove the front end lower

panel(2).

5. Remove two bolts and two nuts to remove the

headlight assembly (with bracket).

6. Remove the headlight bulb.

7. Remove two screws, two nuts and the spring for the

headlight aim adjustment to remove the bracket.

8. Remove four screws to remove the rear cover.

9. Remove the headlight rim.

10. Remove the headlight.

Installation

To install, follow the removal steps in the reverse order.

CAUTION: After installing the headlight, be sure to

adjust the headlight aim.

Headlight Adjustment

Preparation

Place the unloaded vehicle on a level surface and check

to see if the inflation pressure of the tires is correct, the

lenses are clean, and the battery is sufficiently charged.

Adjust the aim with the headlight tester, if necessary.

When adjusting, follow the procedure of the tester

manufacturer’s.

801RS009

Page 3450 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–13

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE

DRIVER AIR BAG ASSEMBLY. DEPLOYMENT

HARNESS SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE AIR

BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED TO

IT. WEAR SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

NOTE: This information applies only to driver air bag

assembly . Refer to “Deployment Outside Vehicle

(Passenger Air Bag assembly)” in this section for

information on passenger air bag assembly scrapping.

1. Turn ignition switch to “LOCK”, remove key.

2. Inspect 5–8840–2468–0 SRS Deployment Harness

and appropriate pigtail adapter for damage. If

harness or pigtail adapter is damaged, discard and

obtain a replacement.

3. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. SRS deployment harness shall remain shorted

and not be connected to a power source until the air

bag is to be deployed.

827RS004

4. Connect the appropriate pigtail adapter to the SRS

deployment harness.

5. Remove the driver air bag assembly from vehicle.

Refer to “Inflator Module Removal” in this manual.

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR OTHER

SURFACE, ALWAYS FACE THE AIR BAG AND TRIM

COVER UP AND AWAY FROM THE SURFACE. THIS

IS NECESSARY SO THAT A FREE SPACE IS

PROVIDED TO ALLOW THE AIR BAG TO EXPAND IN

THE UNLIKELY EVENT OF ACCIDENTAL

DEPLOYMENT. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN PERSONAL INJURY.6. Place the driver air bag assembly on a work bench or

other surface away from all loose or flammable

objects with its trim cover facing up, away from the

surface.

827RV003

7. Clear a space on the ground about 183 cm (six feet) in

clearance where the driver air bag assembly is to be

deployed. A paved, outdoor location where there is

no activity is preferred. If an outdoor location is not

available, a space on the shop floor where there is no

activity and sufficient ventilation is recommended.

Ensure no loose or flammable objects are within the

deployment area.

827RX032

8. Place the driver air bag assembly, with its trim cover

facing up, on the ground in the space just cleared.

9. Stretch the SRS deployment harness and pigtail

adapter from the driver air bag assembly to its full

length.

Page 3454 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–17

COOL BEFORE HANDLING ANY METAL PORTION

OF IT. DO NOT PLACE THE DEPLOYED INFLATOR

MODULE NEAR ANY FLAMMABLE OBJECTS.

FAILURE TO FOLLOW PROCEDURES MAY RESULT

IN FIRE OR PERSONAL INJURY. AFTER AN AIR BAG

ASSEMBLY HAS BEEN DEPLOYED, THE METAL

CANISTER AND SURROUNDING AREAS OF THE AIR

BAG ASSEMBLY WILL BE HOT. DO NOT TOUCH THE

METAL AREAS OF THE AIR BAG ASSEMBLY FOR

ABOUT THIRTY MINUTES AFTER DEPLOYMENT. IF

THE DEPLOYED AIR BAG ASSEMBLY MUST BE

MOVED BEFORE IT IS COOL, WEAR GLOVES AND

HANDLE BY THE AIR BAG ITSELF.

21. Disconnect the pigtail adapter from the air bag

assembly as soon after deployment as possible to

avoid damage to the pigtail adapter or SRS

deployment harness from contacting the hot air bag

assembly canister. The pigtail adapter and SRS

deployment harness are designed to be reused.

They should, however, be inspected for damage after

each deployment and replaced if necessary.

22. Dispose of the deployed air bag assembly through

normal refuse channels after it has cooled for at least

30 minutes.

23. Wash your hands with mild soap and water afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the air bag assembly did not deploy

after following the above procedures.

24. Ensure that the SRS deployment harness has been

disconnected from the power source and that its two

banana plugs have been shorted together by fully

seating one banana plug into the other.

25. Disconnect the pigtail adapter from the air bag

assembly.

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR OTHER

SURFACE, ALWAYS FACE THE BAG UP AND AWAY

FROM THE SURFACE. THIS IS NECESSARY SO

THAT A FREE SPACE IS PROVIDED TO ALLOW THE

AIR BAG TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN PERSONAL INJURY.

26. Temporarily store the air bag assembly with the bag

facing up, away from the surface upon which it rests.

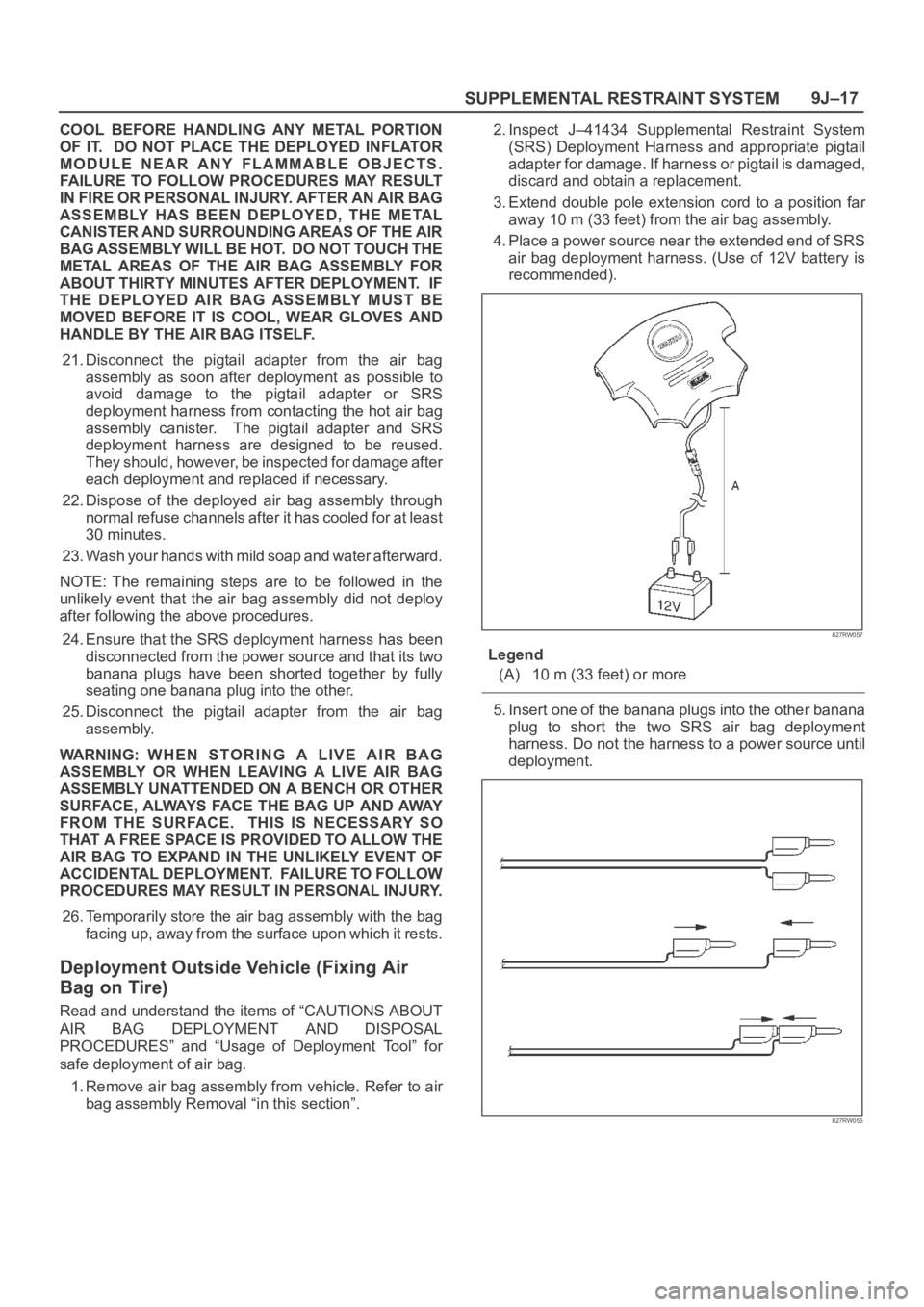

Deployment Outside Vehicle (Fixing Air

Bag on Tire)

Read and understand the items of “CAUTIONS ABOUT

AIR BAG DEPLOYMENT AND DISPOSAL

PROCEDURES” and “Usage of Deployment Tool” for

safe deployment of air bag.

1. Remove air bag assembly from vehicle. Refer to air

bag assembly Removal “in this section”.2. Inspect J–41434 Supplemental Restraint System

(SRS) Deployment Harness and appropriate pigtail

adapter for damage. If harness or pigtail is damaged,

discard and obtain a replacement.

3. Extend double pole extension cord to a position far

away 10 m (33 feet) from the air bag assembly.

4. Place a power source near the extended end of SRS

air bag deployment harness. (Use of 12V battery is

recommended).

827RW057

Legend

(A) 10 m (33 feet) or more

5. Insert one of the banana plugs into the other banana

plug to short the two SRS air bag deployment

harness. Do not the harness to a power source until

deployment.

827RW055

Page 3456 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–19

NOTE: Ensure that the pigtail adapter is firmly seated into

the air bag assembly connector. Failure to fully seat the

connectors may leave the shorting bar located in the air

bag assembly connector functioning (shorting the

deployment circuit) and may result in non deployment of

the air bag assembly.

827RW054

3. Put a tire without wheel on another, put the tire on

which the air bag is fixing, put a tire without a

wheel, and finally put a tire with a wheel on top.

Bind the tires with a rope so that the tires pile may

not collapse.

827RW050

Legend

(A) 10 m (33 feet) or more

9. Notify all people in the immediate area of your

intention to deploy the passenger air bag assembly.

The deployment will be accompanied by a substantial

noise which may startle the uninformed.

WARNING: DEPLOYED HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A CONNECTING THE

DEPLOYMENT HARNESS TO THE POWER SOURCE

SHOULD ALWAYS BE THE LAST STEP IN THE AIR

BAG ASSEMBLY DEPLOYMENT PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED MAY RESULT IN PERSONAL

INJURY.

10. Connect the Supplemental Restraint System (SRS)

deployment harness wires to the power source to

immediately deploy the air bag assembly.

Recommended application : 12 volts minimum, 2

amps minimum. A vehicle battery is suggested.

827LW011

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDING A DEPLOYED AIR BAG

ASSEMBLY. AFTER DEPLOYMENT, THE METAL

SURFACES OF THE AIR BAG ASSEMBLY WILL BE

VERY HOT. ALLOW THE AIR BAG ASSEMBLY TO

COOL BEFORE HANDLING ANY METAL PORTION

OF IT. DO NOT PLACE THE DEPLOYED INFLATOR

MODULE NEAR ANY FLAMMABLE OBJECTS.

FAILURE TO FOLLOW PROCEDURES MAY RESULT

I N F IR E O R PE RSO NAL IN JU RY. A FT ER A N A IR BAG

ASSEMBLY HAS BEEN DEPLOYED, THE METAL

CANISTER AND SURROUNDING AREAS OF THE AIR

BAG ASSEMBLY WILL BE HOT. DO NOT TOUCH THE

METAL AREAS OF THE AIR BAG ASSEMBLY FOR

ABOUT THIRTY MINUTES AFTER DEPLOYMENT. IF

THE DEPLOYED AIR BAG ASSEMBLY MUST BE

MOVED BEFORE IT IS COOL, WEAR GLOVES AND

HANDLE BY THE AIR BAG IT SELF.

11. Disconnect the pigtail adapter from the air bag

assembly as soon after deployment as possible to

avoid damage to the pigtail adapter or SRS

deployment harness from contacting the hot air bag

assembly canister. The pigtail adapter and SRS

deployment harness are designed to be reused. They

should, however, be inspected for damage after each

deployment and replaced if necessary.

12. Dispose of the deployed air bag assembly through

normal refuse channels after it has cooled for at least

30 minutes.