automatic transmission fluid OPEL FRONTERA 1998 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2271 of 6000

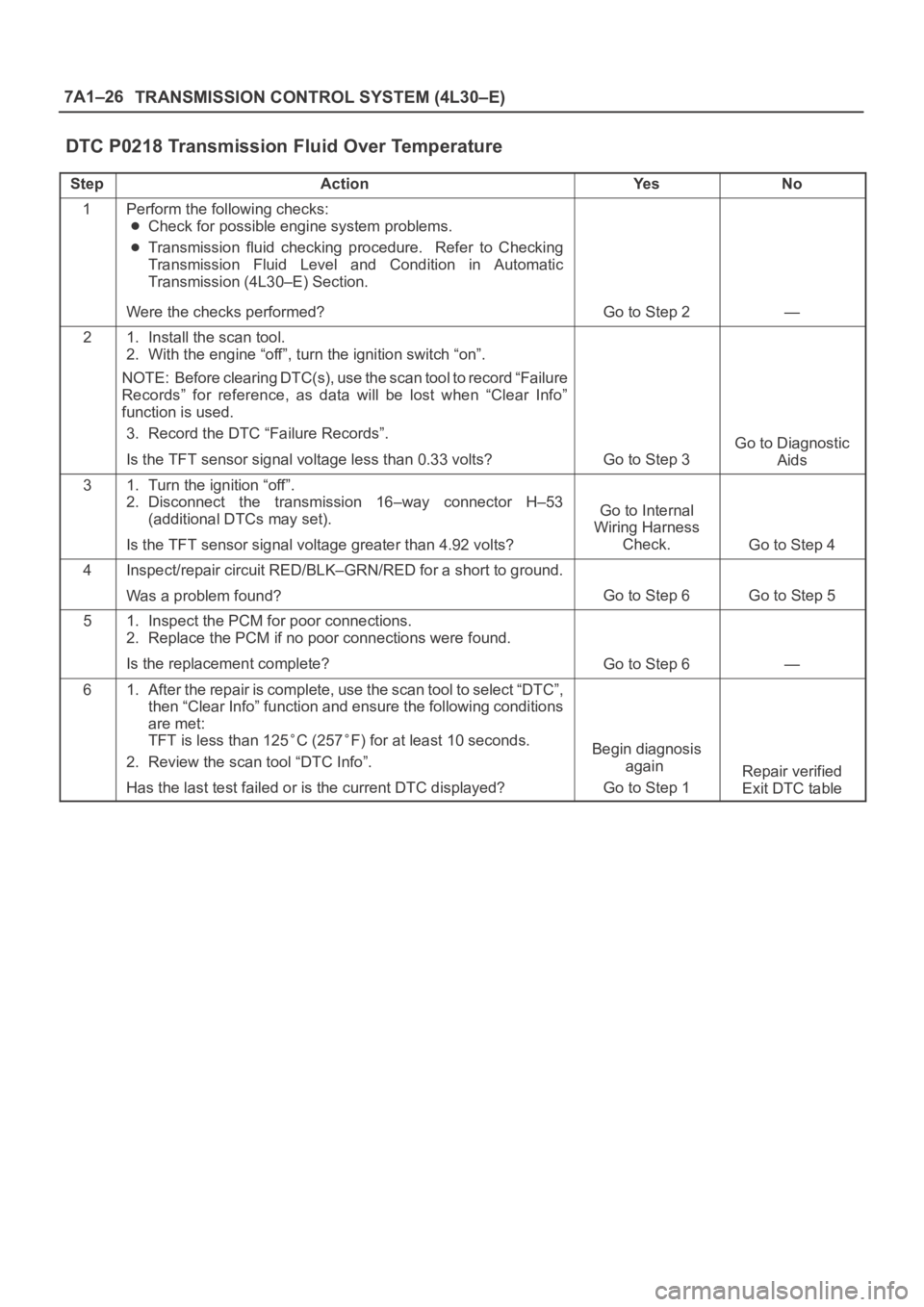

7A1–26

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0218 Transmission Fluid Over Temperature

StepActionYe sNo

1Perform the following checks:

Check for possible engine system problems.

Transmission fluid checking procedure. Refer to Checking

Transmission Fluid Level and Condition in Automatic

Transmission (4L30–E) Section.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

Is the TFT sensor signal voltage less than 0.33 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53

(additional DTCs may set).

Is the TFT sensor signal voltage greater than 4.92 volts?

Go to Internal

Wiring Harness

Check.

Go to Step 4

4Inspect/repair circuit RED/BLK–GRN/RED for a short to ground.

Was a problem found?

Go to Step 6Go to Step 5

51. Inspect the PCM for poor connections.

2. Replace the PCM if no poor connections were found.

Is the replacement complete?

Go to Step 6—

61. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

TFT is less than 125

C (257F) for at least 10 seconds.

2. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 2282 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–37

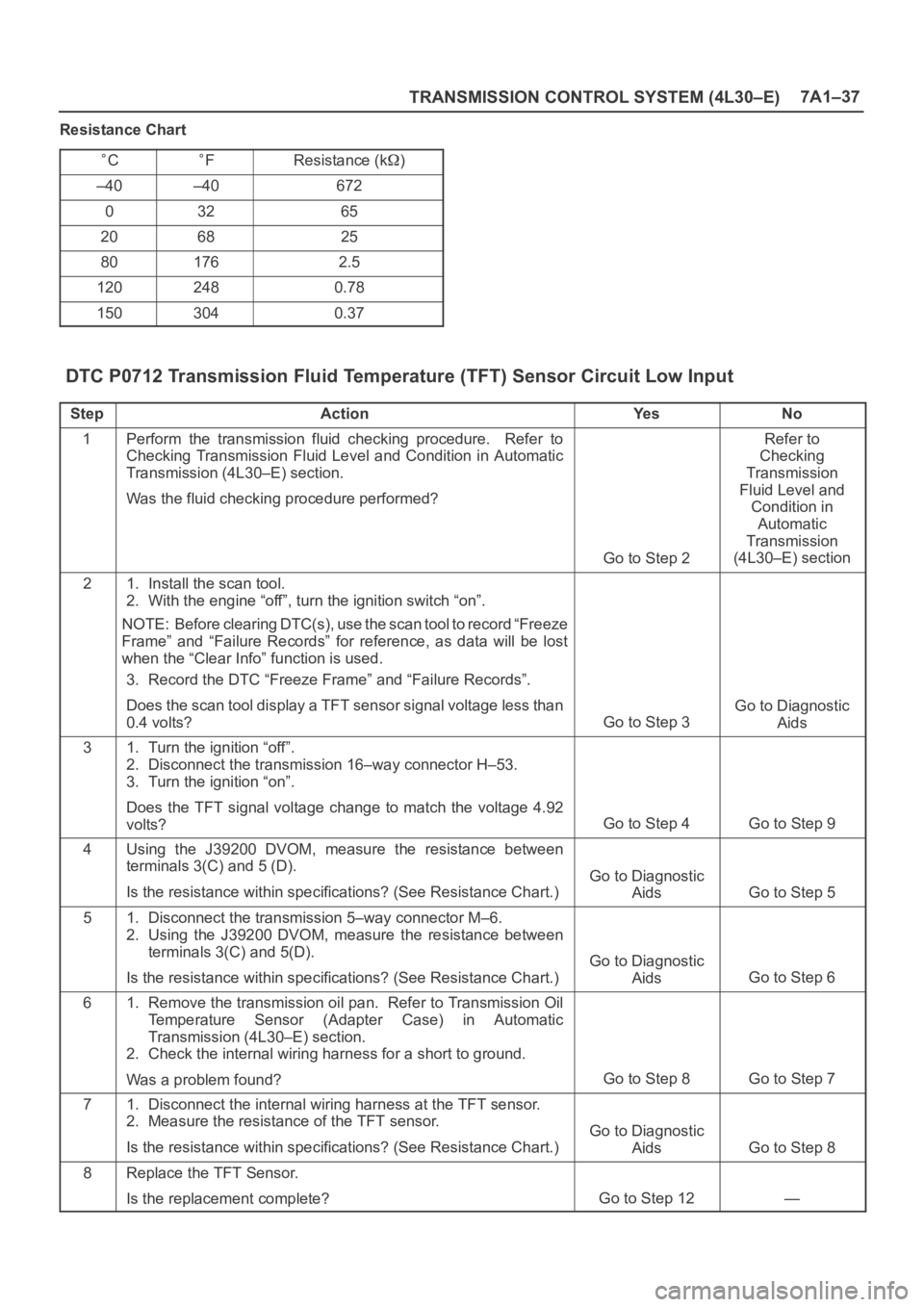

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0712 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input

StepActionYe sNo

1Perform the transmission fluid checking procedure. Refer to

Checking Transmission Fluid Level and Condition in Automatic

Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Freeze

Frame” and “Failure Records” for reference, as data will be lost

when the “Clear Info” function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage less than

0.4 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Turn the ignition “on”.

Does the TFT signal voltage change to match the voltage 4.92

volts?

Go to Step 4Go to Step 9

4Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5 (D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan. Refer to Transmission Oil

Temperature Sensor (Adapter Case) in Automatic

Transmission (4L30–E) section.

2. Check the internal wiring harness for a short to ground.

Was a problem found?

Go to Step 8Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

8Replace the TFT Sensor.

Is the replacement complete?

Go to Step 12—

Page 2283 of 6000

7A1–38

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0712 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input (Cont’d)

StepNo Ye s Action

9Check circuit RED/BLK–GRN/RED for a short to ground.

Was a problem found?

Go to Step 12Go to Step 10

10Check the PCM for faulty connections.

Was a problem found?

Go to Step 12Go to Step 11

11Replace the PCM. Refer to Powertrain Control Module (PCM) in

Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 12—

121. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

TFT sensor indicates a voltage greater than 0.33 volts for 2

seconds.

2. Review the scan tool “DTC info”.

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 2285 of 6000

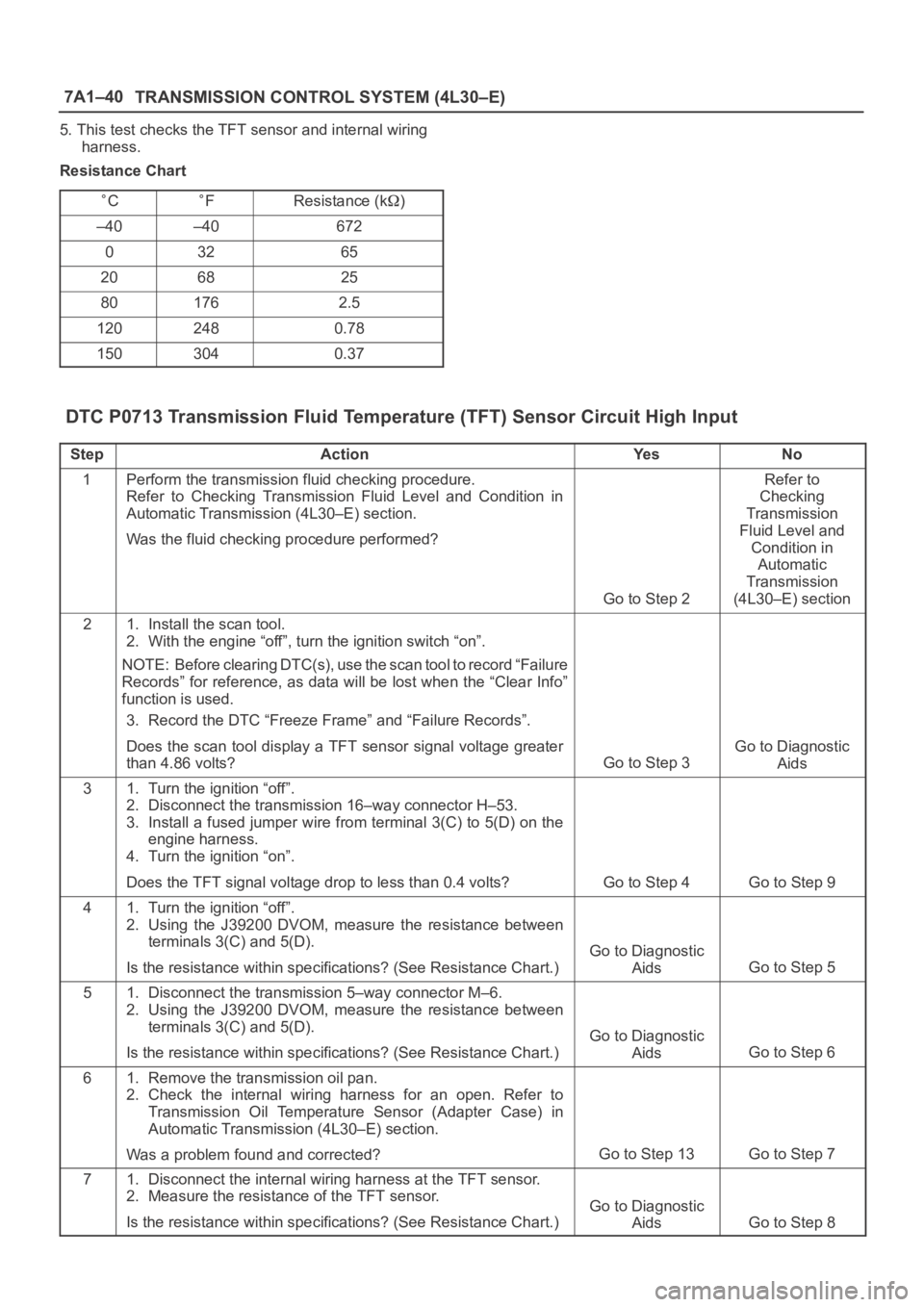

7A1–40

TRANSMISSION CONTROL SYSTEM (4L30–E)

5. This test checks the TFT sensor and internal wiring

harness.

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

StepActionYe sNo

1Perform the transmission fluid checking procedure.

Refer to Checking Transmission Fluid Level and Condition in

Automatic Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage greater

than 4.86 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Install a fused jumper wire from terminal 3(C) to 5(D) on the

engine harness.

4. Turn the ignition “on”.

Does the TFT signal voltage drop to less than 0.4 volts?

Go to Step 4Go to Step 9

41. Turn the ignition “off”.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan.

2. Check the internal wiring harness for an open. Refer to

Transmission Oil Temperature Sensor (Adapter Case) in

Automatic Transmission (4L30–E) section.

Was a problem found and corrected?

Go to Step 13Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

Page 2286 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–41

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input (Cont’d)

StepNo Ye s Action

8Replace TFT sensor. Refer to Transmission Oil Temperature

Sensor (Adapter Case) in Automatic Transmission (4L30–E)

section.

Is the replacement complete?

Go to Step 13—

9Check circuit RED/BLK–GRN/RED for an open or short to B+.

Was a problem found?

Go to Step 13Go to Step 10

10Check circuit GRY–GRN for an open.

Was a problem found?

Go to Step 13Go to Step 11

11Check the PCM for faulty or intermittent connections.

Was a problem found?

Go to Step 13Go to Step 12

12Replace the PCM. Refer to Powertrain Control Module (PCM) in

Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 13—

131. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

2. TFT sensor indicates a voltage less than 4.92 volts for 2

seconds.

3. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 2297 of 6000

7A1–52

TRANSMISSION CONTROL SYSTEM (4L30–E)

Conditions For Clearing The DTC/CHECK

TRANS Lamp

The PCM will turn “off” the CHECK TRANS Lamp

after three consecutive ignition cycles without a

failure reported.

The DTC can be cleared from PCM memory by using

a scan tool.

The DTC can also be cleared from memory when the

vehicle has made 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC Actions Taken items

when the fault conditions no longer exist and the

ignition is cycles “off” long enough to power down the

PCM.

Diagnostic Aids

Check for intermittent output speed sensor circuit

problems.

Check for possible incorrect calibration. (PCM part

No., tire specification, and rear axle ratio)

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This step checks for possible low fluid level causing

slipping resulting in an undefined gear ratio.

4. This step checks for correct gear ratios for

commanded gears.

5. This step checks for low line pressure.

DTC P0730 Transmission Incorrect Gear Ratio

StepActionYe sNo

1Visually inspect the transmission cooling system for fluid leaks.

Refer to Chart 16: Possible Causes of Transmission Fluid

Leaks of Mechanical/Hydraulic Diagnosis Symptoms Index in

Automatic Transmission (4L30–E) section

Was condition found and corrected?

Go to Step 6Go to Step 2

2Refer to Checking Transmission Fluid Level and Condition in

Automatic Transmission (4L30–E) section.

Has transmission fluid checking procedure been performed?

Go to Step 3

Go to Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

31. Install the scan tool.

2. Turn the ignition switch to the “on” position.

3. Engine not running.

NOTE: Before clearing DTC(s) use the scan tool to record the

“Failure Records” for reference, as data will be lost when the “Clear

Info” function is used.

4. Record the Failure Record data.

5. Use the scan tool snapshot mode to record transmission gear

ratios.

6. Drive vehicle in transmission gear ranges 1, 2, 3, and D with

the engine speed is greater than 3,500 rpm for 5.5 seconds.

7. Record each transmission gear.

1st:2.73 – 2.99

2nd:1.54 – 1.71

3rd:0.93 – 1.05

4th:0.66 – 0.78

Does commanded gear ratio match ranges as shown?

Refer to

Diagnostic Aids

Go to Step 4

4Perform line pressure check.

Refer to Line Pressure Test in Automatic Transmission

(4L30–E) section.

Was condition found and corrected?

Go to Step 6Go to Step 5

Page 2311 of 6000

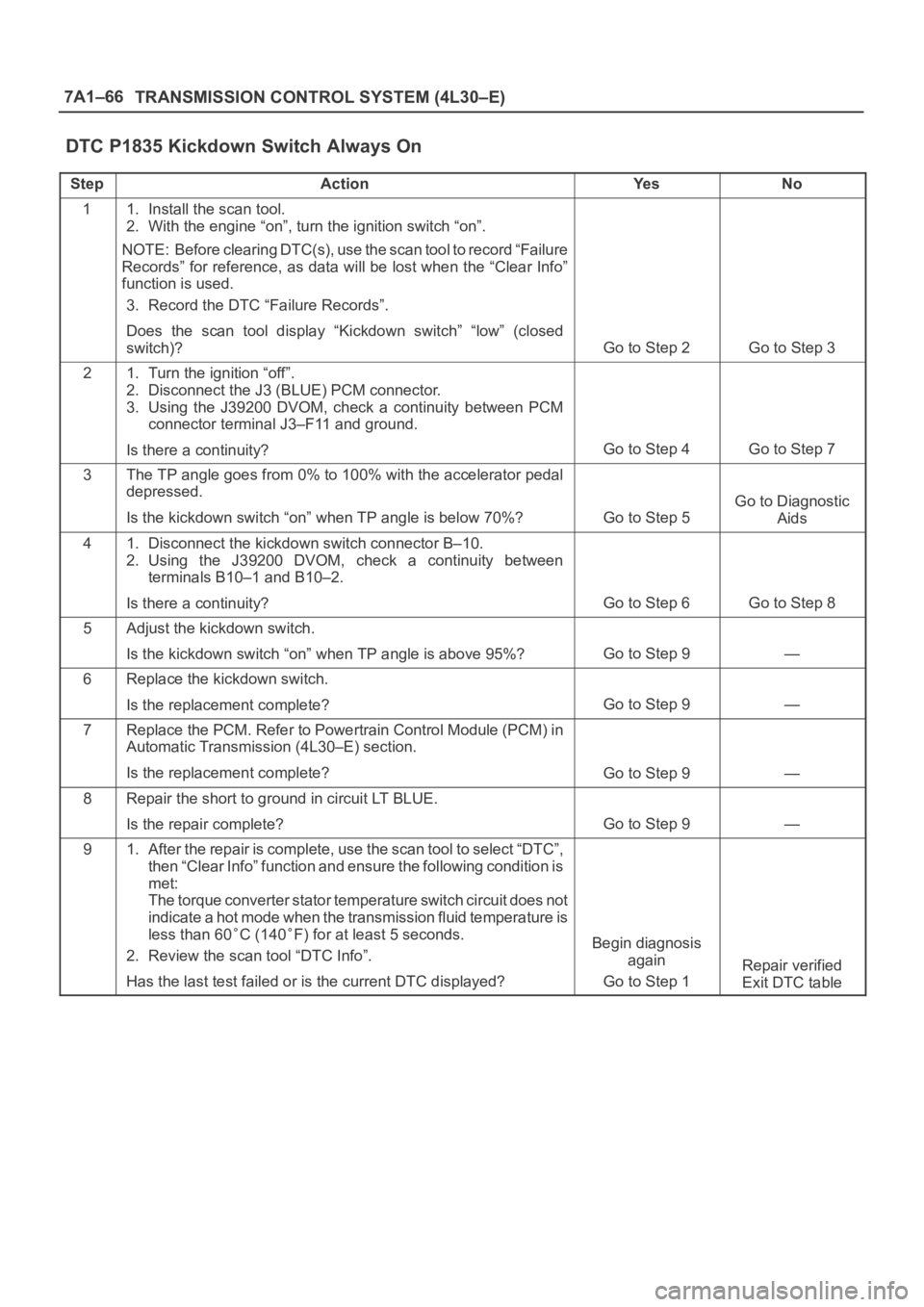

7A1–66

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P1835 Kickdown Switch Always On

StepActionYe sNo

11. Install the scan tool.

2. With the engine “on”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

Does the scan tool display “Kickdown switch” “low” (closed

switch)?

Go to Step 2Go to Step 3

21. Turn the ignition “off”.

2. Disconnect the J3 (BLUE) PCM connector.

3. Using the J39200 DVOM, check a continuity between PCM

connector terminal J3–F11 and ground.

Is there a continuity?

Go to Step 4Go to Step 7

3The TP angle goes from 0% to 100% with the accelerator pedal

depressed.

Is the kickdown switch “on” when TP angle is below 70%?

Go to Step 5

Go to Diagnostic

Aids

41. Disconnect the kickdown switch connector B–10.

2. Using the J39200 DVOM, check a continuity between

terminals B10–1 and B10–2.

Is there a continuity?

Go to Step 6Go to Step 8

5Adjust the kickdown switch.

Is the kickdown switch “on” when TP angle is above 95%?

Go to Step 9—

6Replace the kickdown switch.

Is the replacement complete?

Go to Step 9—

7Replace the PCM. Refer to Powertrain Control Module (PCM) in

Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 9—

8Repair the short to ground in circuit LT BLUE.

Is the repair complete?

Go to Step 9—

91. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following condition is

met:

The torque converter stator temperature switch circuit does not

indicate a hot mode when the transmission fluid temperature is

less than 60

C (140F) for at least 5 seconds.

2. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 4595 of 6000

6B–2

ENGINE COOLING

General Description

030RW001

Legend

(1) Water Pump

(2) Thermostat

(3) Radiator

(4) Reserve Tank

(5) Cooling Fan

(6) Cylinder Block(7) Cylinder Head

(8) Right Bank

(9) Throttle Body

(10) Cylinder Block

(11) Cylinder Head

(12) Left Bank

(13) Heater

The cooling system is a pressurized Engine Coolant (EC)

forced circulation type which consists of a water pump,

thermostat cooling fan, radiator and other components.

The automatic transmission fluid is cooled by the EC in

radiator.

Water Pump

The EC pump is a centrifugal impeller type and is driven

by a timing belt.

030RS001

Page 4599 of 6000

6B–6

ENGINE COOLING

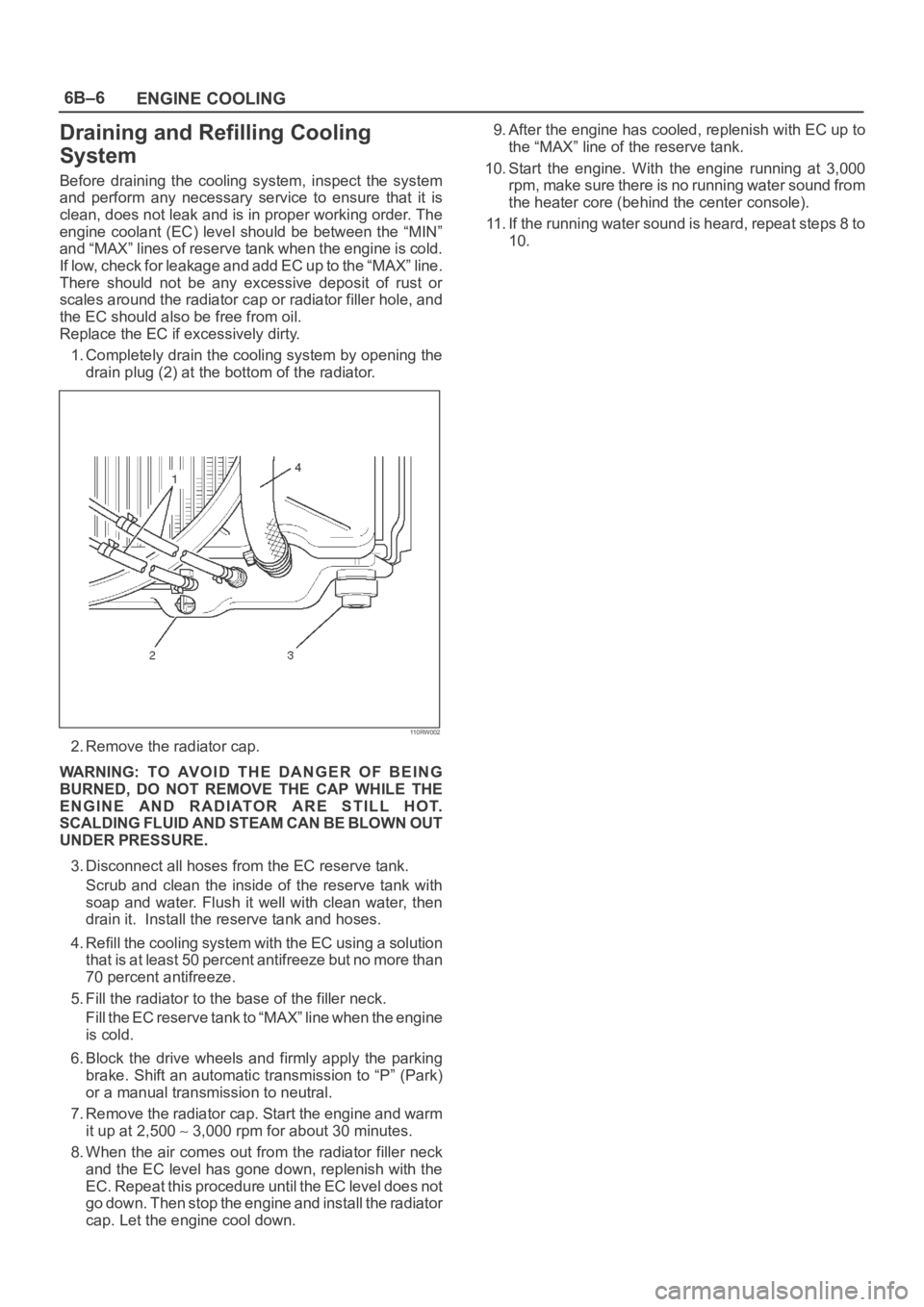

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to “MAX” line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to “P” (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500

3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the “MAX” line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.

Page 4622 of 6000

ENGINE ELECTRICAL6D1–3

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.