fuse OPEL FRONTERA 1998 Manual Online

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2275 of 6000

7A1–30

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

D07RW031

Circuit Description

The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

lever position: P, R, N, D 3, 2 or L. The selector lever

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

The range switch is also used to provide the

information P or N to the engine crank wiring. The

engine can be cranked only if connector M–25

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

The range switch is also used to provide the backup

lamp power in reverse. This is why the range switch is

supplied through a 10A fuse (C–3). This fuse can

burn due to a short circuit in the backup lamp.

This DTC detects when a fuse is open or the range switch

circuit does not work. This is a type “D” DTC.

Conditions For Setting The DTC

Range switch illegal positions met for 5 seconds.

Action Taken When The DTC Sets

Default to D position.

Inhibit torque management.

Maximum line pressure.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Refer to accompanying chart for the normal range

signals and the illegal combinations.

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Page 2276 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–31

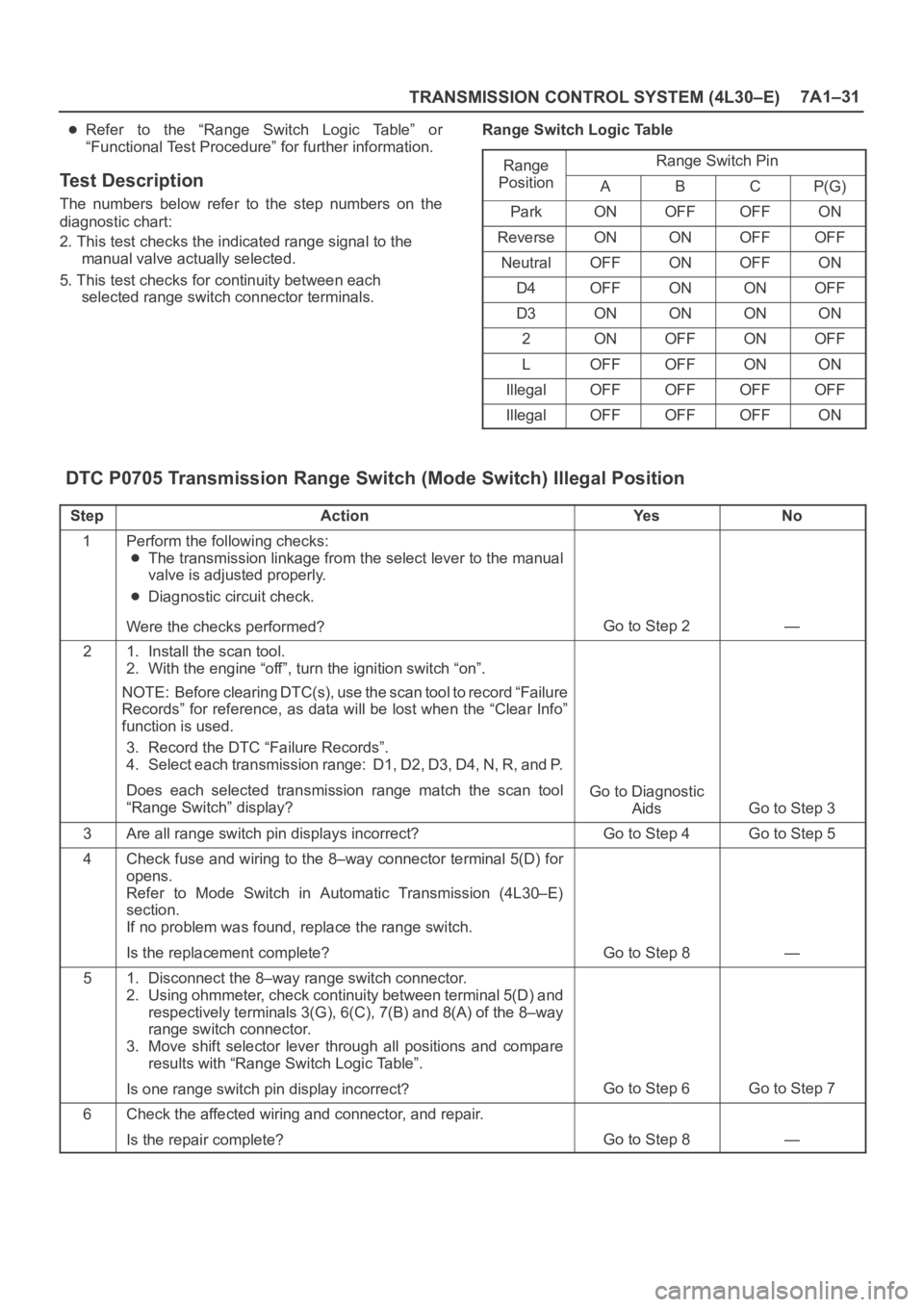

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.

5. This test checks for continuity between each

selected range switch connector terminals.Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—

Page 2278 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–33

DTC P0706 Transmission Range Switch (Mode Switch) Performance

D07RW031

Circuit Description

The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

l e v e r p o s i t i o n : P, R , N , D , 3 , 2 o r L . T h e s e l e c t o r l e v e r

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

The range switch is also used to provide the

information P or N to the engine crank wiring. The

engine can be cranked only if connector M–25

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

The range switch is also used to provide the backup

lamp power in reverse. This is why the mode switch is

supplied through a 10A fuse (C–3). This fuse can

burn due to a shot circuit in the backup lamp.

This DTC detects an invalid state of the range switch

or the range switch circuit by deciphering the range

switch inputs. This is a type “D” DTC.

Conditions For Setting The DTC

This DTC will set if any of the following conditions occurs:

Condition 1 (“R” bad position):

Engine is running.

No output speed DTCP0722, P0723.

Output speed greater then 3,200 RPM.

Range switch indicates “R”.

All conditions met for 4 seconds.

Condition 2 (“P” or “N” bad position):

Engine is running.

No TPS codes.

Engine speed is less than 3,000 RPM.

TP angle is greater than 20%.

Range switch indicates “P” or “N”.

All conditions met for 4 seconds.

Action Taken When The DTC Sets

Default to “D” position.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Page 2279 of 6000

7A1–34

TRANSMISSION CONTROL SYSTEM (4L30–E)

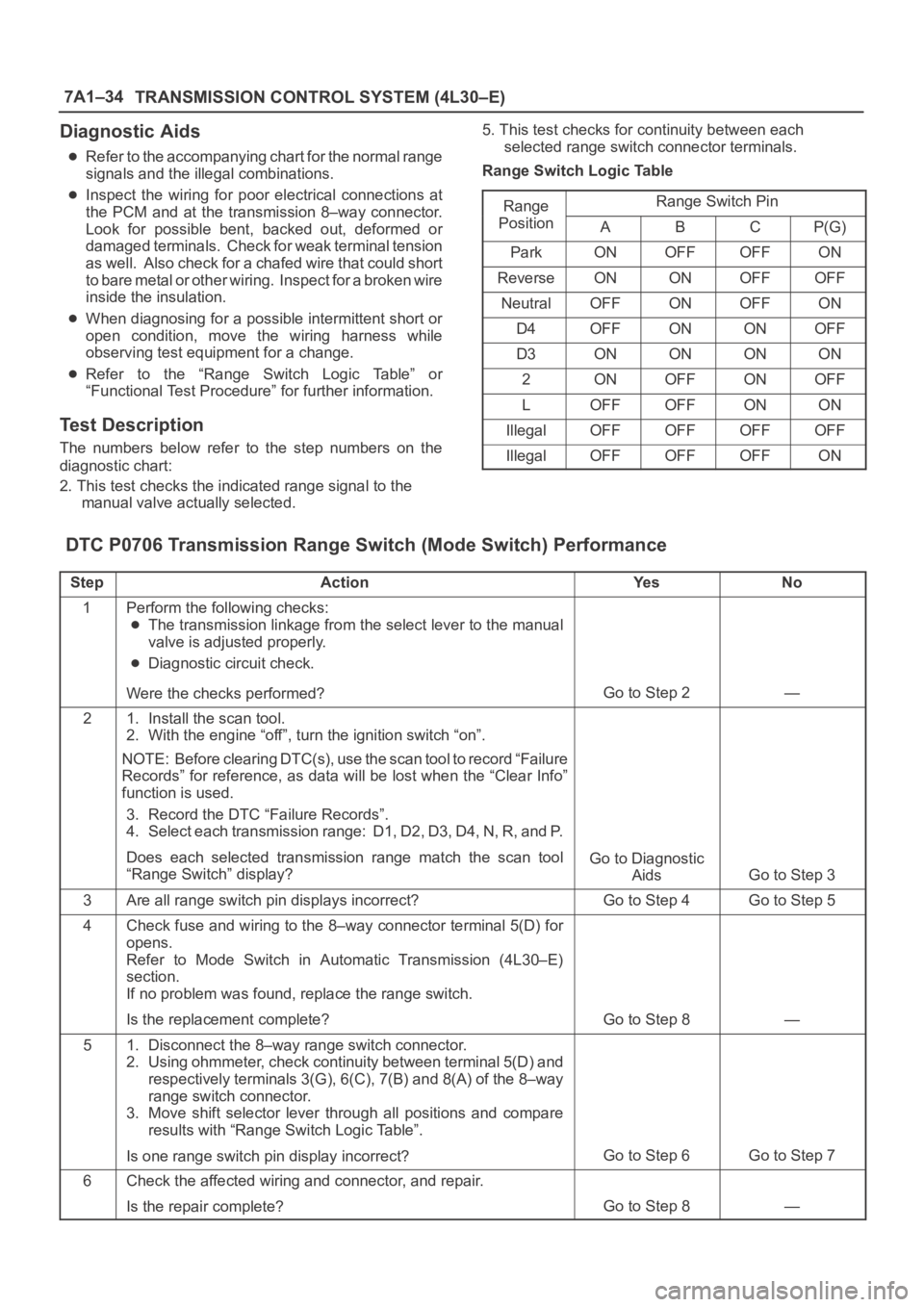

Diagnostic Aids

Refer to the accompanying chart for the normal range

signals and the illegal combinations.

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as well. Also check for a chafed wire that could short

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.5. This test checks for continuity between each

selected range switch connector terminals.

Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0706 Transmission Range Switch (Mode Switch) Performance

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—

Page 2285 of 6000

7A1–40

TRANSMISSION CONTROL SYSTEM (4L30–E)

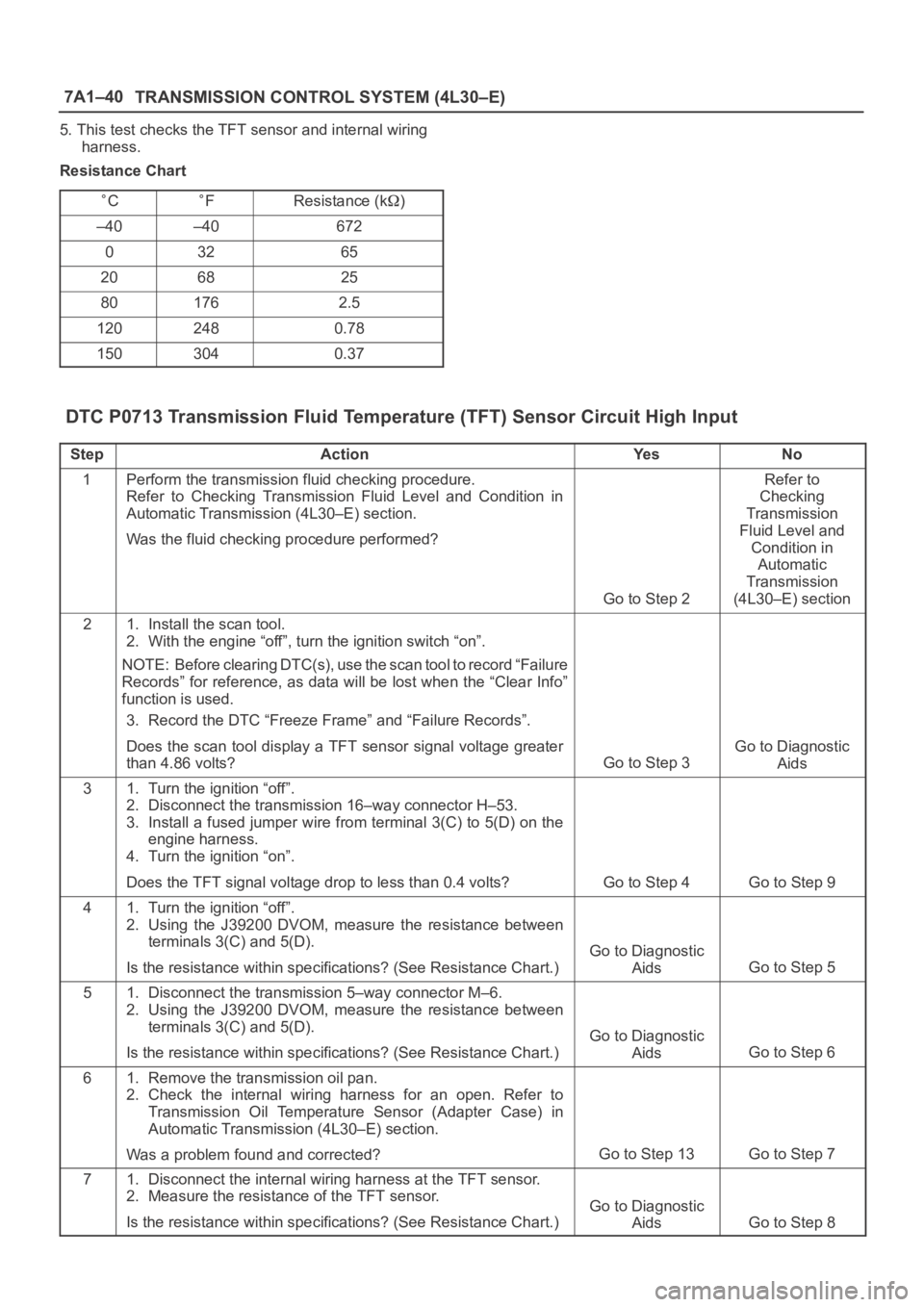

5. This test checks the TFT sensor and internal wiring

harness.

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

StepActionYe sNo

1Perform the transmission fluid checking procedure.

Refer to Checking Transmission Fluid Level and Condition in

Automatic Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage greater

than 4.86 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Install a fused jumper wire from terminal 3(C) to 5(D) on the

engine harness.

4. Turn the ignition “on”.

Does the TFT signal voltage drop to less than 0.4 volts?

Go to Step 4Go to Step 9

41. Turn the ignition “off”.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan.

2. Check the internal wiring harness for an open. Refer to

Transmission Oil Temperature Sensor (Adapter Case) in

Automatic Transmission (4L30–E) section.

Was a problem found and corrected?

Go to Step 13Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

Page 2288 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–43

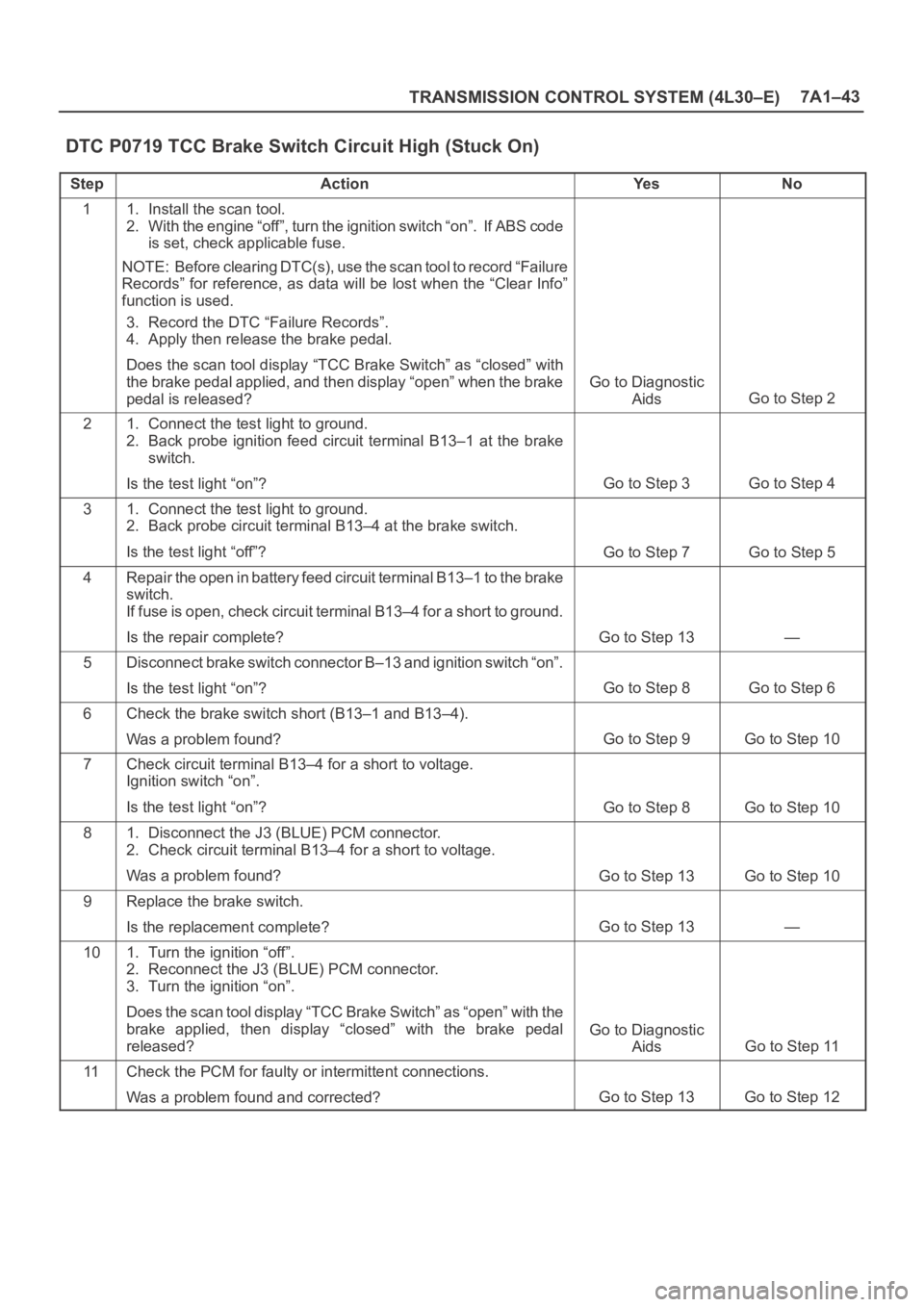

DTC P0719 TCC Brake Switch Circuit High (Stuck On)

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”. If ABS code

is set, check applicable fuse.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Apply then release the brake pedal.

Does the scan tool display “TCC Brake Switch” as “closed” with

the brake pedal applied, and then display “open” when the brake

pedal is released?

Go to Diagnostic

Aids

Go to Step 2

21. Connect the test light to ground.

2. Back probe ignition feed circuit terminal B13–1 at the brake

switch.

Is the test light “on”?

Go to Step 3Go to Step 4

31. Connect the test light to ground.

2. Back probe circuit terminal B13–4 at the brake switch.

Is the test light “off”?

Go to Step 7Go to Step 5

4Repair the open in battery feed circuit terminal B13–1 to the brake

switch.

If fuse is open, check circuit terminal B13–4 for a short to ground.

Is the repair complete?

Go to Step 13—

5Disconnect brake switch connector B–13 and ignition switch “on”.

Is the test light “on”?

Go to Step 8Go to Step 6

6Check the brake switch short (B13–1 and B13–4).

Was a problem found?

Go to Step 9Go to Step 10

7Check circuit terminal B13–4 for a short to voltage.

Ignition switch “on”.

Is the test light “on”?

Go to Step 8Go to Step 10

81. Disconnect the J3 (BLUE) PCM connector.

2. Check circuit terminal B13–4 for a short to voltage.

Was a problem found?

Go to Step 13Go to Step 10

9Replace the brake switch.

Is the replacement complete?

Go to Step 13—

101. Turn the ignition “off”.

2. Reconnect the J3 (BLUE) PCM connector.

3. Turn the ignition “on”.

Does the scan tool display “TCC Brake Switch” as “open” with the

brake applied, then display “closed” with the brake pedal

released?

Go to Diagnostic

Aids

Go to Step 11

11Check the PCM for faulty or intermittent connections.

Was a problem found and corrected?

Go to Step 13Go to Step 12

Page 2597 of 6000

The chassis electrical system is a 12–volt system with a

negative ground polarity.

Wire size are appropriate to respective circuits, and

classified by color. (The classification of harnesses by

color is shown on the circuit diagram for ease of harness

identification.)

The wire size is determined by load capacity and the

length of wire required.

The vehicle harnesses are: body harness, chassis

harness, engine room harness, instrument harness,

transmission harness, engine ECGI harness, dome light

harness, door harness, rear body harness, tailgate

harness, SRS harness and battery cables.

The harnesses are protected either by tape or corrugated

tube, depending on harness location.

The circuit for each system consists of the power source,

wire, fuse, relay, switch, load parts and ground, all of

which are shown on the circuit diagram.

In this section, each electrical device is classified by

system.

For major parts shown on the circuit based on the circuit

diagram for each system, a summary, diagnosis of

troubles and inspection procedures are detailed.

Notes for Working on Electrical

Items

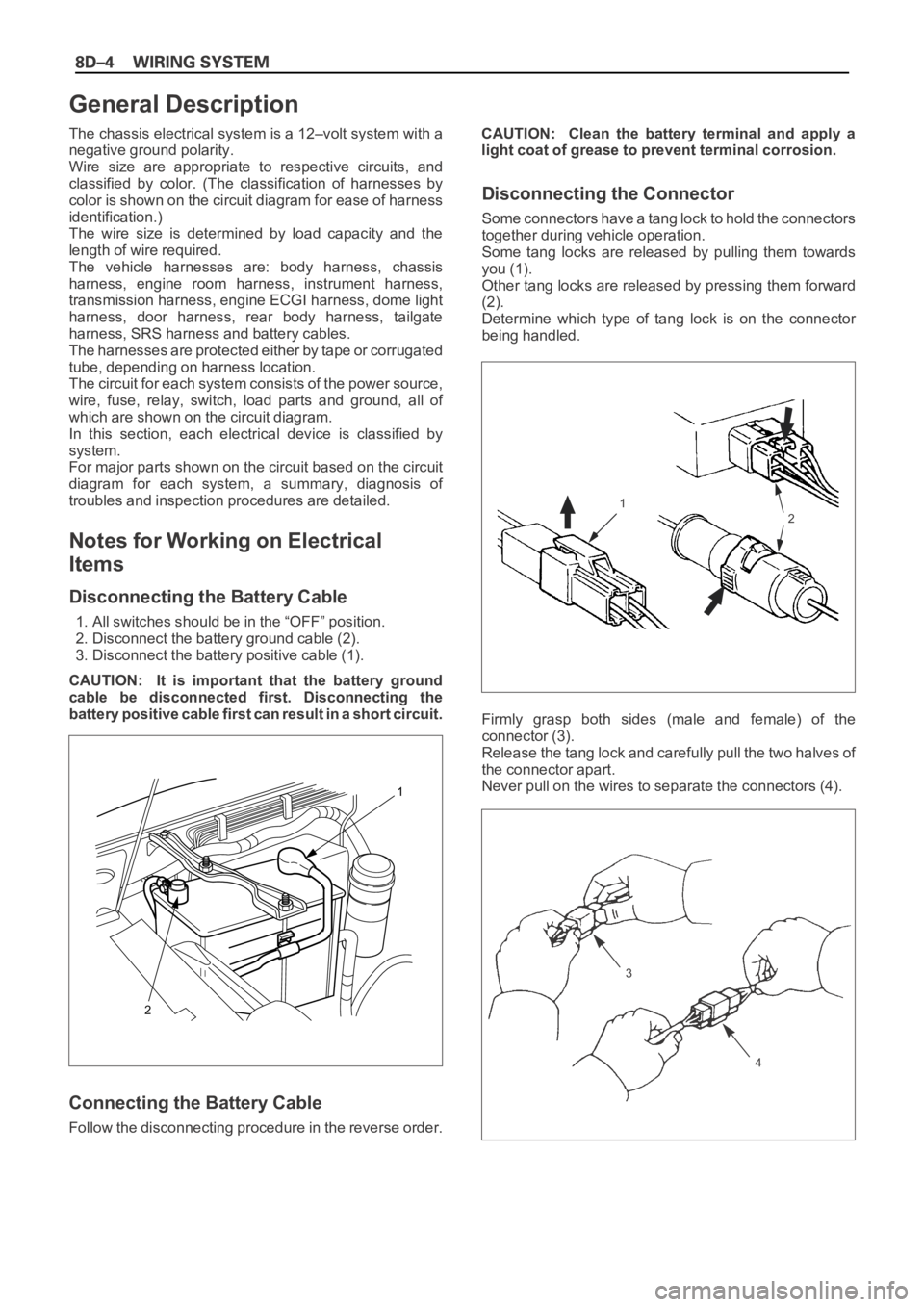

Disconnecting the Battery Cable

1. All switches should be in the “OFF” position.

2. Disconnect the battery ground cable (2).

3. Disconnect the battery positive cable (1).

CAUTION: It is important that the battery ground

cable be disconnected first. Disconnecting the

battery positive cable first can result in a short circuit.

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse order.CAUTION: Clean the battery terminal and apply a

light coat of grease to prevent terminal corrosion.

Disconnecting the Connector

Some connectors have a tang lock to hold the connectors

together during vehicle operation.

Some tang locks are released by pulling them towards

you (1).

Other tang locks are released by pressing them forward

(2).

Determine which type of tang lock is on the connector

being handled.

Firmly grasp both sides (male and female) of the

connector (3).

Release the tang lock and carefully pull the two halves of

the connector apart.

Never pull on the wires to separate the connectors (4).

2

1

General Description

1

2

3

4

Page 2607 of 6000

Fuse

Fuses are the most common form of circuit protection

used in vehicle wiring. A fuse is a thin piece of wire or strip

of metal encased in a glass or plastic housing. It is wired

in series with the circuit it protects. When there is an

overload of current in a circuit, such as a short of a ground,

the metal strip is designed to burn out and interrupt the

flow of current. This prevents a surge of high current from

reaching and damaging other components in the circuit.

Determine the cause of the overloaded before replacing

the fuse.

The replacement fuse must have the same amperage

specification as the original fuse.

Never replace a blown fuse with a fuse of a different

amperage specification.

Doing so can result in an electrical fire or other serious

circuit damage. A blown fuse is easily identified as shown

in the figure.

Page 2608 of 6000

Fusible Link

The fusible link is primarily used to protect circuits where

high amounts of current flow and where it would not be

practical to use a fuse. For example, the starter circuit.

When a current overload occurs, the fusible link melts

open and interrupts the flow of current so as to prevent

the rest of the wiring harness from burning.

Determine the cause of the overload before replacing the

fusible link. the replacement fusible link must have the

same amperage specification as the original fusible link.

Never replace a blown fusible link with fusible link of a

different amperage specification. Doing so can result in

an electrical fire or other serious circuit damage.

A blown fusible link is easily identified as shown in the

figure.

Fusible Link Specifications

Type Rating Case Color Maximum Circuit Current (A)

Connector 30A Pink 15

Connector 40A Green 20

Bolted 50A Red 25

Bolted 60A Yellow 30

Bolted 80A Black 40

Page 2617 of 6000

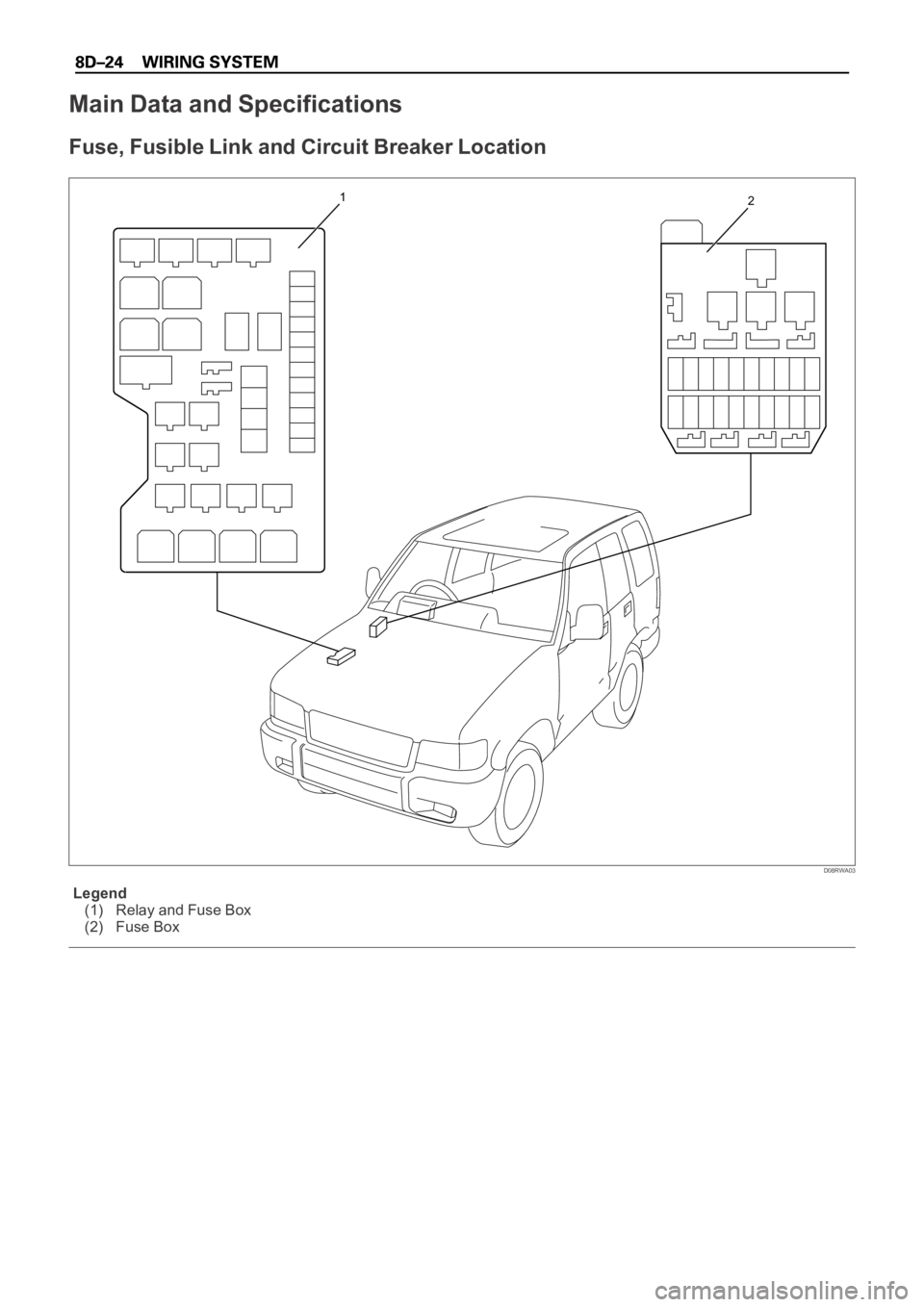

12

D08RWA03

Legend

(1) Relay and Fuse Box

(2) Fuse Box

Main Data and Specifications

Fuse, Fusible Link and Circuit Breaker Location