air condition OPEL FRONTERA 1998 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 755 of 6000

4D1–34

TRANSFER CASE (STANDARD TYPE)

2. If the measured value exceeds the specified limit, the

gear must be replaced.

Gear inside diameter

Standard : 48.000–48.013 mm (1.8898–1.8903 in)

Limit : 48.10 mm (1.894 in)

226RS040

Clutch Hub Spline Play

1. Set a dial indicator to the clutch hub to measured.

2. Move the clutch hub as far as possible to both the right

and the left.

Note the dial indicator reading.

3. If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch hub spline play

Standard : 0–0.1 mm (0–0.004 in)

Limit : 0.2 mm (0.008 in)

226RS042

Bearings

1. Inspect the condition of all the needles and ball

bearings. Wash bearings thoroughly in a cleaning

solvent. Apply compressed air to the bearings.

NOTE: Do not allow the bearings to spin. Turn them

slowly by hand. Spinning bearings may damage the

rollers.

2. Lubricate the bearings with a light oil and check them

for roughness by slowly turning the race by hand.

Ball Bearing Play

1. Use a dial indicator to measure the ball bearing play.

2. If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Limit : 0.2 mm (0.008 in)

226RS043

Synchronizers

The synchronizer hubs and sliding sleeves are a selected

assembly and should be kept together as originally

assembled.

Clean synchronizer components with clean solvent and

air dry.

Inspect the components for the following:

Teeth for wear, scuffs, nicks, burrs or breaks.

Keys and springs for wear, cracks or distortion,

replace if these conditions are present.

If scuffed, nicked or burred conditions cannot be

corrected with a soft stone or crocus cloth, replace the

component.

Block Ring and Insert Clearance

1. Use a vernier caliper to measure the clearance

between the block ring and the insert.

2. If the measured value exceeds the specified limit, the

block ring and the insert must be replaced.

Block ring and insert clearance

Standard : 2.46–2.74 mm (0.097–0.108 in)

Page 846 of 6000

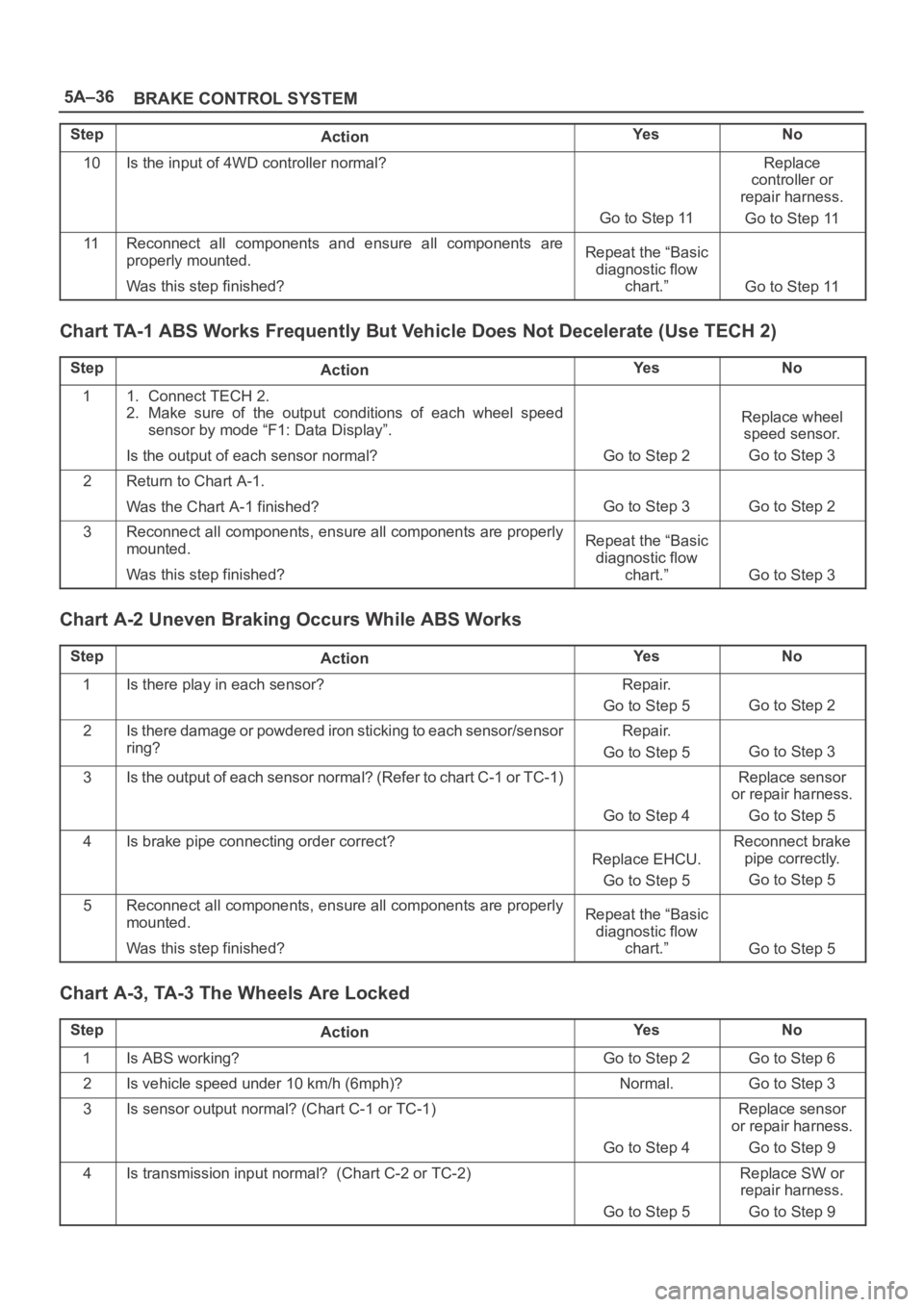

5A–36

BRAKE CONTROL SYSTEM

StepNo Ye s

Action

10Is the input of 4WD controller normal?

Go to Step 11

Replace

controller or

repair harness.

Go to Step 11

11Reconnect all components and ensure all components are

properly mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 11

Chart TA-1 ABS Works Frequently But Vehicle Does Not Decelerate (Use TECH 2)

StepActionYe sNo

11. Connect TECH 2.

2. Make sure of the output conditions of each wheel speed

sensor by mode “F1: Data Display”.

Is the output of each sensor normal?

Go to Step 2

Replace wheel

speed sensor.

Go to Step 3

2Return to Chart A-1.

Was the Chart A-1 finished?

Go to Step 3Go to Step 2

3Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart A-2 Uneven Braking Occurs While ABS Works

StepActionYe sNo

1Is there play in each sensor?Repair.

Go to Step 5

Go to Step 2

2Is there damage or powdered iron sticking to each sensor/sensor

ring?Repair.

Go to Step 5

Go to Step 3

3Is the output of each sensor normal? (Refer to chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair harness.

Go to Step 5

4Is brake pipe connecting order correct?

Replace EHCU.

Go to Step 5

Reconnect brake

pipe correctly.

Go to Step 5

5Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 5

Chart A-3, TA-3 The Wheels Are Locked

StepActionYe sNo

1Is ABS working?Go to Step 2Go to Step 6

2Is vehicle speed under 10 km/h (6mph)?Normal.Go to Step 3

3Is sensor output normal? (Chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair harness.

Go to Step 9

4Is transmission input normal? (Chart C-2 or TC-2)

Go to Step 5

Replace SW or

repair harness.

Go to Step 9

Page 848 of 6000

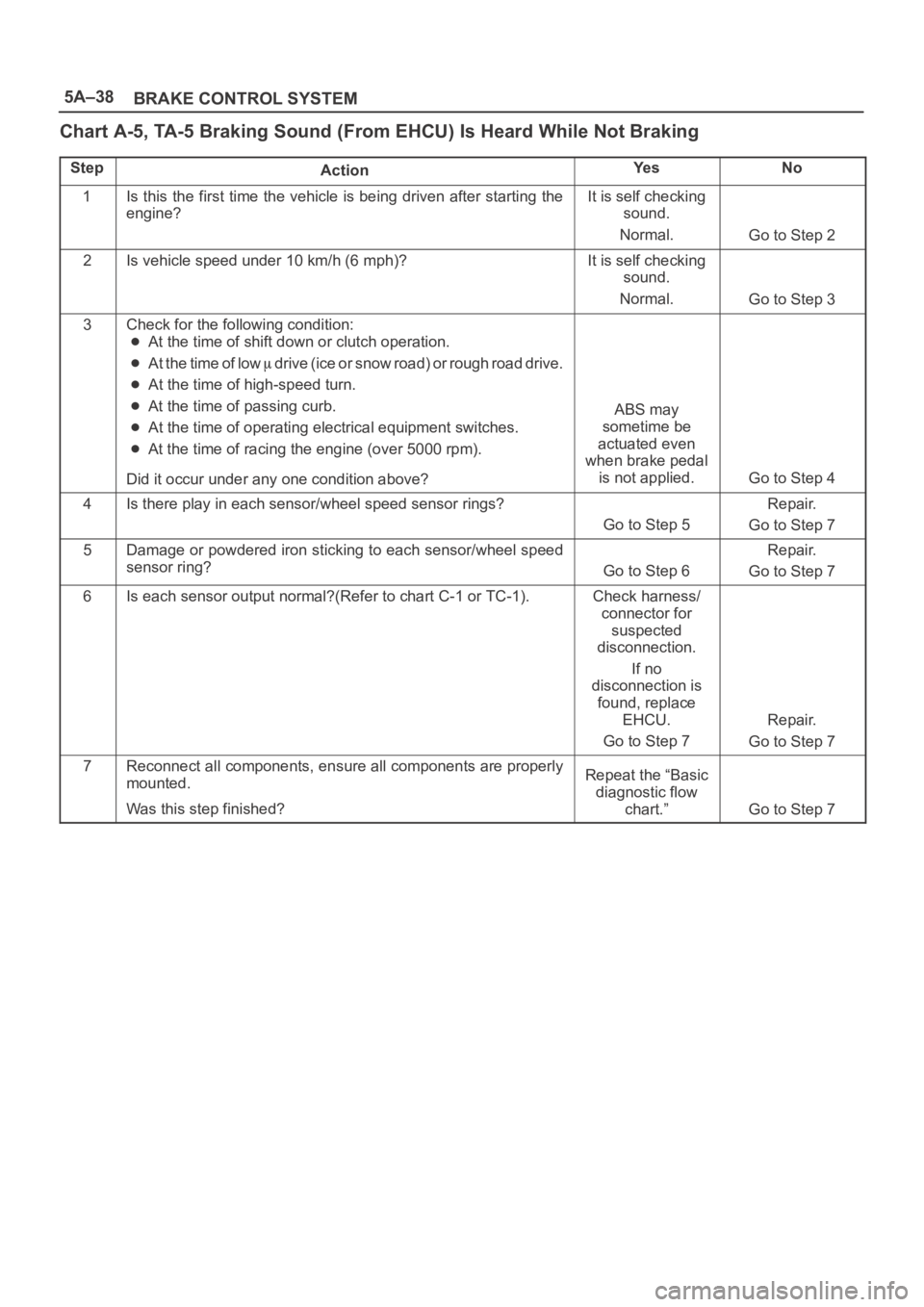

5A–38

BRAKE CONTROL SYSTEM

Chart A-5, TA-5 Braking Sound (From EHCU) Is Heard While Not Braking

StepActionYe sNo

1Is this the first time the vehicle is being driven after starting the

engine?It is self checking

sound.

Normal.

Go to Step 2

2Is vehicle speed under 10 km/h (6 mph)?It is self checking

sound.

Normal.

Go to Step 3

3Check for the following condition:

At the time of shift down or clutch operation.

A t t h e t i m e o f l o w drive (ice or snow road) or rough road drive.

At the time of high-speed turn.

At the time of passing curb.

At the time of operating electrical equipment switches.

At the time of racing the engine (over 5000 rpm).

Did it occur under any one condition above?

ABS may

sometime be

actuated even

when brake pedal

is not applied.

Go to Step 4

4Is there play in each sensor/wheel speed sensor rings?

Go to Step 5

Repair.

Go to Step 7

5Damage or powdered iron sticking to each sensor/wheel speed

sensor ring?

Go to Step 6

Repair.

Go to Step 7

6Is each sensor output normal?(Refer to chart C-1 or TC-1).Check harness/

connector for

suspected

disconnection.

If no

disconnection is

found, replace

EHCU.

Go to Step 7

Repair.

Go to Step 7

7Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 7

Page 850 of 6000

5A–40

BRAKE CONTROL SYSTEM

Diagnosis By “ABS” Warning Light

Illumination Pattern

In the event that there is abnormality in the “ABS” warning

light illumination pattern while the key is in the ON position

or if the warning light is actuated during driving, trouble

should be diagnosed on a illumination pattern basis as

follows:

No.

Condition“ABS” Warning Light Illumination PatternDiagnostic

1Warning light is actu-

ated normallyNormal

2Warning light is not litWarning light lighting circuit

trouble

Go to Chart B-1

3Warning light remains

ONDiagnostic trouble codes are

stored.

Display diagnostic trouble

codes and diagnose on a

code basis according to the

flow charts.

4Warning light is actu-

ated while drivingDiagnostic trouble codes are

stored.

Display diagnostic trouble

codes and diagnose on a

code basis according to the

flow charts.

Diagnostic Trouble Codes (DTCs)

When the warning light in the meter remains ON, the

EHCU stores the fault identification and disables the

ABS.

1. How to display and erase DTCs:

NOTE:

If DTCs are not displayed, harness C-4 connector

terminal 30 and I-10 connector terminal 2 may be

disconnected. Repair the harness and try DTC

display again.

DTCs can be displayed also by TECH 2. Select mode

“F0: Diagnostic Trouble Codes” from Application

Menu.

1. How to start DTC display:

Confirm that the vehicle has come to a complete

stop (with the wheels standing still) and that the

brake pedal is not depressed. (Unless these two

conditions are satisfied, DTC display cannot be

started.)

With IGN OFF, connect #12 terminal with #4

terminal or # 5 terminal (GND) . Then turn IGN ON.

Page 866 of 6000

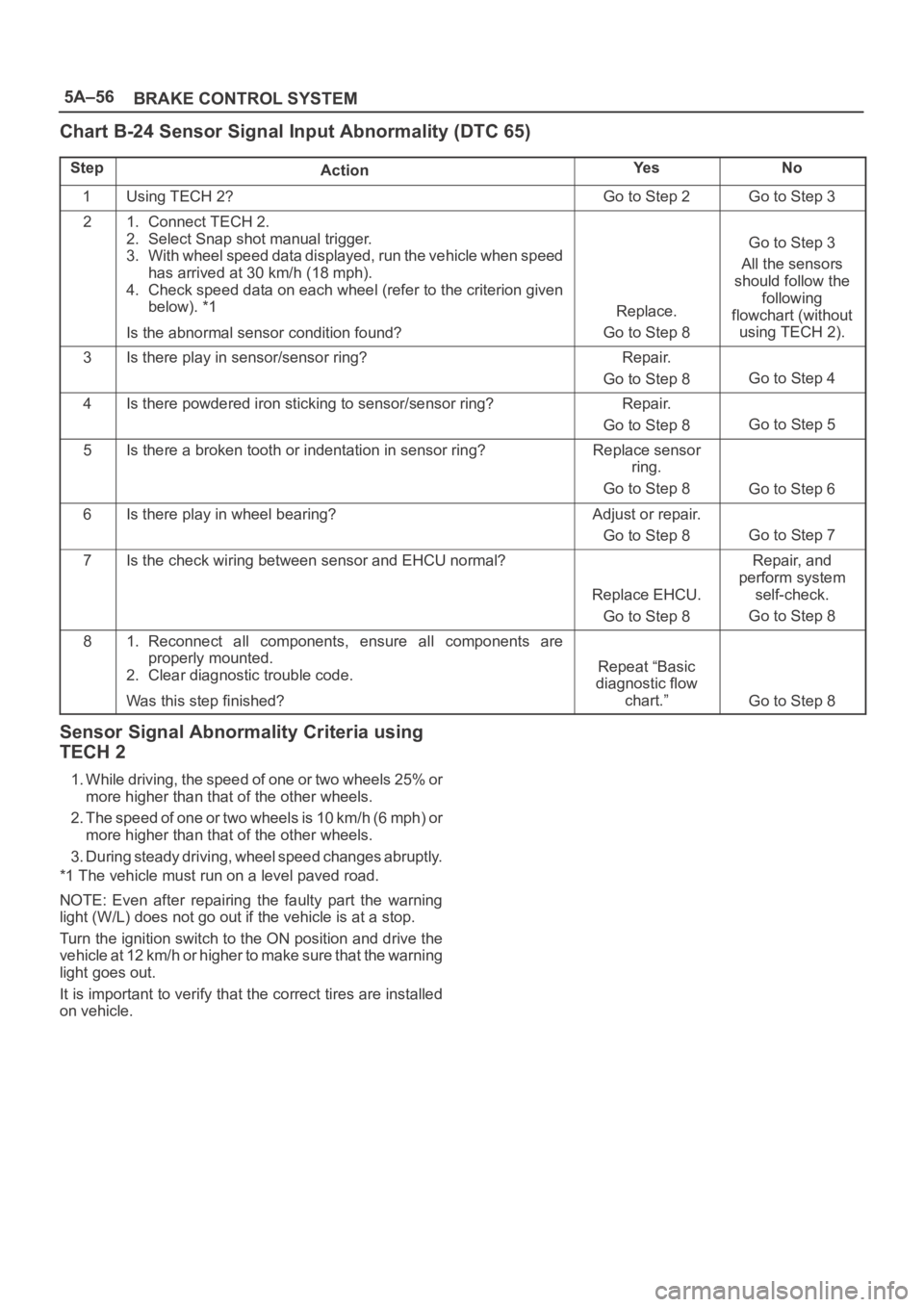

5A–56

BRAKE CONTROL SYSTEM

Chart B-24 Sensor Signal Input Abnormality (DTC 65)

StepActionYe sNo

1Using TECH 2?Go to Step 2Go to Step 3

21. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when speed

has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). *1

Is the abnormal sensor condition found?

Replace.

Go to Step 8

Go to Step 3

All the sensors

should follow the

following

flowchart (without

using TECH 2).

3Is there play in sensor/sensor ring?Repair.

Go to Step 8

Go to Step 4

4Is there powdered iron sticking to sensor/sensor ring?Repair.

Go to Step 8

Go to Step 5

5Is there a broken tooth or indentation in sensor ring?Replace sensor

ring.

Go to Step 8

Go to Step 6

6Is there play in wheel bearing?Adjust or repair.

Go to Step 8

Go to Step 7

7Is the check wiring between sensor and EHCU normal?

Replace EHCU.

Go to Step 8

Repair, and

perform system

self-check.

Go to Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat “Basic

diagnostic flow

chart.”

Go to Step 8

Sensor Signal Abnormality Criteria using

TECH 2

1. While driving, the speed of one or two wheels 25% or

more higher than that of the other wheels.

2. The speed of one or two wheels is 10 km/h (6 mph) or

more higher than that of the other wheels.

3. During steady driving, wheel speed changes abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h or higher to make sure that the warning

light goes out.

It is important to verify that the correct tires are installed

on vehicle.

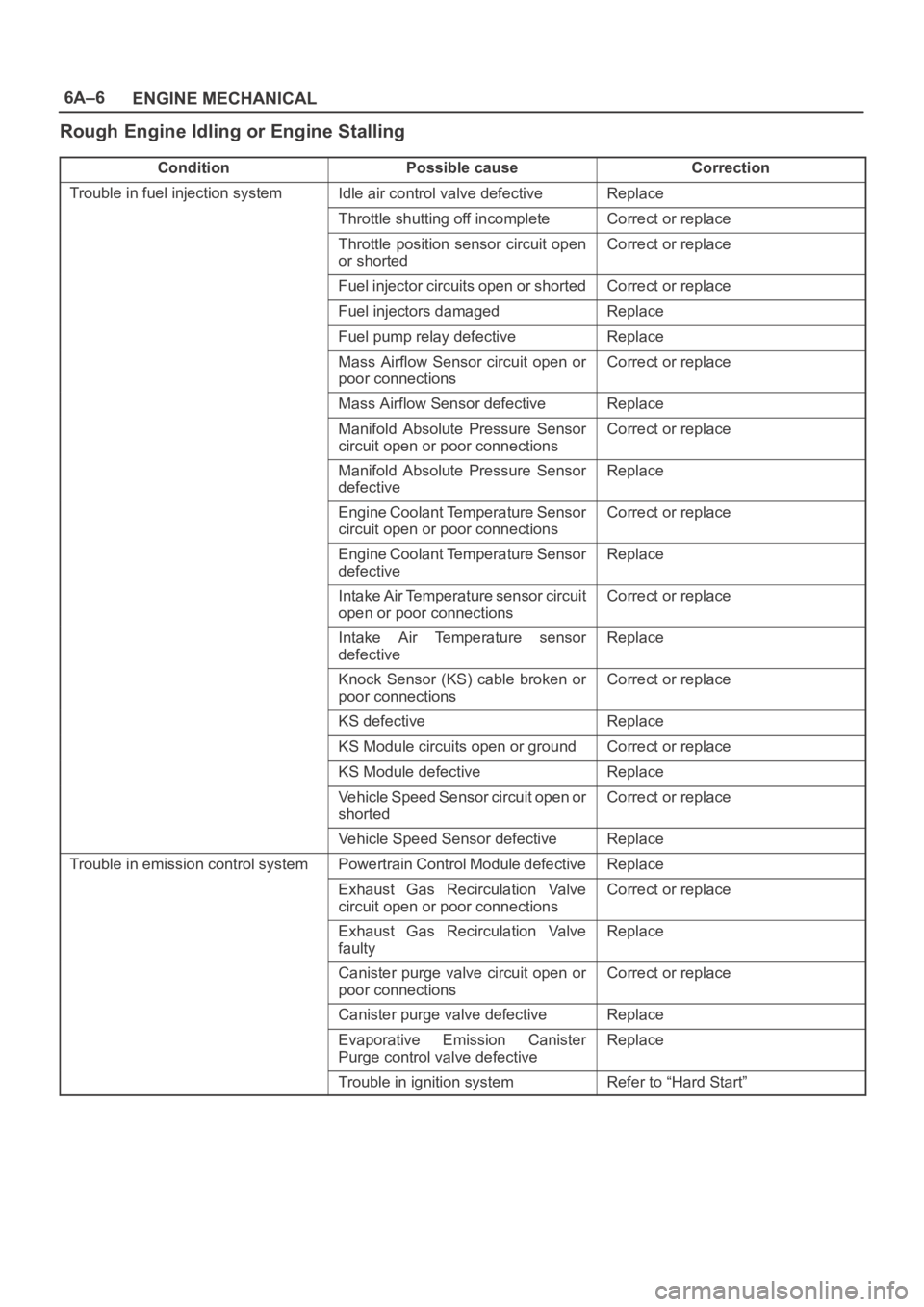

Page 962 of 6000

6A–6

ENGINE MECHANICAL

Rough Engine Idling or Engine Stalling

ConditionPossible causeCorrection

Trouble in fuel injection systemIdle air control valve defectiveReplace

Throttle shutting off incompleteCorrect or replace

Throttle position sensor circuit open

or shortedCorrect or replace

Fuel injector circuits open or shortedCorrect or replace

Fuel injectors damagedReplace

Fuel pump relay defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or poor connectionsCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature Sensor

circuit open or poor connectionsCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Intake Air Temperature sensor circuit

open or poor connectionsCorrect or replace

Intake Air Temperature sensor

defectiveReplace

Knock Sensor (KS) cable broken or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or groundCorrect or replace

KS Module defectiveReplace

Vehicle Speed Sensor circuit open or

shortedCorrect or replace

Vehicle Speed Sensor defectiveReplace

Trouble in emission control systemPowertrain Control Module defectiveReplace

Exhaust Gas Recirculation Valve

circuit open or poor connectionsCorrect or replace

Exhaust Gas Recirculation Valve

faultyReplace

Canister purge valve circuit open or

poor connectionsCorrect or replace

Canister purge valve defectiveReplace

Evaporative Emission Canister

Purge control valve defectiveReplace

Trouble in ignition systemRefer to “Hard Start”

Page 963 of 6000

6A–7

ENGINE MECHANICAL

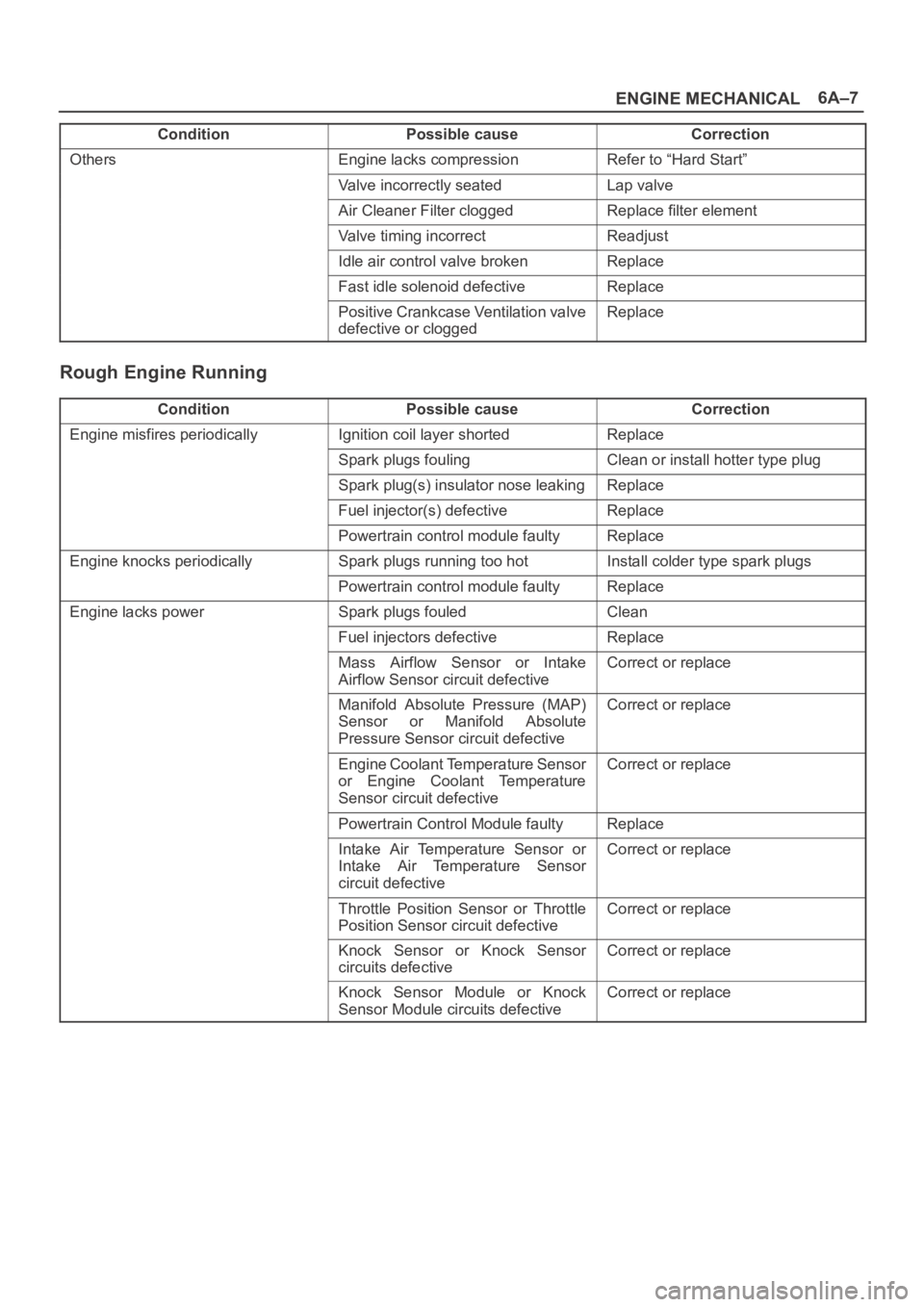

Condition CorrectionPossible cause

OthersEngine lacks compressionRefer to “Hard Start”

Valve incorrectly seatedLap valve

Air Cleaner Filter cloggedReplace filter element

Valve timing incorrectReadjust

Idle air control valve brokenReplace

Fast idle solenoid defectiveReplace

Positive Crankcase Ventilation valve

defective or cloggedReplace

Rough Engine Running

ConditionPossible causeCorrection

Engine misfires periodicallyIgnition coil layer shortedReplace

Spark plugs foulingClean or install hotter type plug

Spark plug(s) insulator nose leakingReplace

Fuel injector(s) defectiveReplace

Powertrain control module faultyReplace

Engine knocks periodicallySpark plugs running too hotInstall colder type spark plugs

Powertrain control module faultyReplace

Engine lacks powerSpark plugs fouledClean

Fuel injectors defectiveReplace

Mass Airflow Sensor or Intake

Airflow Sensor circuit defectiveCorrect or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defectiveCorrect or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defectiveCorrect or replace

Powertrain Control Module faultyReplace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defectiveCorrect or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defectiveCorrect or replace

Knock Sensor or Knock Sensor

circuits defectiveCorrect or replace

Knock Sensor Module or Knock

Sensor Module circuits defectiveCorrect or replace

Page 964 of 6000

6A–8

ENGINE MECHANICAL

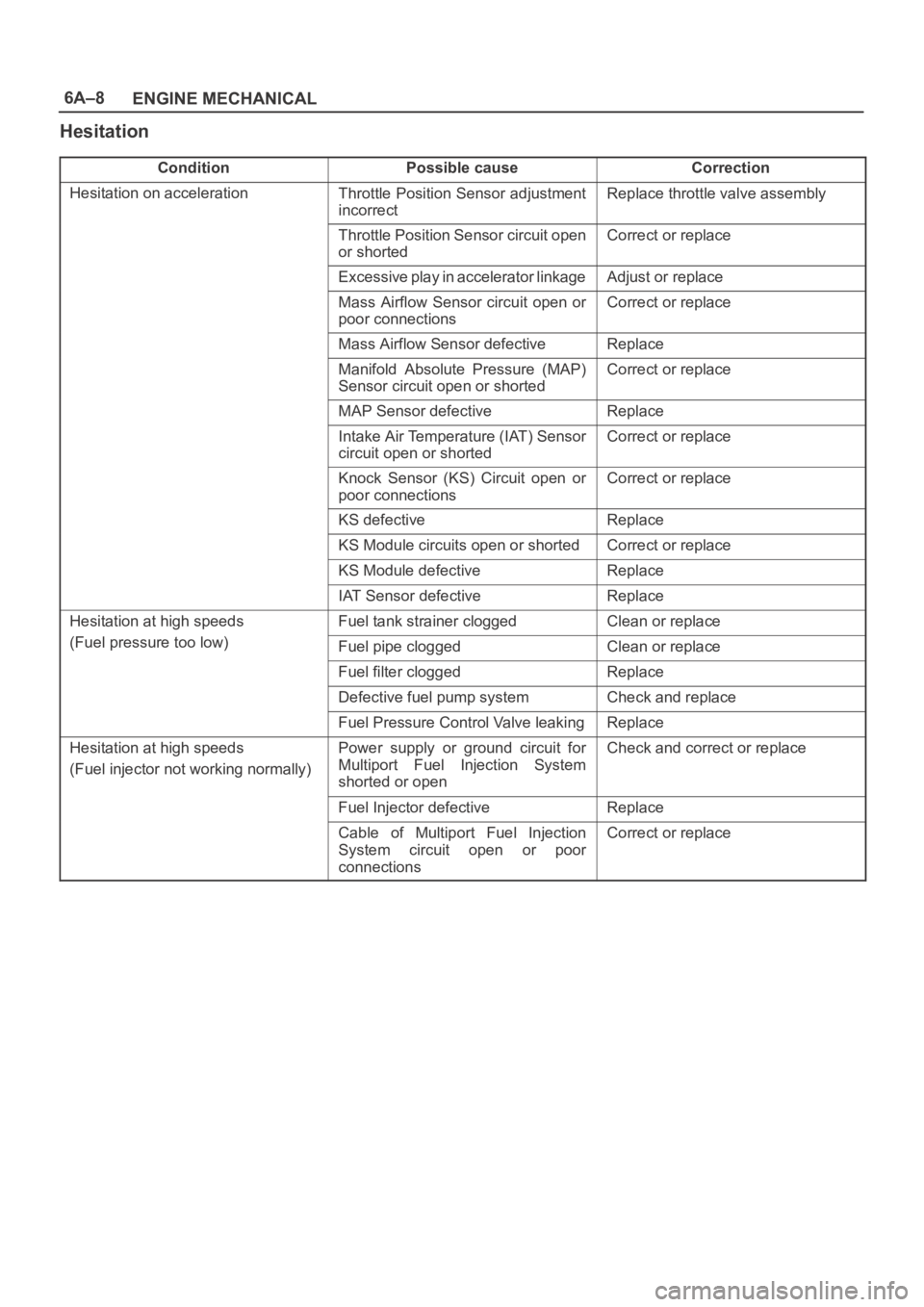

Hesitation

ConditionPossible causeCorrection

Hesitation on accelerationThrottle Position Sensor adjustment

incorrectReplace throttle valve assembly

Throttle Position Sensor circuit open

or shortedCorrect or replace

Excessive play in accelerator linkageAdjust or replace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure (MAP)

Sensor circuit open or shortedCorrect or replace

MAP Sensor defectiveReplace

Intake Air Temperature (IAT) Sensor

circuit open or shortedCorrect or replace

Knock Sensor (KS) Circuit open or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or shortedCorrect or replace

KS Module defectiveReplace

IAT Sensor defectiveReplace

Hesitation at high speedsFuel tank strainer cloggedClean or replace

(Fuel pressure too low)Fuel pipe cloggedClean or replace

Fuel filter cloggedReplace

Defective fuel pump systemCheck and replace

Fuel Pressure Control Valve leakingReplace

Hesitation at high speeds

(Fuel injector not working normally)Power supply or ground circuit for

Multiport Fuel Injection System

shorted or openCheck and correct or replace

Fuel Injector defectiveReplace

Cable of Multiport Fuel Injection

System circuit open or poor

connectionsCorrect or replace

Page 965 of 6000

6A–9

ENGINE MECHANICAL

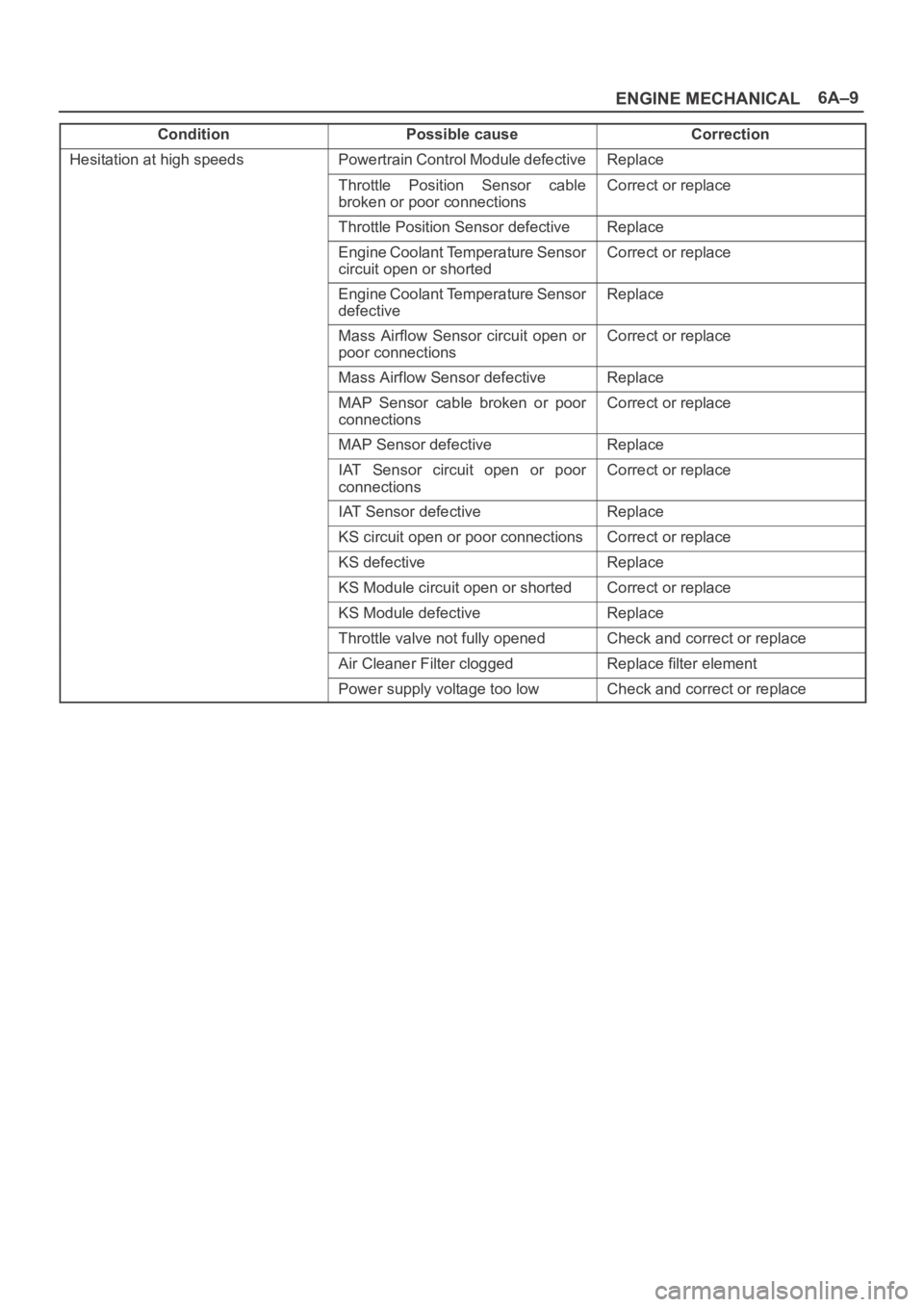

Condition CorrectionPossible cause

Hesitation at high speedsPowertrain Control Module defectiveReplace

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

MAP Sensor cable broken or poor

connectionsCorrect or replace

MAP Sensor defectiveReplace

IAT Sensor circuit open or poor

connectionsCorrect or replace

IAT Sensor defectiveReplace

KS circuit open or poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuit open or shortedCorrect or replace

KS Module defectiveReplace

Throttle valve not fully openedCheck and correct or replace

Air Cleaner Filter cloggedReplace filter element

Power supply voltage too lowCheck and correct or replace

Page 966 of 6000

6A–10

ENGINE MECHANICAL

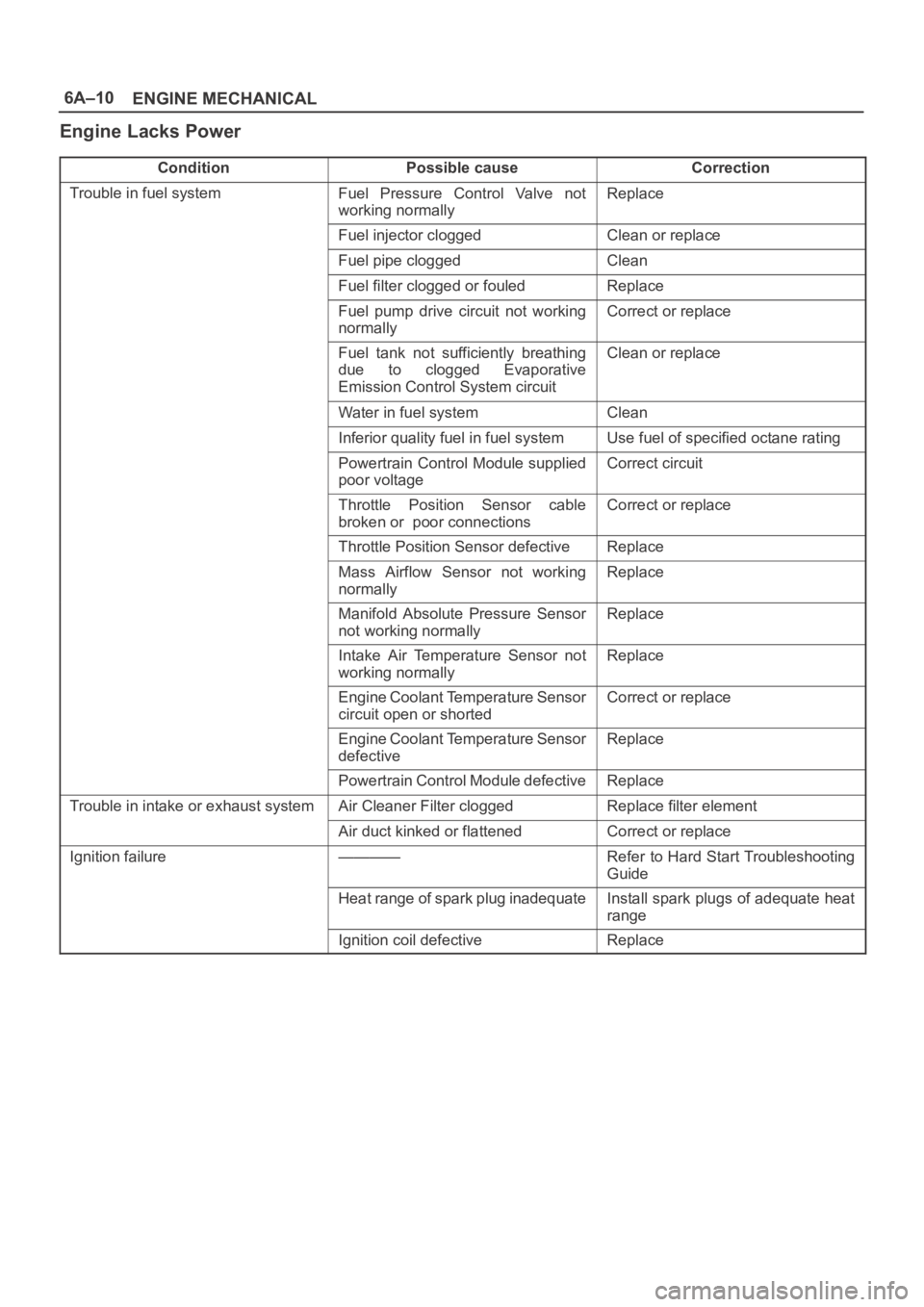

Engine Lacks Power

ConditionPossible causeCorrection

Trouble in fuel systemFuel Pressure Control Valve not

working normallyReplace

Fuel injector cloggedClean or replace

Fuel pipe cloggedClean

Fuel filter clogged or fouledReplace

Fuel pump drive circuit not working

normallyCorrect or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuitClean or replace

Water in fuel systemClean

Inferior quality fuel in fuel systemUse fuel of specified octane rating

Powertrain Control Module supplied

poor voltageCorrect circuit

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Mass Airflow Sensor not working

normallyReplace

Manifold Absolute Pressure Sensor

not working normallyReplace

Intake Air Temperature Sensor not

working normallyReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Powertrain Control Module defectiveReplace

Trouble in intake or exhaust systemAir Cleaner Filter cloggedReplace filter element

Air duct kinked or flattenedCorrect or replace

Ignition failure————Refer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequateInstall spark plugs of adequate heat

range

Ignition coil defectiveReplace