load capacity OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1084 of 6000

ENGINE ELECTRICAL6D1–5

Main Data and Specifications

General Specifications

Model (JIS)95D31R–MF80D26R–MF75D26R–MF

Voltage (V)121212

Cold Cranking Performance (Amp)622582490

Reserve Capacity (Min)159133123

Load Test (Amp)310290245

Fast Charge Maximum Amperage (Amp)202020

BCI Group No.272424

Page 1737 of 6000

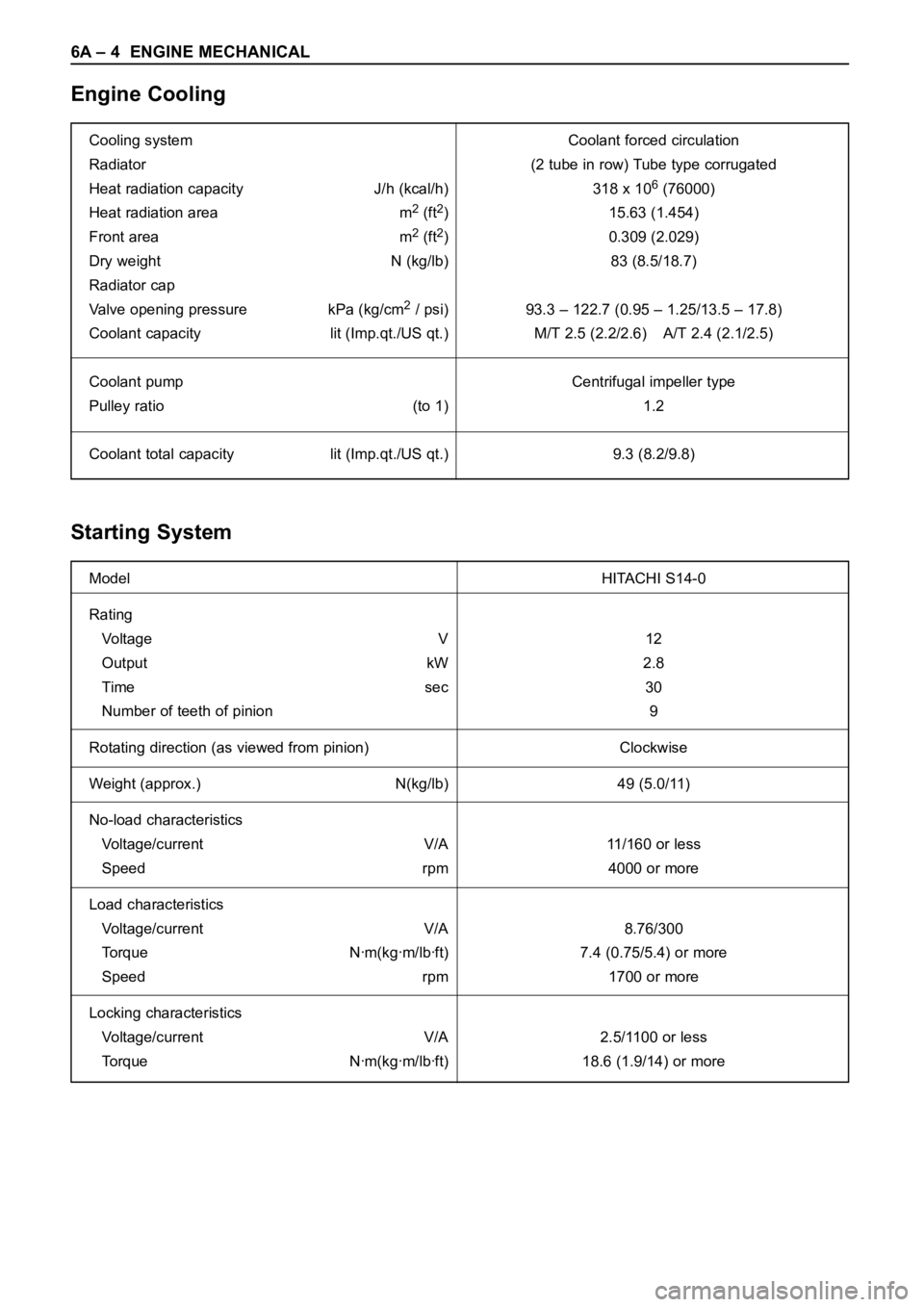

6A – 4 ENGINE MECHANICAL

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2/ psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio (to 1) 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Vo l t a ge V 1 2

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 1871 of 6000

6D – 4 ENGINE ELECTRICAL

REMOVAL AND INSTALLATION OF THE

BATTERY

REMOVAL

1. Negative cable

2. Positive cable

3. Retainer screw and rods

4. Retainer

5. Battery

INSTALLATION

To install the battery, follow the removal procedure in

the reverse order, noting the following points:

1. Make sure that the rod is hooked on the body side.

065RW029

MAIN DATA AND SPECIFICATIONS

Model (JIS) 80D26R–MF 75D26R–MF

Voltage (V) 12 12

Cold-Cranking Performance (Amp) 582 490

Reserve Capacity (Min) 133 123

Load Test (Amp) 300 300

Fast Charge Maximum Amperage (Amp) 6.5 6.5

Page 2597 of 6000

The chassis electrical system is a 12–volt system with a

negative ground polarity.

Wire size are appropriate to respective circuits, and

classified by color. (The classification of harnesses by

color is shown on the circuit diagram for ease of harness

identification.)

The wire size is determined by load capacity and the

length of wire required.

The vehicle harnesses are: body harness, chassis

harness, engine room harness, instrument harness,

transmission harness, engine ECGI harness, dome light

harness, door harness, rear body harness, tailgate

harness, SRS harness and battery cables.

The harnesses are protected either by tape or corrugated

tube, depending on harness location.

The circuit for each system consists of the power source,

wire, fuse, relay, switch, load parts and ground, all of

which are shown on the circuit diagram.

In this section, each electrical device is classified by

system.

For major parts shown on the circuit based on the circuit

diagram for each system, a summary, diagnosis of

troubles and inspection procedures are detailed.

Notes for Working on Electrical

Items

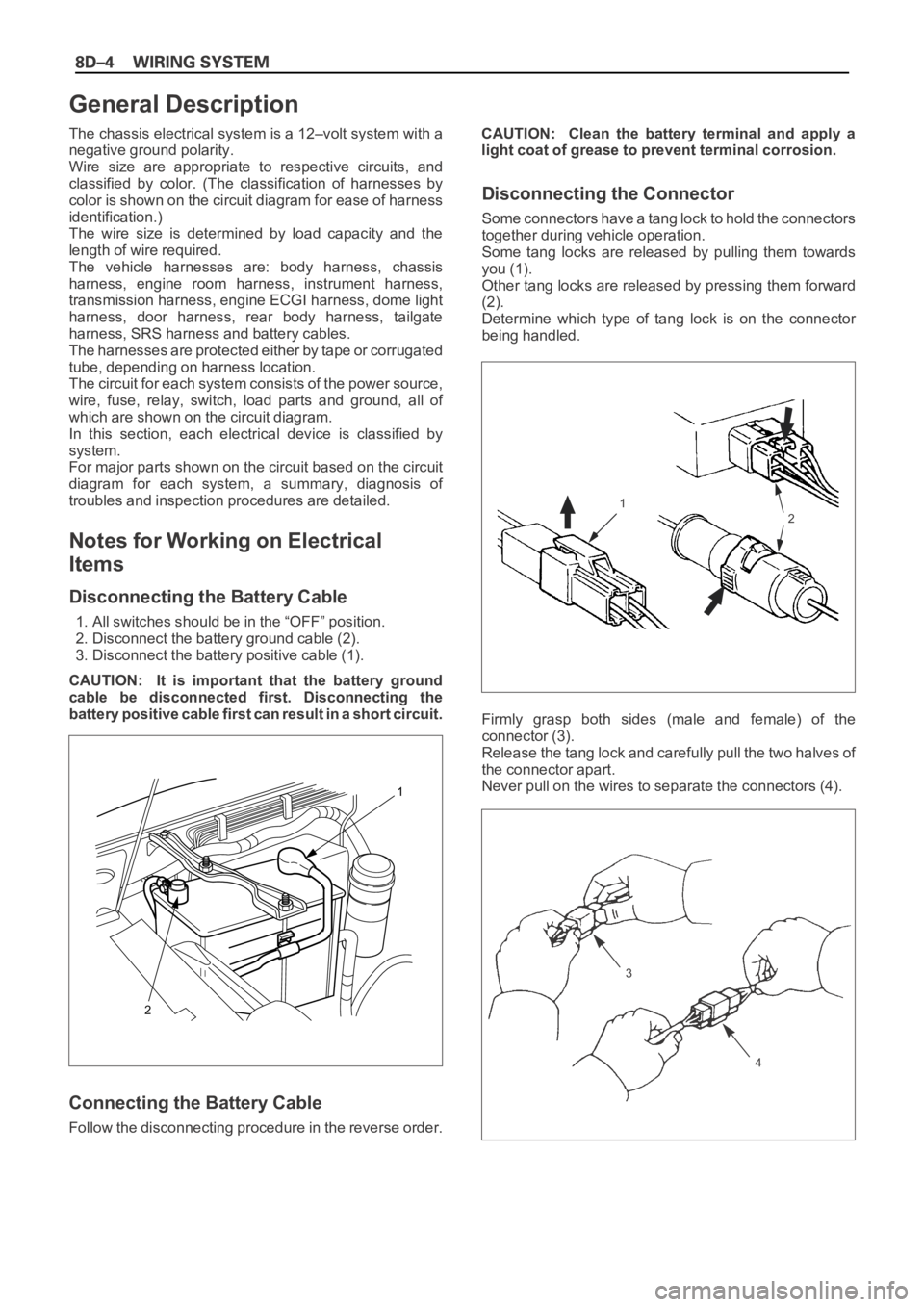

Disconnecting the Battery Cable

1. All switches should be in the “OFF” position.

2. Disconnect the battery ground cable (2).

3. Disconnect the battery positive cable (1).

CAUTION: It is important that the battery ground

cable be disconnected first. Disconnecting the

battery positive cable first can result in a short circuit.

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse order.CAUTION: Clean the battery terminal and apply a

light coat of grease to prevent terminal corrosion.

Disconnecting the Connector

Some connectors have a tang lock to hold the connectors

together during vehicle operation.

Some tang locks are released by pulling them towards

you (1).

Other tang locks are released by pressing them forward

(2).

Determine which type of tang lock is on the connector

being handled.

Firmly grasp both sides (male and female) of the

connector (3).

Release the tang lock and carefully pull the two halves of

the connector apart.

Never pull on the wires to separate the connectors (4).

2

1

General Description

1

2

3

4

Page 2606 of 6000

Wiring – Wire Size

The size of wire used in a circuit is determined by the

amount of current (amperage), the length of the circuit,

and the voltage drop allowed. The following wire size and

load capacity, shown below, are specified by AWG

(American Wire Gauge). (Nominal size means

approximate cross sectional area (1).)

Wiring – Wire Size Table

Nominal sizeCross sectional Outside diameter Allowable

area (mm2) (mm) current (A)

0.3 0.372 1.5 9

0.5 0.563 1.7 12

0.85 0.885 1.9 16

1.25 1.287 2.2 21

22.0912.728

3 3.296 3.6 37.5

55.2274.453

87.9525.567

15 13.36 7.0 75

20 20.61 8.2 97

1

Page 2609 of 6000

Circuit Breaker

The circuit breaker is a protective device designed to

open the circuit when a current load is in excess of rated

breaker capacity. If there is a short or other type of

overload condition in the circuit, the excessive current will

open the circuit between the circuit breaker terminals.

The reset knob (1) pops out when the circuit is open. Push

the reset knob in place to restore the circuit after repairing

it.

Relay

Battery and load location may require that a switch be

placed some distance from either component. This

means a longer wire and a higher voltage drop (1).

The installation of a relay between the battery and the

load reduces the voltage drop (2).

Because the switch controls the relay, amperage through

the switch can be reduced.

LOAD

12LOAD

RELAY

D08RW404

1

Page 4624 of 6000

ENGINE ELECTRICAL6D1–5

Main Data and Specifications

General Specifications

Model (JIS)95D31R–MF80D26R–MF75D26R–MF

Voltage (V)121212

Cold Cranking Performance (Amp)622582490

Reserve Capacity (Min)159133123

Load Test (Amp)310290245

Fast Charge Maximum Amperage (Amp)202020

BCI Group No.272424

Page 5277 of 6000

6A – 4 ENGINE MECHANICAL

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Voltage V 12

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 5407 of 6000

6D – 4 ENGINE ELECTRICAL

REMOVAL AND INSTALLATION OF THE

BATTERY

REMOVAL

1. Negative cable

2. Positive cable

3. Retainer screw and rods

4. Retainer

5. Battery

INSTALLATION

To install the battery, follow the removal procedure in

the reverse order, noting the following points:

1. Make sure that the rod is hooked on the body side.

065RW029

MAIN DATA AND SPECIFICATIONS

Model (JIS) 80D26R–MF 75D26R–MF

Voltage (V) 12 12

Cold-Cranking Performance (Amp) 582 490

Reserve Capacity (Min) 133 123

Load Test (Amp) 300 300

Fast Charge Maximum Amperage (Amp) 6.5 6.5