lock OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4320 of 6000

4D2–13 TRANSFER CASE (TOD)

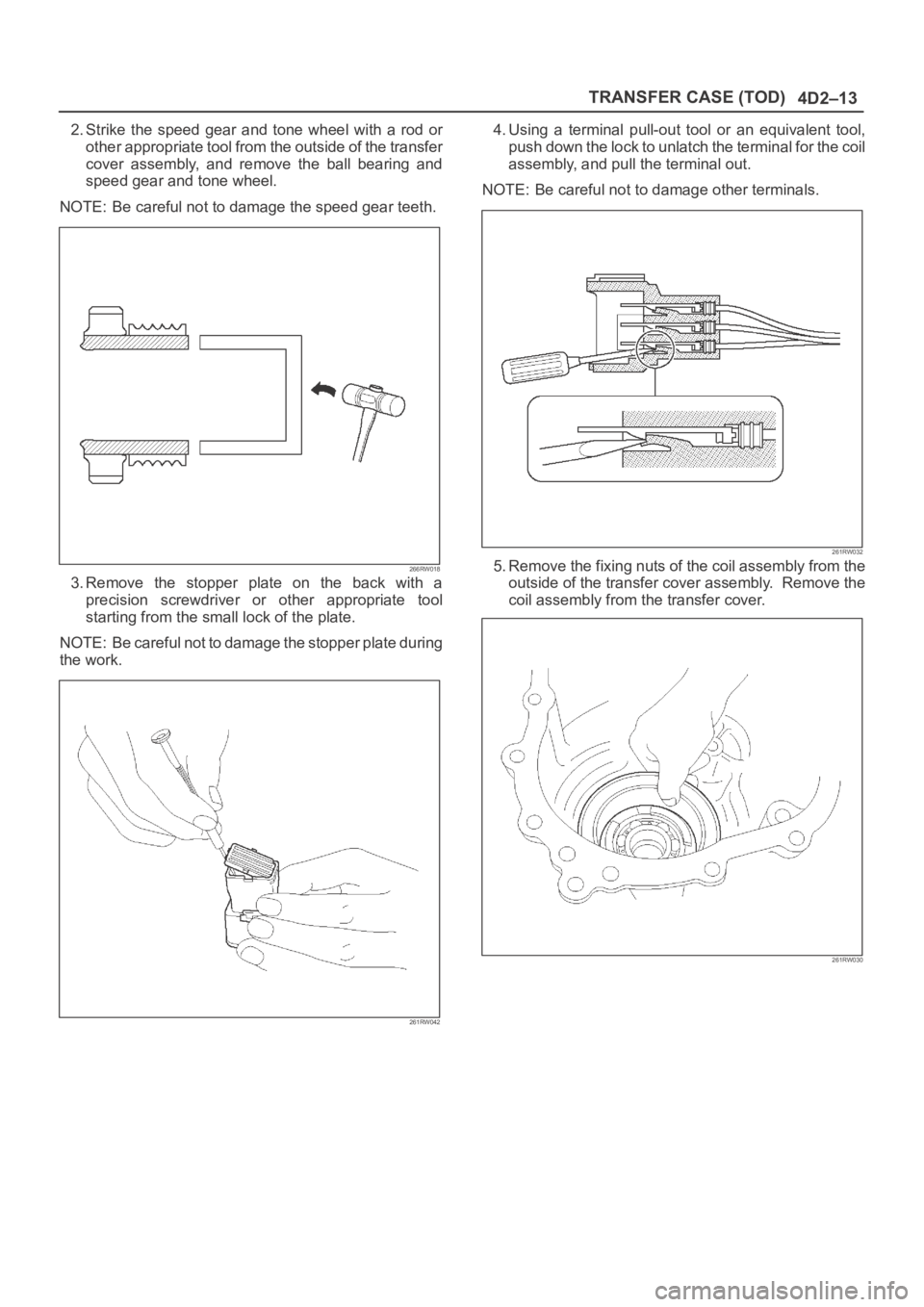

2. Strike the speed gear and tone wheel with a rod or

other appropriate tool from the outside of the transfer

cover assembly, and remove the ball bearing and

speed gear and tone wheel.

NOTE: Be careful not to damage the speed gear teeth.

266RW018

3. Remove the stopper plate on the back with a

precision screwdriver or other appropriate tool

starting from the small lock of the plate.

NOTE: Be careful not to damage the stopper plate during

the work.

261RW042

4. Using a terminal pull-out tool or an equivalent tool,

push down the lock to unlatch the terminal for the coil

assembly, and pull the terminal out.

NOTE: Be careful not to damage other terminals.

261RW032

5. Remove the fixing nuts of the coil assembly from the

outside of the transfer cover assembly. Remove the

coil assembly from the transfer cover.

261RW030

Page 4325 of 6000

4D2–18

TRANSFER CASE (TOD)

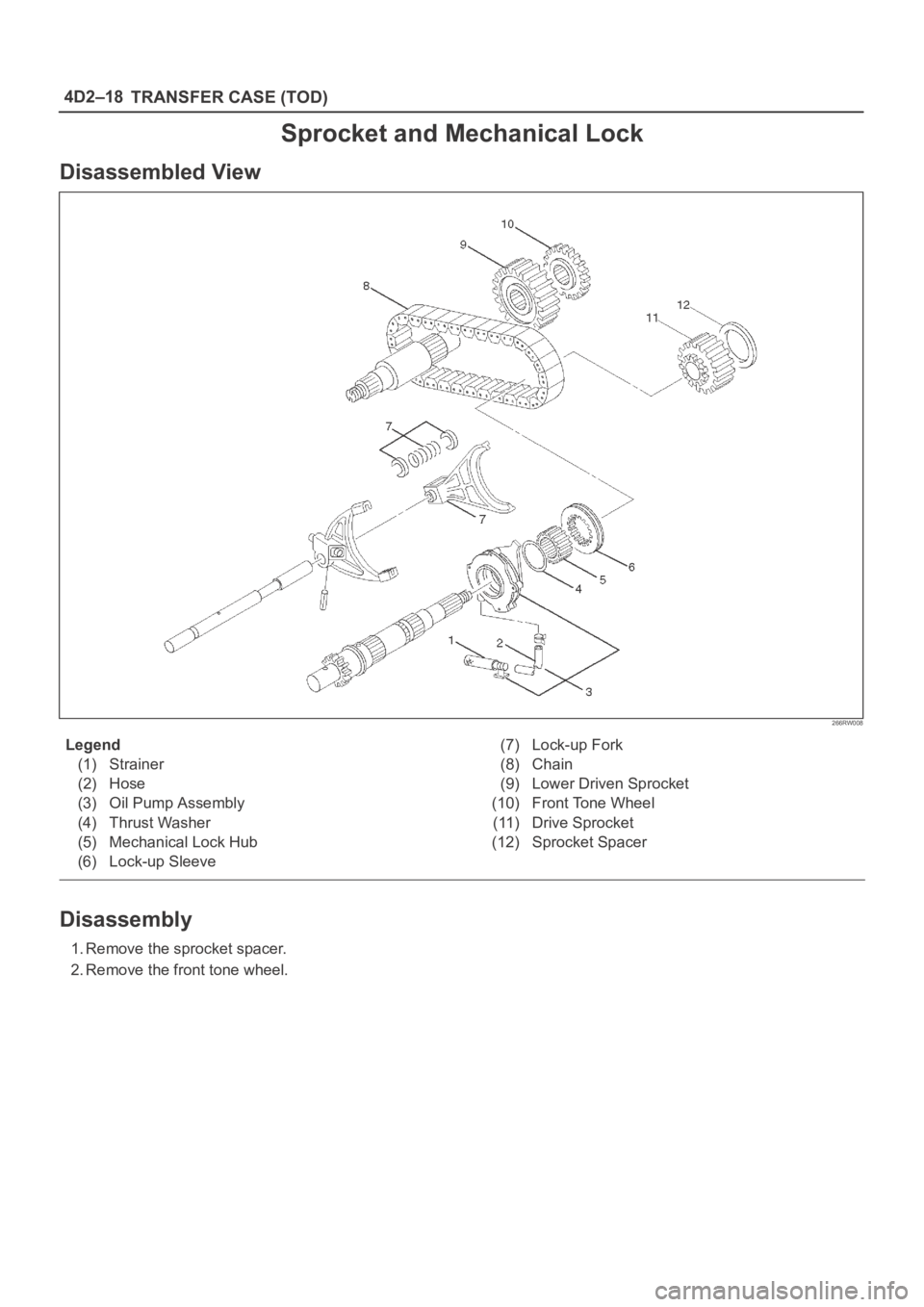

Sprocket and Mechanical Lock

Disassembled View

266RW008

Legend

(1) Strainer

(2) Hose

(3) Oil Pump Assembly

(4) Thrust Washer

(5) Mechanical Lock Hub

(6) Lock-up Sleeve(7) Lock-up Fork

(8) Chain

(9) Lower Driven Sprocket

(10) Front Tone Wheel

(11) Drive Sprocket

(12) Sprocket Spacer

Disassembly

1. Remove the sprocket spacer.

2. Remove the front tone wheel.

Page 4326 of 6000

4D2–19 TRANSFER CASE (TOD)

3.Remove the drive sprocket, lower driven sprocket,

and chain together from the front and rear output

shafts.

266RW010

4. Remove the mechanical lock hub.

5. Remove the lock-up fork.

6. Remove the spring retainers from the connection

between the rail shaft and lock-up fork.

7. Remove the lock-up sleeve.

261RW018

8. Remove the thrust washer.

9. Remove the magnet from the strainer set position

together with the oil pump assembly.

10. Remove the strainer from the oil pump assembly.

11. Remove the hose from the oil pump assembly.

Page 4327 of 6000

4D2–20

TRANSFER CASE (TOD)

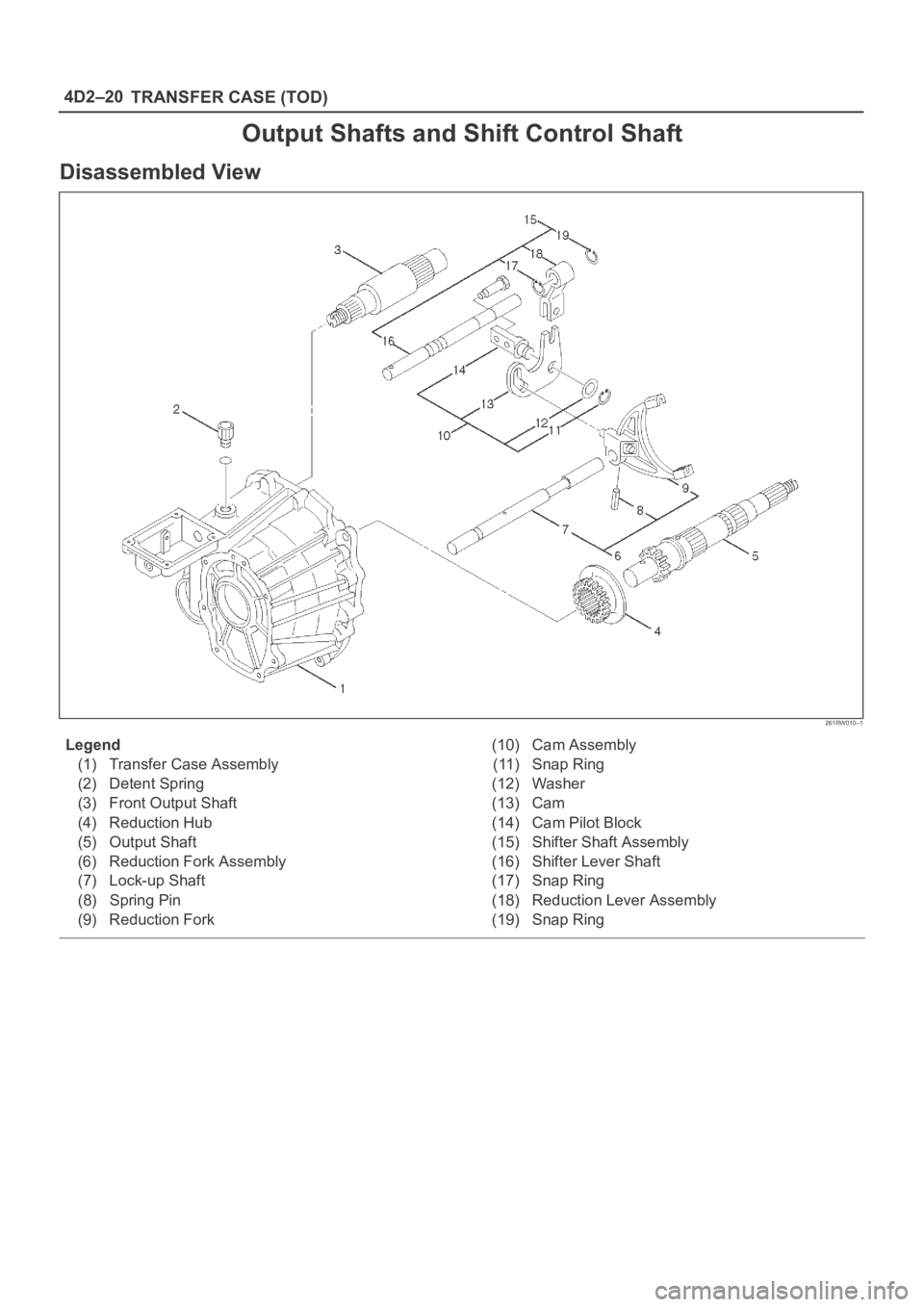

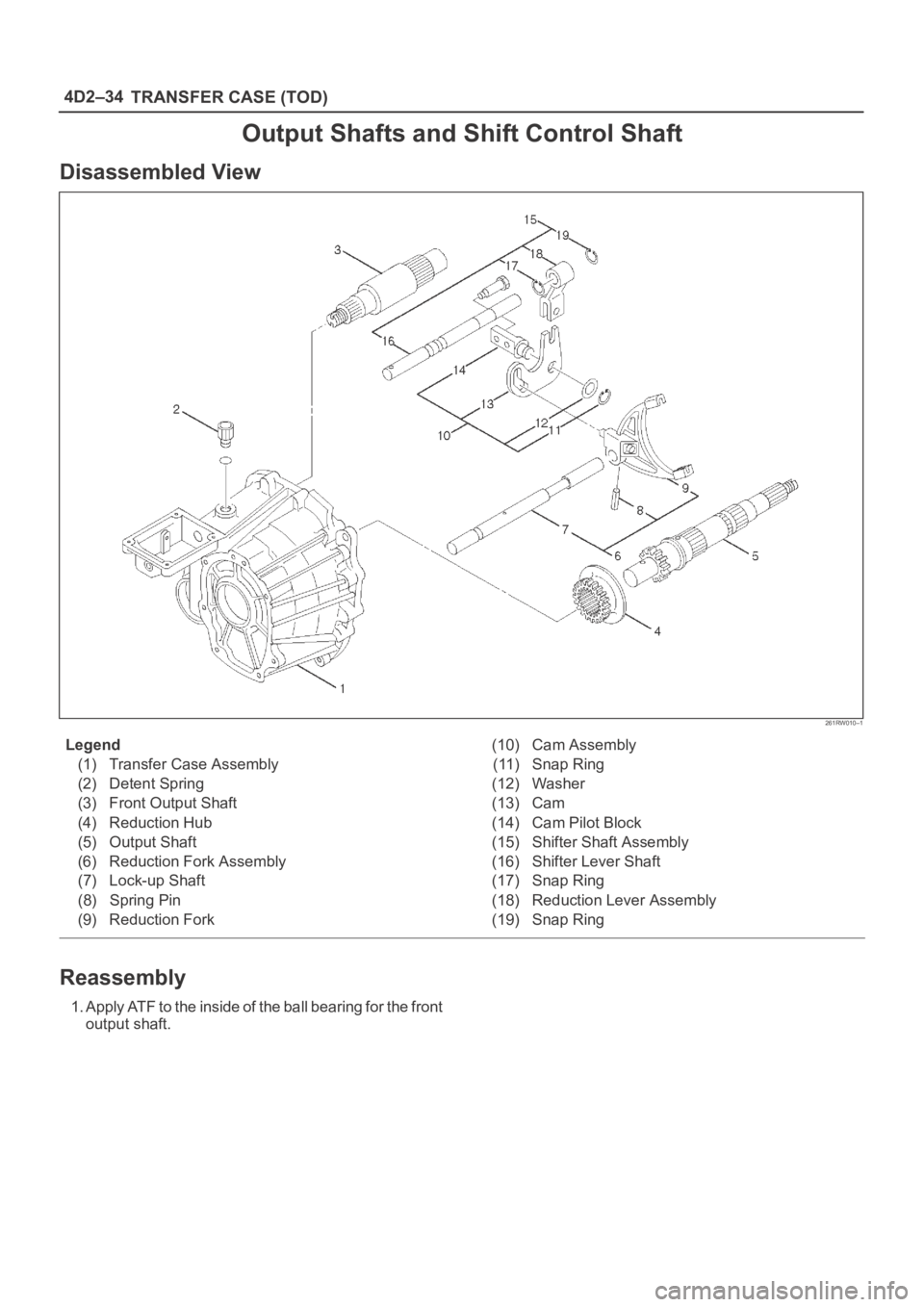

Output Shafts and Shift Control Shaft

Disassembled View

261RW010–1

Legend

(1) Transfer Case Assembly

(2) Detent Spring

(3) Front Output Shaft

(4) Reduction Hub

(5) Output Shaft

(6) Reduction Fork Assembly

(7) Lock-up Shaft

(8) Spring Pin

(9) Reduction Fork(10) Cam Assembly

(11) Snap Ring

(12) Washer

(13) Cam

(14) Cam Pilot Block

(15) Shifter Shaft Assembly

(16) Shifter Lever Shaft

(17) Snap Ring

(18) Reduction Lever Assembly

(19) Snap Ring

Page 4328 of 6000

4D2–21 TRANSFER CASE (TOD)

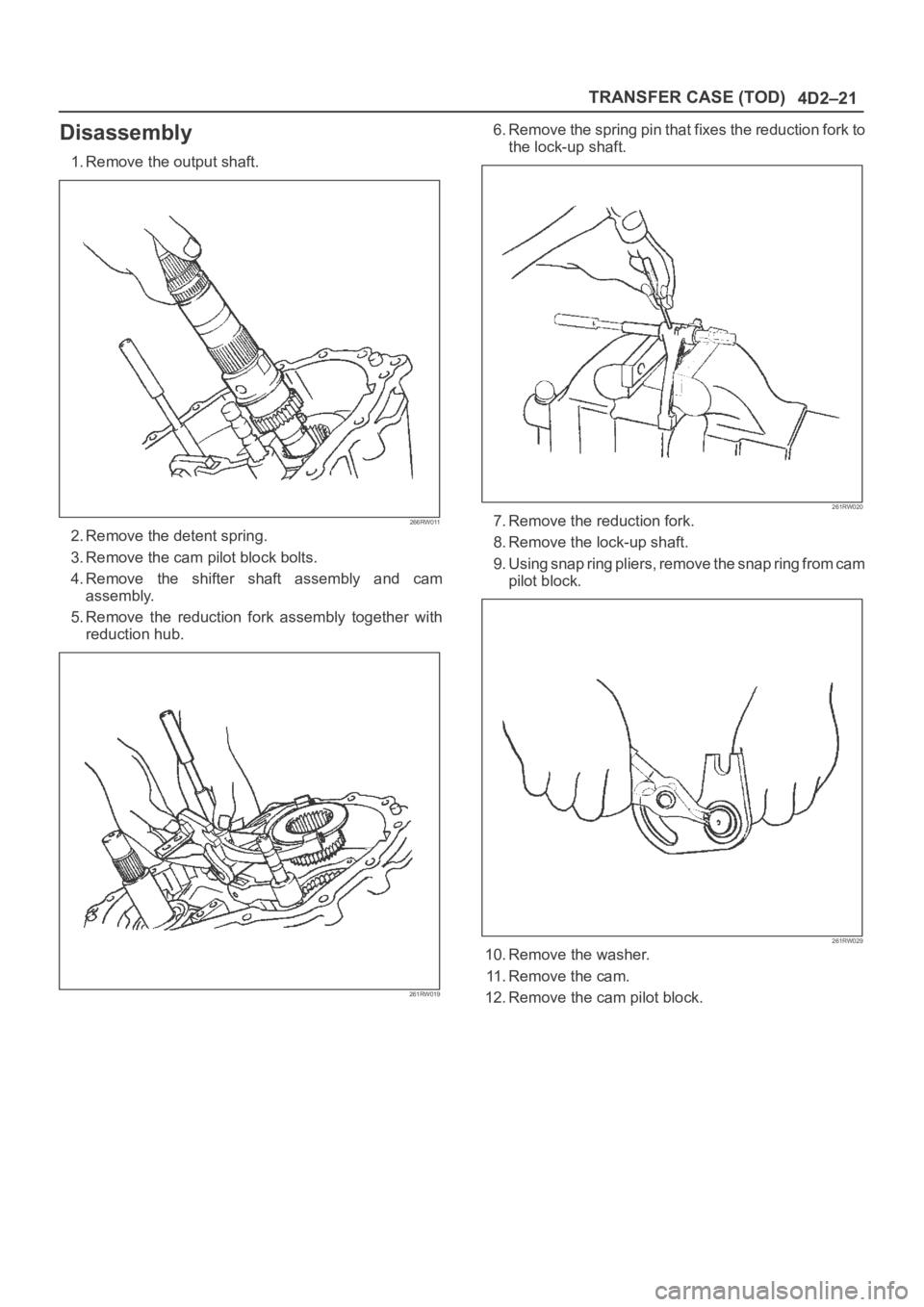

Disassembly

1. Remove the output shaft.

266RW011

2. Remove the detent spring.

3. Remove the cam pilot block bolts.

4. Remove the shifter shaft assembly and cam

assembly.

5. Remove the reduction fork assembly together with

reduction hub.

261RW019

6. Remove the spring pin that fixes the reduction fork to

the lock-up shaft.

261RW020

7. Remove the reduction fork.

8. Remove the lock-up shaft.

9. Using snap ring pliers, remove the snap ring from cam

pilot block.

261RW029

10. Remove the washer.

11. Remove the cam.

12. Remove the cam pilot block.

Page 4333 of 6000

4D2–26

TRANSFER CASE (TOD)

265RW007

Inspection and Repair

When wear, damage, or any other defects are observed

during the inspection, the part or parts must be repaired or

replaced. Wash all the parts with clean solvent, and

check that old oil, metallic particles, dirt, or foreign

materials are completely removed. Blow the air into oil

holes and grooves to remove foreign materials or residual

detergent.

Chain

Check whether the face that contacts the sprocket is

free from excessive wear or damage. If defects are

observed, replace the part.

If the chain interference mark is found on the inside

w a l l o f t h e t r a n s f e r c o v e r o r t h e c h a i n i s s o s l a c k t h a t a

skipped engagement occurs between the chain and

sprocket, replace the chain.

Sprocket

Check whether the sprocket tooth surface is

excessively worn or damaged, and there is evidence

of burrs, chipping, wear, or damage on the gear

spline. Remove minor flaws or scratches with oil

stone. If excessive wear or damage is observed,

replace the part.

If excessive wear or damage is observed on the

sprocket inside sliding surface, replace the part.

Gear

Check whether the gear tooth surface is excessively

worn or damaged, and there is evidence of burrs,

chipping, wear, or damage on the gear spline.

Remove minor flaws or scratches with oil stone. If

excessive wear or damage is observed, replace the

part.

Thickness of Reduction Hub

Measure the thickness with a micrometer.

If the measurement exceeds the limit, replace the

reduction hub.

Standard : 3.05-3.30 mm (0.120-0.130 in)

Allowable limit : 2.5 mm (0.098 in)

265RW005

Lock-up Sleeve

Mount the mechanical lock hub, drive sprocket

assembly, and lock-up sleeve to the output shaft.

If the lock-up sleeve does not move smoothly, replace

the sleeve.

NOTE: Apply ATF to the area engaging the gear.

Thickness of Lock-up Sleeve

If the measurement exceeds the limit, replace the

lock-up sleeve.

Standard : 7.16-7.32 mm (0.282-0.288 in)

Allowable limit : 7.9 mm (0.311 in)

266RW014

Page 4334 of 6000

4D2–27 TRANSFER CASE (TOD)

Reduction Fork

Check the reduction fork and shaft for wear, distortion,

and scratches. If defects are observed, replace the

parts.

Thickness of Reduction Fork

If the measurement exceeds the limit, replace the

reduction fork.

Standard : 3.41-3.79 mm (0.134-0.149 in)

Allowable limit : 4.4 mm (0.173 in)

261RW026

Lock-up Fork

Check the lock-up fork and shaft for wear, distortion,

and scratches. If defects are observed, replace the

parts.

Thickness Lock-up Fork

If the measurement exceeds the limit, replace the

lock-up fork.

Standard : 6.99-7.09 mm (0.275-0.279 in)

Allowable limit : 6.3 mm (0.248 in)

261RW027

Bearing

Check the profile of the needle, roller, ball, and thrust

bearings. Wash the bearings with clean solvent

completely, and dry with air.

NOTE: If the bearing is rotated excessively, the rollers

may be damaged. So, rotate the bearing slowly with your

hand. Apply grease to the bearing, and check the

smoothness of the bearing while slowly rotating the race

with your hand.

Use a dial indicator to measure the ball bearing play.

Allowable limit : 0.23 mm (0.009 in)

226RW143

Lock-up Fork Spring

Check the lock-up fork spring for distortion, cracking,

and wear. If defects are observed, replace the part.

Free Length of the Lock-up Fork Spring

If the measurement exceeds the limit, replace the

spring.

Standard : 60.96 mm (2.40 in)

Allowable limit : 55.0 mm (2.17 in)

220RW045

Page 4335 of 6000

4D2–28

TRANSFER CASE (TOD)

Tension of Lock-up Fork Spring

If the measurement exceeds the limit, replace the

spring. (When compressed to 41.4 mm)

Standard : 27.1-33.8 N {2.76-3.45 kg/6.08-7.61 Ib}

Allowable limit : 24.5 N {2.5 kg/5.5 Ib}

014RW048

Tension of Detent Spring Assembly

If the measurement exceeds the limit, replace the

spring. N {kg} (When compressed by 3 mm from the

free length)

Standard : 139 N -203 {14.2-20.7 kg/31.3-45.6 Ib}

Allowable limit : 130 N {13.3 kg/29.3 Ib}

261RW041

Oil Pump

Remove foreign materials from the strainer. If the

strainer is damaged, replace it.

If the area into which the shaft is inserted is

excessively worn or damaged, replace the pump.

Multi Plate Disk Clutch

If the burned, mirror-surfaced clutch facing, or

scraping is observed on the clutch plates, clutch

housing, armature plate, and insulator washer,

replace the part or parts.

266RW003

Coil Assembly

Check the resistance of the coil with a tester. If

defects are observed, replace the assembly.

* (ordinary temperature)

Standard : 1.4

2.0

Allowable limit : 1.05.0

261RW031

Page 4341 of 6000

4D2–34

TRANSFER CASE (TOD)

Output Shafts and Shift Control Shaft

Disassembled View

261RW010–1

Legend

(1) Transfer Case Assembly

(2) Detent Spring

(3) Front Output Shaft

(4) Reduction Hub

(5) Output Shaft

(6) Reduction Fork Assembly

(7) Lock-up Shaft

(8) Spring Pin

(9) Reduction Fork(10) Cam Assembly

(11) Snap Ring

(12) Washer

(13) Cam

(14) Cam Pilot Block

(15) Shifter Shaft Assembly

(16) Shifter Lever Shaft

(17) Snap Ring

(18) Reduction Lever Assembly

(19) Snap Ring

Reassembly

1. Apply ATF to the inside of the ball bearing for the front

output shaft.

Page 4342 of 6000

4D2–35 TRANSFER CASE (TOD)

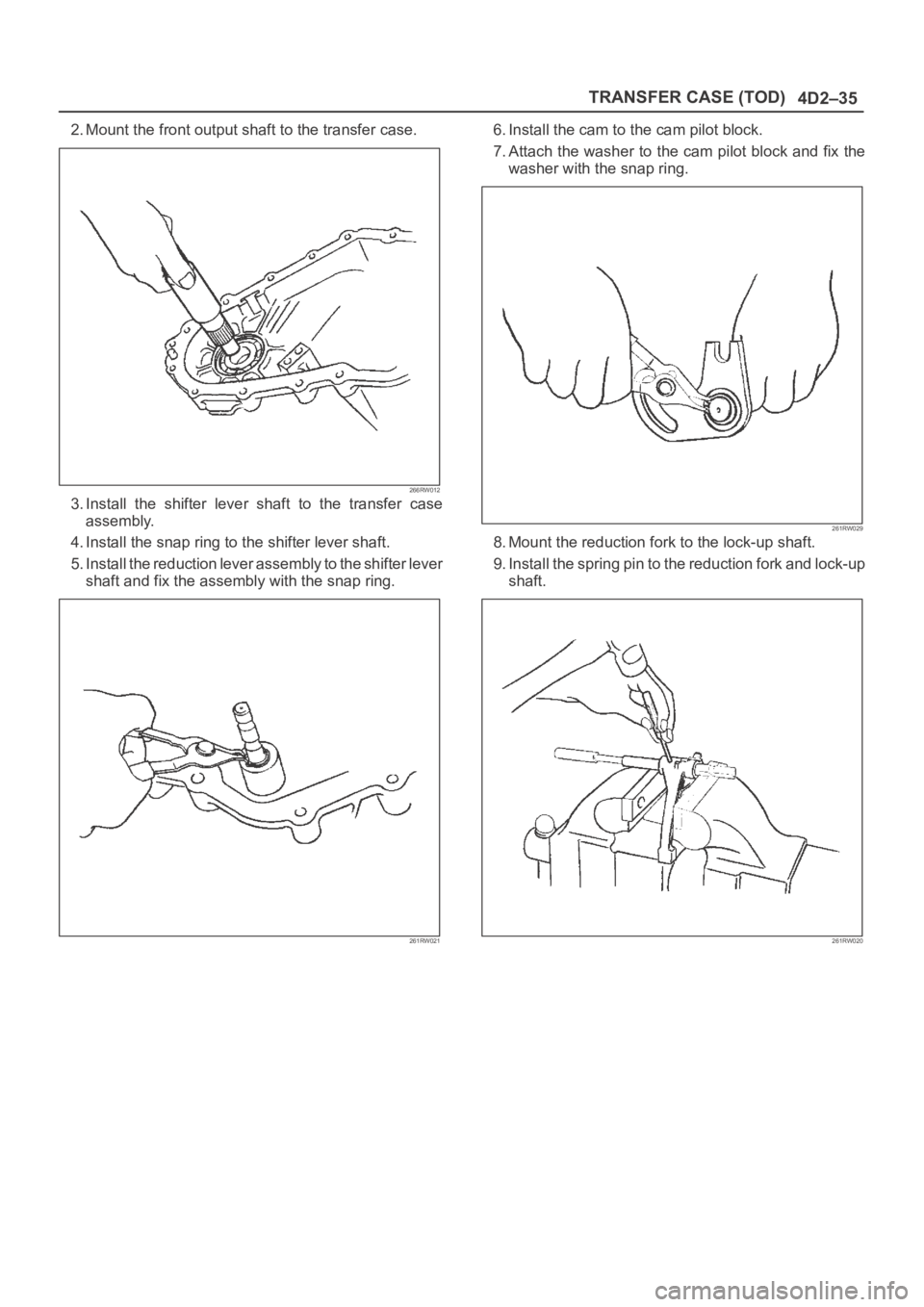

2. Mount the front output shaft to the transfer case.

266RW012

3. Install the shifter lever shaft to the transfer case

assembly.

4. Install the snap ring to the shifter lever shaft.

5. Install the reduction lever assembly to the shifter lever

shaft and fix the assembly with the snap ring.

261RW021

6. Install the cam to the cam pilot block.

7. Attach the washer to the cam pilot block and fix the

washer with the snap ring.

261RW029

8. Mount the reduction fork to the lock-up shaft.

9. Install the spring pin to the reduction fork and lock-up

shaft.

261RW020