display OPEL FRONTERA 1998 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1336 of 6000

6E–219 ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0355 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0355 – Ignition 5 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0355 until the DTC P0355 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0355 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 5 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 5 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 5 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 5 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1339 of 6000

6E–222

ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0356 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0356 – Ignition 6 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0356 until the DTC P0356 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0356 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 6 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 6 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 6 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 6 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1341 of 6000

6E–224

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0402 EGR Pintle Crank Error

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to commands from the PCM, and to

detect a fault if pintle position is stuck open. If the PCM

detects a pintle position signal indicates more than 21.5%

and more than for 625 msec during cranking, the PCM will

set DTC P0402.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

Intake Air temp is more than 3C

At Engine revolution less than 600 RPM, EGR pintle

position indicates more than 21.5% and more than for

625 msecs.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

w h e n t h e D T C w a s s e t a s F r e e z e F r a m e a n d i n F a i l u r e

Records data.

Conditions for Clearing the MIL/DTC

DTC P0402 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Foreign material on EGR valve between pintle and

seat may cause EGR stuck open. Inspect foreign

material in EGR valve.

Excessive carbon deposit may cause unsmooth

operation of EGR valve shaft. Inspect carbon deposit

and clean up inside of carbon deposit.

Poor connection or damaged harness–inspect the

wiring harness for damage If the harness appears to be

OK, observe the EGR actual position display on Tech

2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

NOTE: If the EGR valve shows signs of excessive heat,

check the exhaust system for blockage (possibly a

plugged catalytic converter) using the “Restricted

Exhaust System Check”.

Page 1343 of 6000

6E–226

ENGINE DRIVEABILITY AND EMISSIONS

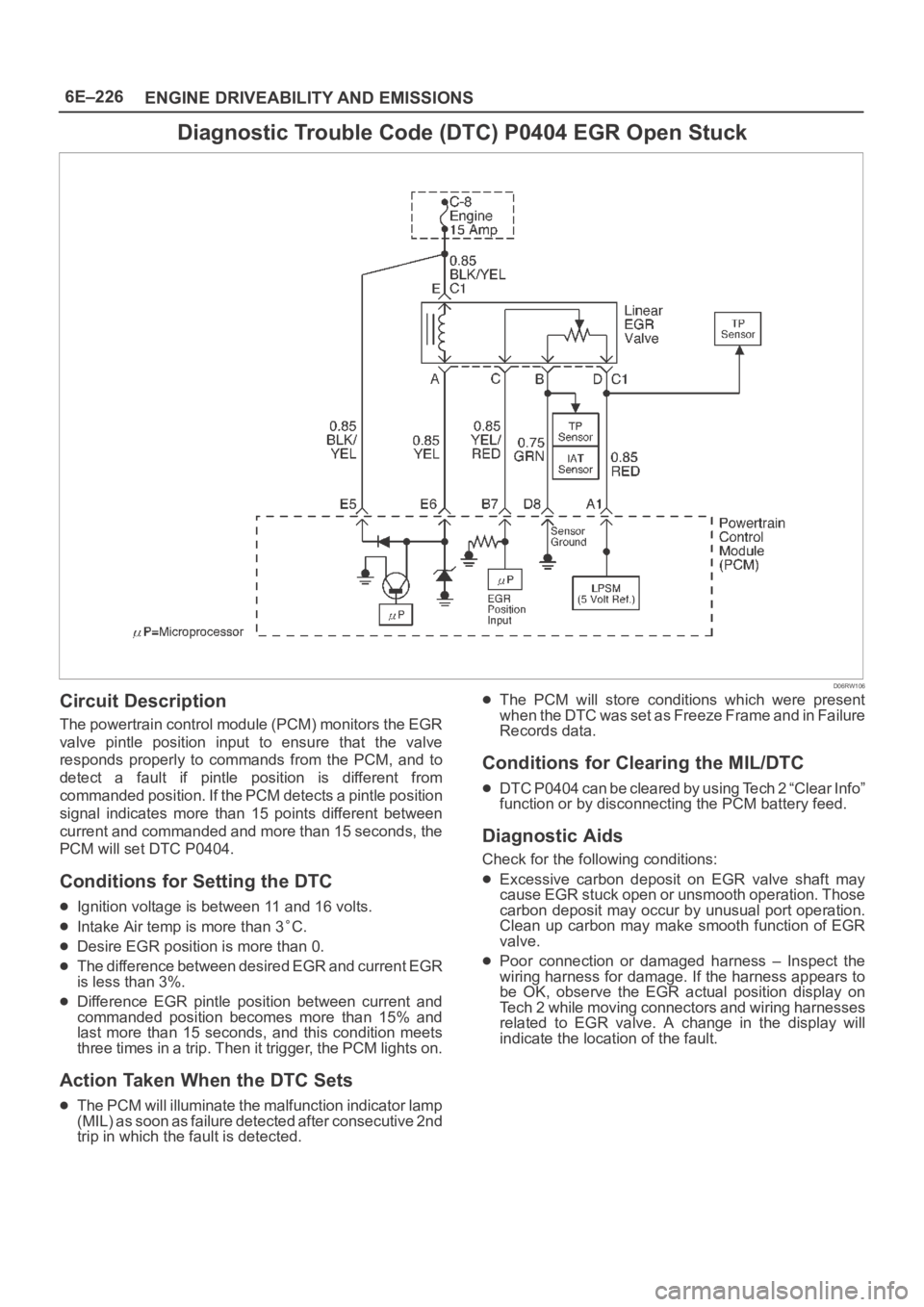

Diagnostic Trouble Code (DTC) P0404 EGR Open Stuck

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to commands from the PCM, and to

detect a fault if pintle position is different from

commanded position. If the PCM detects a pintle position

signal indicates more than 15 points different between

current and commanded and more than 15 seconds, the

PCM will set DTC P0404.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

Intake Air temp is more than 3C.

Desire EGR position is more than 0.

The difference between desired EGR and current EGR

is less than 3%.

Difference EGR pintle position between current and

commanded position becomes more than 15% and

last more than 15 seconds, and this condition meets

three times in a trip. Then it trigger, the PCM lights on.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) as soon as failure detected after consecutive 2nd

trip in which the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P0404 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Excessive carbon deposit on EGR valve shaft may

cause EGR stuck open or unsmooth operation. Those

carbon deposit may occur by unusual port operation.

Clean up carbon may make smooth function of EGR

valve.

Poor connection or damaged harness – Inspect the

wiring harness for damage. If the harness appears to

be OK, observe the EGR actual position display on

Tech 2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

Page 1345 of 6000

6E–228

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0405 EGR Low Voltage

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to command from the PCM. If current

pintle position voltage indicates less than 0.1 V and last

more than 10 seconds, then the PCM will set DTC P0405.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

EGR pintle position output voltage is less than 0.1 volt

and last more than 10 sec. Action taken when the DTC

sets.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) as soon as failure detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P0405 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

wiring harness for damage. If the harness appears to

be OK, observe the EGR actual position display on

Tech 2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

Page 1348 of 6000

6E–231 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0406 EGR High Voltage

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to command from the PCM. If current

pintle position voltage indicates more than 4.8 V and last

more than 10 seconds, then the PCM will set DTC P0406.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

EGR pintle position output voltage is more than 4.8 volt

and last more than 10 sec.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) as soon as failure detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P0404 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

wiring harness for damage. If the harness appears to

be OK, observe the EGR actual position display on

Tech 2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

Page 1380 of 6000

6E–263 ENGINE DRIVEABILITY AND EMISSIONS

Hard Start Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION: Engine cranks, but does not start

for a long time. Does eventually run, or may start

but immediately stalls.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

4Check engine coolant temperature (ECT) sensor for

shift in value. After 8 hours with the hood up and the

engine not running, connect Tech 2. With the ignition

“ON” and the engine not running, compare engine

coolant temperature to intake air temperature.

Are ECT and IAT within the specified value of each

other?

5C ( 9F)Go to Step 8Go to Step 5

51. Using Tech 2, display the engine coolant

temperature and note the value.

2. Check the resistance of the engine coolant

temperature sensor.

3. Refer to

Engine Coolant Temperature Sensor

Temperature vs. Resistance

chart on DTC P0118

Diagnostic Support

for resistance specifications.

Is the resistance value near the resistance for the

temperature noted?

—Go to Step 7Go to Step 6

6Replace the ECT sensor.

Is the action complete?

—Verify repair—

7Locate and repair high resistance or poor connection in

the ECT signal circuit or the ECT sensor ground.

Is the action complete?

—Verify repair—

81. Check for a faulty, plugged, or incorrectly installed

PCV valve.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for water- or alcohol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Perform the procedure in Fuel System Pressure

Te s t

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

111. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electric Ignition

System

for procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

Page 1393 of 6000

6E–276

ENGINE DRIVEABILITY AND EMISSIONS

Poor Fuel Economy Symptom

StepNo Ye s Va l u e ( s ) Action

101. Check for an incorrect or faulty engine thermostat.

Refer to

Engine Cooling.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

111. Check for low engine compression. Refer to Engine

Mechanical

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

121. Check the TCC operation. Refer to 4L30-E

Transmission Diagnosis

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 13

131. Check the exhaust system for possible restriction:

Inspect the exhaust system for damaged or

collapsed pipes.

Inspect the muffler for heat distress or possible

internal failure.

Check for a possible plugged three-way

catalytic converter by checking the exhaust

system back pressure. Refer to

Restricted

Exhaust System Check

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 14

14Check for proper calibration of the speedometer.

Does the speed indicated on the speedometer closely

match the vehicle speed displayed on Tech 2?

—Go to Step 16Go to Step 15

15Diagnose and repair an inaccurate speedometer

condition as necessary. Refer to

Vehicle Speed

Sensor

in Electrical Diagnosis.

Was a problem found?

—Verify repair—

161. Check the air intake system and the crankcase for

air leaks. Refer to

Air Intake System and

Crankcase Ventilation System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 17

171. Review all diagnostic procedures within this table.

2. When all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records buffer

All connections within a suspected circuit

and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 18

18Perform the procedure in Fuel System Pressure Test.

Was the fuel pressure normal?

—

Contact

Te c h n i c a l

Assistance

Verify repair

Page 1402 of 6000

6E–285 ENGINE DRIVEABILITY AND EMISSIONS

Hesitation, Sag, Stumble Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Momentary lack of response as the accelerator is

pushed down. Can occur at any vehicle speed. Usually

most pronounced when first trying to make the vehicle

move, as from a stop sign. May cause the engine to stall

if severe enough.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check the fuel control heated oxygen sensors

(HO2S, B1S1 and B2S1). The fuel control heated

oxygen sensors (HO2S) should respond quickly to

different throttle positions. If they don’t, check them

for silicon or other contaminants from fuel or use of

improper RTV sealant. The sensors may have a

white powdery coating.

Silicon contamination causes a high but false

HO2S signal voltage (rich exhaust indication).

The PCM will then reduce the amount of fuel

delivered to the engine, causing a severe

driveability problem. For more information, refer

to

Powertrain Control Module (PCM) and Sensors.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check the fuel pressure. Refer to Fuel System

Pressure Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

6Observe the TP angle display on Tech 2 while slowly

increasing throttle pedal.

Does the TP angle display steadily increase from 0% at

closed throttle to 100% at WOT?

—Go to Step 7Go to Step 18

7Monitor the long term fuel trim on Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—Go to Step 8Go to Step 9

81. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

91. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

Page 1452 of 6000

6E–335 ENGINE DRIVEABILITY AND EMISSIONS

General Description

General Description (PCM and

Sensors)

58X Reference PCM Input

The powertrain control module (PCM) uses this signal

from the crankshaft position (CKP) sensor to calculate

engine RPM and crankshaft position at all engine speeds.

The PCM also uses the pulses on this circuit to initiate

injector pulses. If the PCM receives no pulses on this

circuit, DTC P0337 will set. The engine will not start and

run without using the 58X reference signal.

A/C Request Signal

This signal tells the PCM when the A/C mode is selected

at the A/C control head. The PCM uses this to adjust the

idle speed before turning “ON” the A/C clutch. The A/C

compressor will be inoperative if this signal is not

available to the PCM.

Refer to

A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for the A/C electrical system.

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor provides a signal

used by the powertrain control module (PCM) to calculate

the ignition sequence. The CKP sensor initiates the 58X

reference pulses which the PCM uses to calculate RPM

and crankshaft position.

Refer to

Electronic Ignition System for additional

information.

0013

Camshaft Position (CMP) Sensor and

Signal

The camshaft position (CMP) sensor sends a CMP signal

t o t h e P C M . T h e P C M u s e s t h i s s i g n a l a s a “ s y n c p u l s e ” t otrigger the injectors in the proper sequence. The PCM

uses the CMP signal to indicate the position of the #1

piston during its power stroke. This allows the PCM to

calculate true sequential fuel injection (SFI) mode of

operation. If the PCM detects an incorrect CMP signal

while the engine is running, DTC P0341 will set. If the

CMP signal is lost while the engine is running, the fuel

injection system will shift to a calculated sequential fuel

injection mode based on the last fuel injection pulse, and

the engine will continue to run. As long as the fault is

present, the engine can be restarted. It will run in the

calculated sequential mode with a 1-in-6 chance of the

injector sequence being correct.

Refer to

DTC P0341 for further information.

0014

Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature (ECT) sensor is a

thermistor (a resistor which changes value based on

temperature) mounted in the engine coolant stream. Low

coolant temperature produces a high resistance of

100,000 ohms at –40

C (–40F). High temperature

causes a low resistance of 70 ohms at 130

C (266F).

The PCM supplies a 5-volt signal to the ECT sensor

through resistors in the PCM and measures the voltage.

The signal voltage will be high when the engine is cold and

low when the engine is hot. By measuring the voltage, the

PCM calculates the engine coolant temperature. Engine

coolant temperature affects most of the systems that the

PCM controls.

Tech 2 displays engine coolant temperature in degrees.

After engine start-up, the temperature should rise steadily

to about 85

C (185F). It then stabilizes when the

thermostat opens. If the engine has not been run for

several hours (overnight), the engine coolant

temperature and intake air temperature displays should

be close to each other. A hard fault in the engine coolant

sensor circuit will set DTC P0177 or DTC P0118. An

intermittent fault will set a DTC P1114 or P1115.