fuel consumption OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 971 of 6000

6A–15

ENGINE MECHANICAL

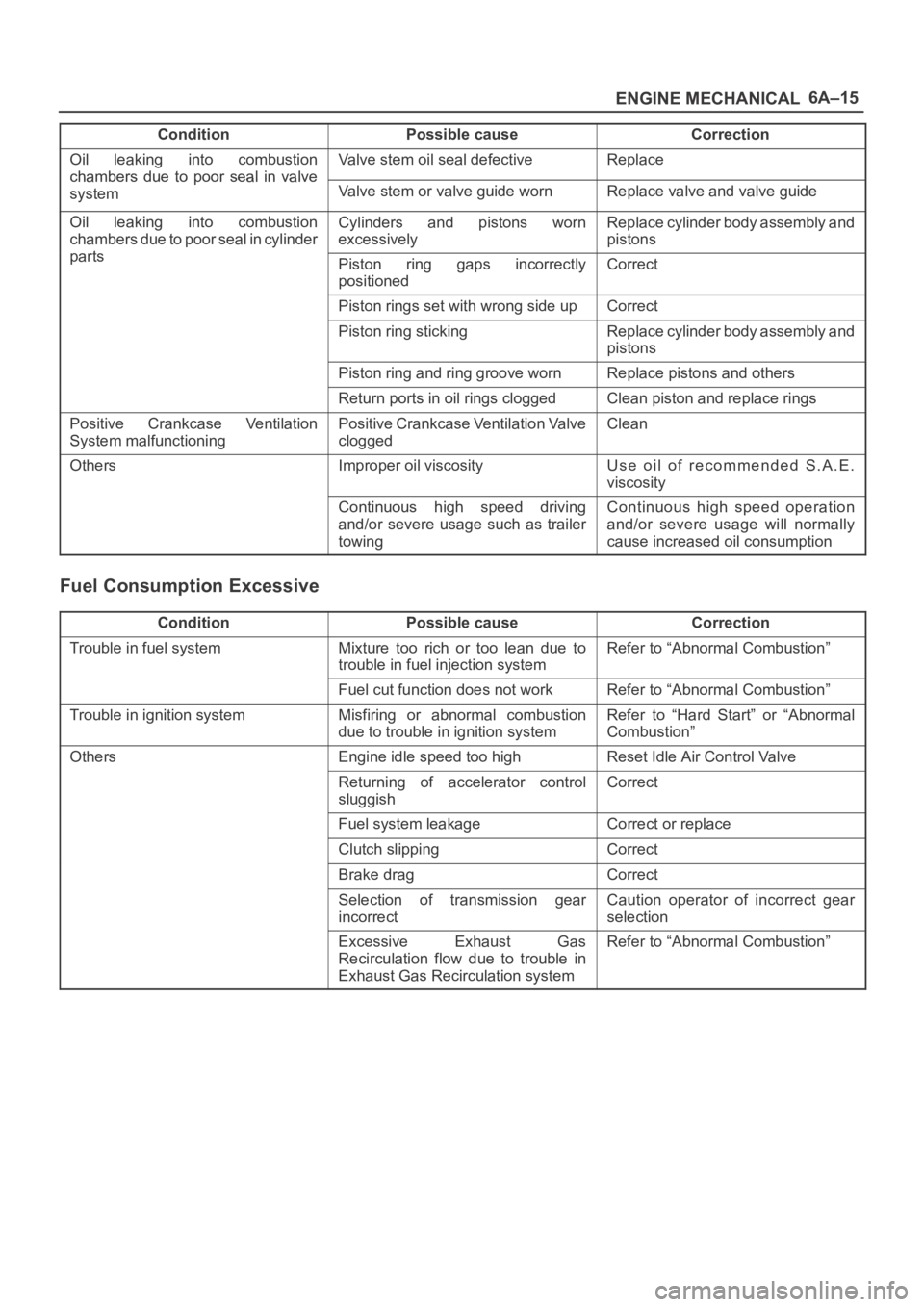

Condition CorrectionPossible cause

Oil leaking into combustion

chambers due topoor seal in valve

Valve stem oil seal defectiveReplace

chambers due to oor seal in valve

systemValve stem or valve guide wornReplace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in cylinder

t

Cylinders and pistons worn

excessivelyReplace cylinder body assembly and

pistons

partsPiston ring gaps incorrectly

positionedCorrect

Piston rings set with wrong side upCorrect

Piston ring stickingReplace cylinder body assembly and

pistons

Piston ring and ring groove wornReplace pistons and others

Return ports in oil rings cloggedClean piston and replace rings

Positive Crankcase Ventilation

System malfunctioningPositive Crankcase Ventilation Valve

cloggedClean

OthersImproper oil viscosityUse oil of recommended S.A.E.

viscosity

Continuous high speed driving

and/or severe usage such as trailer

towingContinuous high speed operation

and/or severe usage will normally

cause increased oil consumption

Fuel Consumption Excessive

ConditionPossible causeCorrection

Trouble in fuel systemMixture too rich or too lean due to

trouble in fuel injection systemRefer to “Abnormal Combustion”

Fuel cut function does not workRefer to “Abnormal Combustion”

Trouble in ignition systemMisfiring or abnormal combustion

due to trouble in ignition systemRefer to “Hard Start” or “Abnormal

Combustion”

OthersEngine idle speed too highReset Idle Air Control Valve

Returning of accelerator control

sluggishCorrect

Fuel system leakageCorrect or replace

Clutch slippingCorrect

Brake dragCorrect

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Excessive Exhaust Gas

Recirculation flow due to trouble in

Exhaust Gas Recirculation systemRefer to “Abnormal Combustion”

Page 1360 of 6000

6E–243 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepNo Ye s Va l u e ( s ) Action

12Check for leaks at the exhaust manifold.

Are there leaks at the exhaust manifold?

—Go to Step 13Go to Step 14

13Tighten the bolts to specifications or replace the

manifold if necessary.

Is your action complete?

—Go to Step 2—

14Visually/physically inspect the following items:

Ensure that the Bank 2 HO2S 1 is securely

installed.

Check for corrosion on terminals.

Check terminal tension (at Bank 2 HO2S 1 and at

the PCM).

Check for damaged wiring.

Was a problem found in any of the above areas?

—Go to Step 18Go to Step 15

151. Disconnect Bank 1 HO2S 1.

2. Ignition “ON.”

3. Using a DVM at the PCM side of the HO2S 1

connector, measure the voltage between the high

signal circuit and ground.

Also measure the voltage between the low signal

circuit and ground.

Are both voltages in the specified range?

3-4 V

Go to Step

16

Go to Step 19

161. With Bank 1 HO2S 1 disconnected, jumper the high

and low (PCM side) signal circuits to ground.

2. Ignition “ON.”

3. Using Tech 2, monitor the Bank 2 HO2S 1 voltage.

Does the scan too indicate less than 10 mV and

immediately return to about 450 mV when the jumper is

removed?

—Go to Step 21Go to Step 22

17Replace affected heated oxygen sensors.

NOTE: Before replacing sensors, the cause of the

contamination must be determined and corrected.

Fuel contamination.

Use of improper RTV sealant.

Engine oil/coolant consumption.

Is the action complete?

—Verify repair—

18Repair condition as necessary.

Is the action complete?

—Verify repair—

19Check for faulty PCM connections or terminal damage.

Is the action complete?

—Verify repairGo to Step 20

20Repair open, short or grounded signal circuit.

Is the action complete?

—Verify repair—

Page 2247 of 6000

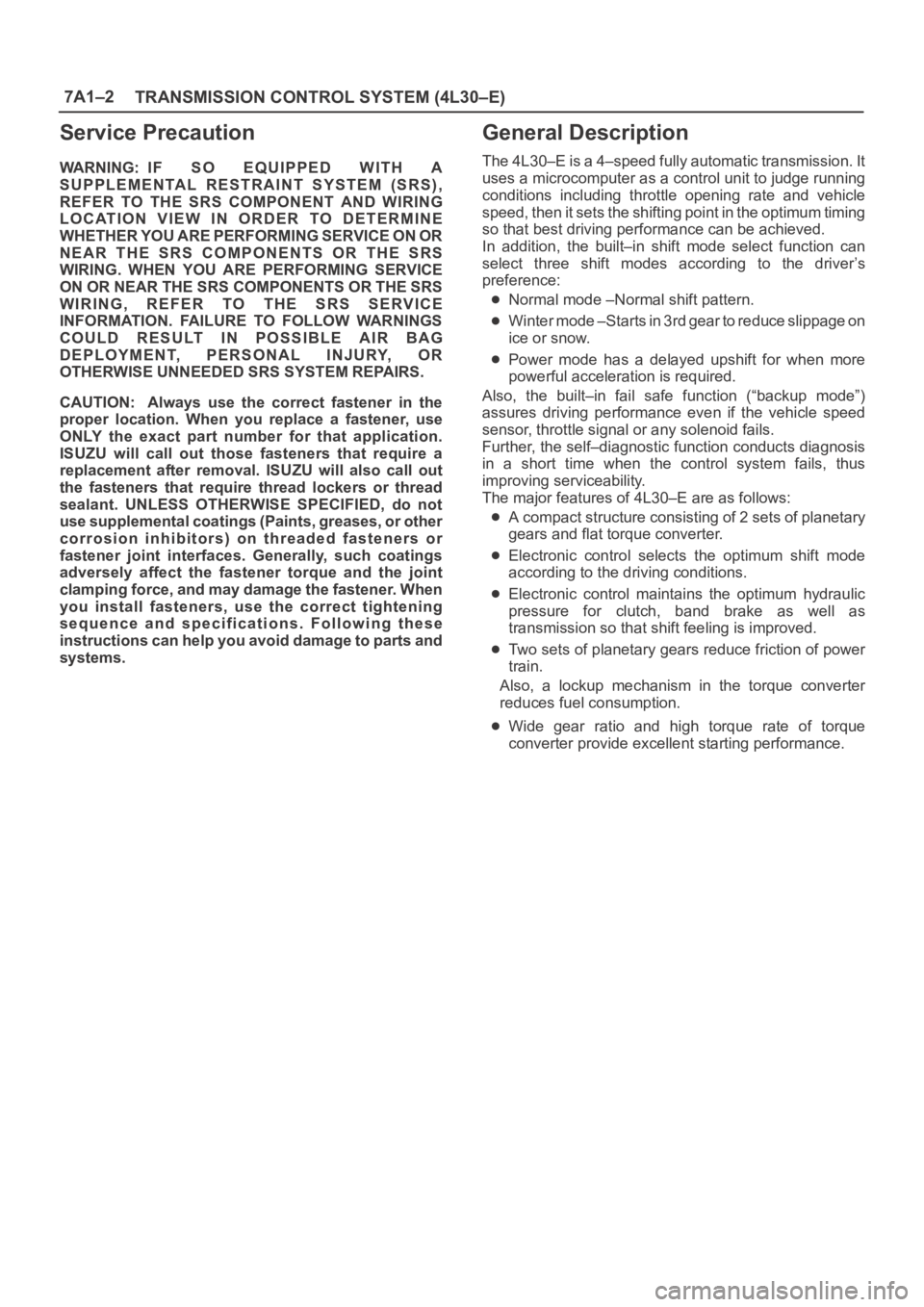

7A1–2

TRANSMISSION CONTROL SYSTEM (4L30–E)

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The 4L30–E is a 4–speed fully automatic transmission. It

uses a microcomputer as a control unit to judge running

conditions including throttle opening rate and vehicle

speed, then it sets the shifting point in the optimum timing

so that best driving performance can be achieved.

In addition, the built–in shift mode select function can

select three shift modes according to the driver’s

preference:

Normal mode –Normal shift pattern.

Winter mode –Starts in 3rd gear to reduce slippage on

ice or snow.

Power mode has a delayed upshift for when more

powerful acceleration is required.

Also, the built–in fail safe function (“backup mode”)

assures driving performance even if the vehicle speed

sensor, throttle signal or any solenoid fails.

Further, the self–diagnostic function conducts diagnosis

in a short time when the control system fails, thus

improving serviceability.

The major features of 4L30–E are as follows:

A compact structure consisting of 2 sets of planetary

gears and flat torque converter.

Electronic control selects the optimum shift mode

according to the driving conditions.

Electronic control maintains the optimum hydraulic

pressure for clutch, band brake as well as

transmission so that shift feeling is improved.

Two sets of planetary gears reduce friction of power

train.

Also, a lockup mechanism in the torque converter

reduces fuel consumption.

Wide gear ratio and high torque rate of torque

converter provide excellent starting performance.

Page 4511 of 6000

6A–15

ENGINE MECHANICAL

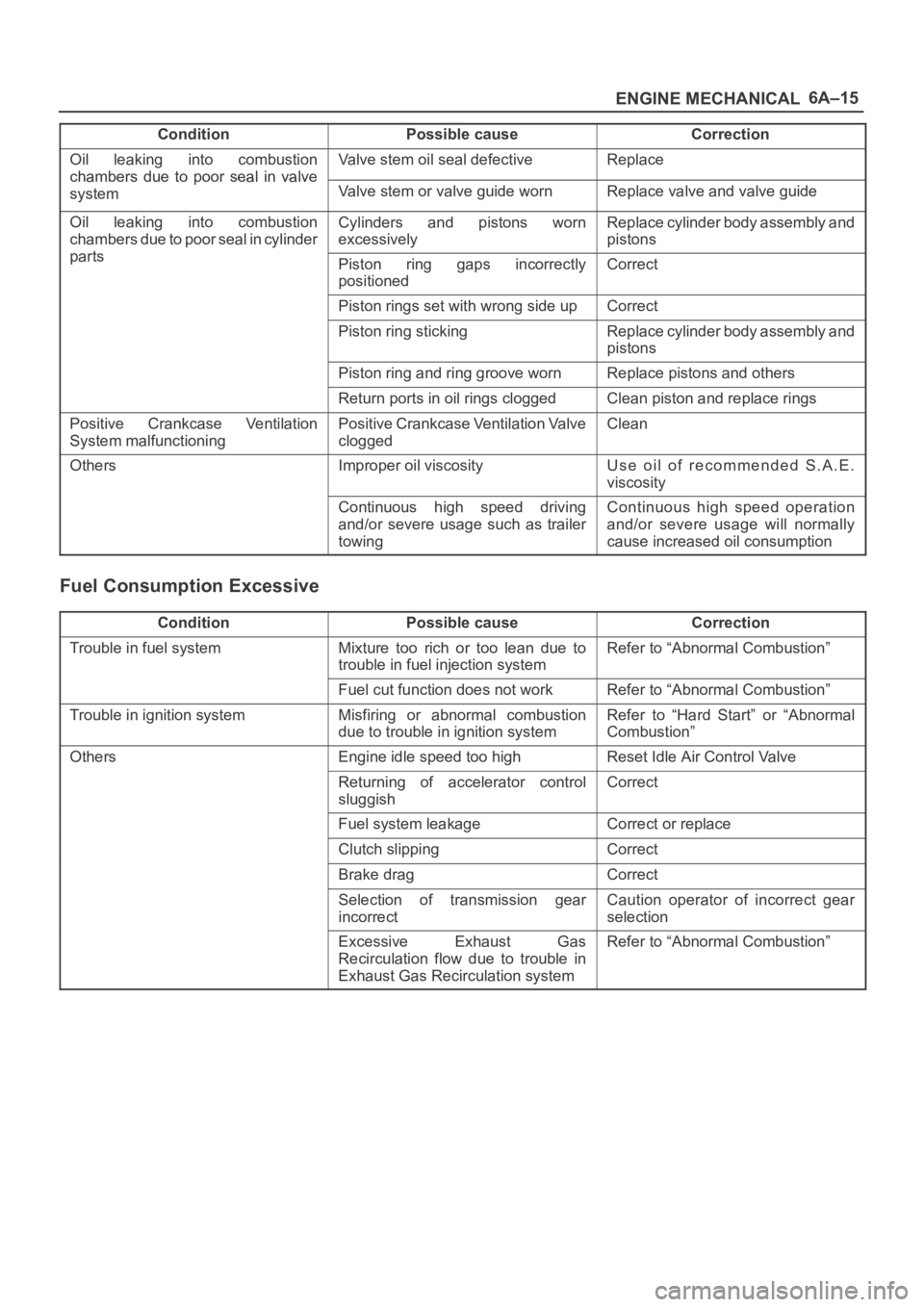

Condition CorrectionPossible cause

Oil leaking into combustion

chambers due topoor seal in valve

Valve stem oil seal defectiveReplace

chambers due to oor seal in valve

systemValve stem or valve guide wornReplace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in cylinder

t

Cylinders and pistons worn

excessivelyReplace cylinder body assembly and

pistons

partsPiston ring gaps incorrectly

positionedCorrect

Piston rings set with wrong side upCorrect

Piston ring stickingReplace cylinder body assembly and

pistons

Piston ring and ring groove wornReplace pistons and others

Return ports in oil rings cloggedClean piston and replace rings

Positive Crankcase Ventilation

System malfunctioningPositive Crankcase Ventilation Valve

cloggedClean

OthersImproper oil viscosityUse oil of recommended S.A.E.

viscosity

Continuous high speed driving

and/or severe usage such as trailer

towingContinuous high speed operation

and/or severe usage will normally

cause increased oil consumption

Fuel Consumption Excessive

ConditionPossible causeCorrection

Trouble in fuel systemMixture too rich or too lean due to

trouble in fuel injection systemRefer to “Abnormal Combustion”

Fuel cut function does not workRefer to “Abnormal Combustion”

Trouble in ignition systemMisfiring or abnormal combustion

due to trouble in ignition systemRefer to “Hard Start” or “Abnormal

Combustion”

OthersEngine idle speed too highReset Idle Air Control Valve

Returning of accelerator control

sluggishCorrect

Fuel system leakageCorrect or replace

Clutch slippingCorrect

Brake dragCorrect

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Excessive Exhaust Gas

Recirculation flow due to trouble in

Exhaust Gas Recirculation systemRefer to “Abnormal Combustion”

Page 4900 of 6000

6E–243 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepNo Ye s Va l u e ( s ) Action

12Check for leaks at the exhaust manifold.

Are there leaks at the exhaust manifold?

—Go to Step 13Go to Step 14

13Tighten the bolts to specifications or replace the

manifold if necessary.

Is your action complete?

—Go to Step 2—

14Visually/physically inspect the following items:

Ensure that the Bank 2 HO2S 1 is securely

installed.

Check for corrosion on terminals.

Check terminal tension (at Bank 2 HO2S 1 and at

the PCM).

Check for damaged wiring.

Was a problem found in any of the above areas?

—Go to Step 18Go to Step 15

151. Disconnect Bank 1 HO2S 1.

2. Ignition “ON.”

3. Using a DVM at the PCM side of the HO2S 1

connector, measure the voltage between the high

signal circuit and ground.

Also measure the voltage between the low signal

circuit and ground.

Are both voltages in the specified range?

3-4 V

Go to Step

16

Go to Step 19

161. With Bank 1 HO2S 1 disconnected, jumper the high

and low (PCM side) signal circuits to ground.

2. Ignition “ON.”

3. Using Tech 2, monitor the Bank 2 HO2S 1 voltage.

Does the scan too indicate less than 10 mV and

immediately return to about 450 mV when the jumper is

removed?

—Go to Step 21Go to Step 22

17Replace affected heated oxygen sensors.

NOTE: Before replacing sensors, the cause of the

contamination must be determined and corrected.

Fuel contamination.

Use of improper RTV sealant.

Engine oil/coolant consumption.

Is the action complete?

—Verify repair—

18Repair condition as necessary.

Is the action complete?

—Verify repair—

19Check for faulty PCM connections or terminal damage.

Is the action complete?

—Verify repairGo to Step 20

20Repair open, short or grounded signal circuit.

Is the action complete?

—Verify repair—

Page 5821 of 6000

7A–40 AUTOMATIC TRANSMISSION (AW30-40LE)

DTC P0743 (FLASHING CODE 33) TORQUE CONVERTER CLUTCH CONTROL LOCK-UP (ON/

OFF) SOLENOID FA I L U R E ( S L )

D07RY00047Circuit description:

The lock-up solenoid SL of the torque converter clutch

(TCC) controls the lock-up clutch by a signal according to

the lock-up range judgement of the TCM when the

vehicle runs.

This function can improve the fuel consumption to almost

the same extent as the manual transmission. The lock-up

solenoid SL is put into B+ by the TCM, so that the

solenoid is actuated with the result of lock-up.

Fail-safe control:

The TCM controls fail-safe by detecting SL solenoid

fai lu re.

Failure detection:

GND SHORT detection

•When SHORT detection continues for 0.3 sec.

•When SHORT failure detection continues 8 times.

Open detection

•When OPEN detection continues for 0.5 sec.

•When OPEN failure detection continues 8 times.

Contents of control:

At failure detection

• Lock-up control inhibit

• If + B short failure is detected, keeps 1st gear when

the vehicle speed calculated by output revolution

sensor is less than 10km/h to prevent stall.

(Canceled at more than 15km/h)

At failure decision

Executes following items in addition to above control

items at failure detection.

•Stores the failure information in failure-memory.

Conditions of turning “CHECK TRANS” lamp off:

NoneReversion conditions from fail-safe:

When a normal condition is judged by rechecking on the

state of lock-up ON/OFF

Test description:

The following numbers correspond to circled numbers on

the diagnostic char t.

(1) When the key is ON, the voltage between the TCM

connector terminals (C78-12) and (C78-15 or 19) is

1.0 V or less.

(2) When the gear is of the 2nd speed in the D range

and the throttle opening is about 50% at a higher

speed than about 40km/h, the TCM supplies 8 to 16

V, so that the solenoid is actuated with the result of

lock-up.

(3) The resistance range of the solenoid is 11 to 15

.

Diagnostic aids:

In case of faulty connection, open or shorted circuit. to

the TCM terminal (C78-12), DTC P0743 is displayed. A

intermittent failure may be caused by a poor connection,

rubbed through wire insulation or a wire broke inside the

insulation.

Page 5995 of 6000

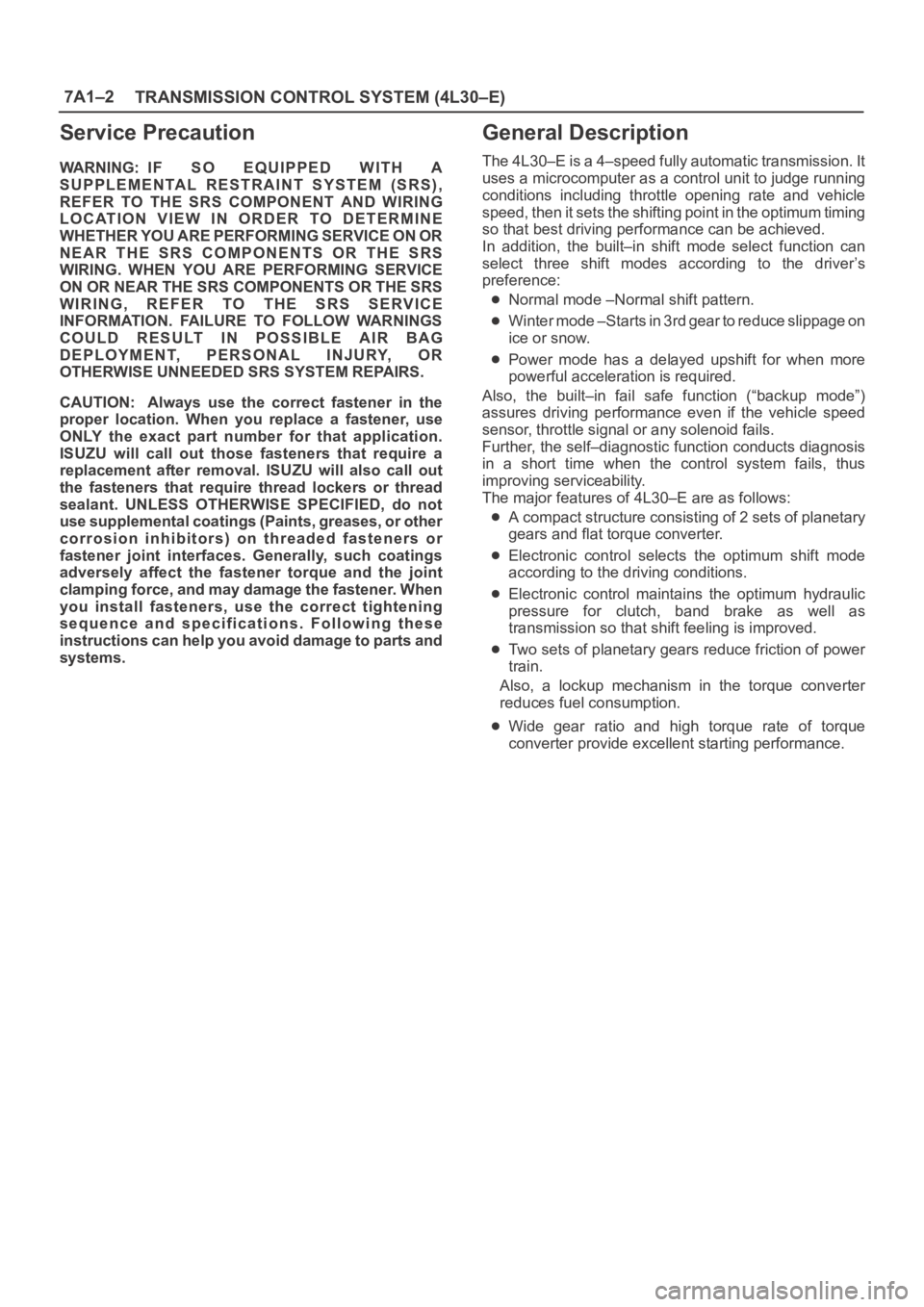

7A1–2

TRANSMISSION CONTROL SYSTEM (4L30–E)

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The 4L30–E is a 4–speed fully automatic transmission. It

uses a microcomputer as a control unit to judge running

conditions including throttle opening rate and vehicle

speed, then it sets the shifting point in the optimum timing

so that best driving performance can be achieved.

In addition, the built–in shift mode select function can

select three shift modes according to the driver’s

preference:

Normal mode –Normal shift pattern.

Winter mode –Starts in 3rd gear to reduce slippage on

ice or snow.

Power mode has a delayed upshift for when more

powerful acceleration is required.

Also, the built–in fail safe function (“backup mode”)

assures driving performance even if the vehicle speed

sensor, throttle signal or any solenoid fails.

Further, the self–diagnostic function conducts diagnosis

in a short time when the control system fails, thus

improving serviceability.

The major features of 4L30–E are as follows:

A compact structure consisting of 2 sets of planetary

gears and flat torque converter.

Electronic control selects the optimum shift mode

according to the driving conditions.

Electronic control maintains the optimum hydraulic

pressure for clutch, band brake as well as

transmission so that shift feeling is improved.

Two sets of planetary gears reduce friction of power

train.

Also, a lockup mechanism in the torque converter

reduces fuel consumption.

Wide gear ratio and high torque rate of torque

converter provide excellent starting performance.