maintenance OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3 of 6000

PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

0A General Information

0B Maintenance and Lubrication

HOME

0A

0B

Page 586 of 6000

4B2–15 DRIVE LINE CONTROL SYSTEM (TOD)

7. Slowly start the vehicle in the 4L mode, and

accelerate to at least 20 km/h. Apply the brake to

completely stop the vehicle.

If the CHECK lamp starts blinking during the test run, read

the trouble codes and give appropriate maintenance

according to the fault diagnostic procedure. If the TOD

indicator lamps are lit abnormally during the run, check

the lighting condition and give appropriate maintenance

according to the fault diagnostic procedure. Even if the

phenomena are not observed, try to reproduce the

abnormal state reported by the customer to the possible

extent.

Post-Repair Check

As long as the starter is not turned off, the TOD indicator

lamps continue blinking even after the failed control unit is

repaired. Therefore, upon completion of repair, be sure to

turn off the starter switch once and then turn on it to

conduct the test run sequence specified in steps 1

through 6 above and check that the TOD indicator lamps

no longer show any faulty status.

Page 668 of 6000

4C–2

DRIVE SHAFT SYSTEM

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV) drive

shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint, refer

to Front/Rear Propeller Shaft in this section.

Page 972 of 6000

6A–16

ENGINE MECHANICAL

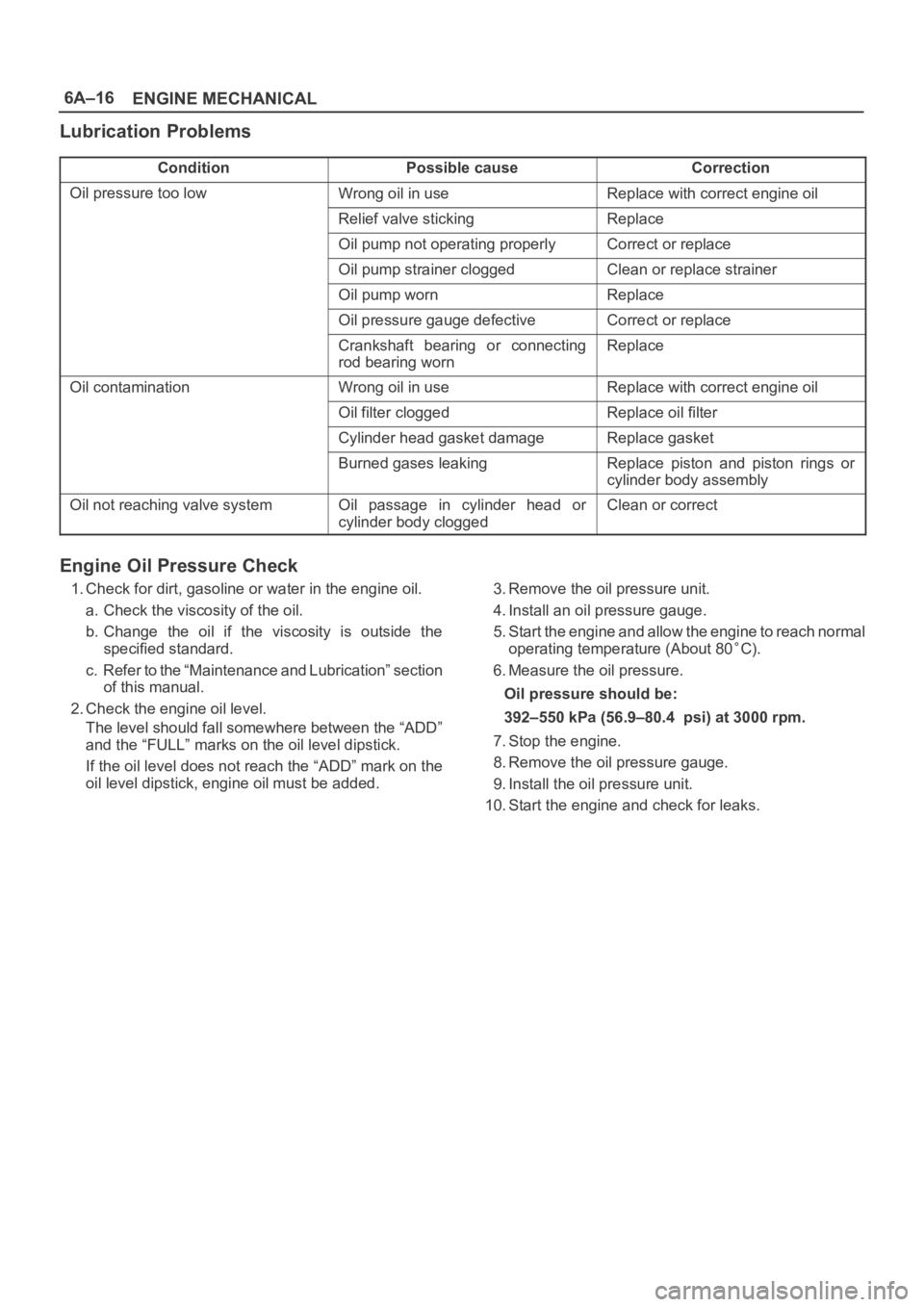

Lubrication Problems

ConditionPossible causeCorrection

Oil pressure too lowWrong oil in useReplace with correct engine oil

Relief valve stickingReplace

Oil pump not operating properlyCorrect or replace

Oil pump strainer cloggedClean or replace strainer

Oil pump wornReplace

Oil pressure gauge defectiveCorrect or replace

Crankshaft bearing or connecting

rod bearing wornReplace

Oil contaminationWrong oil in useReplace with correct engine oil

Oil filter cloggedReplace oil filter

Cylinder head gasket damageReplace gasket

Burned gases leakingReplace piston and piston rings or

cylinder body assembly

Oil not reaching valve systemOil passage in cylinder head or

cylinder body cloggedClean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the

specified standard.

c. Refer to the “Maintenance and Lubrication” section

of this manual.

2. Check the engine oil level.

The level should fall somewhere between the “ADD”

and the “FULL” marks on the oil level dipstick.

If the oil level does not reach the “ADD” mark on the

oil level dipstick, engine oil must be added.3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal

operating temperature (About 80

C).

6. Measure the oil pressure.

Oil pressure should be:

392–550 kPa (56.9–80.4 psi) at 3000 rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

Page 1072 of 6000

6C–5

ENGINE FUEL

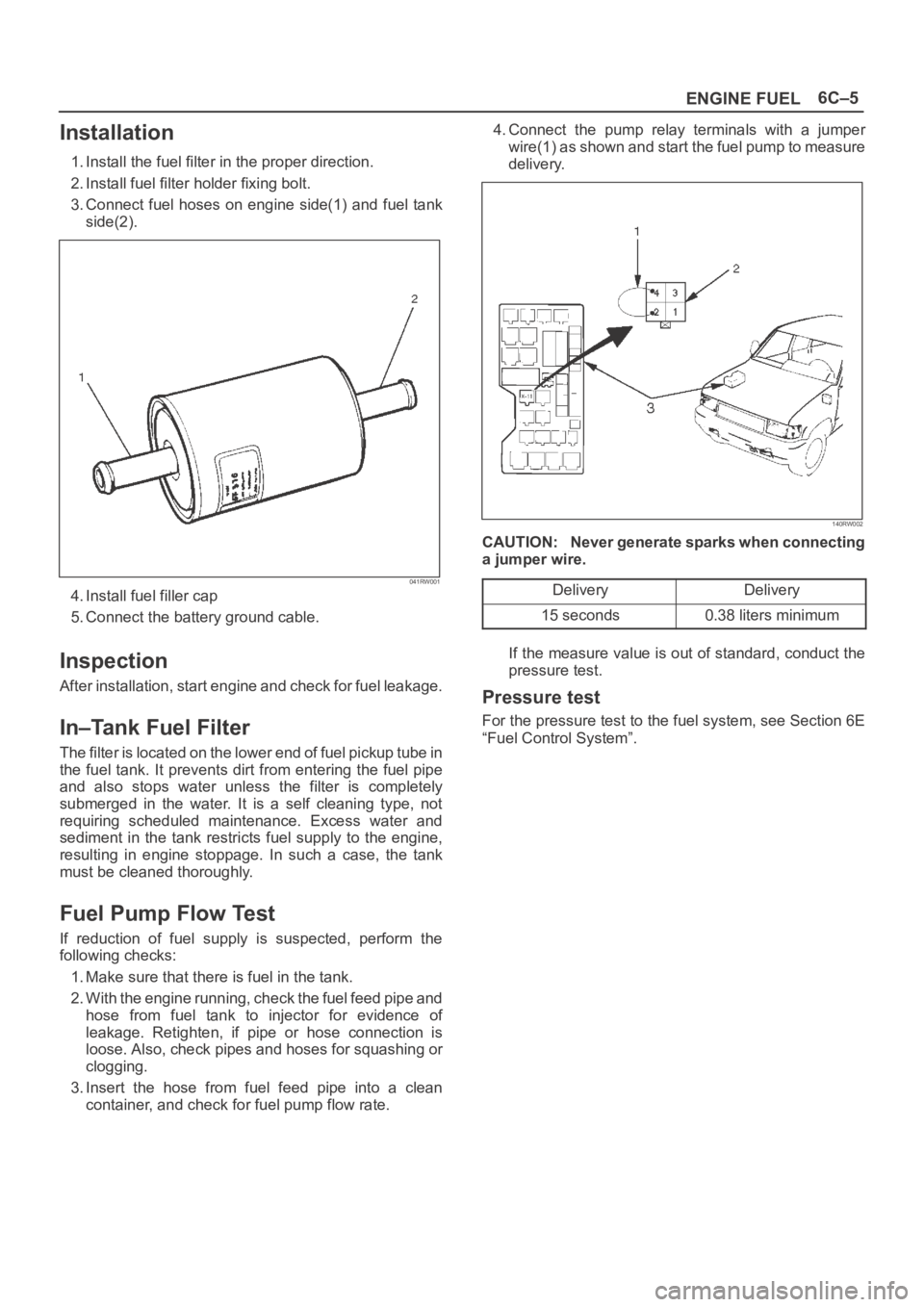

Installation

1. Install the fuel filter in the proper direction.

2. Install fuel filter holder fixing bolt.

3. Connect fuel hoses on engine side(1) and fuel tank

side(2).

041RW001

4. Install fuel filler cap

5. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube in

the fuel tank. It prevents dirt from entering the fuel pipe

and also stops water unless the filter is completely

submerged in the water. It is a self cleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks:

1. Make sure that there is fuel in the tank.

2. With the engine running, check the fuel feed pipe and

hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, check pipes and hoses for squashing or

clogging.

3. Insert the hose from fuel feed pipe into a clean

container, and check for fuel pump flow rate.4. Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to measure

delivery.

140RW002

CAUTION: Never generate sparks when connecting

a jumper wire.

Delivery

Delivery

15 seconds0.38 liters minimum

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

“Fuel Control System”.

Page 1109 of 6000

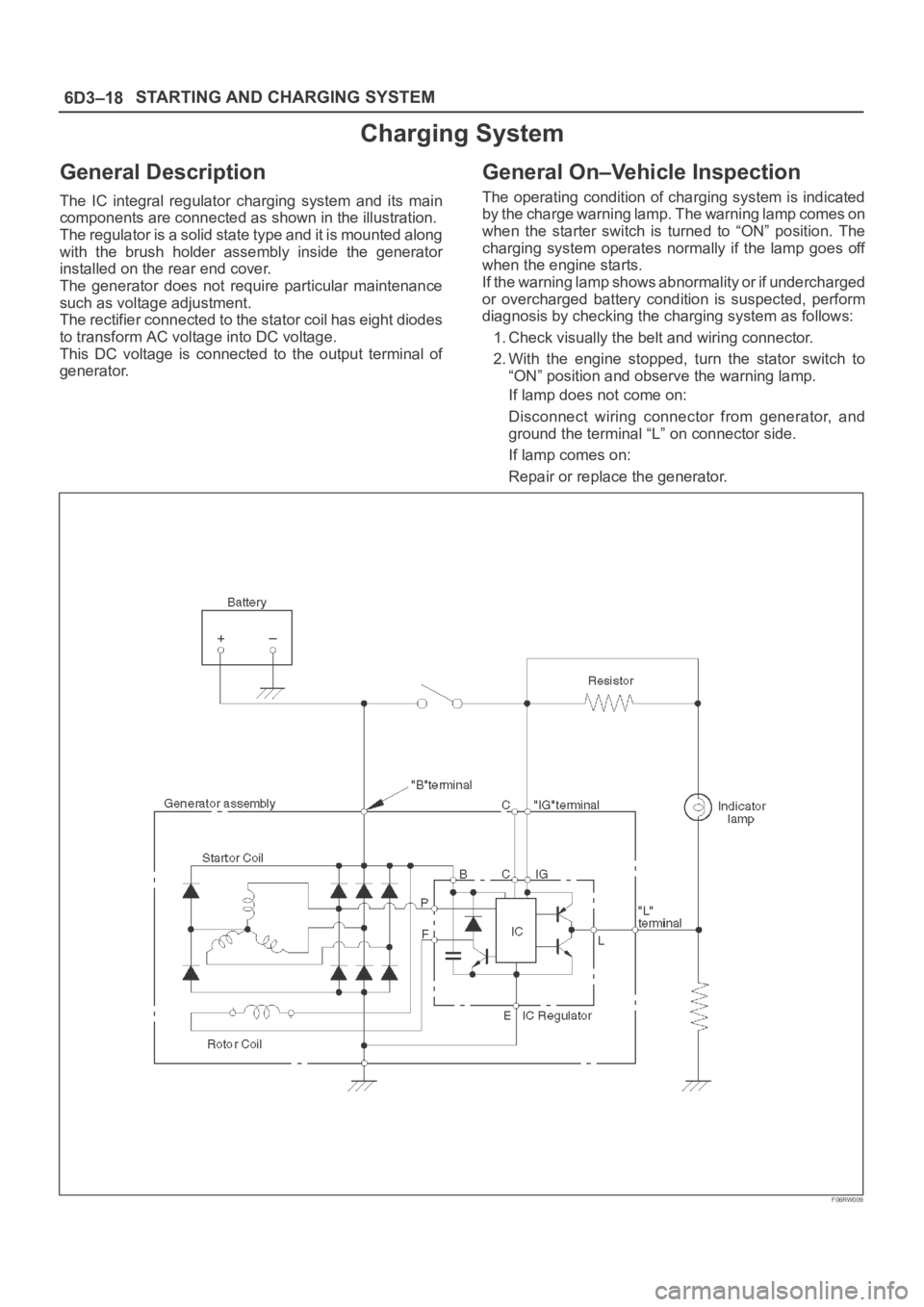

6D3–18STARTING AND CHARGING SYSTEM

Charging System

General Description

The IC integral regulator charging system and its main

components are connected as shown in the illustration.

The regulator is a solid state type and it is mounted along

with the brush holder assembly inside the generator

installed on the rear end cover.

The generator does not require particular maintenance

such as voltage adjustment.

The rectifier connected to the stator coil has eight diodes

to transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

General On–Vehicle Inspection

The operating condition of charging system is indicated

by the charge warning lamp. The warning lamp comes on

when the starter switch is turned to “ON” position. The

charging system operates normally if the lamp goes off

when the engine starts.

If the warning lamp shows abnormality or if undercharged

or overcharged battery condition is suspected, perform

diagnosis by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. With the engine stopped, turn the stator switch to

“ON” position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and

ground the terminal “L” on connector side.

If lamp comes on:

Repair or replace the generator.

F06RW009

Page 1118 of 6000

6E–1 ENGINE DRIVEABILITY AND EMISSIONS

ENGINE

ENGINE DRIVEABILITY AND EMISSIONS

CONTENTS

Specifications 6E–5. . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–5. . . . . . . . . . . . . . .

Vehicle Type Specifications 6E–5. . . . . . . . . . . . .

Diagrams and Schematics 6E–6. . . . . . . . . . . . . . . .

PCM Wiring Diagram (1 of 11) 6E–6. . . . . . . . . . .

PCM Wiring Diagram (2 of 11) For EC,

THAILAND, SOUTH EAST ASIA, LATIN

AMERICA, GULF, SAUDI, CHINA. 6E–7. . . . . .

PCM Wiring Diagram (3 of 11) For SOUTH

AFRICA and EXP. 6E–8. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (4 of 11) 6E–9. . . . . . . . . . .

PCM Wiring Diagram (5 of 11) 6E–10. . . . . . . . . . .

PCM Wiring Diagram (6 of 11) For

AUSTRALIA, THAILAND, SOUTH EAST

ASIA, LATIN AMERICA, GULF, SAUDI,

LATIN AMERICA. 6E–11. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (7 of 11) For EC. 6E–12. . .

PCM Wiring Diagram (8 of 11) For EXPORT

and SOUTH AFRICA. 6E–13. . . . . . . . . . . . . . . . .

PCM Wiring Diagram (9 of 11) Except EXP

and SOUTH AFRICA 6E–14. . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (10 of 11) For

EXPORT and SOUTH AFRICA 6E–15. . . . . . . . .

PCM Wiring Diagram (11 of 11) 6E–16. . . . . . . . . .

PCM Pinouts 6E–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “A” 6E–17. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “B” 6E–19. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For EC) 6E–20. . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For except EC) 6E–21. . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For except EXPORT and SOUTH

AFRICA) 6E–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For EXPORT and SOUTH AFRICA) 6E–23. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For except EXPORT and SOUTH

AFRICA) 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For EXPORT and SOUTH AFRICA) 6E–26. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “F” 6E–27. . . . . . . . . . . . . . . . . .

Component Locators 6E–28. . . . . . . . . . . . . . . . . . . .

Engine Component Locator (This illustration

is based on RHD model.) 6E–28. . . . . . . . . . . . . . Engine Component Locator Table 6E–29. . . . . . . .

Engine Component Locator Table 6E–31. . . . . . . .

Undercarriage Component Locator 6E–32. . . . . .

Undercarriage Component Locator Table

(Automatic Transmission) 6E–32. . . . . . . . . . . . . .

Undercarriage Component Locator Table

(Manual Transmission) 6E–33. . . . . . . . . . . . . . . .

Fuse and Relay Panel (Underhood

Electrical Center) 6E–33. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

DTC Stored 6E–37

. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–37. . . . . . . . . . . . . . . . .

Intermittents 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–37. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–37. . . . . . . . . . . . . . . .

General Service Information 6E–38. . . . . . . . . . . . . .

OBD Serviceablity Issues 6E–38. . . . . . . . . . . . . . .

Maintenance Schedule 6E–38. . . . . . . . . . . . . . . . .

Visual / Physical Engine Compartment

Inspection 6E–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–38. . . . . .

Serial Data Communications 6E–38. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–38. . . . .

On-Board Diagnostic (OBD) 6E–39. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–39. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–39. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–40. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–40. . . . . . . . . . . . . . .

DTC Types 6E–41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–42. . . . . . . . . . . . . . . .

Reading Diagnostic Trouble Codes Using

A Tech 2 6E–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Tech 2 6E–43. . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Features 6E–43. . . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure (For Example) 6E–44. . . . .

DTC Modes 6E–45. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–46. . . . . . . . . . . . . . . . .

Injector Balance Test 6E–46. . . . . . . . . . . . . . . . . . .

EGR Control Test 6E–47. . . . . . . . . . . . . . . . . . . . . .

Idle Air Control System Test 6E–48. . . . . . . . . . . . .

Page 1155 of 6000

6E–38

ENGINE DRIVEABILITY AND EMISSIONS

General Service Information

OBD Serviceablity Issues

The list of non-vehicle faults that could affect the

performance of the OBD system has been compiled.

These non-vehicle faults vary from environmental

conditions to the quality of fuel used.

The illumination of the MIL (“Check Engine” lamp) due to

a non-vehicle fault could lead to misdiagnosis of the

vehicle, increased warranty expense and customer

dissatisfaction. The following list of non-vehicle faults

does not include every possible fault and may not apply

equally to all product lines.

Fuel Quality

Using fuel with the wrong octane rating for your vehicle

may cause driveability problems. Many of the major fuel

companies advertise that using “premium” gasoline will

improve the performance of your vehicle. Most premium

fuels use alcohol to increase the octane rating of the fuel.

Although alcohol-enhanced fuels may raise the octane

rating, the fuel’s ability to turn into vapor in cold

temperatures deteriorates. This may affect the starting

ability and cold driveability of the engine.

Low fuel levels can lead to fuel starvation, lean engine

operation, and eventually engine misfire.

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Something as simple as a

high-performance exhaust system that affects exhaust

system back pressure could potentially interfere with the

operation of the EGR valve and thereby turn on the MIL

(“Check Engine” lamp). Small leaks in the exhaust

system near the post catalyst oxygen sensor can also

cause the MIL (“Check Engine” lamp) to turn on.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the MIL (“Check

Engine” lamp).

Environment

Temporary environmental conditions, such as localized

flooding, will have an effect on the vehicle ignition system.

If the ignition system is rain-soaked, it can temporarily

cause engine misfire and turn on the MIL (“Check Engine”

lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lamp) to turn on if the vehicle is not

maintained properly. Restricted air filters, fuel filters, and

crankcase deposits due to lack of oil changes or improper

oil viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics, vehicle

maintenance schedules must be more closely followed.Related System Faults

Many of the OBD system diagnostics will not run if the

PCM detects a fault on a related system or component.

One example would be that if the PCM detected a Misfire

fault, the diagnostics on the catalytic converter would be

suspended until Misfire fault was repaired. If the Misfire

fault was severe enough, the catalytic converter could be

damaged due to overheating and would never set a

Catalyst DTC until the Misfire fault was repaired and the

Catalyst diagnostic was allowed to run to completion. If

this happens, the customer may have to make two trips to

the dealership in order to repair the vehicle.

Maintenance Schedule

Refer to the Maintenance Schedule.

Visual / Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any diagnostic

procedure or diagnosing the cause of an emission test

failure. This can often lead to repairing a problem without

further steps. Use the following guidelines when

performing a visual/physical inspection:

Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

Inspect hoses that are difficult to see behind other

components.

Inspect all wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires,

contact with sharp edges or contact with hot exhaust

manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in an

incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-

tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.

Each bit of information can have one of two lengths: long

or short. This allows vehicle wiring to be reduced by

transmitting and receiving multiple signals over a single

wire. The messages carried on Class II data streams are

also prioritized. If two messages attempt to establish

communications on the data line at the same time, only

the message with higher priority will continue. The device

with the lower priority message must wait. The most

significant result of this regulation is that it provides Tech 2

manufacturers with the capability to access data from any

make or model vehicle that is sold.

Page 1462 of 6000

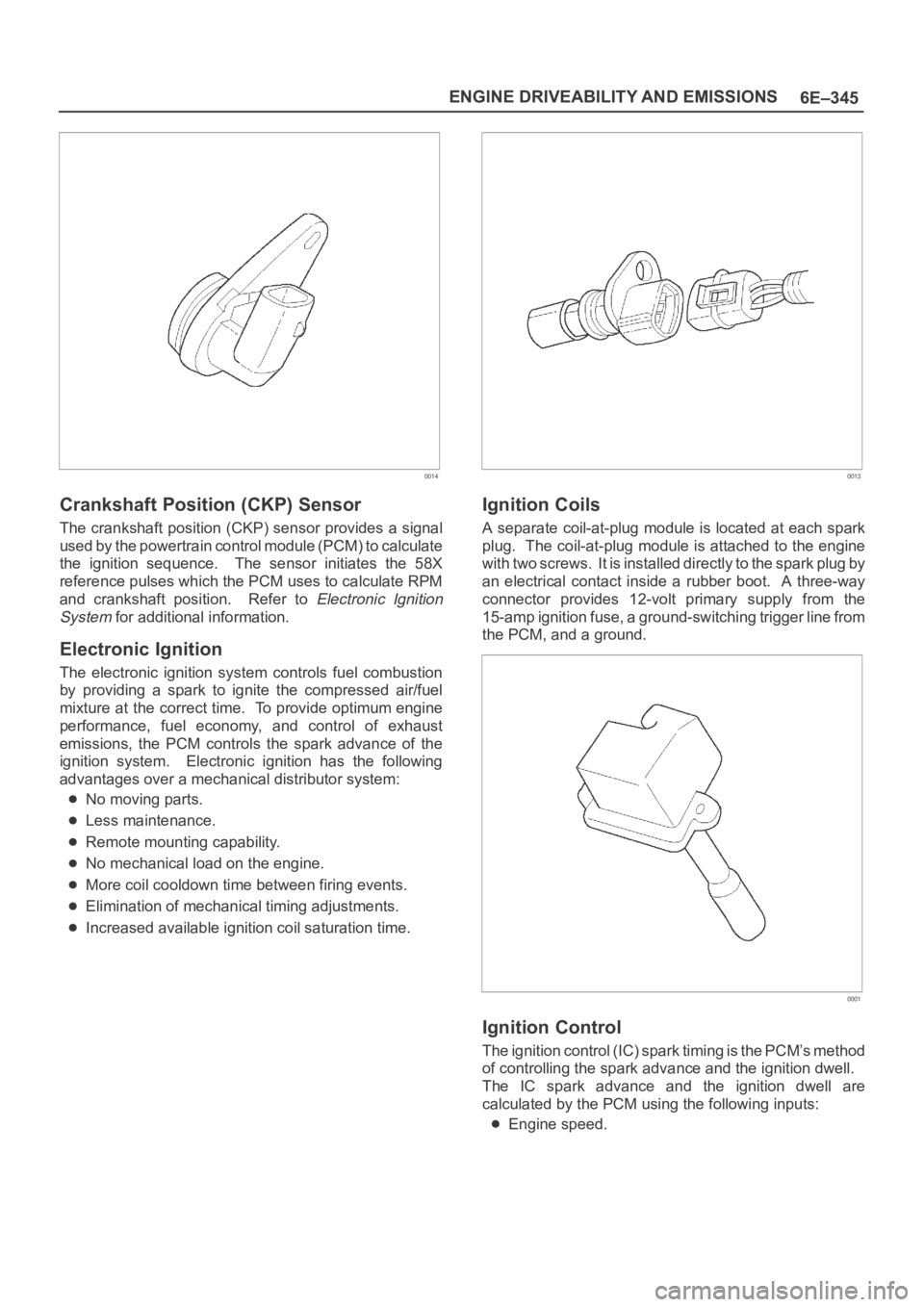

6E–345 ENGINE DRIVEABILITY AND EMISSIONS

0014

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor provides a signal

used by the powertrain control module (PCM) to calculate

the ignition sequence. The sensor initiates the 58X

reference pulses which the PCM uses to calculate RPM

and crankshaft position. Refer to

Electronic Ignition

System

for additional information.

Electronic Ignition

The electronic ignition system controls fuel combustion

by providing a spark to ignite the compressed air/fuel

mixture at the correct time. To provide optimum engine

performance, fuel economy, and control of exhaust

emissions, the PCM controls the spark advance of the

ignition system. Electronic ignition has the following

advantages over a mechanical distributor system:

No moving parts.

Less maintenance.

Remote mounting capability.

No mechanical load on the engine.

More coil cooldown time between firing events.

Elimination of mechanical timing adjustments.

Increased available ignition coil saturation time.

0013

Ignition Coils

A separate coil-at-plug module is located at each spark

plug. The coil-at-plug module is attached to the engine

with two screws. It is installed directly to the spark plug by

an electrical contact inside a rubber boot. A three-way

connector provides 12-volt primary supply from the

15-amp ignition fuse, a ground-switching trigger line from

the PCM, and a ground.

0001

Ignition Control

The ignition control (IC) spark timing is the PCM’s method

of controlling the spark advance and the ignition dwell.

The IC spark advance and the ignition dwell are

calculated by the PCM using the following inputs:

Engine speed.

Page 1464 of 6000

6E–347 ENGINE DRIVEABILITY AND EMISSIONS

the secondary ignition circuit to flow through the spark

plug to the ground.

TS24047

Ignition Control PCM Output

The PCM provides a zero volt (actually about 100 mV to

200 mV) or a 5-volt output signal to the ignition control (IC)

module. Each spark plug has its own primary and

secondary coil module (”coil-at-plug”) located at the spark

plug itself. When the ignition coil receives the 5-volt signal

from the PCM, it provides a ground path for the B+ supply

to the primary side of the coil-at -plug module. This

energizes the primary coil and creates a magnetic field in

the coil-at-plug module. When the PCM shuts off the

5-volt signal to the ignition control module, the ground

path for the primary coil is broken. The magnetic field

collapses and induces a high voltage secondary impulse

which fires the spark plug and ignites the air/fuel mixture.

The circuit between the PCM and the ignition coil is

monitored for open circuits, shorts to voltage, and shorts

to ground. If the PCM detects one of these events, it will

set one of the following DTCs:

P0351: Ignition coil Fault on Cylinder #1

P0352: Ignition coil Fault on Cylinder #2

P0353: Ignition coil Fault on Cylinder #3

P0354: Ignition coil Fault on Cylinder #4

P0355: Ignition coil Fault on Cylinder #5

P0356: Ignition coil Fault on Cylinder #6

Knock Sensor (KS) PCM Input

The knock sensor (KS) system is comprised of a knock

sensor and the PCM. The PCM monitors the KS signals

to determine when engine detonation occurs. When a

knock sensor detects detonation, the PCM retards the

spark timing to reduce detonation. Timing may also be

retarded because of excessive mechanical engine or

transmission noise.

Powertrain Control Module (PCM)

The PCM is responsible for maintaining proper spark and

fuel injection timing for all driving conditions. To provideoptimum driveability and emissions, the PCM monitors

the input signals from the following components in order

to calculate spark timing:

Engine coolant temperature (ECT) sensor.

Intake air temperature (IAT) sensor.

Mass air flow (MAF) sensor.

PRNDL input from transmission range switch.

Throttle position (TP) sensor.

Vehicle speed sensor (VSS) .

Crankshaft position (CKP) sensor.

Spark Plug

Although worn or dirty spark plugs may give satisfactory

operation at idling speed, they frequency fail at higher

engine speeds. Faulty spark plugs may cause poor fuel

economy, power loss, loss of speed, hard starting and

generally poor engine performance. Follow the

scheduled maintenance service recommendations to

ensure satisfactory spark plug performance. Refer to

Maintenance and Lubrication.

Normal spark plug operation will result in brown to

grayish-tan deposits appearing on the insulator portion of

the spark plug. A small amount of red-brown, yellow, and

white powdery material may also be present on the

insulator tip around the center electrode. These deposits

are normal combustion by-products of fuels and

lubricating oils with additives. Some electrode wear will

also occur. Engines which are not running properly are

often referred to as “misfiring.” This means the ignition

spark is not igniting the air/fuel mixture at the proper time.

While other ignition and fuel system causes must also be

considered, possible causes include ignition system

conditions which allow the spark voltage to reach ground

in some other manner than by jumping across the air gap

at the tip of the spark plug, leaving the air/fuel mixture

unburned. Misfiring may also occur when the tip of the

spark plug becomes overheated and ignites the mixture

before the spark jumps. This is referred to as

“pre-ignition.”

Spark plugs may also misfire due to fouling, excessive

gap, or a cracked or broken insulator. If misfiring occurs

before the recommended replacement interval, locate

and correct the cause.

Carbon fouling of the spark plug is indicated by dry, black

carbon (soot) deposits on the portion of the spark plug in

the cylinder. Excessive idling and slow speeds under

light engine loads can keep the spark plug temperatures

so low that these deposits are not burned off. Very rich

fuel mixtures or poor ignition system output may also be

the cause. Refer to DTC P0172.

Oil fouling of the spark plug is indicated by wet oily

deposits on the portion of the spark plug in the cylinder,

usually with little electrode wear. This may be caused by

oil during break-in of new or newly overhauled engines.

Deposit fouling of the spark plug occurs when the normal

red-brown, yellow or white deposits of combustion by

products become sufficient to cause misfiring. In some

c a s e s , t h e s e d e p o s i t s m a y m e l t a n d f o r m a s h i n y g l a z e o n

the insulator around the center electrode. If the fouling is

found in only one or two cylinders, valve stem clearances

or intake valve seals may be allowing excess lubricating