cooling OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 518 of 625

HEATER SYSTEM. GT9A- 9

REMOVAL AND INSTALLATION HEATER VALVE

Removal

1. Remove lower radiator hose and drain and collect

coolant.

2. Disconnect control cable.

3. Loosen heater hose clamps and remove valve from

hoses. See Figure 9A-17.SPECIFICATIONS

EngineRecommended Coolant

.__,.__...._...__.,.,...,......Thermostat Opens At (Degrees) F.

..__..___...Installation

1. Install valve into heater hoses and install hose

clamps.

2. Connect control cable.

3. Install lower radiator hose and add collected coo-

lant.

.....................................Ethylene-Glycol Base

...................................................................189Cooling

SystemCapacity(WithHeater)..........................................................................6Qt.BlowerMotorType

......................................................................................................12VDC

BlowerFanType

..................................................................................................SquirrelCage

Page 525 of 625

9A-16 1973 OPEL SERVICE MANUAL

Figure 9A-44 Shroud Cover AttachmentsFigure 9A-46 Heater Motor Attaching Screws

Figure 9A-45 Heater Motor Wires

InstallationFigure 9A-47 Sealing Shroud

1. Install heater motor, attaching with three (3)

screws. See Figure 9A-46.

2. Connect multiple plug on left side of shroud. See

Figure 9A-45.3. Seal shroud cover front and rear contacting areas

with sealing cement. See Figure 9A-47.

4. Install shroud cover, attaching with five (5)

screws.SPECIFICATIONS

EngineRecommended Coolant

..........................................................................Ethylene-Glycol Base

ThermostatOpensAt(Degrees)

F.......................................................................................189Cooling System Capacity (With Heater)

..........................................................................6 Qt.

Blower Motor Type

......................................................................................................12 VDC

Blower Fan Type

..............................................................................................................Blade

Numberof FanBlades

..............................................................................................................7

Page 528 of 625

REFRIGERANT COMPONENTS ALL MODELS9s. 19

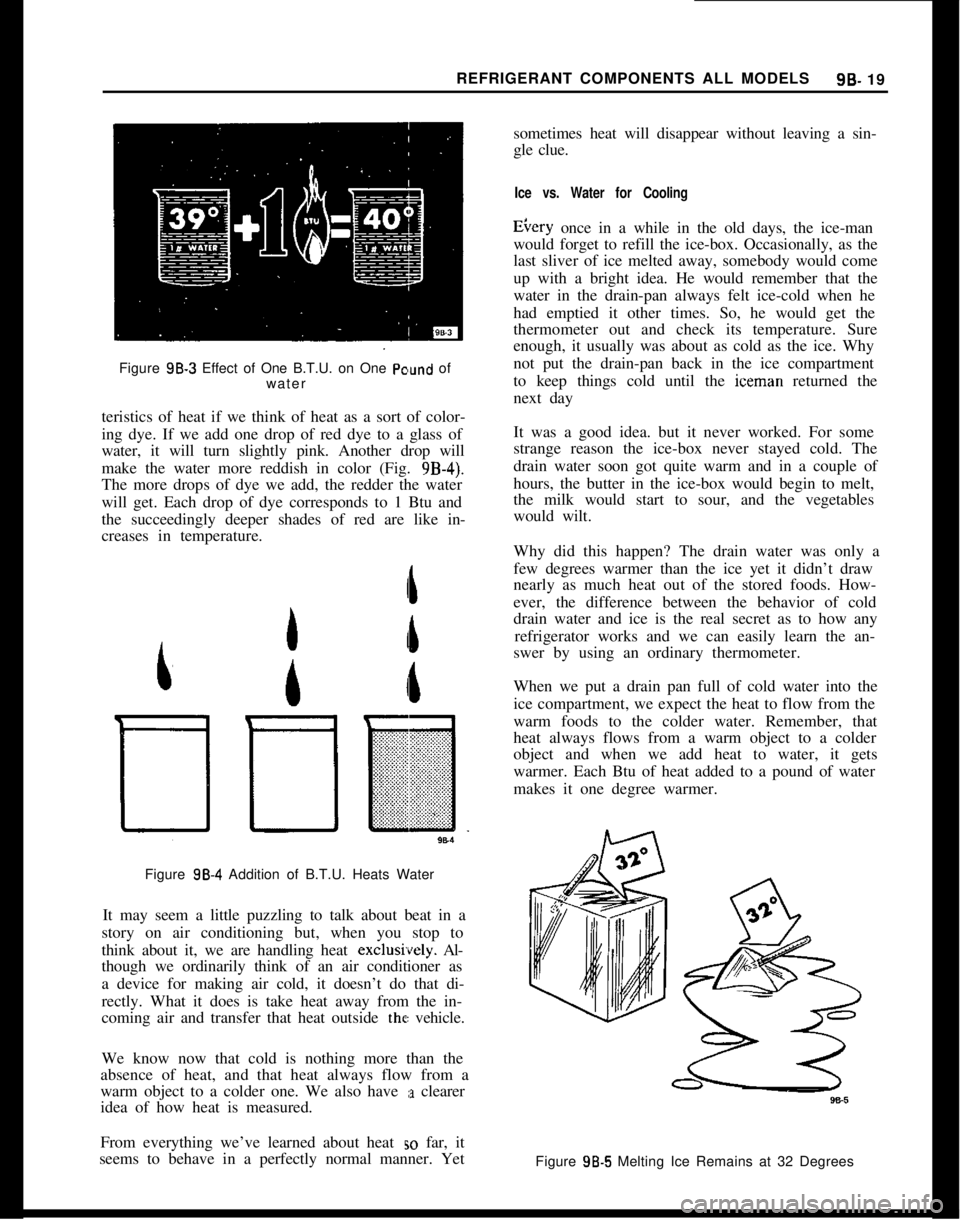

Figure 98.3 Effect of One B.T.U. on One

Pc’und of

water

teristics of heat if we think of heat as a sort of color-

ing dye. If we add one drop of red dye to a glass of

water, it will turn slightly pink. Another drop will

make the water more reddish in color (Fig.

9B-4).The more drops of dye we add, the redder the water

will get. Each drop of dye corresponds to 1 Btu and

the succeedingly deeper shades of red are like in-

creases in temperature.

Figure

98-4 Addition of B.T.U. Heats Water

It may seem a little puzzling to talk about beat in a

story on air conditioning but, when you stop to

think about it, we are handling heat exclusively. Al-

though we ordinarily think of an air conditioner as

a device for making air cold, it doesn’t do that di-

rectly. What it does is take heat away from the in-

coming air and transfer that heat outside the vehicle.

We know now that cold is nothing more than the

absence of heat, and that heat always flow from a

warm object to a colder one. We also have

:a clearer

idea of how heat is measured.

From everything we’ve learned about heat

EO far, it

seems to behave in a perfectly normal manner. Yetsometimes heat will disappear without leaving a sin-

gle clue.

Ice vs. Water for CoolingEtery once in a while in the old days, the ice-man

would forget to refill the ice-box. Occasionally, as the

last sliver of ice melted away, somebody would come

up with a bright idea. He would remember that the

water in the drain-pan always felt ice-cold when he

had emptied it other times. So, he would get the

thermometer out and check its temperature. Sure

enough, it usually was about as cold as the ice. Why

not put the drain-pan back in the ice compartment

to keep things cold until the iceman returned the

next day

It was a good idea. but it never worked. For some

strange reason the ice-box never stayed cold. The

drain water soon got quite warm and in a couple of

hours, the butter in the ice-box would begin to melt,

the milk would start to sour, and the vegetables

would wilt.

Why did this happen? The drain water was only a

few degrees warmer than the ice yet it didn’t draw

nearly as much heat out of the stored foods. How-

ever, the difference between the behavior of cold

drain water and ice is the real secret as to how any

refrigerator works and we can easily learn the an-

swer by using an ordinary thermometer.

When we put a drain pan full of cold water into the

ice compartment, we expect the heat to flow from the

warm foods to the colder water. Remember, that

heat always flows from a warm object to a colder

object and when we add heat to water, it gets

warmer. Each Btu of heat added to a pound of water

makes it one degree warmer.

Figure 98.5 Melting Ice Remains at 32 Degrees

Page 529 of 625

98-20 1973 OPEL SERVICE MANUAL

If we were to put a thermometer in the cold drain

water, we would see the temperature gradually creep

upwards. That is to be expected because heat is flow-

ing into the cold water making it warmer. Before

long the water would be as warm as the stored foods.

Then the water could no longer attract heat because

heat will not flow from one warm object to another

equally warm object. Since we no longer can draw

heat out of the foods we no longer are cooling them.

Now, let’s see what happens when we put ice instead

of cold water into the ice-box. This time, we’ll set the

thermometer on top of the ice (Fig. 9B-5). When wefirst look at the thermometer, it reads 32 degrees. A

couple of hours later, we open the ice compartment

door. The ice block is smaller because some of the ice

has already melted away

- but the thermometer still

reads 32 degrees. Again, still later, even more of the

ice has melted, yet the termometer continues to read

32 degrees. So long as any ice remains, no matter

how much of it has melted away, the temperature of

the ice stays right at 32 degrees.

All this time the ice has been soaking up heat, yet it

never gets any warmer no matter how much heat it

draws from the stored food. On the other hand, the

cold drain water got progressively warmer as it

soaked up heat. Why is it the addition of heat will

make water warmer yet won’t raise the temperature

of ice above the 32 degrees mark? If we till one

drinking glass with ice and another with cold water,

and put both glasses in the same room where they

could absorb equal amounts of heat from the room

air, we will find it takes much, much longer for the

ice to melt and reach room temperature than it did

for the water in the other glass to reach the same

temperature. Obviously, most of the heat was being

used to melt the ice. But it was the heat that appar-

ently disappeared or went into hiding because if

couldn’t be located with a thermometer. To best de-

scribe this disappearing heat, scientists turned to

Latin for the right word. They chose the word “la-

tent” which means hidden.

Latent Heat

So latent heat is nothing more nor less than hidden

heat which can’t be found with a thermometer.

What happens to the latent heat? Where does it

disappear to? At first it was thought it was in the

water that melted from the ice. But that wasn’t ex-

actly the right answer because, upon checking water

temperature as it melts from ice, it will be found that

it is only a shade warmer than the ice itself. It is not

nearly warm enough to account for all the heat the

ice had absorbed. The only possible answer is that

the latent heat had been used up to change the ice

from a solid into a liquid.

Many substances can be either a solid, or a liquid, ora gas. It just depends on the temperature whether

water for example was a liquid, or a solid (ice), or gas

(steam) (Fig.

9B-6).Figure 99-6 Temperature Determines State of Water

If we put some water in a tea-kettle, set it over a tire

and watch the thermometer as the water gets hotter

and hotter, the mercury will keep rising until the

water starts to boil. Then the mercury seems to stick

at the 212 degrees mark. If we put more wood on the

fire, despite all the increased heat, the mercury will

not budge above the 212 degree mark (Fig.

9B-7).Figure 98.7 Boiling Water Never Exceeds 2 12

DegreesEven though many housewives won’t believe it, no

matter how large or hot you make the flame, you

can’t make water hotter than 2 12 degrees. As a liquid

changes into a gas, it absorbs abnormally great

amounts of heat without getting any hotter. Here is

another instance where heat disappears.

Now we have two different kinds of latent heat,

which are quite alike. To keep their identities sepa-

rate, the first one is called latent heat of fusion. Since

fusion means the same as melting, it is a good de-

scriptive name. The other kind is called latent heat

of vaporization because‘ that means the same as

evaporation.

It may seem as though we have drifted into a story

Page 532 of 625

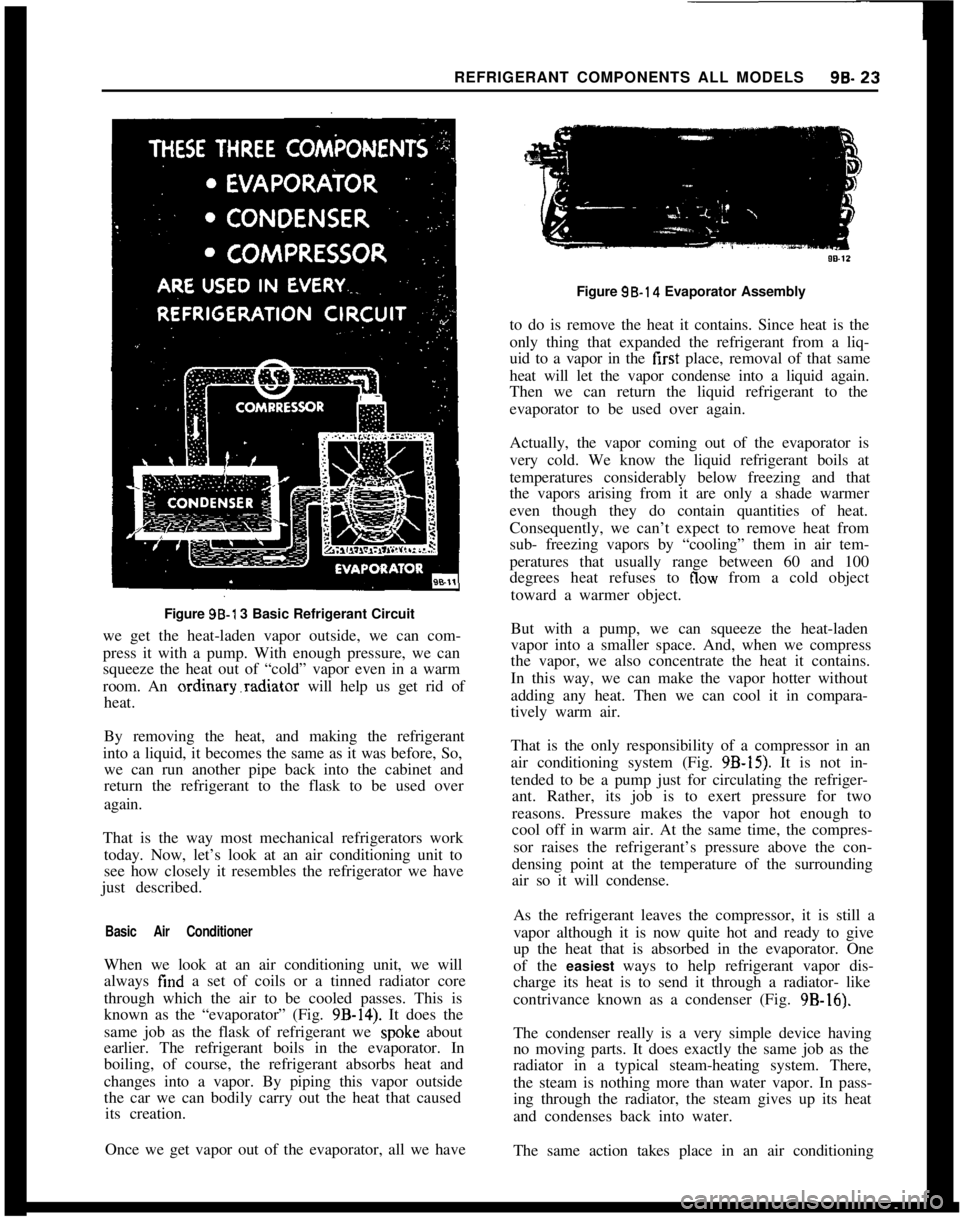

REFRIGERANT COMPONENTS ALL MODELS96.23Figure 96-l 3 Basic Refrigerant Circuit

we get the heat-laden vapor outside, we can com-

press it with a pump. With enough pressure, we can

squeeze the heat out of “cold” vapor even in a warm

room. An ordinary.radiator will help us get rid of

heat.

By removing the heat, and making the refrigerant

into a liquid, it becomes the same as it was before, So,

we can run another pipe back into the cabinet and

return the refrigerant to the flask to be used over

again.

That is the way most mechanical refrigerators work

today. Now, let’s look at an air conditioning unit to

see how closely it resembles the refrigerator we have

just described.

Basic Air ConditionerWhen we look at an air conditioning unit, we will

always find a set of coils or a tinned radiator core

through which the air to be cooled passes. This is

known as the “evaporator” (Fig.

9B-14). It does the

same job as the flask of refrigerant we

spok.e about

earlier. The refrigerant boils in the evaporator. In

boiling, of course, the refrigerant absorbs heat and

changes into a vapor. By piping this vapor outside

the car we can bodily carry out the heat that caused

its creation.

Once we get vapor out of the evaporator, all we haveFigure 98.14 Evaporator Assembly

to do is remove the heat it contains. Since heat is the

only thing that expanded the refrigerant from a liq-

uid to a vapor in the first place, removal of that same

heat will let the vapor condense into a liquid again.

Then we can return the liquid refrigerant to the

evaporator to be used over again.

Actually, the vapor coming out of the evaporator is

very cold. We know the liquid refrigerant boils at

temperatures considerably below freezing and that

the vapors arising from it are only a shade warmer

even though they do contain quantities of heat.

Consequently, we can’t expect to remove heat from

sub- freezing vapors by “cooling” them in air tem-

peratures that usually range between 60 and 100

degrees heat refuses to

flow from a cold object

toward a warmer object.

But with a pump, we can squeeze the heat-laden

vapor into a smaller space. And, when we compress

the vapor, we also concentrate the heat it contains.

In this way, we can make the vapor hotter without

adding any heat. Then we can cool it in compara-

tively warm air.

That is the only responsibility of a compressor in an

air conditioning system (Fig.

9B-15). It is not in-

tended to be a pump just for circulating the refriger-

ant. Rather, its job is to exert pressure for two

reasons. Pressure makes the vapor hot enough to

cool off in warm air. At the same time, the compres-

sor raises the refrigerant’s pressure above the con-

densing point at the temperature of the surrounding

air so it will condense.

As the refrigerant leaves the compressor, it is still a

vapor although it is now quite hot and ready to give

up the heat that is absorbed in the evaporator. One

of the easiest ways to help refrigerant vapor dis-

charge its heat is to send it through a radiator- like

contrivance known as a condenser (Fig. 9B-16).

The condenser really is a very simple device having

no moving parts. It does exactly the same job as the

radiator in a typical steam-heating system. There,

the steam is nothing more than water vapor. In pass-

ing through the radiator, the steam gives up its heat

and condenses back into water.

The same action takes place in an air conditioning

Page 534 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 2596.15

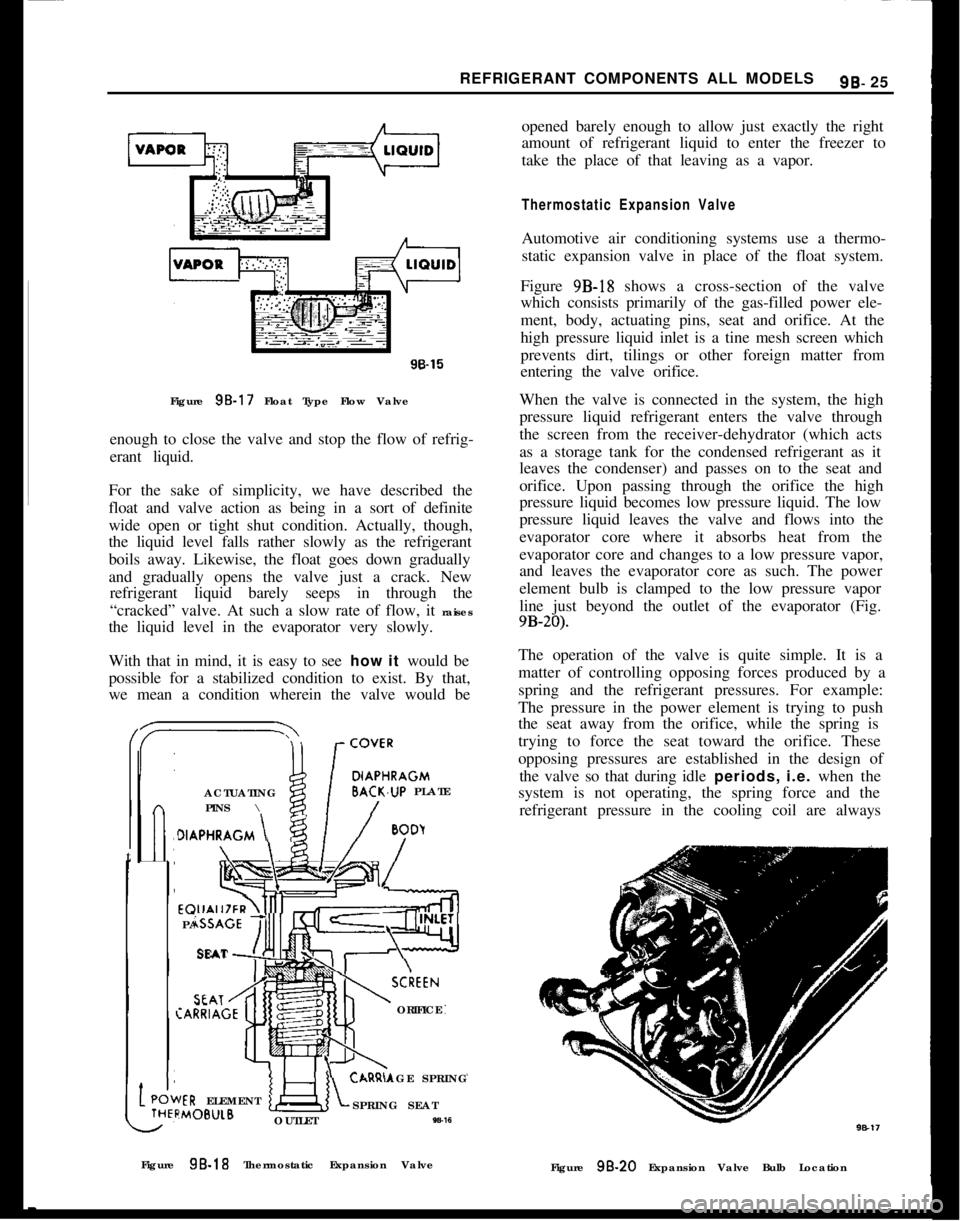

Figure 95.17 Float Type Flow Valve

enough to close the valve and stop the flow of refrig-

erant liquid.

For the sake of simplicity, we have described the

float and valve action as being in a sort of definite

wide open or tight shut condition. Actually, though,

the liquid level falls rather slowly as the refrigerant

boils away. Likewise, the float goes down gradually

and gradually opens the valve just a crack. New

refrigerant liquid barely seeps in through the

“cracked” valve. At such a slow rate of flow, it raises

the liquid level in the evaporator very slowly.

With that in mind, it is easy to see how it would be

possible for a stabilized condition to exist. By that,

we mean a condition wherein the valve would be/

DIAPHRAGMACTUATINGBACK.UP PLATE

PINS \

t

>IAPHRAGM \

/

BoDyEQUALIZER\4]

PASSAGE

‘!!!ISEATSCkEEN:ARRIAGEORIFICE

AGE SPRINGIER ELEMENT:MOB”LBSPRING SEAT

OUTLET

W-16opened barely enough to allow just exactly the right

amount of refrigerant liquid to enter the freezer to

take the place of that leaving as a vapor.

Thermostatic Expansion ValveAutomotive air conditioning systems use a thermo-

static expansion valve in place of the float system.

Figure 9B-18 shows a cross-section of the valve

which consists primarily of the gas-filled power ele-

ment, body, actuating pins, seat and orifice. At the

high pressure liquid inlet is a tine mesh screen which

prevents dirt, tilings or other foreign matter from

entering the valve orifice.

When the valve is connected in the system, the high

pressure liquid refrigerant enters the valve through

the screen from the receiver-dehydrator (which acts

as a storage tank for the condensed refrigerant as it

leaves the condenser) and passes on to the seat and

orifice. Upon passing through the orifice the high

pressure liquid becomes low pressure liquid. The low

pressure liquid leaves the valve and flows into the

evaporator core where it absorbs heat from the

evaporator core and changes to a low pressure vapor,

and leaves the evaporator core as such. The power

element bulb is clamped to the low pressure vapor

line just beyond the outlet of the evaporator (Fig.

9B-20).The operation of the valve is quite simple. It is a

matter of controlling opposing forces produced by a

spring and the refrigerant pressures. For example:

The pressure in the power element is trying to push

the seat away from the orifice, while the spring is

trying to force the seat toward the orifice. These

opposing pressures are established in the design of

the valve so that during idle periods, i.e. when the

system is not operating, the spring force and the

refrigerant pressure in the cooling coil are always

Figure 9B-18 Thermostatic Expansion Valve

Figure

98.20 Expansion Valve Bulb Location

Page 535 of 625

98-26 1973 OPEL SERVICE MANUAL

greater than the opposing pressure in the power ele-

ment. Therefore, the valve remains closed. When the

compressor is started, it will reduce the pressure and

temperature of the refrigerant in the cooling coil to

a point where the vapor pressure in the power ele-

ment becomes the stronger. The seat then moves off

the orifice and liquid starts to flow through the valve

orifice into the cooling coil.

The purpose of the power element is to help deter-

mine the quantity of liquid that is being metered into

the cooling coil. As the temperature of the low pres-

sure line changes at the bulb, the pressure of

the

vapor in the power element changes, resulting in a

change of the position of the seat. For example, if the

cooling coil gets more liquid than is required, the

temperature of the low pressure line is reduced and

the resultant lowering of the bulb temperature

reduces the pressure of the vapor in the power ele-

ment, allowing the seat to move closer to the orifice.

This immediately reduces the amount of liquid leav-

ing the valve. Under normal operation, the power

element provides accurate control of the quantity of

refrigerant to the cooling coil.

To employ our tire pump analogy once more for

clarity, it is the same situation that would exist if you were inflating a tire with a very slow leak. Providing

you pumped the air into the tire as fast as it leaked

out, you would be able to maintain pressure even

though the air would merely be circulating through the tire and leaking out through the puncture.

To Sum Up

So far, we’ve discussed only what each unit in an air

conditioning system does. We’ve learned that the

evaporator is the unit in which liquid refrigerant

soaks up heat from the air, the compressor is a pump

for squeezing this heat out of the vapor, the con-

denser is a radiator for getting rid of the heat, and the

thermostatic expansion valve is a device for regulat-

ing the pressure on the refrigerant. Now, let’s

find

out how the temperature of the cooled air is con-

trolled.

METHOD OF TEMPERATURE CONTROL

To achieve temperature control, the compressor is

run intermittently, automatically turning on and off

as necessary to maintain proper temperature.

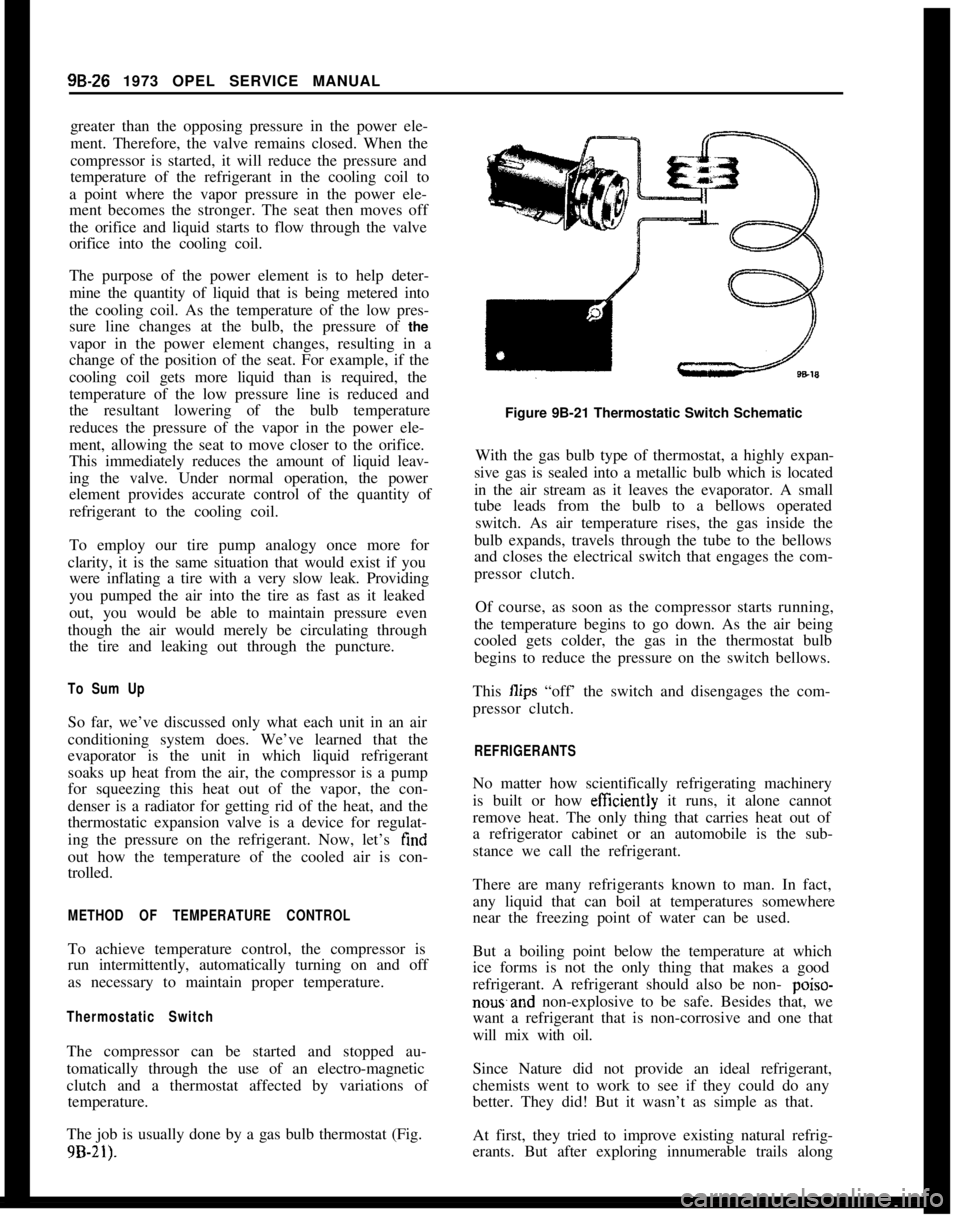

Thermostatic Switch

The compressor can be started and stopped au-

tomatically through the use of an electro-magnetic

clutch and a thermostat affected by variations of temperature.

The job is usually done by a gas bulb thermostat (Fig.

9B-21).

Figure 9B-21 Thermostatic Switch Schematic

With the gas bulb type of thermostat, a highly expan-

sive gas is sealed into a metallic bulb which is located

in the air stream as it leaves the evaporator. A small

tube leads from the bulb to a bellows operated switch. As air temperature rises, the gas inside the

bulb expands, travels through the tube to the bellows

and closes the electrical switch that engages the com-

pressor clutch.

Of course, as soon as the compressor starts running,

the temperature begins to go down. As the air being

cooled gets colder, the gas in the thermostat bulb

begins to reduce the pressure on the switch bellows.

This

Ilips “off’ the switch and disengages the com-

pressor clutch.

REFRIGERANTS

No matter how scientifically refrigerating machinery

is built or how

efftciently it runs, it alone cannot

remove heat. The only thing that carries heat out of

a refrigerator cabinet or an automobile is the sub-

stance we call the refrigerant.

There are many refrigerants known to man. In fact,

any liquid that can boil at temperatures somewhere

near the freezing point of water can be used.

But a boiling point below the temperature at which

ice forms is not the only thing that makes a good

refrigerant. A refrigerant should also be non-

poiso-

nowand non-explosive to be safe. Besides that, we

want a refrigerant that is non-corrosive and one that

will mix with oil.

Since Nature did not provide an ideal refrigerant,

chemists went to work to see if they could do any

better. They did! But it wasn’t as simple as that.

At first, they tried to improve existing natural refrig-

erants. But after exploring innumerable trails along

Page 536 of 625

REFRIGERANT COMPONENTS ALL MODELS99.27that line, they still hadn’t gotten anywhere. So, they

started from scratch and juggled molecules around

to make an entirely new refrigerant. Eventually they

succeeded by remodeling the molecules in carbon

tetrachloride. This is the same fluid that is used in

fire extinguishers and dry-cleaners’ solvents.

From this fluid, the chemists removed two chlorine

atoms and replaced them with two fluorine atoms.

This newly-formed fluid carried the technical chemi-

cal name of dichlorodifluoromethane. Today, we

know it as Refrigerant-12 or R-12.

Fluorine is an extremely temperamental substance.

Under most conditions it is toxic and highly corro-

sive, and after is is manufactured, it has to be stored

in special containers because it will eat through glass

and will dissolve most metals in short order.

Despite its rambunctious character though, fluorine

is completely tamed when it is combined with the

other substances that go to make up the refrigerant.

Each is non-toxic, non-inflammable, non-explosive,

and non- poisonous; however, breathing large quan-

tities of R-12 should be avoided.

Pressure. Temperature Relationship of R-12A definite pressure and temperature relationship ex-

ists in the case of liquid refrigerants and their satu-

rated vapors. Increasing the temperature of a

substance causes it to expand. When the substance is

confined in a closed container, the increase in tem-

perature will be accompanied by an increase in pres-

sure, even though no mechanical device was used.

For every temperature, there will be a corresponding

pressure within the container of refrigerant. A table

of the temperature-pressure relationship of R-12 is

presented below. Pressures are indicated in gauge

pressure, either positive pressure (above atmos-

pheric) m pounds or negative pressure (below atmos-

pheric) in inches of vacuum.

“F-40

-35

i#Pressure

11.0*

8.3*

“F

50

50#Pressure

46.1

52.0

-30~

5.5*6057.7

-252.3*6s67 7__.

-200.6

io70.1

-152.4

76.9

-104.584.1

1;6.8 9.2tz99.6 91.71;

11.8 14.712116.9 108.1

1517.7105126.2

2021.1110136.0

2524.6115146.5

3028.5120157.1

;:

30.1

125167.5

32.6

131)179n

4037.0

4541.7*Inches of Vacuum.-. _.-

1402045

150232.0Thus if a gauge is attached to a container of R- 12 and

the room temperature is 70 degrees, the gauge will

register 70 psi pressure; in a 100 degrees room the

pressure will be 117

ps~

AIR CONDITIONINGBecause air conditioning has always been very

closely allied with mechanical refrigeration, most of

us are apt to think of it only as a process for cooling

room air.

But true air conditioning goes beyond the mere cool-

ing of the air. It controls the humidity, cleanliness,

and circulation of the air as well.

Whenever it gets warm and muggy in the summer-

time, someone is almost sure to say, “It’s not the heat

it’s the humidity.” But that is only partly right.

Actually it is a combination of the two that makes us

feel so warm temperature alone is not the only

thing that makes us uncomfortable.

Humidity is nothing more nor less that the moisture

content of the air. To a certain extent, it is tied in

with the temperature of the air. Warm air will hold

more moisture than will cold air. When air contains

all the moisture it can hold, we say it is saturated,

and the relative humidity is 100 percent. If the air

contains only half as much water as it could possibly

hold at any given temperature, we say that the rela-

tive humidity is 50 percent. If it contains only a fifth

of its maximum capacity, we say that the relative

humidity is 20 percent and so on. This amount

of water vapor, or relative humidity, affects the way

we perspire on hot days.

Nature has equipped our bodies with a network of

sweat glands that carry perspiration to the skin

sur-faces. Normally, this perspiration evaporates and, in

doing so, absorbs heat just like a refrigerant absorbs

heat when it is vaporized in a freezer. Most of the

heat thus absorbed is drawn from our bodies, giving

us a sensation of coolness. A drop of alcohol on the

back of your hand will demonstrate this principle

very convincingly. Because it is highly volatile, al-

cohol will evaporate very rapidly and absorb quite a

bit of heat in doing so, thereby making the spot on

your hand feel unusually cool.

The ease and rapidity with which evaporation takes

place, whether it be alcohol or perspiration, governs

our sensation of coolness and to a certain extent,

independently of the temperature. Of even more im-

portance, the ease and rapidity of the evaporation are

directly affected by the relative humidity or com-

parative dampness of the air. When the air is dry,

perspiration will evaporate quite readily. But when

the air contains a lot of moisture, perspiration will

evaporate more slowly; consequently less heat is car-

ried away from our body.

Page 537 of 625

9B-28 1973 OPEL SERVICE MANUAL

Thus, from the standpoint of comfort, complete air

conditioning should control the relative humidity of

the air as well as its temperature.

By reducing the humidity, we sometimes can be just

as “cool” in a higher room temperature than other-

wise would be comfortable. Laboratory tests have

shown that the average person will feel just as cool

in a temperature of 79 degrees when the relative

humidity is down around 30 percent as he will in a

cooler temperature of 72 degrees with a high relative

humidity of 90 percent.

There are practical limits though within which wemust stay when it comes to juggling humidity. For

human comfort, we can’t go much below a relative

humidity of 30 percent because anything lower than

that would cause an unpleasant and unhealthy dry-

ness in the throat and nasal passages.

Summertime temperatures of 85 degrees sometimes

bring with them relative humidities around 75 to 80

percent. Some coastal cities have relative humidities

averaging as high as 87 percent. To gain maximum

human comfort, an air conditioning system should

cool the air down and reduce the humidity to com-

fortable limits.

The cooling job usually is done just as it is in a

refrigerator. A compressor sends refrigerant through

a chilling unit where it absorbs heat. The heat is

drawn out of the air which circulates through the

chilling unit. Along with the cooling job it does, the

evaporator unit also removes much of the moisture

from the air. Everyone is familiar with the sight of

thick frost on the freezer of a refrigerator. That frost

is simply frozen moisture that has come out of the

air.

Figure 99.22 Condensation

The evaporator unit in an air-conditioning system

does the same thing with this one exception. Becauseits temperature is above the freezing point, the mois-

ture does not collect in the form of ice or frost.

Instead, the moisture remains fluid and drips off the

chilling unit. This action is similar to what occurs on

the cool bathroom mirror when a hot shower is

turned on (Fig. 9B-22). A further advantage of airconditioning is that dust and pollen particles are

trapped by the wet surfaces of

.the evaporator core

and then drained off with the condensed moisture.

This provides very clean, pure air for breathing, and

is of great benefit to those who suffer from asthma

or ahergies such as hay fever.

Basic Refrigeration CycleLet’s review the basic refrigeration cycle. Keep this

basic cycle in mind because knowledge of the cycle,

knowledge of the particular system you are working

on and proper use of the gauges will permit quick,

accurate diagnosis of problems as they arise.

Any refrigeration system takes advantage of the

principles just described. The air conditioning sys-

tem illustrated in Fig. 9B-23 contains

five basic parts;

a compressor, a condenser, a receiver, an expansion

valve and an evaporator. Assuming R-12 as our re-

frigerant, let us follow through the refrigeration cy-

cle.Refrigerant gas under low pressure is drawn into the

compressor where it is compressed to a high pres-

sure. During compression, the refrigerant gas is

heated. When sufficient pressure is built up, the hot

gas passes into the condenser where it cools by giving

off heat to the air passing over the condenser sur-

faces.As the refrigerant gas cools, it condenses into a liquid

at high pressure and accumulates in the receiver. The

high pressure liquid refrigerant passes to the expan-

sion valve at the entrance to the evaporator. At the

valve orifice the pressure is lowered and the refriger-

ant enters the evaporator core as a low pressure liq-

uid. When the refrigerant is exposed to the lower

evaporator pressure, it begins to boil and is changed

to a vapor state. As the refrigerant passes through

the evaporator, it continues to boil by absorbing heat

from the air passing over the evaporator surfaces

until it is completely vaporized. From the evaporator

the cool low pressure refrigerant gas is drawn back

to the compressor and the cycle repeated.

Thus the air passing over the evaporator surfaces is

cooled simply by giving up heat to the refrigerant

during the boiling process.

CHEMICAL INSTABILITY AND REFRIGERATING

SYSTEM FAILURESA sealed refrigerating system is a complex physical-

chemical combination which is designed for stability

Page 541 of 625

98-32 1973 OPEL SERVICE MANUAL

inserting it in the connection. Another precaution -inspect the fitting for burrs which can cut the

“0”ring.

Restrictions

Restrictions may be due to powdered desiccant or

dirt and foreign matter. This may result in starved

evaporator and loss of cooling, or a seized compres-

SOT.When the amount of moisture in a system sufti-

ciently exceeds the capacity of the desiccant, it can

break down the desiccant and cause it to powder.

The powder passes through the dehydrator screen

with the refrigerant liquid and is carried to the ex-

pansion valve screen. While some of it may pass

through the valve screen into the evaporator, it may

quickly build up to cause a restriction.

Due to the fact that sufftcient oil can not be returned

to the compressor, it may seize.

Dirt

Dirt, which is any foreign material, may come from

cleaner residues, cutting, machining, or preserving

oils, metal dust or chips, lint or dust, loose rust,

soldering or brazing fluxes, paint or loose oxide

scale. These can also cause seized bearings by abra-

sion or wedging, discharge and expansion valve fail-

ure, decomposition of refrigerant and oil, or

corrosion of metal parts.

CorrosionCorrosion and its by-products can restrict valve and

drier screens, rough bearing surfaces or rapid fatigu-

ing of discharge reeds. This can result in high tem-

perature and pressure, decomposition or leaks. In

any event, this means a wrecked compressor.

From this, we can see the vicious circle that can be

produced in a refrigerating system to cause its fail-

ure. Corrosion can be the indirect cause of leaks, and

leaks can be the direct cause of corrosion. We can

also see the important role we as servicemen play in

maintaining chemical stability.

The major cause of corrosion is moisture.

Moisture

Moisture is the greatest enemy of refrigerating sys-

tems. Combined with metal, it produces oxide, Iron

Hydroxide and Aluminum Hydroxide. Combined

with R-12 it produces Carbonic acid, Hydrochloric

acid, and Hydrofluoric acid. Moisture can also cause

freeze-up of expansion valve and powdered desic-

cant.Although high temperature and dirt are responsible

for many difficulties in refrigerating systems, in most

instances it is the presence of moisture in the system

that accelerates these conditions. It can be said,themfore, that moisture is the greatest enemy of all.

The acids that it produces, in combination with both

the metals and the refrigerant, cause damaging

COT-

rosion. While the corrosion may not form as rapidly

with R-12 as with some other refrigerants, the even-

tual formation is as damaging.

If the operating pressure and temperature in the

evaporator is reduced to the freezing point, moisture

in the refrigerant can collect at the orifice of the

expansion valve and freeze. This temporarily re-

stricts the flow of liquid causing erratic cooling.

As previously mentioned, moisture in excess of the

desiccant’s capacity can cause it to powder.

YOU SHOULD KNOW AND REMEMBER..That the inside of the refrigerat,ion system is com-

pletely sealed from the outside world. And if that

seal remains broken at any point

- the system will

soon be destroyed. That complete and positive seal-

ing of the entire system is vitally important and that

this sealed condition is absolutely necessary to retain

the chemicals and keep them in a pure and proper

condition.

That all parts of the refrigeration system are under

pressure at all times, whether operating or idle, and

that any leakage. points are continuously losing re-

frigerant and oil.

That the leakage of refrigerant can be so silent that

the complete charge may be lost without warning.

That refrigerant gas is heavier than air and will rap-

idly drop to the floor as it flows from a point of

leakage.

That the pressure in the system may momentarily

become as high as 400 lbs. per square inch, and that

under such pressure the molecules of refrigerant are

forced out through the smallest opening or pore.

That the compressor is continually giving up some

lubricating oil to the circulating refrigerant and de-

pends upon oil in the returning refrigerant for con-

tinuous replenishment. Any stoppage or major loss

of refrigerant will therefore be fatal to the compres-

SOT.That the extreme internal dryness of a properly proc-

essed system is a truly desert condition, with the

drying material in the receiver holding tightly on to

the tiny droplets of residual moisture.