display OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1247 of 6000

6E–130

ENGINE DRIVEABILITY AND EMISSIONS

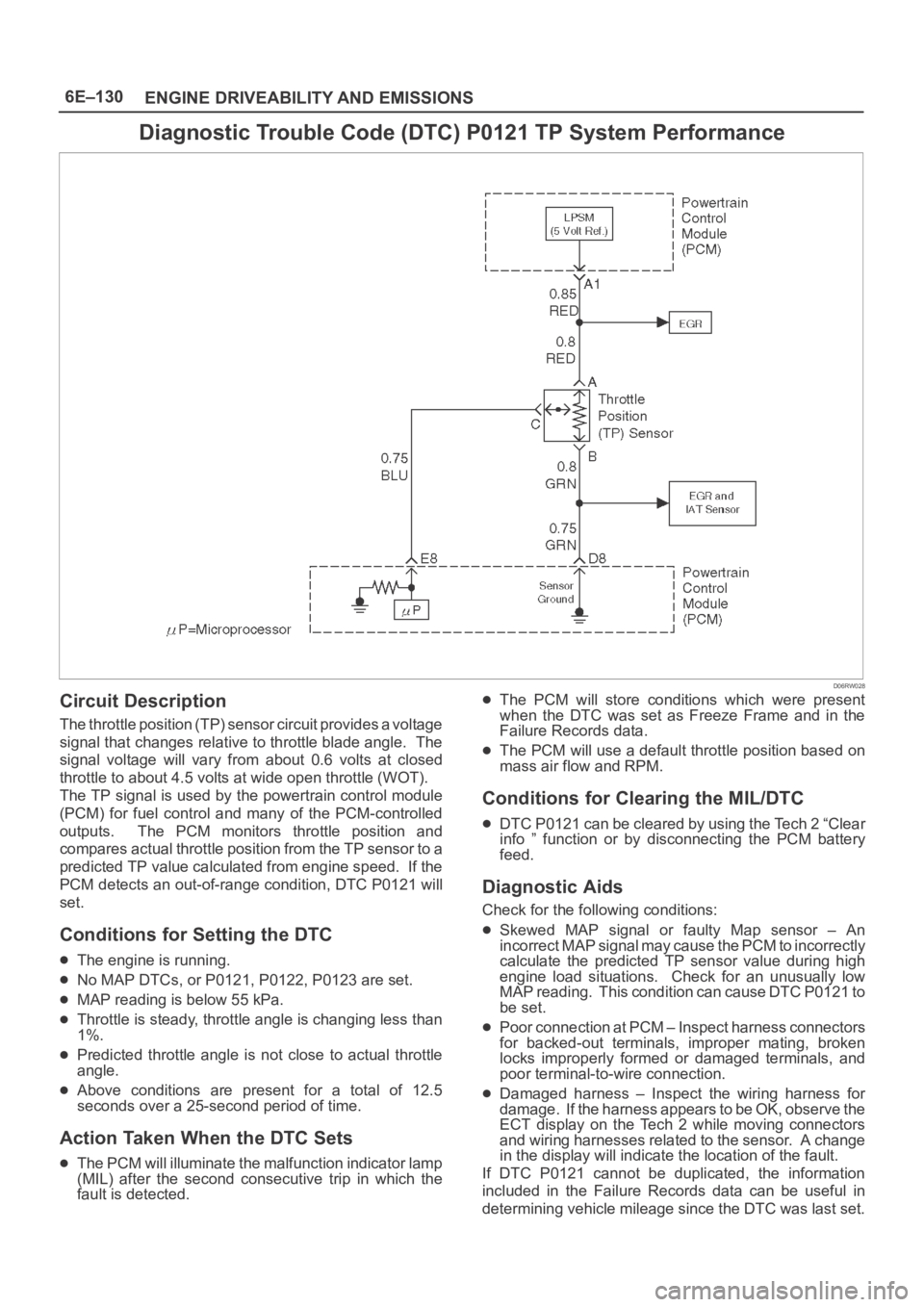

Diagnostic Trouble Code (DTC) P0121 TP System Performance

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from about 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is used by the powertrain control module

(PCM) for fuel control and many of the PCM-controlled

outputs. The PCM monitors throttle position and

compares actual throttle position from the TP sensor to a

predicted TP value calculated from engine speed. If the

PCM detects an out-of-range condition, DTC P0121 will

set.

Conditions for Setting the DTC

The engine is running.

No MAP DTCs, or P0121, P0122, P0123 are set.

MAP reading is below 55 kPa.

Throttle is steady, throttle angle is changing less than

1%.

Predicted throttle angle is not close to actual throttle

angle.

Above conditions are present for a total of 12.5

seconds over a 25-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0121 can be cleared by using the Tech 2 “Clear

info ” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Skewed MAP signal or faulty Map sensor – An

incorrect MAP signal may cause the PCM to incorrectly

calculate the predicted TP sensor value during high

engine load situations. Check for an unusually low

MAP reading. This condition can cause DTC P0121 to

be set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0121 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 1250 of 6000

6E–133 ENGINE DRIVEABILITY AND EMISSIONS

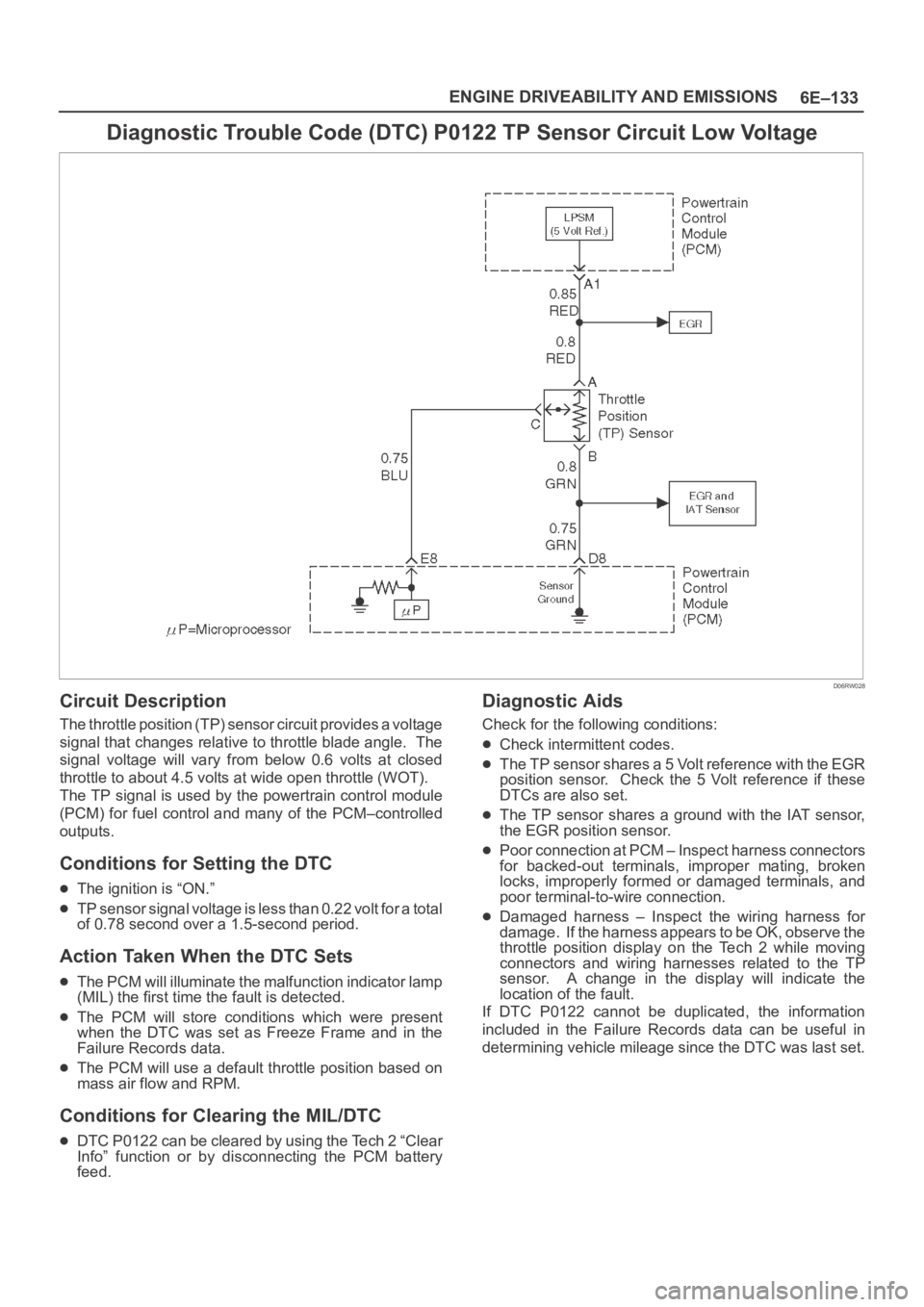

Diagnostic Trouble Code (DTC) P0122 TP Sensor Circuit Low Voltage

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from below 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is used by the powertrain control module

(PCM) for fuel control and many of the PCM–controlled

outputs.

Conditions for Setting the DTC

The ignition is “ON.”

TP sensor signal voltage is less than 0.22 volt for a total

of 0.78 second over a 1.5-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0122 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check intermittent codes.

The TP sensor shares a 5 Volt reference with the EGR

position sensor. Check the 5 Volt reference if these

DTCs are also set.

The TP sensor shares a ground with the IAT sensor,

the EGR position sensor.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

throttle position display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

If DTC P0122 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 1251 of 6000

6E–134

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0122 –TP Sensor Circuit Low Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. With the throttle closed, observe the “TP Sensor”

display on the Tech 2.

Is the “TP Sensor” below the specified value?

0.22 VGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor the “DTC” info for DTC

P0122.

Does the Tech 2 indicate DTC P0122 failed?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Ignition “OFF.”

2. Disconnect the TP sensor electrical connector.

3. Jumper the 5 volt reference “A” circuit and the TP

signal together at the TP sensor harness connector.

4. Ignition “ON.”

Observe the “TP Sensor” display on the Tech 2.

Is the “TP Sensor” at the specified value?

5 VGo to Step 10Go to Step 5

51. Disconnect jumper.

2. Connect a test light between B+ and the TP sensor

signal circuit at the TP sensor harness connector.

Observe the “TP Sensor” display on the Tech 2.

Is the “TP Sensor” at the specified value?

5 VGo to Step 6Go to Step 8

61. Ignition “OFF.”

2. Disconnect the PCM and check the 5 volt reference

“A” circuit for an open or short to ground.

3. If the 5 volt reference “A” circuit is open or shorted to

ground, repair it as necessary.

Was the 5 volt reference “A” circuit open or shorted to

ground?

—Verify repairGo to Step 7

7Check the 5 volt reference “A” circuit for a poor

connection at the PCM and replace the terminal if

necessary.

Did the terminal require replacement?

—Verify repairGo to Step 12

81. Ignition “OFF.”

2. Disconnect the PCM, and check the TP signal

circuit for an open, short to ground, or short to the

sensor ground circuit.

3. If the TP sensor signal circuit is open or shorted to

ground, repair it as necessary.

Was the TP signal circuit open or shorted to ground?

—Verify repairGo to Step 9

9Check the TP sensor signal circuit for a poor

connection at the PCM and replace the terminal if

necessary.

Did the terminal require replacement?

—Verify repairGo to Step 12

Page 1253 of 6000

6E–136

ENGINE DRIVEABILITY AND EMISSIONS

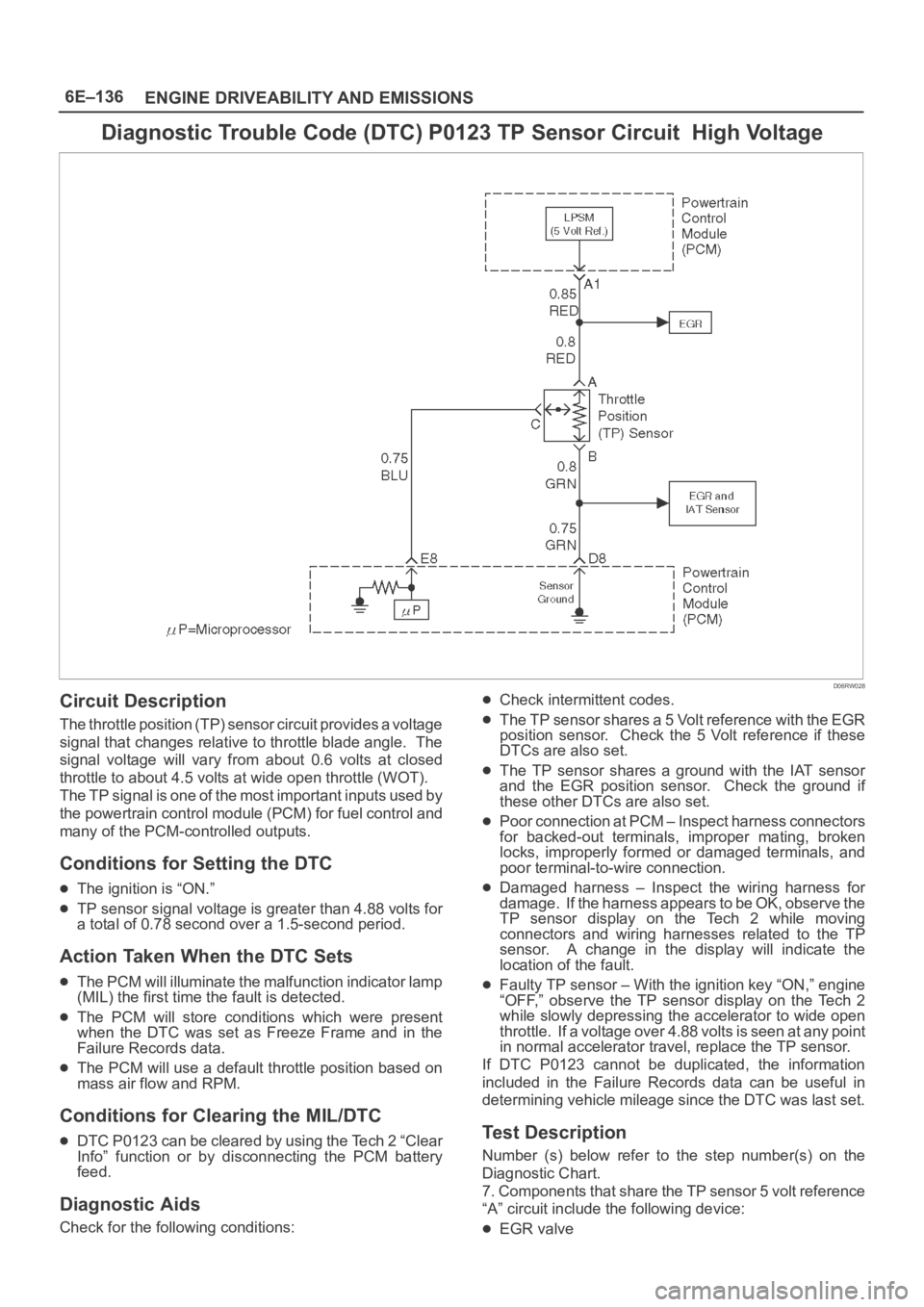

Diagnostic Trouble Code (DTC) P0123 TP Sensor Circuit High Voltage

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from about 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is one of the most important inputs used by

the powertrain control module (PCM) for fuel control and

many of the PCM-controlled outputs.

Conditions for Setting the DTC

The ignition is “ON.”

TP sensor signal voltage is greater than 4.88 volts for

a total of 0.78 second over a 1.5-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0123 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check intermittent codes.

The TP sensor shares a 5 Volt reference with the EGR

position sensor. Check the 5 Volt reference if these

DTCs are also set.

The TP sensor shares a ground with the IAT sensor

and the EGR position sensor. Check the ground if

these other DTCs are also set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

TP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty TP sensor – With the ignition key “ON,” engine

“OFF,” observe the TP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle. If a voltage over 4.88 volts is seen at any point

in normal accelerator travel, replace the TP sensor.

If DTC P0123 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number (s) below refer to the step number(s) on the

Diagnostic Chart.

7. Components that share the TP sensor 5 volt reference

“A” circuit include the following device:

EGR valve

Page 1254 of 6000

6E–137 ENGINE DRIVEABILITY AND EMISSIONS

Disconnect the component while observing the TP

sensor display on the Tech 2. If the reading

changes drastically when this component isdisconnected, replace the component that affected

the reading.

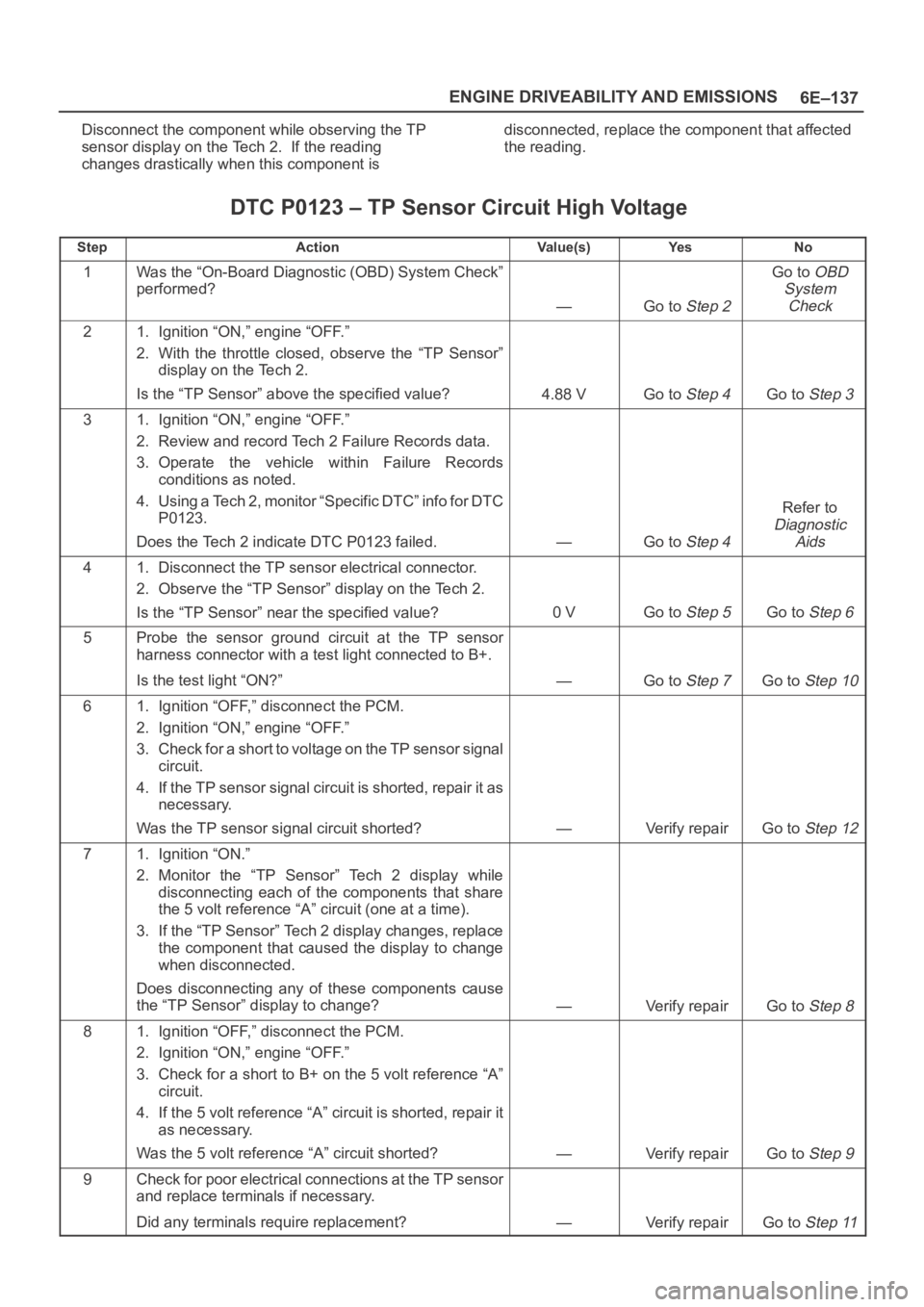

DTC P0123 – TP Sensor Circuit High Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. With the throttle closed, observe the “TP Sensor”

display on the Tech 2.

Is the “TP Sensor” above the specified value?

4.88 VGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “Specific DTC” info for DTC

P0123.

Does the Tech 2 indicate DTC P0123 failed.

—Go to Step 4

Refer to

Diagnostic

Aids

41. Disconnect the TP sensor electrical connector.

2. Observe the “TP Sensor” display on the Tech 2.

Is the “TP Sensor” near the specified value?

0 VGo to Step 5Go to Step 6

5Probe the sensor ground circuit at the TP sensor

harness connector with a test light connected to B+.

Is the test light “ON?”

—Go to Step 7Go to Step 10

61. Ignition “OFF,” disconnect the PCM.

2. Ignition “ON,” engine “OFF.”

3. Check for a short to voltage on the TP sensor signal

circuit.

4. If the TP sensor signal circuit is shorted, repair it as

necessary.

Was the TP sensor signal circuit shorted?

—Verify repairGo to Step 12

71. Ignition “ON.”

2. Monitor the “TP Sensor” Tech 2 display while

disconnecting each of the components that share

the 5 volt reference “A” circuit (one at a time).

3. If the “TP Sensor” Tech 2 display changes, replace

the component that caused the display to change

when disconnected.

Does disconnecting any of these components cause

the “TP Sensor” display to change?

—Verify repairGo to Step 8

81. Ignition “OFF,” disconnect the PCM.

2. Ignition “ON,” engine “OFF.”

3. Check for a short to B+ on the 5 volt reference “A”

circuit.

4. If the 5 volt reference “A” circuit is shorted, repair it

as necessary.

Was the 5 volt reference “A” circuit shorted?

—Verify repairGo to Step 9

9Check for poor electrical connections at the TP sensor

and replace terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 11

Page 1256 of 6000

6E–139 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0131 HO2S Circuit Low Voltage Bank 1

Sensor 1

060RW236

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal high and signal low circuits. When

measured with a 10 megaohm digital voltmeter, this may

display as low as 350 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when exhaust

is lean. The PCM constantly monitors the HO2S signal

during “closed loop” operation and compensates for a rich

or lean condition by decreasing or increasing injector

pulse width as necessary. If the Bank 1 HO2S 1 voltage

remains excessively low for an extended period of time,

DTC P0131 will be set.

Conditions for Setting the DTC

No related DTCs.

Vehicle is operating in “closed loop.”

Engine coolant temperature is above 60C (140F).

“Closed loop” commanded air/fuel ratio is between

14.5 and 14.8.

Throttle angle is between 3% and 19%.

Bank 1 HO2S 1 signal voltage remains below 22 mV

during normal “closed loop” operation for a total of 77

seconds over a 90-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0131 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Heated oxygen sensor wiring – The sensor pigtail may

be routed incorrectly and contacting the exhaust

system.

Poor PCM to engine block grounds.

Fuel pressure – The system will go lean if pressure is

too low. The PCM can compensate for some

decrease. However, If fuel pressure is too low, a DTC

P0131 may be set. Refer to

Fuel System Diagnosis.

Lean injector(s) – Perform “Injector Balance Test.”

Vacuum leaks – Check for disconnected or damaged

vacuum hoses and for vacuum leaks at the intake

manifold, throttle body, EGR system, and PCV system.

Exhaust leaks – An exhaust leak may cause outside air

to be pulled into the exhaust gas stream past the

Page 1259 of 6000

6E–142

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0132 HO2S Circuit High Voltage Bank 1

Sensor 1

060RW236

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal and low circuits. When measured

with a 10 megaohm digital voltmeter, this may display as

low as 320 mV. The oxygen sensor varies the voltage

within a range of about 1000 mV when exhaust is rich,

down through about 10 mV when exhaust is lean. The

PCM constantly monitors the HO2S signal during “closed

loop” operation and compensates for a rich or lean

condition by decreasing or increasing injector pulse width

as necessary. If the Bank 1 HO2S 1 voltage remains

excessively high for an extended period of time, DTC

P0132 will be set.

Conditions for Setting the DTC

No related DTCs.

Engine coolant temperature is above 60C (140F)

“Closed loop” commanded air/fuel ratio is between

14.5 and 14.8.

Throttle angle is between 3% and 19%.

Bank 1 HO2S 1 signal voltage remains above 952 mV

during normal “closed loop” operation for a total of 77

seconds over a 90-second period.

OR

Bank 1 HO2S 1 signal voltage remains above 500 mV

during “deceleration fuel cutoff mode” operation for 3

seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0132 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check the following items:

Fuel pressure – The system will go rich if pressure is

too high. The PCM can compensate for some

increase. However, if fuel pressure is too high, a DTC

P0132 may be set. Refer to

Fuel System Diagnosis.

Perform “Injector Balance Test” – Refer to Fuel System

Diagnosis.

MAF sensor –The system can go rich if MAF sensor

signal indicates an engine airflow measurement that is

not correct. Disconnect the MAF sensor to see it the

rich condition is corrected. If so, replace the MAF

sensor.

Check for a leak in the fuel pressure regulator

diaphragm by checking the vacuum line to the

regulator for the presence of fuel. There should be no

fuel in the vacuum line.

Page 1260 of 6000

6E–143 ENGINE DRIVEABILITY AND EMISSIONS

An intermittent TP sensor output will cause the system

to go rich due to a false indication of the engine

accelerating.

Shorted Heated Oxygen Sensor (HO2S) –If the HO2S

is internally shorted, the HO2S voltage displayed on

the Tech 2 will be over 1 volt. Try disconnecting the

affected HO2S with the key “ON,” engine “OFF.” If the

displayed HO2S voltage changes from over 1000 mV

to around 450 mV, replace the HO2S. Silicon

contamination of the HO2S can also cause a high

HO2S voltage to be indicated. This condition is

indicated by a powdery white deposit on the portion of

the HO2S exposed to the exhaust stream. If

contamination is noticed, replace the affected HO2S.

Open HO2S Signal Circuit or Faulty HO2S–A poor

connection or open in the HO2S signal circuit can

cause the DTC to set during deceleration fuel mode.

A n H O 2 S w h i c h i s f a u l t y a n d n o t a l l o w i n g a f u l l v o l t a g e

swing between the rich and lean thresholds can also

cause this condition. Operate the vehicle by

monitoring the HO2S voltage with a Tech 2. If theHO2S voltage is limited within a range between 300

mV to 600 mV, check the HO2S signal circuit wiring

and associated terminal conditions.

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. DTC P0132 failing during “deceleration fuel cutoff

mode” operation may indicate a condition described

in the “Diagnostic Aids” above. If the DTC P0132

test passes while the Failure Records conditions are

being duplicated, an intermittent condition is

indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0132 – HO2S Circuit High Voltage Bank 1 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install the Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within parameters specified

under “Conditions for Setting the DTC” included in

Diagnostic Support.

4. Using a Tech 2, monitor Bank 1 HO2S 1 voltage.

Does the Bank 1 HO2S 1 voltage remain above the

specified value?

952 mV (500

mV in

deceleration

fuel cutoff

mode)

Go to Step 4Go to Step 3

31. Ignition “ON,” review and record Tech 2 Failure

Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P0132 until the DTC P0132 test runs.

4. Note the test result.

Does the Tech 2 indicate DTC P0132 failed this

ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Ignition “OFF.”

2. Disconnect Bank 1 HO2S 1.

3. Ignition “ON.”

4. At HO2S Bank 1 Sensor 1 connector (PCM side)

use a DVM to measure voltages at the high and low

signal terminals.

Are the voltages in the specified range?

3-4 VGo to Step 5Go to Step 6

5Repair short to voltage in signal circuit.

Is the action complete?

—Verify repair—

Page 1262 of 6000

6E–145 ENGINE DRIVEABILITY AND EMISSIONS

D i a g n o s t i c Tr o u b l e C o d e ( D T C ) P 0 1 3 4 H O 2 S C i r c u i t I n s u f f i c i e n t Activity Bank 1

Sensor 1

060RW237

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

s e n s o r ( H O 2 S ) h i g h a n d l o w c i r c u i t s . W h e n m e a s u r e d

with a 10 megaohm digital voltmeter, this may display

as low as 320 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when

exhaust is lean. The PCM constantly monitors the

HO2S signal during “closed loop” operation and

compensates for a rich or lean condition by decreasing

or increasing injector pulse width as necessary. If the

Bank 1 HO2S 1 voltage remains at or near the 450 mV

bias for an extended period of time, DTC P0134 will be

set, indicating an open sensor signal or sensor low

circuit.

Heated oxygen sensors are used to minimize the

amount of time required for “closed loop” fuel control

operation and to allow accurate catalyst monitoring.

The oxygen sensor heater greatly decreases the

amount of time required for fuel control sensors Bank

1 HO2S 1 and Bank 2 HO2S 1 to become active.

Oxygen sensor heaters are required by post-catalyst

monitor sensors to maintain a sufficiently high

temperature for accurate exhaust oxygen content

readings further from the engine.

Conditions for Setting the DTC

No related DTCs.

Battery voltage is above 10 volts.

Engine run time is longer than 40 seconds.

Oxygen sensor heater has been determined to be

functioning properly.

Bank 1 HO2S 1 signal voltage remains between

400 mV and 500 mV for a total of 77 seconds over a

90-second period of time.

Action Take When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0134 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

Faulty HO2S heater or heater circuit – With the ignition

“ON,” engine “OFF,” after a cool down period, the

HO2S 1 voltage displayed on Tech 2 is normally

455-460 mV. A reading over 1000 mV indicates a

signal line shorted to voltage. A reading under 5 mV

Page 1265 of 6000

6E–148

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0151 HO2S Circuit Low Voltage Bank 2

Sensor 1

060RW190

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal high and signal low circuits. When

measured with a 10 megaohm digital voltmeter, this may

display as low as 320 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when exhaust

is lean. The PCM constantly monitors the HO2S signal

during “closed loop” operation and compensates for a rich

or lean condition by decreasing or increasing injector

pulse width as necessary. If the Bank 2 HO2S 1 voltage

remains excessively low for an extended period of time,

DTC P0151 will be set.

Conditions for Setting the DTC

No related DTCs.

The engine is operating in “closed loop.”

Engine coolant temperature is above 60C (140F).

“Closed loop” commanded air/fuel ratio is between

14.5 and 14.8.

Throttle angle is between 3% and 19%.

Bank 2 HO2S 1 signal voltage remains below 22 mV

during normal “closed loop” operation for a total of 77

seconds over a 90-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0151 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Heated oxygen sensor wiring – The sensor pigtail may

be mispositioned and contacting the exhaust system.

Poor PCM to engine block grounds.

Fuel pressure – The system will go lean if pressure is

too low. The PCM can compensate for some

decrease. However, if fuel pressure is too low, a DTC

P0151 may be set. Refer to

Fuel System Diagnosis.

Lean injector(s) – Perform “Injector Balance Test.”

Vacuum leaks – Check for disconnected or damaged

vacuum hoses and for vacuum leaks at the intake

manifold, throttle body, EGR system, and PCV system.

Exhaust leaks – An exhaust leak may cause outside air

to be pulled into the exhaust gas stream past the

HO2S, causing the system to appear lean. Check for