instrument panel OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 535 of 6000

4B1–2

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Shift on the Fly System (Lever Type)

Outline of Shift on the Fly System

(Lever Type)

The shift on the fly system (Lever type) switches between

2 wheel drive (2WD) and 4 wheel drive (4WD) by driver’s

shifting the transfer control lever on the floor.

This system controls below operations.

1. Connecting front wheels to, and disconnecting them

from, the front axles by vacuum actuator.

2. Indicator on instrument panel.

3. 4WD signal to Electronic Hydraulic Control Unit for

brake system (If anti–lock brake system is equipped).

Page 540 of 6000

4B1–7 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Shift on the Fly System (Push Button Type)

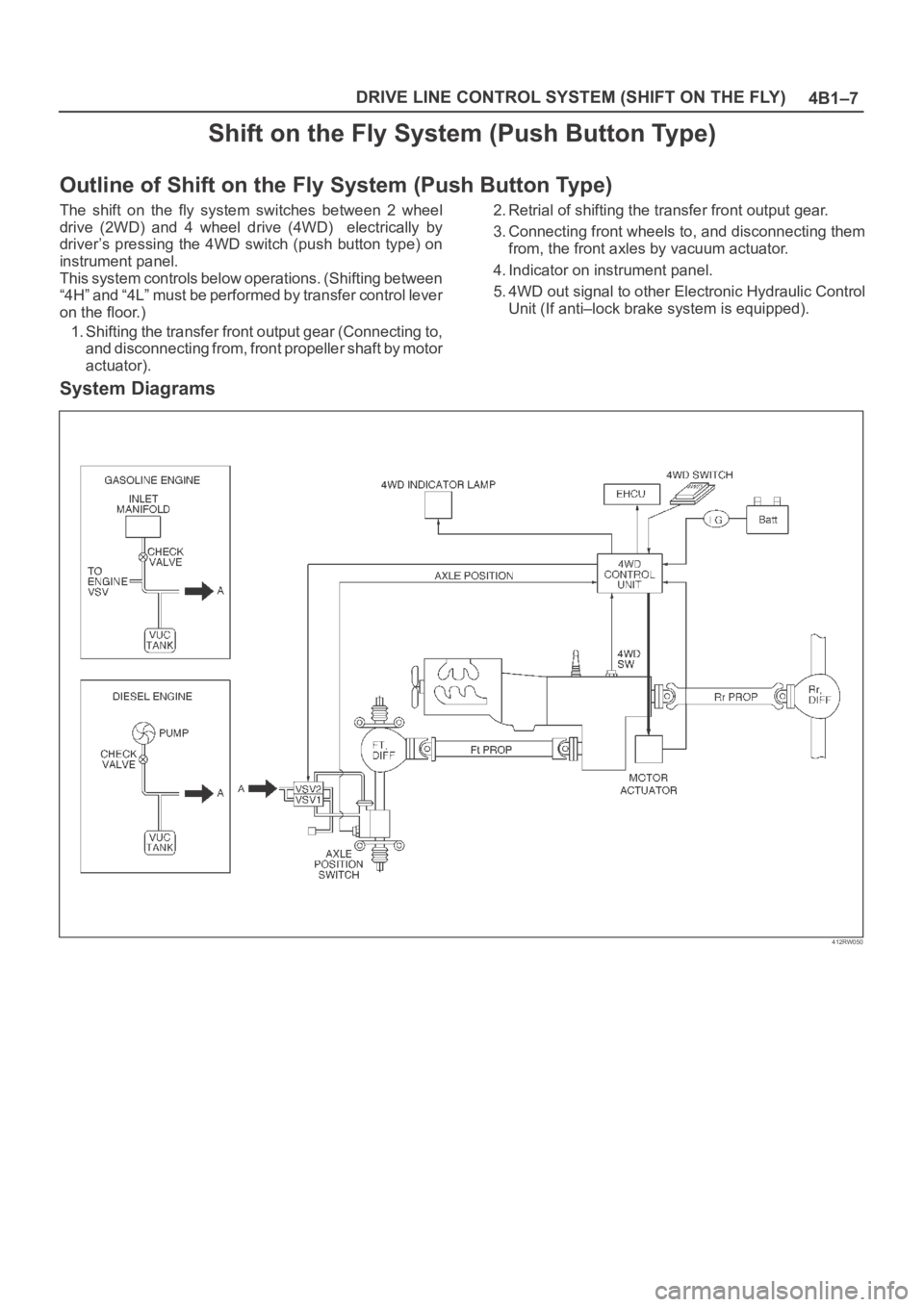

Outline of Shift on the Fly System (Push Button Type)

The shift on the fly system switches between 2 wheel

drive (2WD) and 4 wheel drive (4WD) electrically by

driver’s pressing the 4WD switch (push button type) on

instrument panel.

This system controls below operations. (Shifting between

“4H” and “4L” must be performed by transfer control lever

on the floor.)

1. Shifting the transfer front output gear (Connecting to,

and disconnecting from, front propeller shaft by motor

actuator).2. Retrial of shifting the transfer front output gear.

3. Connecting front wheels to, and disconnecting them

from, the front axles by vacuum actuator.

4. Indicator on instrument panel.

5. 4WD out signal to other Electronic Hydraulic Control

Unit (If anti–lock brake system is equipped).

System Diagrams

412RW050

Page 541 of 6000

4B1–8

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

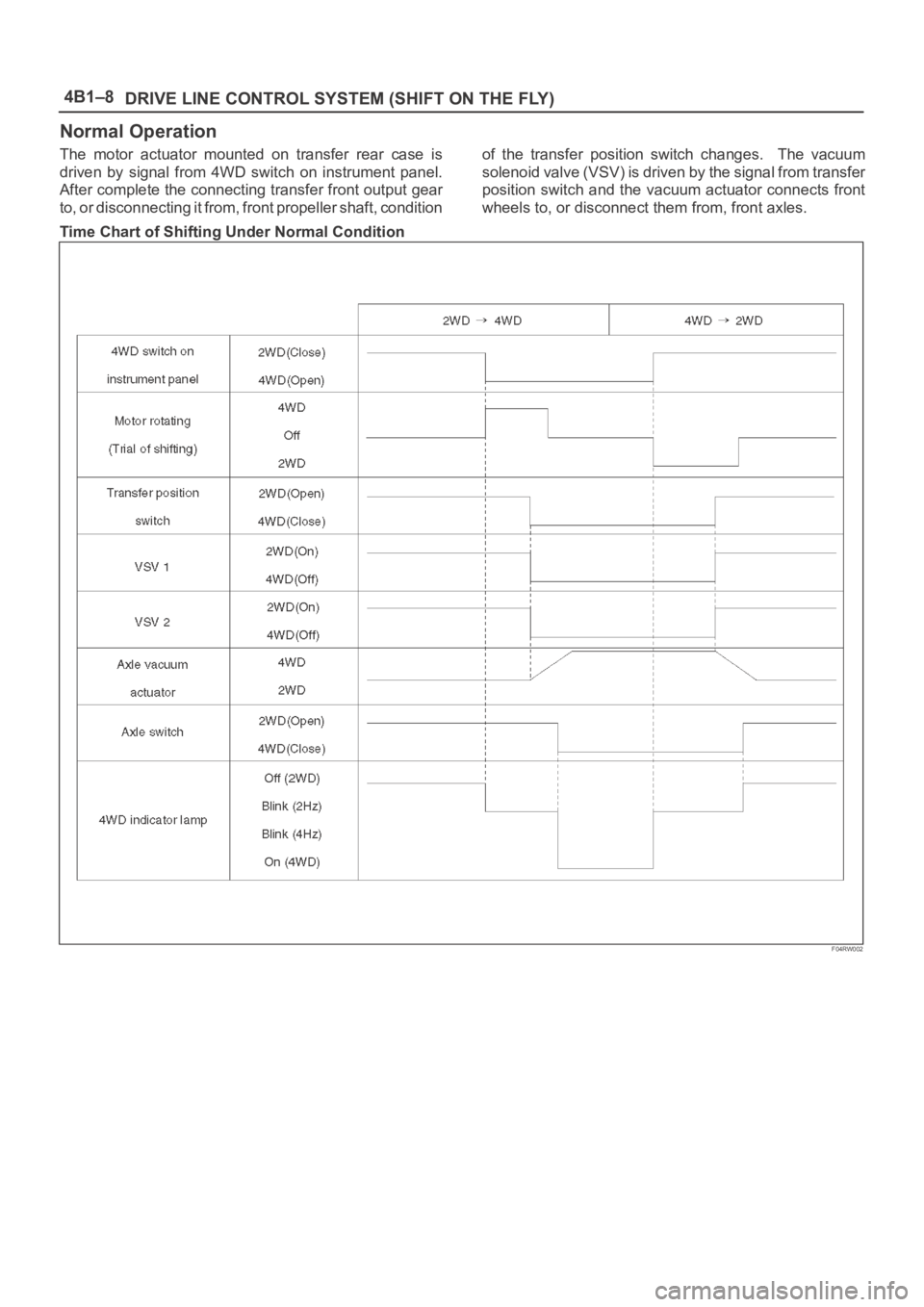

Normal Operation

The motor actuator mounted on transfer rear case is

driven by signal from 4WD switch on instrument panel.

After complete the connecting transfer front output gear

to, or disconnecting it from, front propeller shaft, conditionof the transfer position switch changes. The vacuum

solenoid valve (VSV) is driven by the signal from transfer

position switch and the vacuum actuator connects front

wheels to, or disconnect them from, front axles.

Time Chart of Shifting Under Normal Condition

F04RW002

Page 542 of 6000

4B1–9 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

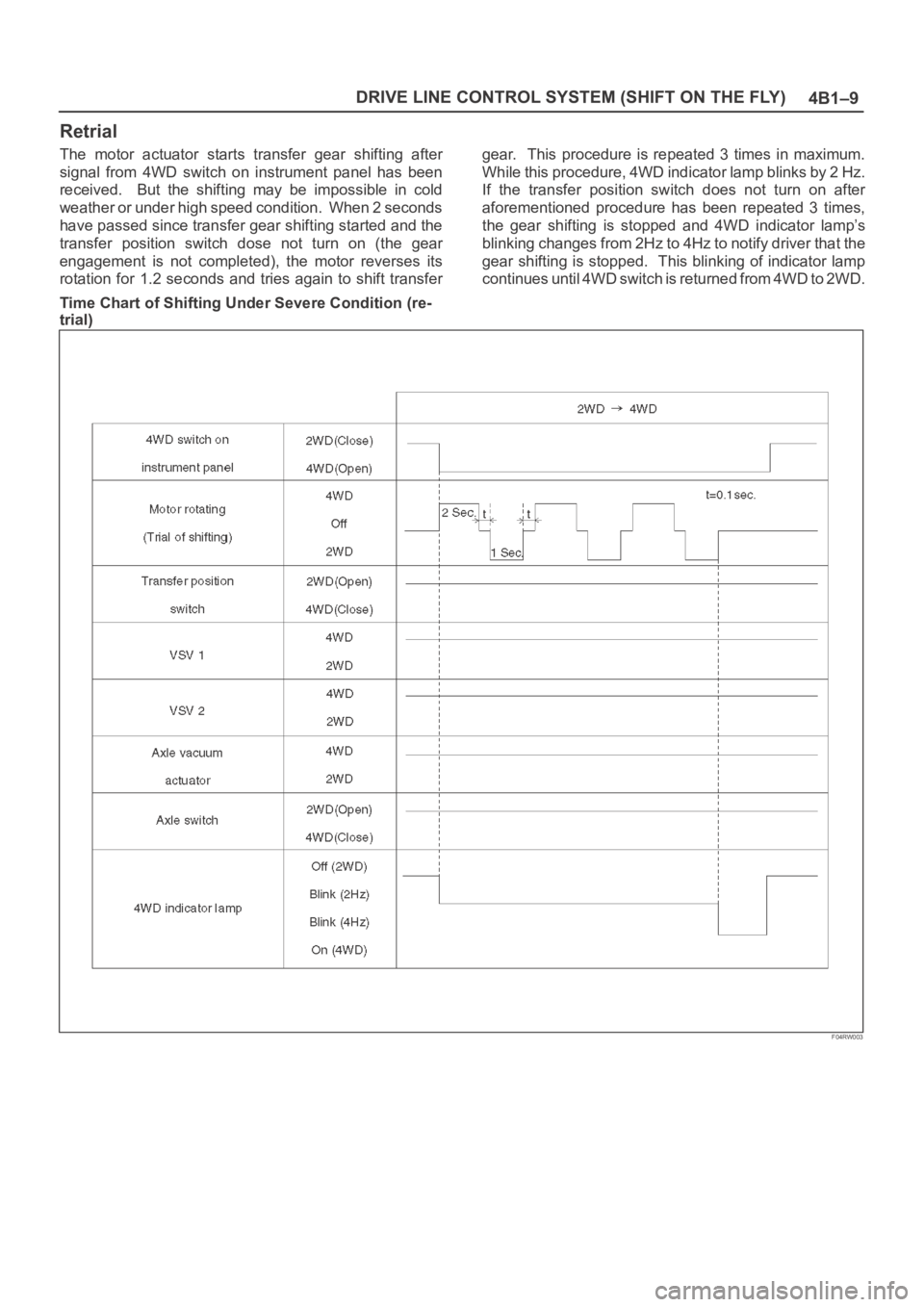

Retrial

The motor actuator starts transfer gear shifting after

signal from 4WD switch on instrument panel has been

received. But the shifting may be impossible in cold

weather or under high speed condition. When 2 seconds

have passed since transfer gear shifting started and the

transfer position switch dose not turn on (the gear

engagement is not completed), the motor reverses its

rotation for 1.2 seconds and tries again to shift transfergear. This procedure is repeated 3 times in maximum.

While this procedure, 4WD indicator lamp blinks by 2 Hz.

If the transfer position switch does not turn on after

aforementioned procedure has been repeated 3 times,

the gear shifting is stopped and 4WD indicator lamp’s

blinking changes from 2Hz to 4Hz to notify driver that the

gear shifting is stopped. This blinking of indicator lamp

continues until 4WD switch is returned from 4WD to 2WD.

Time Chart of Shifting Under Severe Condition (re-

trial)

F04RW003

Page 574 of 6000

4B2–3 DRIVE LINE CONTROL SYSTEM (TOD)

detects the slip condition, determines the optimum torque

based on the feedback control logic, and increases the

torque to the front wheels.

The control unit uses the signal from the throttle position

sensor to predict the future vehicle condition and the

intention of the driver with respect to acceleration and

deceleration, and determines the initial torque distribution

using these data and the information from the speed

sensors.

In case of small circle turning in the parking lot, for

example, the control unit minimizes the clutch pressing

force restrict a braking phenomenon. When the ABS

becomes active, the control unit optimizes the clutch

pressing force to ensure stable braking.

TOD Indicator Control

The TOD indicator on the instrument panel informs the

driver of the current working status of the transfer unit.

The information consists of two items: the drive mode

(2H, TOD, 4L, transition) and the torque split status of the

TOD (torque distribution level). The indicator can display

occasional errors and corresponding error codes.

Page 577 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–6

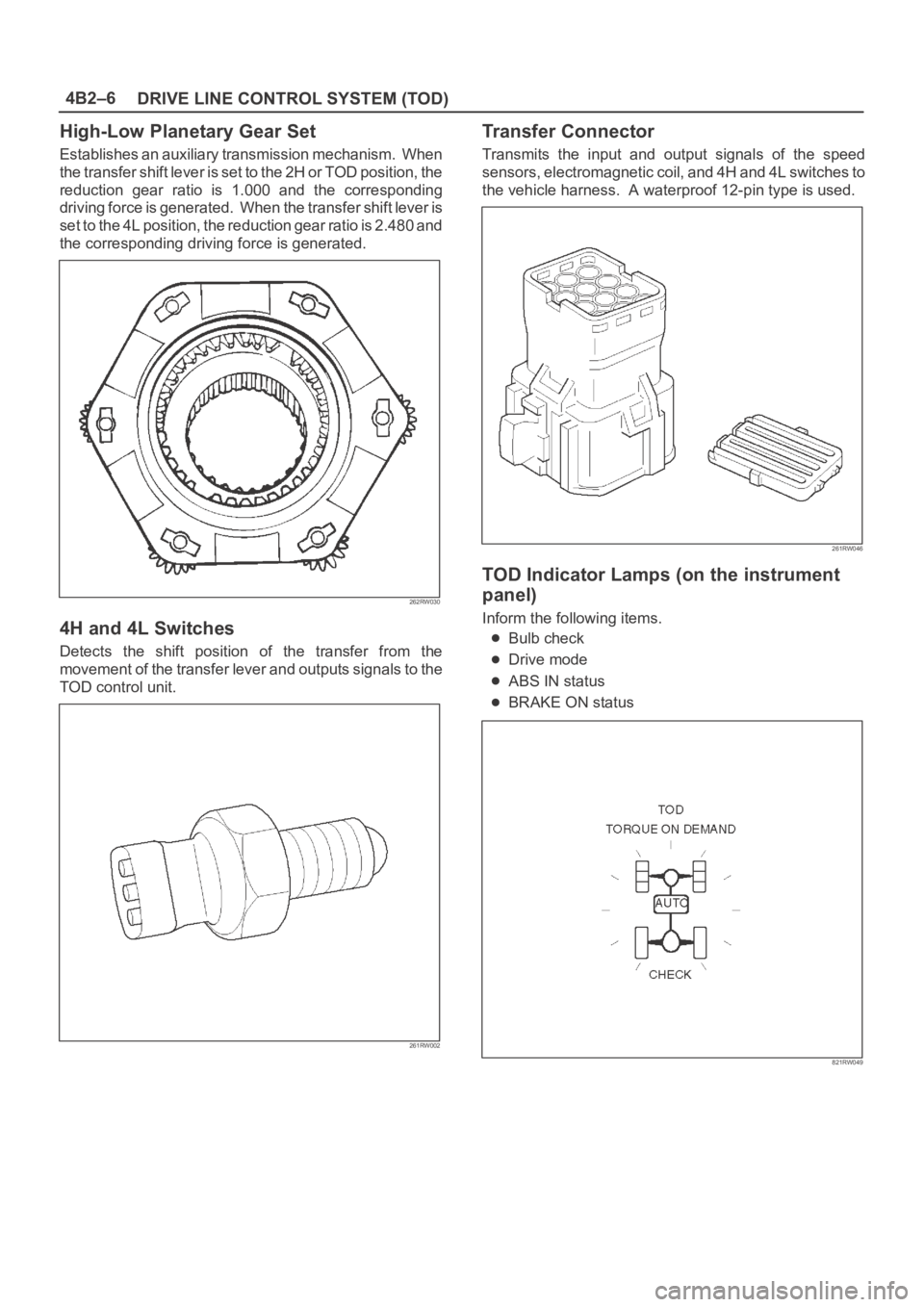

High-Low Planetary Gear Set

Establishes an auxiliary transmission mechanism. When

the transfer shift lever is set to the 2H or TOD position, the

reduction gear ratio is 1.000 and the corresponding

driving force is generated. When the transfer shift lever is

set to the 4L position, the reduction gear ratio is 2.480 and

the corresponding driving force is generated.

262RW030

4H and 4L Switches

Detects the shift position of the transfer from the

movement of the transfer lever and outputs signals to the

TOD control unit.

261RW002

Transfer Connector

Transmits the input and output signals of the speed

sensors, electromagnetic coil, and 4H and 4L switches to

the vehicle harness. A waterproof 12-pin type is used.

261RW046

TOD Indicator Lamps (on the instrument

panel)

Inform the following items.

Bulb check

Drive mode

ABS IN status

BRAKE ON status

821RW049

Page 764 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–43

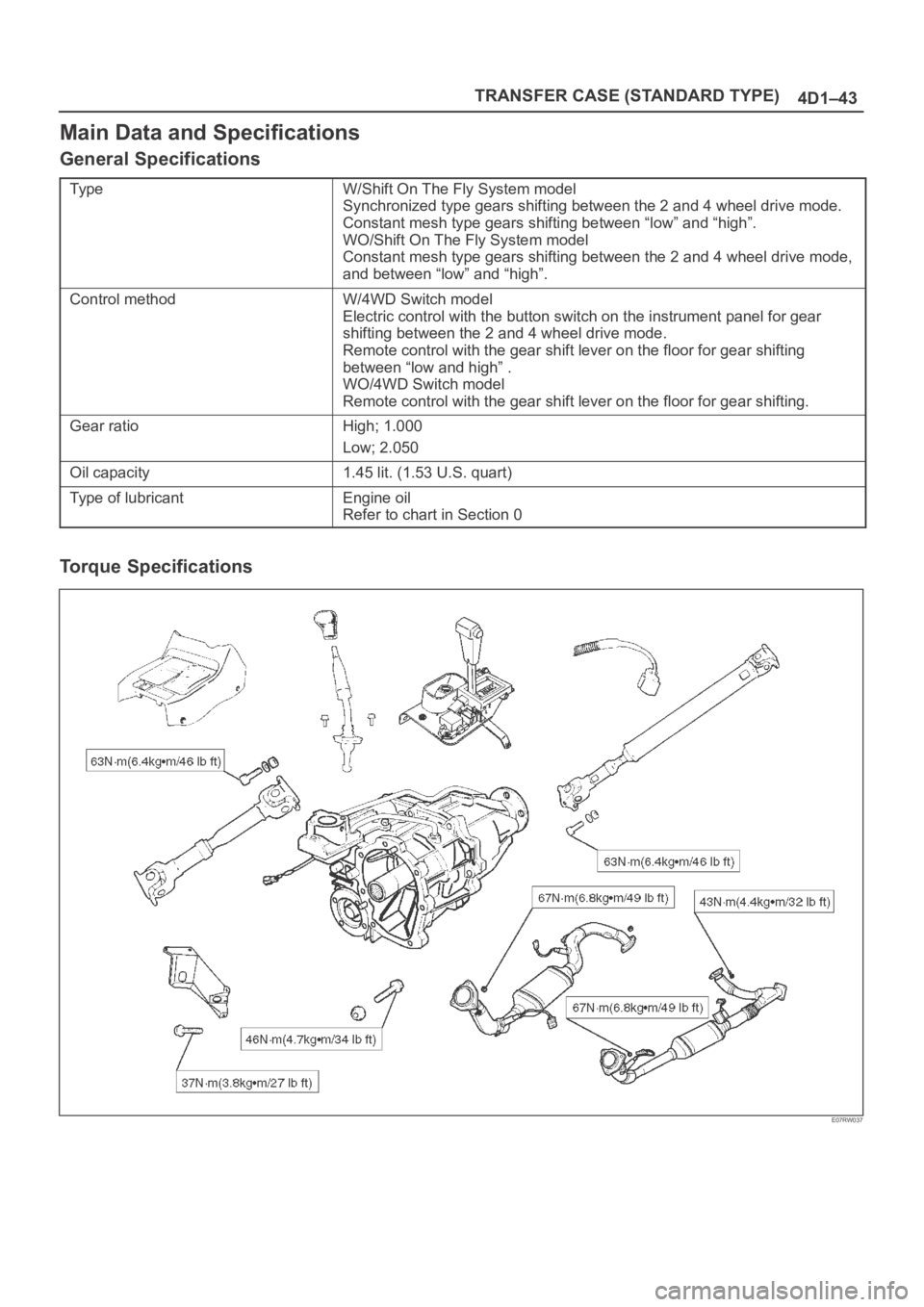

Main Data and Specifications

General Specifications

Ty p eW/Shift On The Fly System model

Synchronized type gears shifting between the 2 and 4 wheel drive mode.

Constant mesh type gears shifting between “low” and “high”.

WO/Shift On The Fly System model

Constant mesh type gears shifting between the 2 and 4 wheel drive mode,

and between “low” and “high”.

Control methodW/4WD Switch model

Electric control with the button switch on the instrument panel for gear

shifting between the 2 and 4 wheel drive mode.

Remote control with the gear shift lever on the floor for gear shifting

between “low and high” .

WO/4WD Switch model

Remote control with the gear shift lever on the floor for gear shifting.

Gear ratioHigh; 1.000

Low; 2.050

Oil capacity1.45 lit. (1.53 U.S. quart)

Type of lubricantEngine oil

Refer to chart in Section 0

Torque Specifications

E07RW037

Page 814 of 6000

5A–4

BRAKE CONTROL SYSTEM

normal braking when a malfunction has occurred in the

ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment front

right side. It consists of a Motor, Plunger Pump, Solenoid

Valves and Check Valve.

On the outside, the relay box containing a motor relay and

a valve relay is installed.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc brakes

according to the signal sent from the EHCU.

Reservoir: Temporarily holds the brake fluid that returns

from the front and rear disc brake caliper so that pressure

of front disc brake caliper can be reduced smoothly.

Plunger Pump: Feeds the brake fluid held in the reservoir

to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

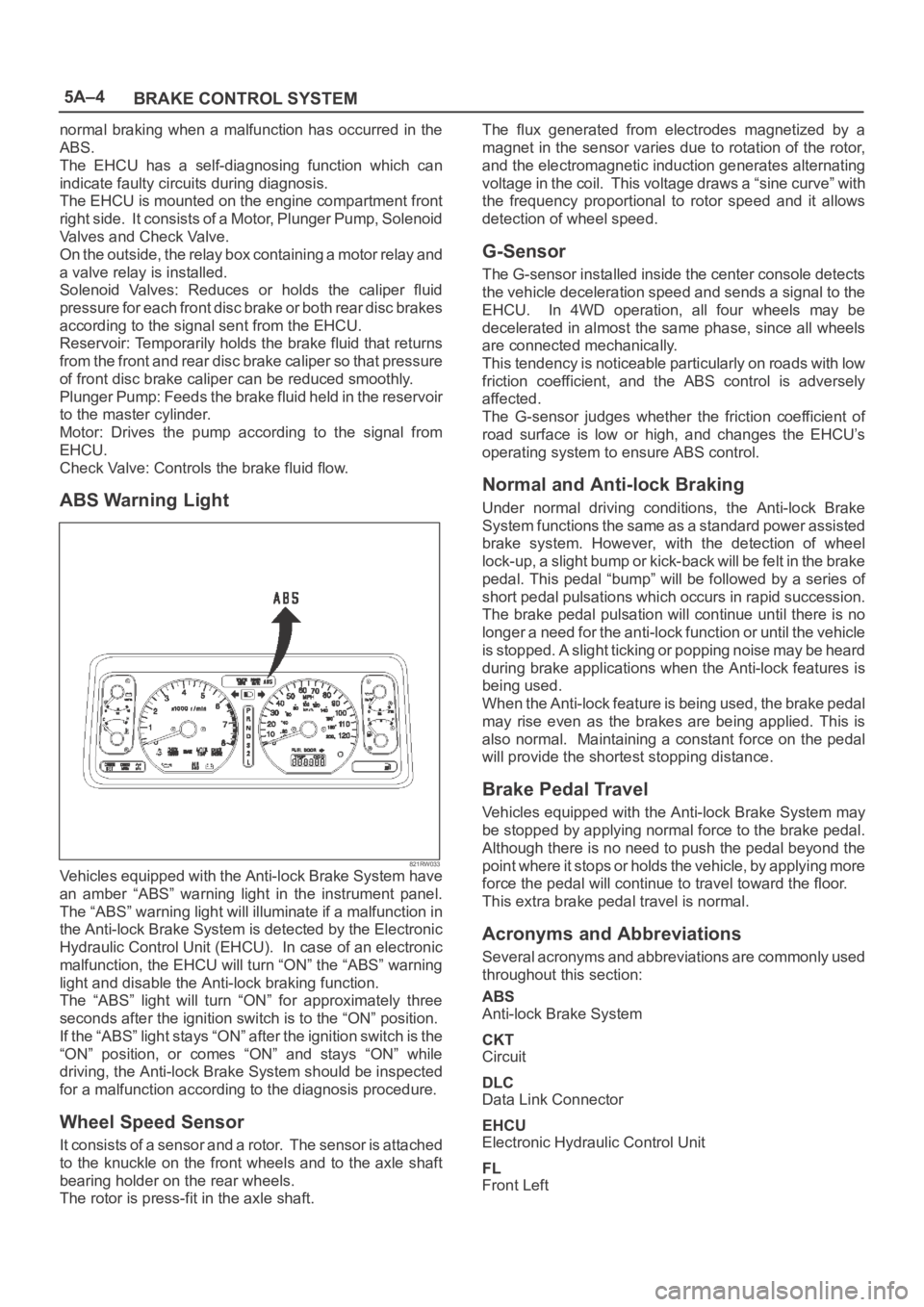

ABS Warning Light

821RW033Vehicles equipped with the Anti-lock Brake System have

an amber “ABS” warning light in the instrument panel.

The “ABS” warning light will illuminate if a malfunction in

the Anti-lock Brake System is detected by the Electronic

Hydraulic Control Unit (EHCU). In case of an electronic

malfunction, the EHCU will turn “ON” the “ABS” warning

light and disable the Anti-lock braking function.

The “ABS” light will turn “ON” for approximately three

seconds after the ignition switch is to the “ON” position.

If the “ABS” light stays “ON” after the ignition switch is the

“ON” position, or comes “ON” and stays “ON” while

driving, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached

to the knuckle on the front wheels and to the axle shaft

bearing holder on the rear wheels.

The rotor is press-fit in the axle shaft.The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve” with

the frequency proportional to rotor speed and it allows

detection of wheel speed.

G-Sensor

The G-sensor installed inside the center console detects

the vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with low

friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU’s

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power assisted

brake system. However, with the detection of wheel

lock-up, a slight bump or kick-back will be felt in the brake

pedal. This pedal “bump” will be followed by a series of

short pedal pulsations which occurs in rapid succession.

The brake pedal pulsation will continue until there is no

longer a need for the anti-lock function or until the vehicle

is stopped. A slight ticking or popping noise may be heard

during brake applications when the Anti-lock features is

being used.

When the Anti-lock feature is being used, the brake pedal

may rise even as the brakes are being applied. This is

also normal. Maintaining a constant force on the pedal

will provide the shortest stopping distance.

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying more

force the pedal will continue to travel toward the floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly used

throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

Page 973 of 6000

6A–17

ENGINE MECHANICAL

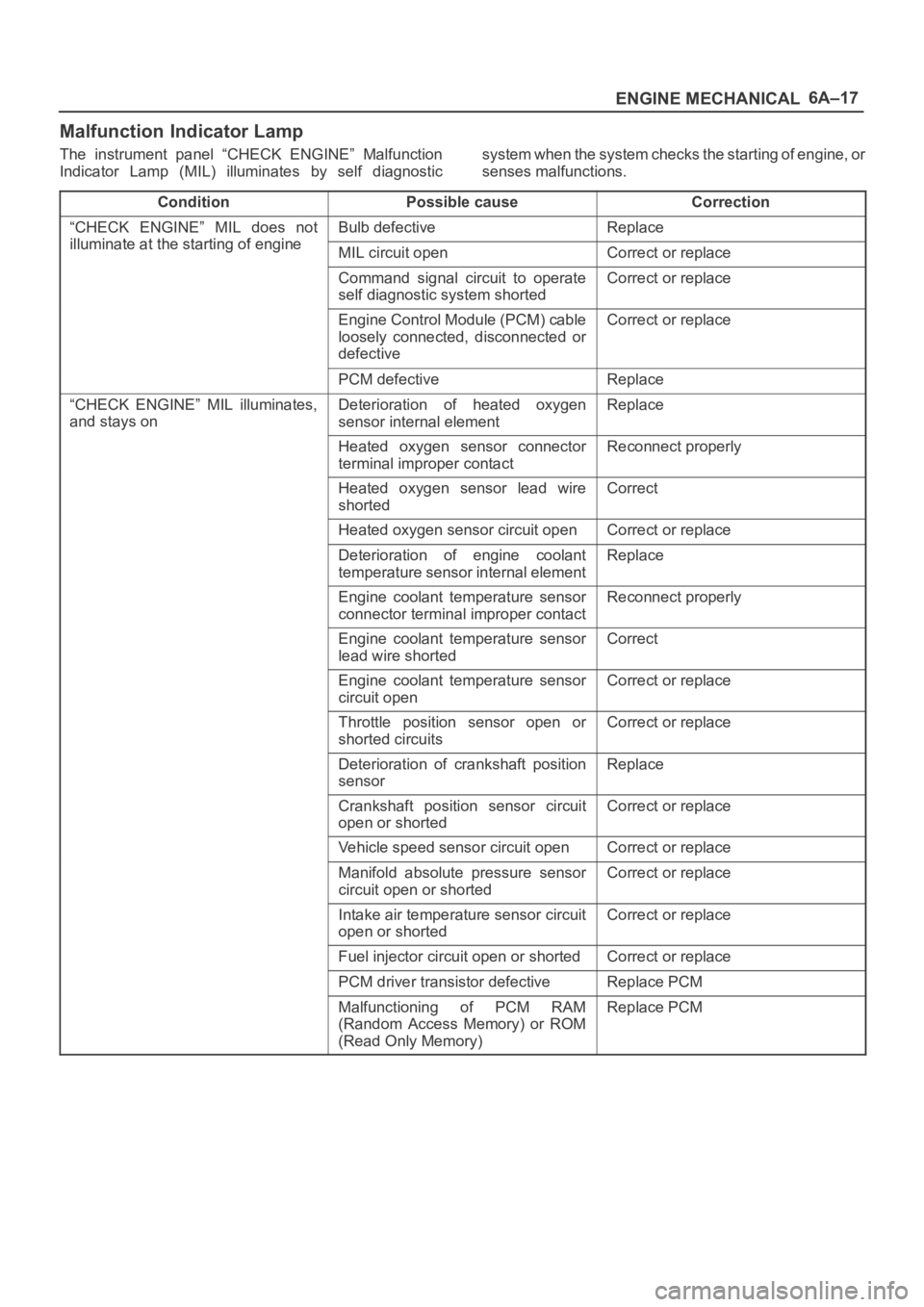

Malfunction Indicator Lamp

The instrument panel “CHECK ENGINE” Malfunction

Indicator Lamp (MIL) illuminates by self diagnosticsystem when the system checks the starting of engine, or

senses malfunctions.

Condition

Possible causeCorrection

“CHECK ENGINE” MIL does not

illuminate at the starting of engine

Bulb defectiveReplace

illuminate at the starting of engineMIL circuit openCorrect or replace

Command signal circuit to operate

self diagnostic system shortedCorrect or replace

Engine Control Module (PCM) cable

loosely connected, disconnected or

defectiveCorrect or replace

PCM defectiveReplace

“CHECK ENGINE” MIL illuminates,

and stays onDeterioration of heated oxygen

sensor internal elementReplace

Heated oxygen sensor connector

terminal improper contactReconnect properly

Heated oxygen sensor lead wire

shortedCorrect

Heated oxygen sensor circuit openCorrect or replace

Deterioration of engine coolant

temperature sensor internal elementReplace

Engine coolant temperature sensor

connector terminal improper contactReconnect properly

Engine coolant temperature sensor

lead wire shortedCorrect

Engine coolant temperature sensor

circuit openCorrect or replace

Throttle position sensor open or

shorted circuitsCorrect or replace

Deterioration of crankshaft position

sensorReplace

Crankshaft position sensor circuit

open or shortedCorrect or replace

Vehicle speed sensor circuit openCorrect or replace

Manifold absolute pressure sensor

circuit open or shortedCorrect or replace

Intake air temperature sensor circuit

open or shortedCorrect or replace

Fuel injector circuit open or shortedCorrect or replace

PCM driver transistor defectiveReplace PCM

Malfunctioning of PCM RAM

(Random Access Memory) or ROM

(Read Only Memory)Replace PCM

Page 1146 of 6000

6E–29 ENGINE DRIVEABILITY AND EMISSIONS

Engine Component Locator Table

Number

NameLocation

1Linear Exhaust Gas Recirculation (EGR) ValveRear right side of the engine

2Throttle Position (TP) SensorOn the rear of the throttle body

3Intake Air Temperature (IAT) SensorOn the intake air duct near the throttle body

4Check Engine (MIL) LightOn the instrument panel beneath the

tachometer

5Positive Crankcase Ventilation (PCV) ValveOn the left of the cylinder head cover

6Air CleanerLeft front of the engine bay

7Mass Air Flow (MAF) SensorAttached to the air filter box

8Camshaft Position (CMP) SensorOn the rear right side at the left of the cylinder

head cover

9Fuel Pressure RegulatorRear right side of the engine

10Idle Air Control (IAC) ValveOn the left of the throttle body

11Upper Intake ManifoldTop of the engine

12Fuse/Relay BoxAlong the inside of the right fender

13Manifold Absolute Pressure (MAP) SensorBolted to the top of the upper intake manifold

14Throttle BodyBetween the intake air duct and the upper

intake manifold

15Engine Coolant Temperature SensorOn the coolant crossover pipe at the front of

the engine, near the throttle body