air condition OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 558 of 6000

4B1–25 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

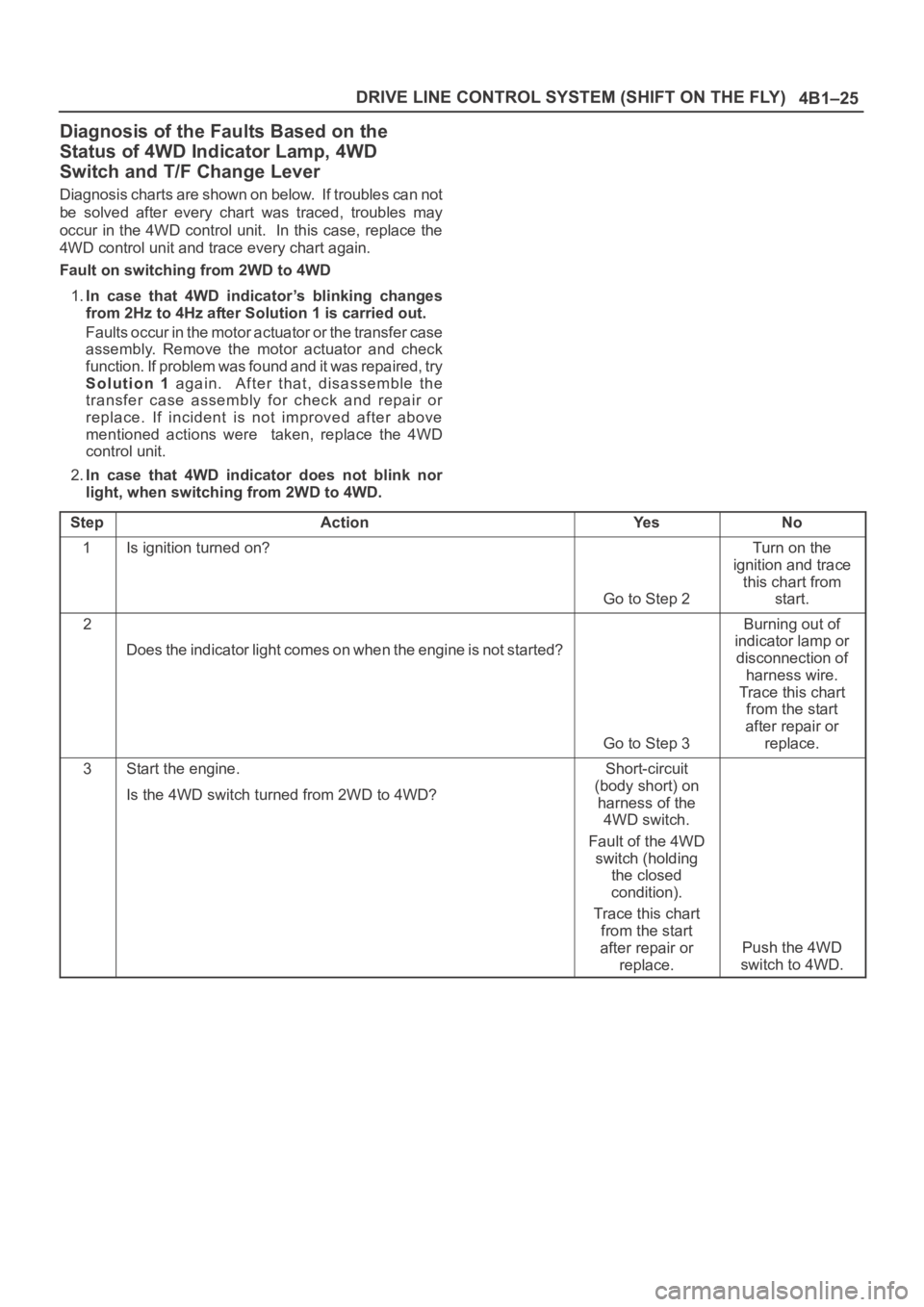

Diagnosis of the Faults Based on the

Status of 4WD Indicator Lamp, 4WD

Switch and T/F Change Lever

Diagnosis charts are shown on below. If troubles can not

be solved after every chart was traced, troubles may

occur in the 4WD control unit. In this case, replace the

4WD control unit and trace every chart again.

Fault on switching from 2WD to 4WD

1.In case that 4WD indicator’s blinking changes

from 2Hz to 4Hz after Solution 1 is carried out.

Faults occur in the motor actuator or the transfer case

assembly. Remove the motor actuator and check

function. If problem was found and it was repaired, try

Solution 1 again. After that, disassemble the

transfer case assembly for check and repair or

replace. If incident is not improved after above

mentioned actions were taken, replace the 4WD

control unit.

2.In case that 4WD indicator does not blink nor

light, when switching from 2WD to 4WD.

Step

ActionYe sNo

1Is ignition turned on?

Go to Step 2

Turn on the

ignition and trace

this chart from

start.

2

Does the indicator light comes on when the engine is not started?

Go to Step 3

Burning out of

indicator lamp or

disconnection of

harness wire.

Trace this chart

from the start

after repair or

replace.

3Start the engine.

Is the 4WD switch turned from 2WD to 4WD?Short-circuit

(body short) on

harness of the

4WD switch.

Fault of the 4WD

switch (holding

the closed

condition).

Trace this chart

from the start

after repair or

replace.

Push the 4WD

switch to 4WD.

Page 586 of 6000

4B2–15 DRIVE LINE CONTROL SYSTEM (TOD)

7. Slowly start the vehicle in the 4L mode, and

accelerate to at least 20 km/h. Apply the brake to

completely stop the vehicle.

If the CHECK lamp starts blinking during the test run, read

the trouble codes and give appropriate maintenance

according to the fault diagnostic procedure. If the TOD

indicator lamps are lit abnormally during the run, check

the lighting condition and give appropriate maintenance

according to the fault diagnostic procedure. Even if the

phenomena are not observed, try to reproduce the

abnormal state reported by the customer to the possible

extent.

Post-Repair Check

As long as the starter is not turned off, the TOD indicator

lamps continue blinking even after the failed control unit is

repaired. Therefore, upon completion of repair, be sure to

turn off the starter switch once and then turn on it to

conduct the test run sequence specified in steps 1

through 6 above and check that the TOD indicator lamps

no longer show any faulty status.

Page 669 of 6000

4C–3 DRIVE SHAFT SYSTEM

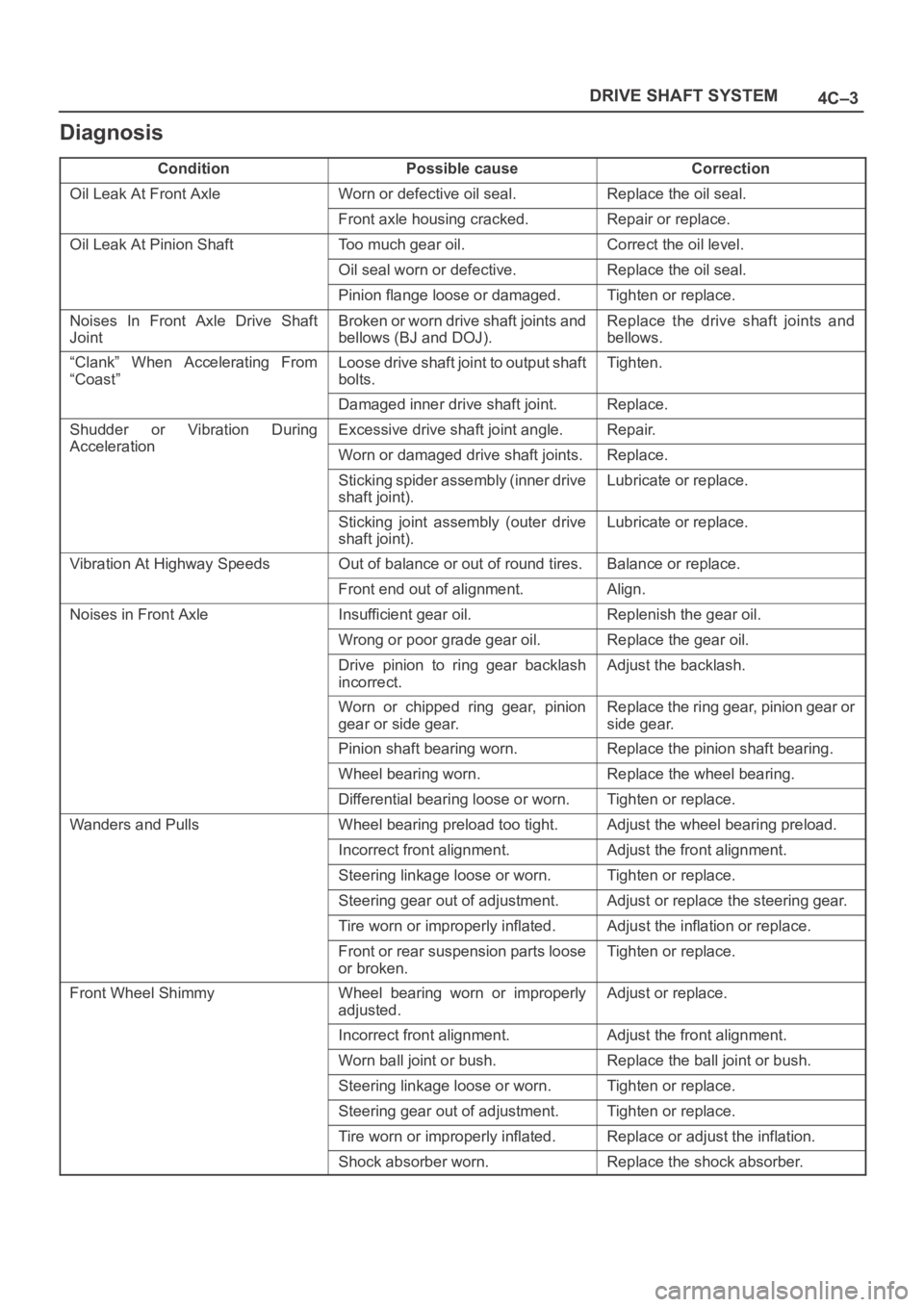

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 671 of 6000

4C–5 DRIVE SHAFT SYSTEM

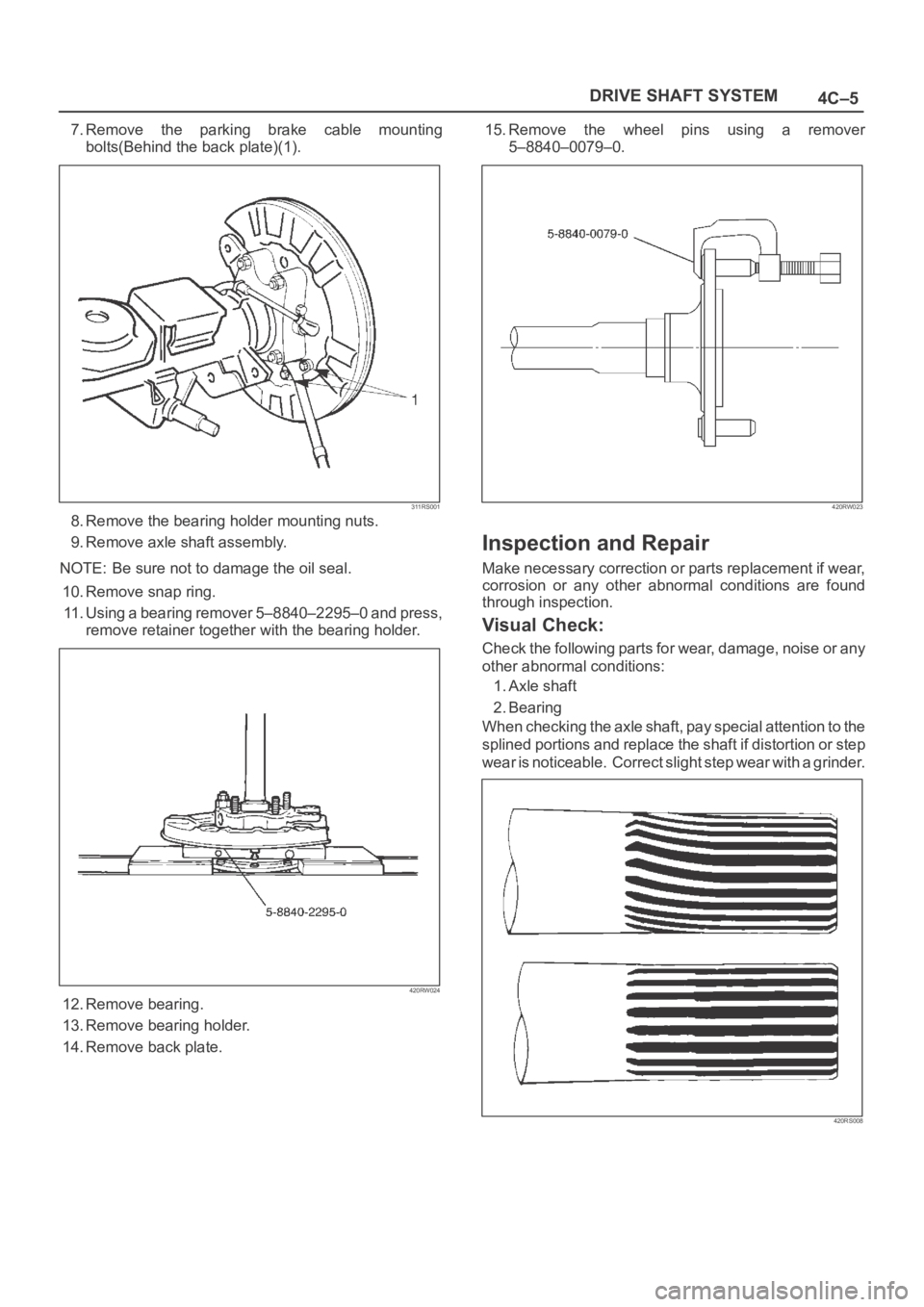

7.Remove the parking brake cable mounting

bolts(Behind the back plate)(1).

311RS001

8. Remove the bearing holder mounting nuts.

9. Remove axle shaft assembly.

NOTE: Be sure not to damage the oil seal.

10. Remove snap ring.

11. Using a bearing remover 5–8840–2295–0 and press,

remove retainer together with the bearing holder.

420RW024

12. Remove bearing.

13. Remove bearing holder.

14. Remove back plate.15. Remove the wheel pins using a remover

5–8840–0079–0.

420RW023

Inspection and Repair

Make necessary correction or parts replacement if wear,

corrosion or any other abnormal conditions are found

through inspection.

Visual Check:

Check the following parts for wear, damage, noise or any

other abnormal conditions:

1. Axle shaft

2. Bearing

When checking the axle shaft, pay special attention to the

splined portions and replace the shaft if distortion or step

wear is noticeable. Correct slight step wear with a grinder.

420RS008

Page 676 of 6000

4C–10

DRIVE SHAFT SYSTEM

8. Remove lock washer and lock screw.

9. Use wrench 5–8840–2117–0, remove hub nut.

411RW005

10. Remove hub and disc assembly.

11. Remove ABS sensor ring (If equipped).

12. Remove outer bearing.

13. Remove oil seal.

14. Remove inner bearing.

15. Remove bolt , if necessary, replace the wheel pin in

the following manner.

Apply a scribe mark(1) to disc to hub.

Clamp the hub and disc assembly in a vise, using

protective pads. Remove the 6 disc–to–hub

retaining bolts.

411RS003

Place hub on a suitable work surface and remove

the studs by using a hammer.

411RS004

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

Hub

Hub bearing oil seal

Knuckle spindle

Disc

Caliper

Shift on the fly system parts (Cap, Hub flange, Shim,

Snap ring)

ABS sensor ring (If equipped)

For inspection and servicing of disc caliper and related

parts, refer to Brakes section.

Page 682 of 6000

4C–16

DRIVE SHAFT SYSTEM

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

Hub

Hub bearing, oil seal

Knuckle spindle

Disc

Caliper

Free wheeling hub parts (Clutch, knob, follower,

inner, ring and spring)

ABS sensor ring (if so equipped)

For inspection and servicing of disc caliper, and relative

parts, refer to Brakes section.

Reassembly

1. Install spacer.

Apply about 1 g wheel bearing grease to both face of

spacer.

2. Install ring.

Apply about 3 g wheel bearing grease to inside face

of ring.

3. Install snap ring

Assembly with grease surplus being left unwiped up

as illustrated.

411RW013

Legend

(1) Inner Assembly

(2) Apply Grease

(3) Body

4. Install inner assembly.

Apply grease to splined portion of body.

5. Install snap ring.6. Install X–ring.

Apply wheel bearing grease to hub lock ring and fit it

in knob paying attention to mounting direction.

NOTE: After fitting, make sure that the hub lock ring is not

twisted.

7. Apply wheel bearing grease to ball and spring and fit

them in knob.

8. Install knob.

1. Apply grease to outer circumference of knob and

inner circumference of cover.

2. Align detent ball (1) to a groove cut in the cover.

411RW014

9. Install snap ring.

Turn the smoother face to knob side.

10. Align the end of retaining spring (1) with clutch spring

groove (2) and fit in the spring.

411RW015

Page 691 of 6000

4C–25 DRIVE SHAFT SYSTEM

8. Using snap ring pliers, remove the snap ring (1)

fastening the ball retainer to the center shaft.

412RS013

9. Remove ball retainer, ball guide and bellows.

10. Raise the hooked end of the band (1) with a

screwdriver or equivalent.

412RS014

11. Remove band.

12. Remove bellows.

13. Remove dust seal.

14. Remove BJ shaft assembly.

15. Remove the mounting bracket fixing bolts, and then

remove DOJ case assembly from the axle case.

16. Remove snap ring and bearing.

17. Remove snap ring and oil seal.

18. Remove bracket.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Drive shaft joint assembly

2. DOJ case, ball, ball guide, ball retainer

3. Bellows

4. Bearing

5. Dust seal, oil seal

Bushing Replacement

Remove the bushings using a remover

5–8840–2309–0 and hammer.

412RW051

By using installer and base 5–8840–2309–0, press fit

the bushings into the bracket.

412RW052

Page 708 of 6000

4C–42

DRIVE SHAFT SYSTEM

3. Make sure of proper position for reinstallation by

applying setting marks, then remove spider .

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is

found through inspection.

NOTE: When any part of the journal assembly (spider,

needle roller bearing) requires replacement, be sure to

replace the entire assembly.

Check the following parts for wear, damage, noise or any

other abnormal conditions:

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

5. Constant velocity joint

Outside Diameter of Spider Pin

Standard: 17.00 mm (0.669 in)

Limit: 16.90 mm (0.665 in)

401RS007

Propeller Shaft Run–out

Support the ends of the propeller shaft on V-blocks (2)

and check for run–out by holding the probe of a dial

indicator (1) in contact with the center part of the shaft. If

the amount of run–out is beyond the standard value for

assembly, correct with a bench press or replace the shaft

with a new propeller shaft assembly.

Standard: 0.3 mm (0.012 in)

Limit: 0.5 mm (0.02 in)

401RS027

Play in Splines in Normal Direction of

Rotation

Check the amount of play between the sleeve yoke (1)

and the propeller shaft spline (2) in the direction of

rotation, using a pointed feeler gauge.

Standard: 0.073 – 0.156 mm (0.003 – 0.006 in)

Limit: 0.3 mm (0.012 in)

401RS009

Page 718 of 6000

4C–52

DRIVE SHAFT SYSTEM

3. Make sure of proper position for reinstallation by

applying setting marks, then remove spider with

grease fitting.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is

found through inspection.

NOTE: When any part of the journal assembly (spider,

needle roller bearing, grease fitting) requires

replacement, be sure to replace the entire assembly.

Check the following parts for wear, damage, noise or any

other abnormal conditions:

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

Outside Diameter of Spider Pin

Standard: 17.00 mm (0.669 in)

Limit: 16.90 mm (0.665 in)

401RS007

Propeller Shaft Run-out

Support the ends of the propeller shaft on V-blocks (2)

and check for run-out by holding the probe of a dial

indicator (1) in contact with the center part of the shaft. If

the amount of run-out is beyond the standard value for

assembly, correct with a bench press or replace the shaft

with a new propeller shaft assembly .

Standard: 0.3 mm (0.012 in)

Limit: 0.5 mm (0.02 in)

401RS008

Play in Splines in Normal Direction of

Rotation

Check the amount of play between the sleeve yoke (1)

and the propeller shaft spline (2) in the direction of

rotation, using a pointed feeler gauge.

Standard: 0.073 – 0.156 mm (0.003 – 0.006 in)

Limit: 0.3 mm (0.012 in)

401RS009

Page 754 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–33

NOTE: Do not reuse the stopper plate. (Shift On The Fly

model)

24. Disassemble the 2WD–4WD clutch hub and sleeve

assembly.

Springs (1) (Shift On The Fly model)

Inserts (2) (Shift On The Fly model)

Clutch Hub (3)

Sleeve (4)

226RW133

25. Use a bench press and the ball bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (4) from front output shaft (5).

262RW071

26. Remove bearing snap ring (29) from transfer case.

27. Remove the counter gear assembly (28) from the

transfer case (1).

28. Use a pair of snap ring pliers to remove the snap ring

(20).29. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (21).

30. Use a pair of snap ring pliers to remove the snap ring

(27).

31. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (26).

226RW191

32. Remove the spacer (25).

33. Remove the belleville spring (24).

34. Remove the sub–gear (anti–lash plate) (23) from the

counter gear (22).

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2. Wash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign

material are removed from the surfaces of every part.

Apply compressed air to each oil feed port and

channel in each case half to remove any obstructions

or cleaning solvent residue.

Gears

1. Inspect all the gear teeth for signs of excessive wear

or damage and check all the gear splines for burrs,

nicks, wear or damage. Remove the minor nicks or

scratches on an oil stone. Replace any part exhibiting

excessive wear or damage.

Front Output Gear Inside Diameter

1. Use an inside dial indicator to measure the gear inside

diameter.