automatic transmission fluid OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5734 of 6000

7A–45 AUTOMATIC TRANSMISSION (4L30–E)

Installation

1. Connect ground wire to converter clutch solenoid

wiring harness connector of the wiring harness

assembly.

2. Install wiring harness assembly to converter clutch

solenoid, force motor, and 5 pin connector of adapter

case.

3. Install oil pan gasket, oil pan, and twelve 10 mm fixing

screws. Tighten the screws to the specified torque.

Torque: 11 N

m (1.1 kgꞏm/96 lb in)4. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque:

43 N

m(4.4kgꞏm/32lbft)

5. Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

To r q u e : 3 7 N

m (3.8 kgꞏm/27 lb ft)

6. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III.

Refer to Changing Transmission Fluid in this section.

7. Connect battery ground cable.

Front Oil Seal (Converter Housing)

Removal

1. Remove transmission assembly with transfer case

from the vehicle. Refer to Transmission (with Transfer

Case) in this section.

2. Remove torque converter from converter housing.

3. Remove three screws and oil seal ring from converter

housing.

241RW008

Installation

1. Apply clean ATF to the new oil seal ring lip.

Install oil seal ring to converter housing. Tighten the

screws to the specified torque.

To r q u e : 3 N

m (0.3 kgꞏm/26 lb in)

2. Install torque converter to converter housing.

3. Install transmission assembly with transfer case to

the vehicle. Refer to Transmission (with Transfer

Case) in this section.

Page 5735 of 6000

7A–46

AUTOMATIC TRANSMISSION (4L30–E)

Rear Oil Seal (Extension Housing)

Removal

1. Remove transfer case assembly from the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

2. Remove rear oil seal from transmission extension

housing.

241RW005

Installation

1. Use 5–8840–2282–0 (J–36797) extension housing

oil seal installer, and install the rear oil seal to the

transmission extension housing.

2. Install the transfer case assembly to the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

Transmission (4L30–E)

Disassembly

NOTE: During the disassembly and reassembly, perform

the following:

Wash each part thoroughly, and blow air through each

oil passage and groove to eliminate blockage.

Seal rings, roll pins, and gaskets should be replaced.

When assembling the components, apply

DEXRON

–III Automatic Transmission Fluid (ATF)

to each seal, rotating part, and sliding part.

Do not dip part facings, such as clutch or brake drive

plates, in cleaner when washing it.

Also, always coat parts with new ATF two or three

times after cleaning with solvent.

1. Remove torque converter (1).

Drain fluid from torque converter.

Attach 5–8840–2278–0 (J–8763–02) holding

fixture to the transmission and set it on

5–8840–0003–0 (J–3289–20) holding fixture base.

NOTE: Do not overtighten the tool, as case damage may

result.

420RW019

2. Remove O–ring (2) from turbine shaft.

3. Remove two 10mm mode switch screws, selector

lever nut, cover, and mode switch (3).

4. Remove twelve 10mm adapter case oil pan (4) fixing

screws, adapter oil pan, and gasket.

5. Disconnect electrical wiring connections (5) from

solenoids and 5 pin connector of adapter case. Pull

on connectors only, not on wiring harness.

Page 5736 of 6000

7A–47 AUTOMATIC TRANSMISSION (4L30–E)

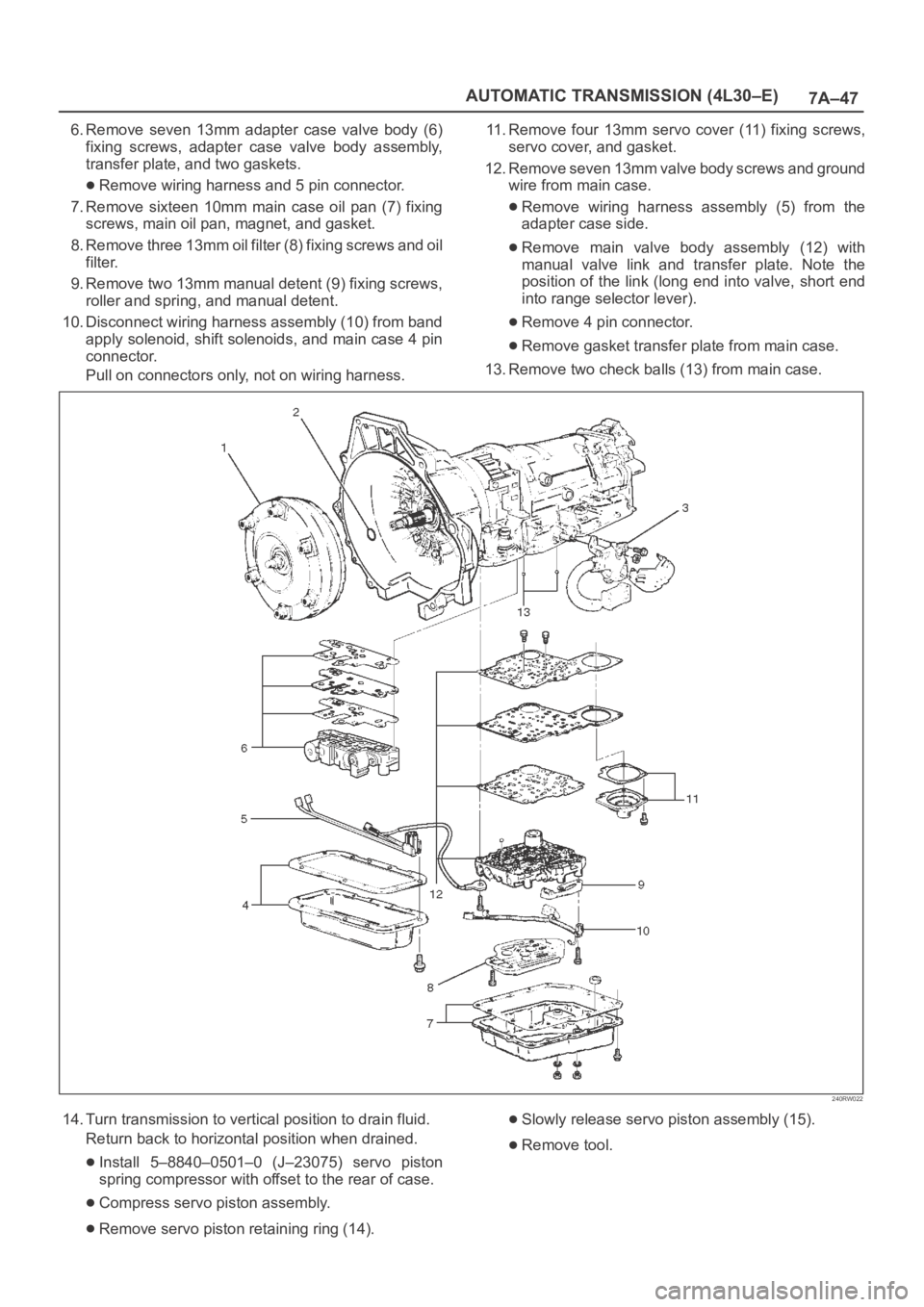

6. Remove seven 13mm adapter case valve body (6)

fixing screws, adapter case valve body assembly,

transfer plate, and two gaskets.

Remove wiring harness and 5 pin connector.

7. Remove sixteen 10mm main case oil pan (7) fixing

screws, main oil pan, magnet, and gasket.

8. Remove three 13mm oil filter (8) fixing screws and oil

filter.

9. Remove two 13mm manual detent (9) fixing screws,

roller and spring, and manual detent.

10. Disconnect wiring harness assembly (10) from band

apply solenoid, shift solenoids, and main case 4 pin

connector.

Pull on connectors only, not on wiring harness.11. Remove four 13mm servo cover (11) fixing screws,

servo cover, and gasket.

12. Remove seven 13mm valve body screws and ground

wire from main case.

Remove wiring harness assembly (5) from the

adapter case side.

Remove main valve body assembly (12) with

manual valve link and transfer plate. Note the

position of the link (long end into valve, short end

into range selector lever).

Remove 4 pin connector.

Remove gasket transfer plate from main case.

13. Remove two check balls (13) from main case.

240RW022

14. Turn transmission to vertical position to drain fluid.

Return back to horizontal position when drained.

Install 5–8840–0501–0 (J–23075) servo piston

spring compressor with offset to the rear of case.

Compress servo piston assembly.

Remove servo piston retaining ring (14).

Slowly release servo piston assembly (15).

Remove tool.

Page 5747 of 6000

7A–58

AUTOMATIC TRANSMISSION (4L30–E)

242RW008

46. Install two check balls (44).

244RW002

47. Inspect main case electrical connector and seal,

replace if necessary.

Install electrical 4 pin connector/main case and

wiring harness.

48. Install two 5–8840–0022–0 (J–25025–B) guide pins

into main case.

Install main case valve body complete assembly

(45) and manual valve link.NOTE: Valve must be extended as the short end of

manual valve link is connected to the range selector lever.

Long end of link goes into valve.

Install seven 13 mm screws.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

Pass ground wire of adapter case wiring harness

assembly through the hole joining adapter fluid area

and main case fluid area.

Assemble 8.5 mm connector of ground wire under

the head of this valve body bolt and reinstall it.

Remove two guide pins.

244RW001

49. Install servo cover gasket, cover (46) and four 13 mm

screws.

To r q u e : 2 5 N

m (2.6 kgꞏm/18 lb ft)

50. Connect wiring harness (47) to band control, shift

solenoids, and main case 4 pin connector.

51. Install manual detent roller and spring assembly (48)

with clip.

Install two 13 mm screws.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

52. Install oil filter (49), and three 13 mm screws.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

53. Install oil pan gasket, magnet, main oil pan (50), and

sixteen 10 mm screws.

To r q u e : 11 N

m (1.1 kgꞏm/96 lb in)

54. Inspect adapter case electrical connector and seal.

Replace if necessary.

Install electrical five pin connector and harness

assembly (52) in bottom of adapter case.

55. Install gasket, transfer plate, and gasket.

Install adapter case valve body (51) and seven 13

mm screws.

Torque: 20 N

m (2.0 kgꞏm/15 lb ft)

Page 5748 of 6000

7A–59 AUTOMATIC TRANSMISSION (4L30–E)

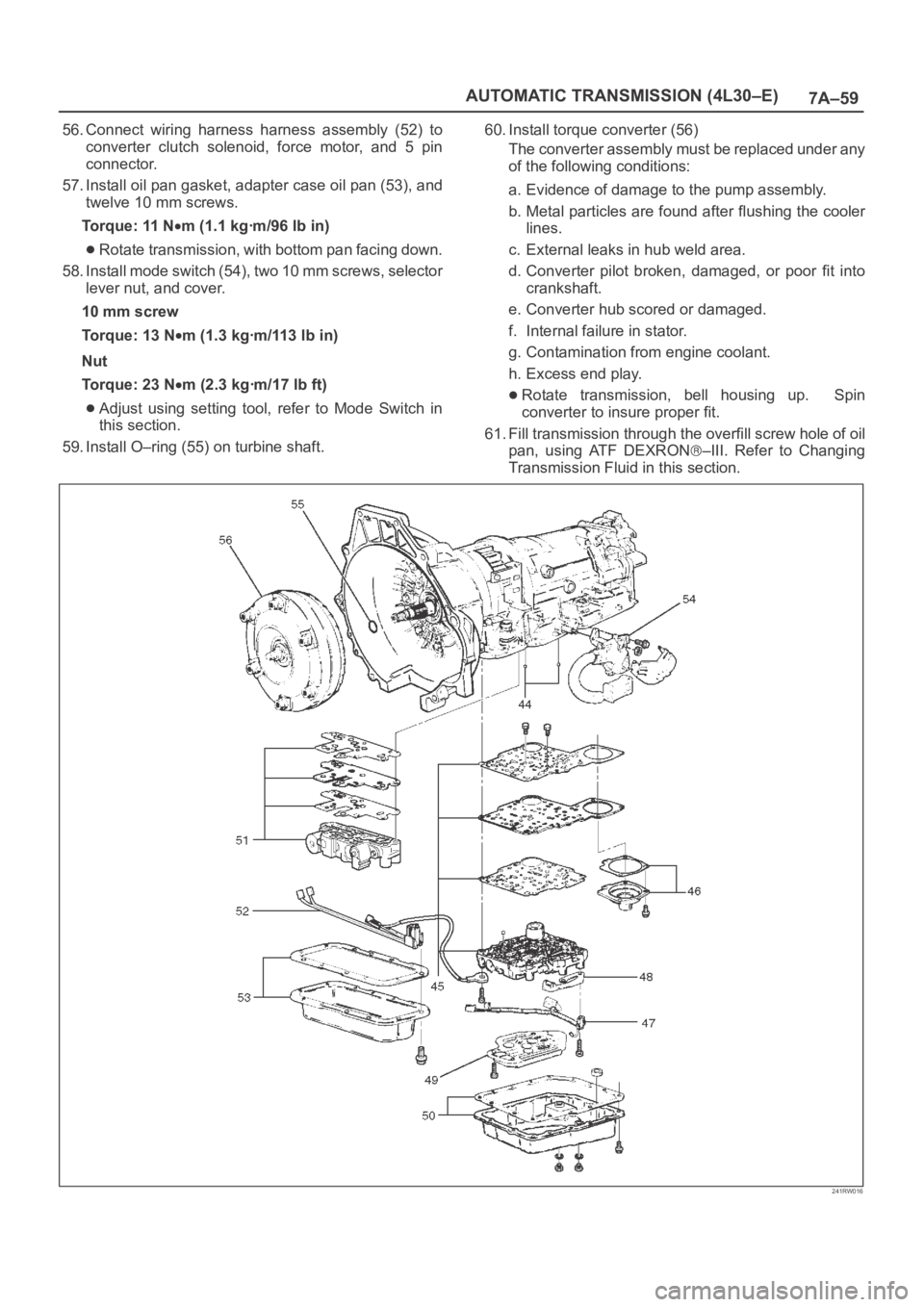

56. Connect wiring harness harness assembly (52) to

converter clutch solenoid, force motor, and 5 pin

connector.

57. Install oil pan gasket, adapter case oil pan (53), and

twelve 10 mm screws.

Torque: 11 N

m (1.1 kgꞏm/96 lb in)

Rotate transmission, with bottom pan facing down.

58. Install mode switch (54), two 10 mm screws, selector

lever nut, and cover.

10 mm screw

Torque: 13 N

m (1.3 kgꞏm/113 lb in)

Nut

Torque: 23 N

m (2.3 kgꞏm/17 lb ft)

Adjust using setting tool, refer to Mode Switch in

this section.

59. Install O–ring (55) on turbine shaft.60. Install torque converter (56)

The converter assembly must be replaced under any

of the following conditions:

a. Evidence of damage to the pump assembly.

b. Metal particles are found after flushing the cooler

lines.

c. External leaks in hub weld area.

d. Converter pilot broken, damaged, or poor fit into

crankshaft.

e. Converter hub scored or damaged.

f. Internal failure in stator.

g. Contamination from engine coolant.

h. Excess end play.Rotate transmission, bell housing up. Spin

converter to insure proper fit.

61. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

241RW016

Page 5756 of 6000

7A–67 AUTOMATIC TRANSMISSION (4L30–E)

Third Clutch

Disassembled View

248RS006

Legend

(1) Retaining Ring

(2) Spring Seat(3) Springs

(4) Piston Assembly

(5) Third Clutch Drum

Disassemble

1. Compress spring seat using the 5–8840–0501–0

(J–23075) spring compressor and 5–8840–2259–0

(J–23075–12) adapter tool.

NOTE: Do not over–stress the springs and seat. This will

cause damage to the spring seat.

Remove the tool.

Remove retaining ring (1).

248RW004

2. Release the spring seat (2).

NOTE: Do not let the spring seat catch in the ring groove.

Remove spring seat (2) and springs (3).

3. Remove piston assembly (4) from third clutch drum

(5).

Inspection And Repair

Visual check:

If any damage, deformation or wear is found, replace the

damaged part.

Operation check:

Shake the piston and listen for check ball movement

indicates proper check ball operation. Replace the piston

if the check ball is missing or falls out.

Reassembly

1. The lip of the piston seal must point toward the front of

the transmission. Lubricate the seal lip with

transmission fluid.

Install piston assembly (4) into the third clutch drum

(5). Use the 5–8840–2260–0 (J–23084) third clutch

piston installer to protect the outer seal during

installation.

Page 5760 of 6000

7A–71 AUTOMATIC TRANSMISSION (4L30–E)

Inspection And Repair

Visual Check:

If any damage, deformation or wear is found, replace the

damaged part.

Operation Check:

Shake the piston and listen for check ball movement.

Movement indicates proper check ball operation.

Replace the piston if the check ball is missing or falls out.

Reassembly

1. Install piston assembly (10) into the second clutch

drum (11).

Lubricate the lip seal with transmission fluid. Use

the 5–8840–2261–0 (J–23080–A) second clutch

piston installer to protect the outer piston lip seal.

NOTE: Lip of the seal should point toward front of

transmission.

Remove the installer.

247RS007

2. Install twenty–two piston springs (9) and spring seat

(8) on the second clutch piston (10). Place retaining

ring (7) onto spring seat.

Use the 5–8840–0195–0 (J–23327) compressor to

compress the piston springs.

NOTE: Do not let spring seat catch in ring groove.

Remove the compressor.

3. Install waved plate (6) and clutch plates (5). Start with

a steel plate and alternate with lined plates.

Align second clutch inner tangs.

4. Install spacer (4), with the fluted end toward clutch

plates.

5. Install retaining ring (3), ring gear (2) and retaining

ring (1).

Page 5782 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–1

SECTION 7A

CONTENTS

AUTOMATIC TRANSMISSION (AW30-40LE)

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–3

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–3

ELECTRONIC CONTROL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–4

TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–5

CONTROL SYSTEM DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–6

CONTROL AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–7

MAJOR INPUT/OUTPUT COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–9

LOCATION OF CLUTCH, BRAKE ONE-WAY CLUTCH AND SOLENOID . . . . . . . . . . . . . . . . . . . . . . . 7A–10

OPERATION OF CLUTCH, BRAKE AND ONE-WAY CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–11

SPEED CHANGE AND LOCK-UP PATTERN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–11

OVERDRIVE AND LOCK-UP OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–12

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–13

BASIC TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–13

SELF-DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–14

DIAGNOSIS WITH TECH2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–17

TECH2 CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–18

TECH2 OPERATING FLOW CHART (START UP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–19

TRANSMISSION DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–21

TCC DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–22

INTERMITTENT CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–23

IDENTIFICATION OF TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–24

DIAGNOSTIC TROUBLE CODES (DTC) CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–25

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–52

CONNECTOR LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–54

TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–56

MANUAL SHIFTING TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–62

STALL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–63

TIME LAG TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–64

HYDRAULIC TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–65

ROAD TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–66

SHIFT POINT CHART AND LOCK-UP POINT CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–69

TCM VOLTAGE CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–71

TCM STANDARD VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–72

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–75

TRANSIMISSION FLUID LEVEL AND CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–75

ATF REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–75

NEUTRAL START SWITCH INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–76

BRAKE SIGNAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–77

VEHICLE SPEED SENSOR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–77

INPUT AND OUTPUT REVOLUTION SENSOR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–77

PATTERN SELECT SWITCH INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–78

OVERDRIVE OFF SWITCH INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–78

SOLENOID INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–78

THROTTLE POSITION SENSOR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–79

ATF TEMPERATURE SENSOR INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–79

SELECTOR LEVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–80

TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–81

SHIFT SOLENOID AND LOCK-UP SOLENOID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–83

Page 5844 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–63

F07RY00002

STALL TEST

The object of this test is to check the overall performance of the

transmission and engine by measuring the maximum engine

speeds at the "D" and "R" ranges.

NOTE:

(1) Perform the test at normal operation fluid temperature

(50 – 80

C or 122 – 176F).

(2) Do not continuously run this test longer than 5

seconds.

MEASURE STALL SPEED

1) Chock the four wheels.

2) Mount an engine tachometer.

3) Fully apply the parking brake.

4) Step down strongly on the brake pedal with your left foot.

5) Star t the engine.

6) Shift into the "D" range. Step all the way down on the

accelerator pedal with your right foot. Quickly read the

highest engine rpm.

7) Perform the same test in the "R" range.

EVALUATION

1) If the engine speed is the same for both ranges but lower

than the specified value:

• Engine output is insufficient.

• Stator one-way clutch is not operating properly.

NOTE:

If more than 600 rpm below the specified value, the torque

converter could be faulty.

2) If the stall speed in only "D" range is higher than specified:

• Line pressure too low

• Forward clutch slipping

• No. 2 one-way clutch not operating properly

3) If the stall speed in only "R" range is higher than specified:

• Line pressure too low

• Direct clutch slipping

• No. 3 brake slipping

4) If the stall speed in the "R" and "D" ranges are higher than

specified:

• Line pressure too low

• Improper fluid levelStall speed 2450

150rpm

Page 5845 of 6000

7A–64 AUTOMATIC TRANSMISSION (AW30-40LE)

F07RY00003

TIME LAG TEST

If the shift lever is shifted while the engine is idling, there will be

a cer tain time elapse or lag before the shock can be felt. This is

used for checking the condition of the forward clutch, direct

clutch, No. 3 brake, and No. 2 one-way clutch.

NOTE:

(1) Perform the test at normal operation fluid temperature

(50 – 80

C or 122 – 176F).

(2) Be sure to allow one minute interval between tests.

(3) Make three measurements and take the average value.

MEASURE TIME LAG

1) Fully apply the parking brake.

2) Start the engine.

Check idling speed (A/C OFF)

3) Shift the shift lever from "N" to "D" range. Using a stop

watch, measure the time it takes from shifting the lever until

the shock is felt.

4) In same manner, measure the time lag for "N"

"R".

EVALUATION

1) If "N" "D" time lag is longer than specified:

• Line pressure too low

• Forward clutch malfunction

• No. 2 one-way clutch not operating properly

2) If "N"

"R" time lag is longer than specified:

• Line pressure too low

• Direct clutch malfunction

• No. 3 brake malfunction

3) If both time lag is longer than specified:

• Line pressure too low"N" range 695 – 745 rpm

Time lag Less than 0.7 seconds

Time lag Less than 1.2 seconds