automatic transmission fluid OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4674 of 6000

6E–17 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinouts

PCM Pinout Table, 32-Way Red Connector – Row “A”

TS23344

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

A15 Volt Reference “A”RED5.0 V5.0 VAppropriate Sensor

A2Knock SensorYEL0.0 V DC

2mV AC0.0 V DC

18mV AC

(at idle)General Description and

Operation, Knock Sensor

A3Not Used————

A4Battery FeedWHTB+B+Chassis Electrical

A5Idle Air Control (IAC) “A”

HighBLUB+/0.8 VB+/0.8 VGeneral Description and

Operation, IAC

A6IAC “A” LowBLU/WHTB+/0.8 VB+/0.8 VGeneral Description and

Operation, IAC

A7IAC “B” LowBLU/BLKB+/0.8 VB+/0.8 VGeneral Description and

Operation, IAC

A8IAC “B” HighBLU/REDB+/0.8 VB+/0.8 VGeneral Description and

Operation, IAC

A9Automatic Transmission

Fluid (ATF) LampORN/BLUB+B+Automatic Transmission

(4L30E)

A10Winter LampPNK/GRNB+B+Automatic Transmission

(4L30E)

A11Power LampGRY/WHTB+B+Automatic Transmission

(4L30E)

A12Antilock Brake System

(ABS)GRYB+B+Antilock Brake System

A13Malfunction Indicator

(Check Engine or MIL)

LampBLU0.0 VB+Chassis Electrical

A14“Check Transmission”

Lamp Driver (AT)ORN/BLKB+B+Chassis Electrical

Up Shift Lamp Driver (MT)ORN/BLU

Page 4684 of 6000

6E–27 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way Blue Connector – Row “F”

TS23346

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

F1Not Used————

F2Transmission Range

Signal “C”BLU/BLK0.0 V0.0 VAutomatic Transmission

(4L30E)

F3Transmission Range

Signal “P”YEL/GRNB+0.0 VAutomatic transmission

(4L30E)

F4Brake SwitchGRN/YEL0.0 V0.0 VAutomatic transmission

(4L30E)

F5Power SwitchPPL/REDB+B+Automatic Transmission

(4L30E)

F6Winter SwitchPPL/GRNB+B+Automatic Transmission

(4L30E)

F7Transmission Fluid

TemperatureRED/BLK0.5-4.9 V

(depends on

temperature)0.5-4.9 V

(depends on

temperature)Automatic Transmission

(4L30E)

F8Manifold Absolute

Pressure (MAP)GRY/BLK3.5-4.9 V

(depends on

altitude and

barometric

pressure)0.6-1.3 VGeneral Description and

Operation, Manifold Absolute

Pressure

F9Not Used————

F10Cruise ControlGRY/BLUB+B+Automatic transmission

(4L30E)

F11Kickdown SwitchLT B L UB+B+Automatic Transmission

(4L30E)

F12DIAGORN/BLUB+B+—

F13Injector “C” Cylinder #3GRNB+B+General Description and

Operation, Fuel Injector

F14Shift “A” SolenoidBRN/REDB+B+Automatic Transmission

(4L30E)

F15Injector Cylinder #5GRN/BLKB+B+General Description and

Operation, Fuel Injector

F16Ignition Feed (1 of 2 E16)RED/BLUB+B+—

Page 4945 of 6000

6E–288

ENGINE DRIVEABILITY AND EMISSIONS

Default Matrix Table

Service Procedure Default Strategy

A referral strategy has been established to assist the

technician with additional information when the cause of

the failure cannot be determined. If no problem is found

after performing diagnostics, then refer to the default

matrix table for further diagnostic information.

Default Matrix Table

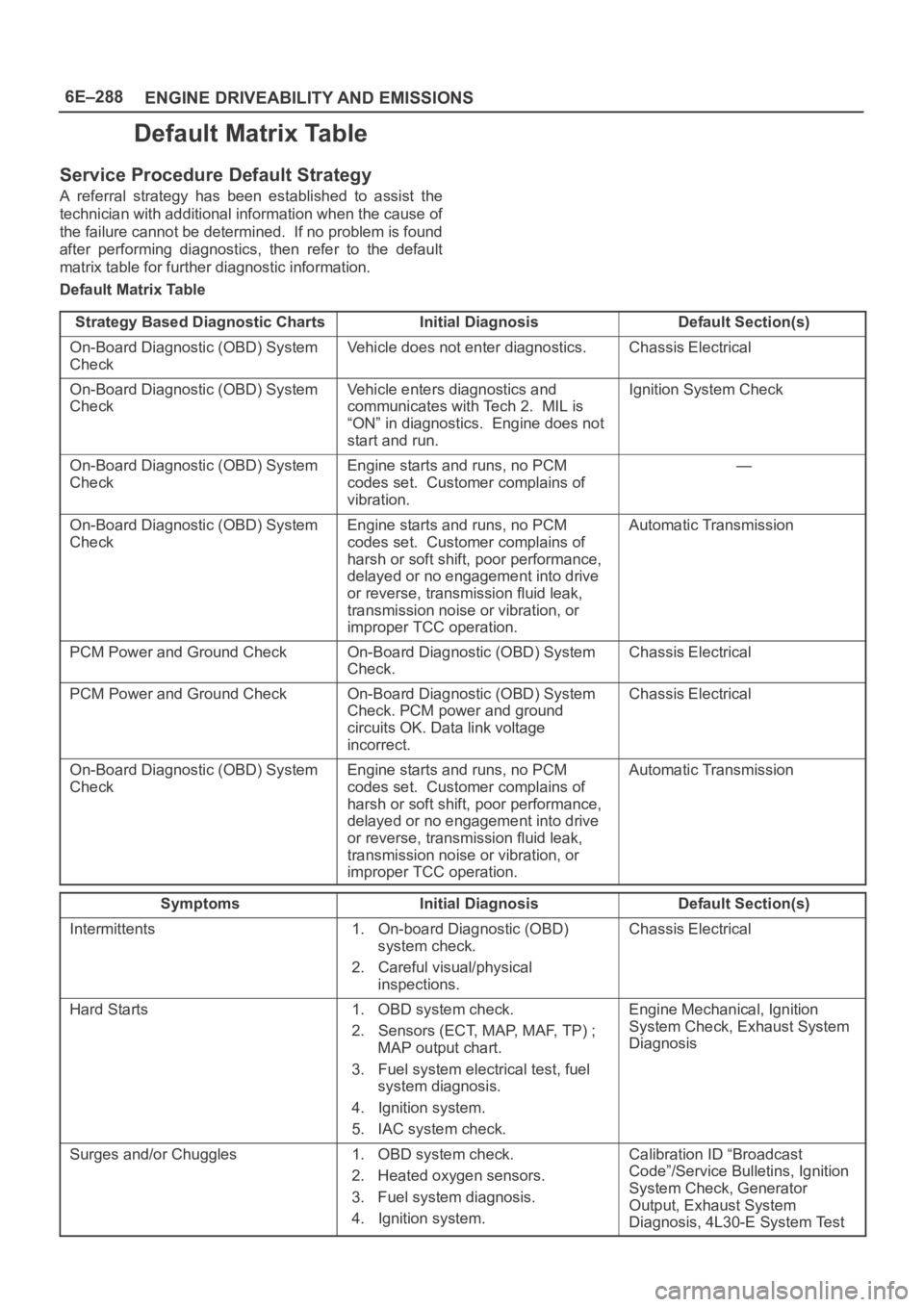

Strategy Based Diagnostic Charts

Initial DiagnosisDefault Section(s)

On-Board Diagnostic (OBD) System

CheckVehicle does not enter diagnostics.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckVehicle enters diagnostics and

communicates with Tech 2. MIL is

“ON” in diagnostics. Engine does not

start and run.Ignition System Check

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no PCM

codes set. Customer complains of

vibration.—

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no PCM

codes set. Customer complains of

harsh or soft shift, poor performance,

delayed or no engagement into drive

or reverse, transmission fluid leak,

transmission noise or vibration, or

improper TCC operation.Automatic Transmission

PCM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check.Chassis Electrical

PCM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check. PCM power and ground

circuits OK. Data link voltage

incorrect.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no PCM

codes set. Customer complains of

harsh or soft shift, poor performance,

delayed or no engagement into drive

or reverse, transmission fluid leak,

transmission noise or vibration, or

improper TCC operation.Automatic Transmission

SymptomsInitial DiagnosisDefault Section(s)

Intermittents1. On-board Diagnostic (OBD)

system check.

2. Careful visual/physical

inspections.Chassis Electrical

Hard Starts1. OBD system check.

2. Sensors (ECT, MAP, MAF, TP) ;

MAP output chart.

3. Fuel system electrical test, fuel

system diagnosis.

4. Ignition system.

5. IAC system check.Engine Mechanical, Ignition

System Check, Exhaust System

Diagnosis

Surges and/or Chuggles1. OBD system check.

2. Heated oxygen sensors.

3. Fuel system diagnosis.

4. Ignition system.Calibration ID “Broadcast

Code”/Service Bulletins, Ignition

System Check, Generator

Output, Exhaust System

Diagnosis, 4L30-E System Test

Page 4997 of 6000

6E–340

ENGINE DRIVEABILITY AND EMISSIONS

the TP sensor is low. As the throttle valve opens, the

output increases so that at wide open throttle (WOT), the

output voltage should be above 4 volts.

The PCM calculates fuel delivery based on throttle valve

angle (driver demand). A broken or loose TP sensor may

cause intermittent bursts of fuel from an injector and

unstable idle because the PCM thinks the throttle is

moving. A hard failure in the TP sensor 5-volt reference

or signal circuits will set a DTC P0123. A hard failure with

the TP sensor ground circuit may set DTC P0123. Once

a DTC is set, the PCM will use an artificial default value

based on engine RPM and mass air flow for the throttle

position, and some vehicle performance will return. A

high idle may result when DTC P0123 is set. The PCM

can also detect a shifted TP sensor. The PCM monitors

throttle position and compares the actual TP sensor

reading to a predicted TP value calculated from engine

speed. If the PCM detects an out-of-range condition,

DTC P0121 will be set.

0021

Transmission Fluid Temperature (TFT)

Sensor

The transmission fluid temperature sensor is a thermistor

which changes its resistance based on the temperature of

the transmission fluid. For a complete description of the

TFT sensor, refer to

4L30-E Automatic Transmission

Diagnosis

.

A failure in the TFT sensor or associated wiring will cause

DTC P0712 or DTC P0713 to set. In this case, engine

coolant temperature will be substituted for the TFT

sensor value and the transmission will operate normally.

Transmission Range Switch

IMPORTANT:The vehicle should not be driven with the

transmission range switch disconnected; idle quality will

be affected.

The four inputs from the transmission range switch

indicate to the PCM which position is selected by the

transmission selector lever. This information is used for

ignition timing, EVAP canister purge, EGR and IAC valve

operation.For more information on the transmission on the

transmission range switch, refer to

4L30-E Automatic

Transmission

.

Vehicle Speed Sensor (VSS)

The PCM determines the speed of the vehicle by

converting a plusing voltage signal from the vehicle speed

sensor (VSS) into miles per hour. The PCM uses this

signal to operate the cruise control, speedometer, and the

TCC and shift solenoids in the transmission. For more

information on the TCC and shift solenoids, refer to

4L30-E Automatic Transmission.

0008

Use of Circuit Testing Tools

Do not use a test light to diagnose the powertrain

electrical systems unless specifically instructed by the

diagnostic procedures. Use Connector Test Adapter Kit J

35616 whenever diagnostic procedures call for probing

connectors.

Aftermarket Electrical and Vacuum

Equipment

Aftermarket (add-on) electrical and vacuum equipment is

defined as any equipment which connects to the vehicle’s

electrical or vacuum systems that is installed on a vehicle

after it leaves the factory. No allowances have been

made in the vehicle design for this type of equipment.

NOTE: No add-on vacuum equipment should be added

to this vehicle.

NOTE: Add-on electrical equipment must only be

connected to the vehicle’s electrical system at the battery

(power and ground).

Add-on electrical equipment, even when installed to

these guidelines, may still cause the powertrain system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such as

portable telephones and radios. Therefore, the first step

in diagnosing any powertrain problem is to eliminate all

aftermarket electrical equipment from the vehicle. After

Page 5406 of 6000

ENGINE ELECTRICAL 6D – 3

ON-VEHICLE SERVICE

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the rate

of charge reduced if the battery feels hot to the

touch.

Battery charging should be discontinued or the rate

of charge reduced if the battery begins to gas or

spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue

dot or ring, it may be necessary to jiggle or tilt the

battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the same

manner as other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: Failure to carefully follow the jump

starting procedure could result in the following:

1. Serious personal injury, particularly to your

eyes.

2. Property damage from a battery explosion,

battery acid, or an electrical fire.

3. Damage to the electronic components of one or

both vehicles.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode. Remove any rings, watches, or other jewelry

before working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with your

eyes or skin.

Never allow battery fluid to come in contact with fabrics

or painted surfaces.

Battery fluid is a highly corrosive acid.Should battery fluid come in contact with your eyes,

skin, fabric, or a painted surface, immediately and

thoroughly rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the “PARK”

position.

If the vehicle is equipped with a manual

transmission place the shift lever in the “NEUTRAL”

position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the A/C compressor

bracket or the generator mounting bracket) of the

vehicle with the discharged battery.

This ground connection must be at least 450 mm

(18 in) from the battery of the vehicle whose battery

is being charged.

WARNING: Never attach the end of the jumper

cable directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical

accessories have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable from

the vehicle with the discharged battery.

Page 5628 of 6000

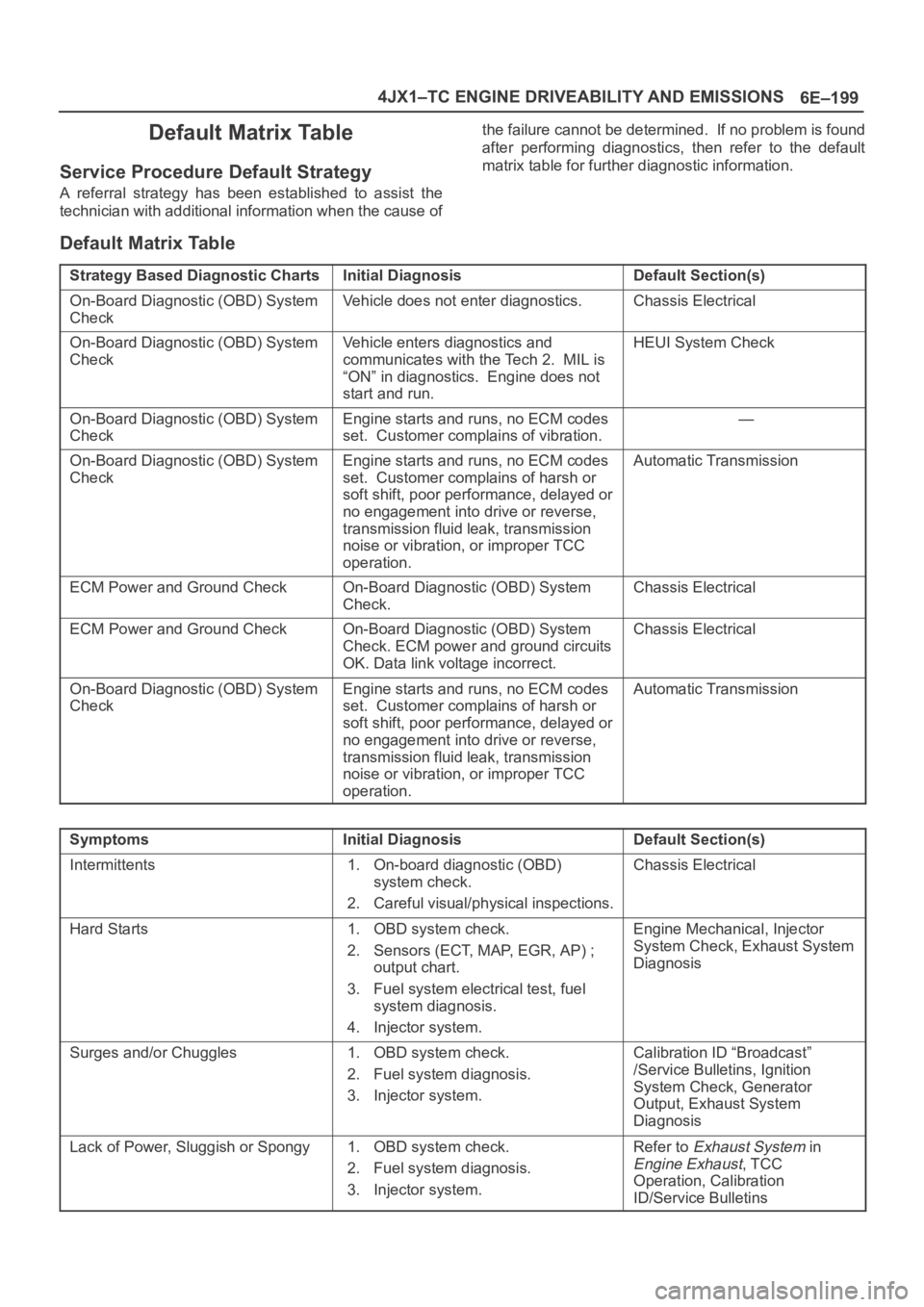

6E–199 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Default Matrix Table

Service Procedure Default Strategy

A referral strategy has been established to assist the

technician with additional information when the cause ofthe failure cannot be determined. If no problem is found

after performing diagnostics, then refer to the default

matrix table for further diagnostic information.

Default Matrix Table

Strategy Based Diagnostic ChartsInitial DiagnosisDefault Section(s)

On-Board Diagnostic (OBD) System

CheckVehicle does not enter diagnostics.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckVehicle enters diagnostics and

communicates with the Tech 2. MIL is

“ON” in diagnostics. Engine does not

start and run.HEUI System Check

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no ECM codes

set. Customer complains of vibration.—

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no ECM codes

set. Customer complains of harsh or

soft shift, poor performance, delayed or

no engagement into drive or reverse,

transmission fluid leak, transmission

noise or vibration, or improper TCC

operation.Automatic Transmission

ECM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check.Chassis Electrical

ECM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check. ECM power and ground circuits

OK. Data link voltage incorrect.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no ECM codes

set. Customer complains of harsh or

soft shift, poor performance, delayed or

no engagement into drive or reverse,

transmission fluid leak, transmission

noise or vibration, or improper TCC

operation.Automatic Transmission

SymptomsInitial DiagnosisDefault Section(s)

Intermittents1. On-board diagnostic (OBD)

system check.

2. Careful visual/physical inspections.Chassis Electrical

Hard Starts1. OBD system check.

2. Sensors (ECT, MAP, EGR, AP) ;

output chart.

3. Fuel system electrical test, fuel

system diagnosis.

4. Injector system.Engine Mechanical, Injector

System Check, Exhaust System

Diagnosis

Surges and/or Chuggles1. OBD system check.

2. Fuel system diagnosis.

3. Injector system.Calibration ID “Broadcast”

/Service Bulletins, Ignition

System Check, Generator

Output, Exhaust System

Diagnosis

Lack of Power, Sluggish or Spongy1. OBD system check.

2. Fuel system diagnosis.

3. Injector system.Refer to Exhaust System in

Engine Exhaust, TCC

Operation, Calibration

ID/Service Bulletins

Page 5690 of 6000

7A–1 AUTOMATIC TRANSMISSION (4L30–E)

TRANSMISSION

AUTOMATIC TRANSMISSION (4L30–E)

CONTENTS

Service Precaution 7A–3. . . . . . . . . . . . . . . . . . . . . .

Construction 7A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Reference Chart 7A–4. . . . . . . . . . . . . . . . . .

Normal Operation Of 2000 4L30–E

Transmission 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Information 7A–5. . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis Procedure 7A–8. . . . . . . . . . . . .

Preliminary Inspection Chart 7A–9. . . . . . . . . . . . . .

Checking Transmission Fluid Level and

Condition 7A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Driving 7A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart 7A–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis

Symptoms Index 7A–13. . . . . . . . . . . . . . . . . . . . . . . .

Stall Test 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Test 7A–23. . . . . . . . . . . . . . . . . . . . . .

Shift Speed Chart (V6 3.2L 6VD1 Model) 7A–24. . .

Shift Speed Chart (V6 3.5L 6VE1 Model) 7A–26. .

Lockup Speed Chart (V6 3.2L 6VD1 Model) 7A–28

Lockup Speed Chart (V6 3.5L 6VE1 Model) 7A–28

Changing Transmission Fluid 7A–29. . . . . . . . . . . . .

Selector Lever 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (With Transfer Case) 7A–33. . . . . . . .

Transmission And Associated Parts 7A–33. . . . . .

Removal 7A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Main Case Valve Body) 7A–39. . . . . . . . .

Removal 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Adapter Case Valve Body) 7A–40. . . . . . .

Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Main Case) 7A–41. . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Adapter Case) 7A–43. . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) 7A–43. . . . . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensor (Extension Housing) 7A–44. . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Oil Temperature Sensor

(Adapter Case) 7A–44. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Oil Seal (Converter Housing) 7A–45. . . . . . . .

Removal 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Extension Housing) 7A–46. . . . . . . . .

Removal 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (4L30–E) 7A–46. . . . . . . . . . . . . . . . . .

Disassembly 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7A–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Converter Housing And Oil Pump Assembly 7A–60

Disassembled View 7A–60. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–60. . . . . . . . . . . . . . . . . .

Reassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–61. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–61. . . . . . . . . . . . . . . . . .

Reassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Case Valve Body 7A–62. . . . . . . . . . . . . . . . . . .

Disassembled View 7A–62. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–62. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–63. . . . . . . . . . . . . . . . . .

Reassembly 7A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Case Valve Body 7A–64. . . . . . . . . . . . . . . .

Disassembled View 7A–64. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–64. . . . . . . . . . . . . . . . . .

Reassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch And Sprag Unit 7A–65. . . . . . . . . . . . . .

Disassembled View 7A–65. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–66. . . . . . . . . . . . . . . . . .

Page 5699 of 6000

7A–10

AUTOMATIC TRANSMISSION (4L30–E)

Checking Transmission Fluid Level

and Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis information

about the transmission. This information may be used to

correct a condition that, if not detected early, could result

in major transmission repairs.

IMPORTANT:When new, automatic transmission fluid

is red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON –III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid, abnor-

mal shifting and possible damage to the transmis-

sion.

1. Park the vehicle on level ground and apply the parking

brake firmly.

2. Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30

C (86F).

3. Move the selector lever through all gear ranges.

4. Move the selector lever to “Park”.

5. Let engine idle for 3 minutes and open the overfill

screw (1).

6. Add released transmission fluid until it flows out over

the overfill screw opening.

7. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached, then close the

overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level

57C (135F)

Maximum fluid level

32C (90F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

Immediately after driving at sustained highway

speeds.

In heavy city traffic during hot weather.

If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for thirty

(30) minutes. After the cool down period, restart the

vehicle and continue from step 2 above.

Page 5700 of 6000

7A–11 AUTOMATIC TRANSMISSION (4L30–E)

Fluid Condition

FLUID CONDITION

NORMAL*CONTAMINATED

COLORRED OR LIGHT

BROWNBROWNNON–TRANSPARENT

/ PINKBROWN

DRAIN

REQUIRED?NOYESYESYES

CONTAMINA–

TIONNONEVery small amount of

foreign material in

bottom of panContamination by

coolant or other sourceLarge pieces of metal

or other foreign

material in bottom of

pan

CORRECT

LEVEL AND

CONDITION

1. LOW LEVEL:

A. Add fluid to

obtain proper

level & check for

external leaks.

B. Correct cause of

leak.

2. HIGH LEVEL:

– Remove excess

fluid– Remove both pans

– Change filter

– Flush cooler

– Add new fluid

– Check level– Repair/replace

radiator cooler

–Transmission

overhaul required

– Check for:

Damaged plates

and seals

Contaminated

solenoids

– Flush cooler

– Add new fluid

– Check level

–Transmission

overhaul required

– Flush cooler and

cooler lines

– Add new fluid

– Check level

*Fluid should be changed according to maintenance

schedule.

Te s t D r i v i n g

Some 4L30–E automatic transmission complaints will

require a test drive as a part of the diagnostic procedure.

Some codes will not set unless the vehicle is moving. The

purpose of the test drive is to duplicate the customer’s

complaint condition and set a current Powertrain Control

Module (PCM) trouble code. Perform this procedure

before each 4L30–E automatic transmission repair, and

again after repairs are made.

IMPORTANT:

Duplicate the condition under which the customer’s

complaint was observed.

Depending on the complaint, the line pressure gauge

and the scan tool may be required during the test

drive.

During the test drive, it is important to record all

necessary data from the areas being monitored, for

use in diagnosis. Also listen for and note any unusual

noises.

The following procedure should be used to test drive

4L30–E automatic transmission complaint vehicles:

1. Turn the ignition ON without starting the engine.

Check that the “CHECK TRANS” lamp comes on for

approximately 2 seconds and then goes out and

remains out.

If the lamp is flashing, GOTO Check Trans Indicator

in Transmission Control System (4L30–E) section.

If no serial data is present, GOTO OBD System

Check. Refer to Driveability and Emissions in

Engine section.

If the lamp stays ON or stays OFF, GOTO “Check

Trans” Check in Transmission Control System

(4L30–E) section.

2. Drive the vehicle. During the test drive, be sure that

the transmission achieves normal operating

temperature (approx. 20 minutes).

Allow the transmission to go through all of its gear

ranges, checking shift timing and firmness. Duplicate

the owner’s complaint condition as closely as

possible during the test drive.

3. If, during the test drive, the “CHECK TRANS” lamp

comes on, use the scan tool to check for trouble

codes.

4. If, during the test drive, a problem is felt, but the

“CHECK TRANS” lamp does not come on and no

trouble codes are present, drive the vehicle with the

PCM disconnected (manually shifting the vehicle).

In Manual L, the vehicle operates in first gear.

In Manual 2, the vehicle operates in third gear.

In Manual 3 or “D”, the vehicle operates in fourth

gear.

If the problem still exists with the PCM disconnected,

refer to Mechanical/Hydraulic Diagnosis in this

section.

5. If no problem has been found at this point, check all

underhood connections that supply power to the PCM

and ignition fuses. Physically and visually inspect all

the PCM harness connectors for loose or corroded

terminals. Inspect the PCM ground points.

Page 5702 of 6000

7A–13 AUTOMATIC TRANSMISSION (4L30–E)

Mechanical / Hydraulic Diagnosis Symptoms Index

Perform Preliminary Inspection First!

CHART

SYMPTOMS

1NO ENGINE START IN NEUTRAL OR PARK

2NO FORWARD GEARS IN ANY RANGE/NO REVERSE

3NO ENGINE BRAKE IN ANY RANGE

4POOR SHIFTING IN ALL GEARS (ALL HARSH OR ALL SOFT)

5aDELAYS IN DRIVE AND REVERSE

5bDELAYS IN REVERSE ONLY

6DIAGNOSTIC TROUBLE CODE (DTC) P0730

7HARSH 1–2 SHIFT

8HARSH 3–4 SHIFT

9a3–2 DOWNSHIFT COMPLAINT

9bHARSH SHIFT WHEN SHIFTING INTO “D” OR ACCELERATING FROM STOP

9cCOASTDOWN HARSH SHIFT OR CLUNK AT 3–2 DOWNSHIFT

10INTERMITTENT 4TH TO 2ND GEAR DOWNSHIFT AT STEADY SPEED

11ENGINE FLARE AT SHIFTING DURING TURNING ONLY (USUALLY WITH WARM ENGINE)

12ENGINE FLARE DURING 1–2 OR 2–3 SHIFT

13SHUDDER ONLY DURING TORQUE CONVERTER CLUTCH (TCC) APPLYING

14POSSIBLE CAUSES OF TRANSMISSION NOISE

15aPOSSIBLE CAUSES OF LOW LINE PRESSURE

15bPOSSIBLE CAUSES OF HIGH LINE PRESSURE

16POSSIBLE CAUSES OF TRANSMISSION FLUID LEAKS

NOTE: Numbers with parenthesis on the following charts

refer to Parts List at end of this section.

Chart 1: No Engine Start In Neutral Or Park

StepActionYe sNo

1Does engine start when shift lever moved from drive to neutral

mostly in hot condition?

Go to Step 2Go to Step 3

2Does engine start in park at any condition?Re–test vehicleGo to Step 4

3Does engine also not start in neutral when shift lever moved from

park to neutral?

Go to Step 4Go to Step 5

4Check mode switch (63) setting. Readjust if necessary.

Problems fixed?

Re–test vehicleGo to Step 5

5Check start circuit of mode switch (63) open in neutral.

Was open found?Locate and repair

open(s)Replace mode

switch (63)