transmission OPEL GT-R 1973 Manual Online

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 418 of 625

AUTOMATIC TRANSMISSION7c-57

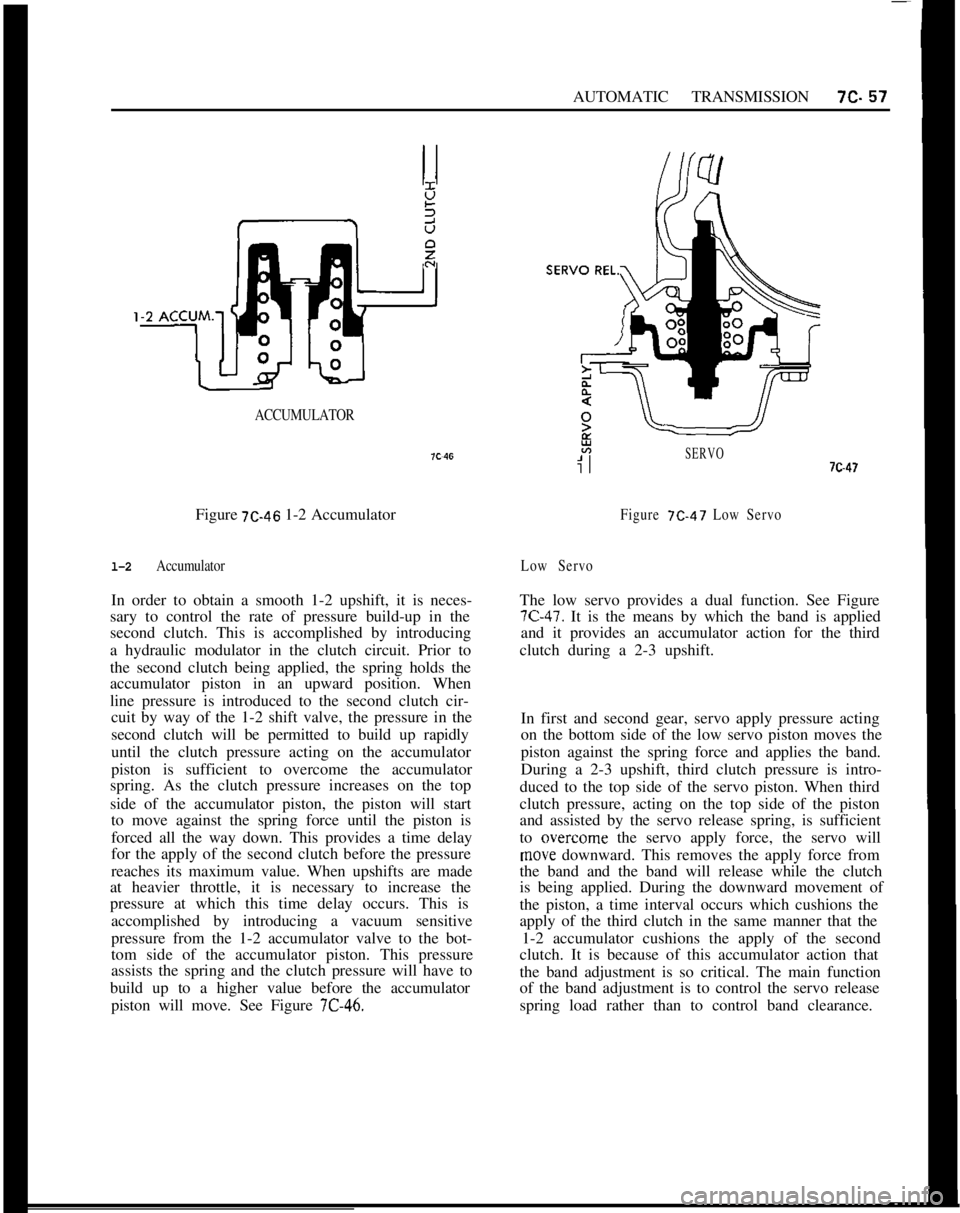

ACCUMULATORFigure

7C-46 1-2 Accumulator

l-2 AccumulatorIn order to obtain a smooth 1-2 upshift, it is neces-

sary to control the rate of pressure build-up in the

second clutch. This is accomplished by introducing

a hydraulic modulator in the clutch circuit. Prior to

the second clutch being applied, the spring holds the

accumulator piston in an upward position. When

line pressure is introduced to the second clutch cir-

cuit by way of the 1-2 shift valve, the pressure in the

second clutch will be permitted to build up rapidly

until the clutch pressure acting on the accumulator

piston is sufficient to overcome the accumulator

spring. As the clutch pressure increases on the top

side of the accumulator piston, the piston will start

to move against the spring force until the piston is

forced all the way down. This provides a time delay

for the apply of the second clutch before the pressure

reaches its maximum value. When upshifts are made

at heavier throttle, it is necessary to increase the

pressure at which this time delay occurs. This is

accomplished by introducing a vacuum sensitive

pressure from the 1-2 accumulator valve to the bot-

tom side of the accumulator piston. This pressure

assists the spring and the clutch pressure will have to

build up to a higher value before the accumulator

piston will move. See Figure

7C-46.

SERVO7c-47

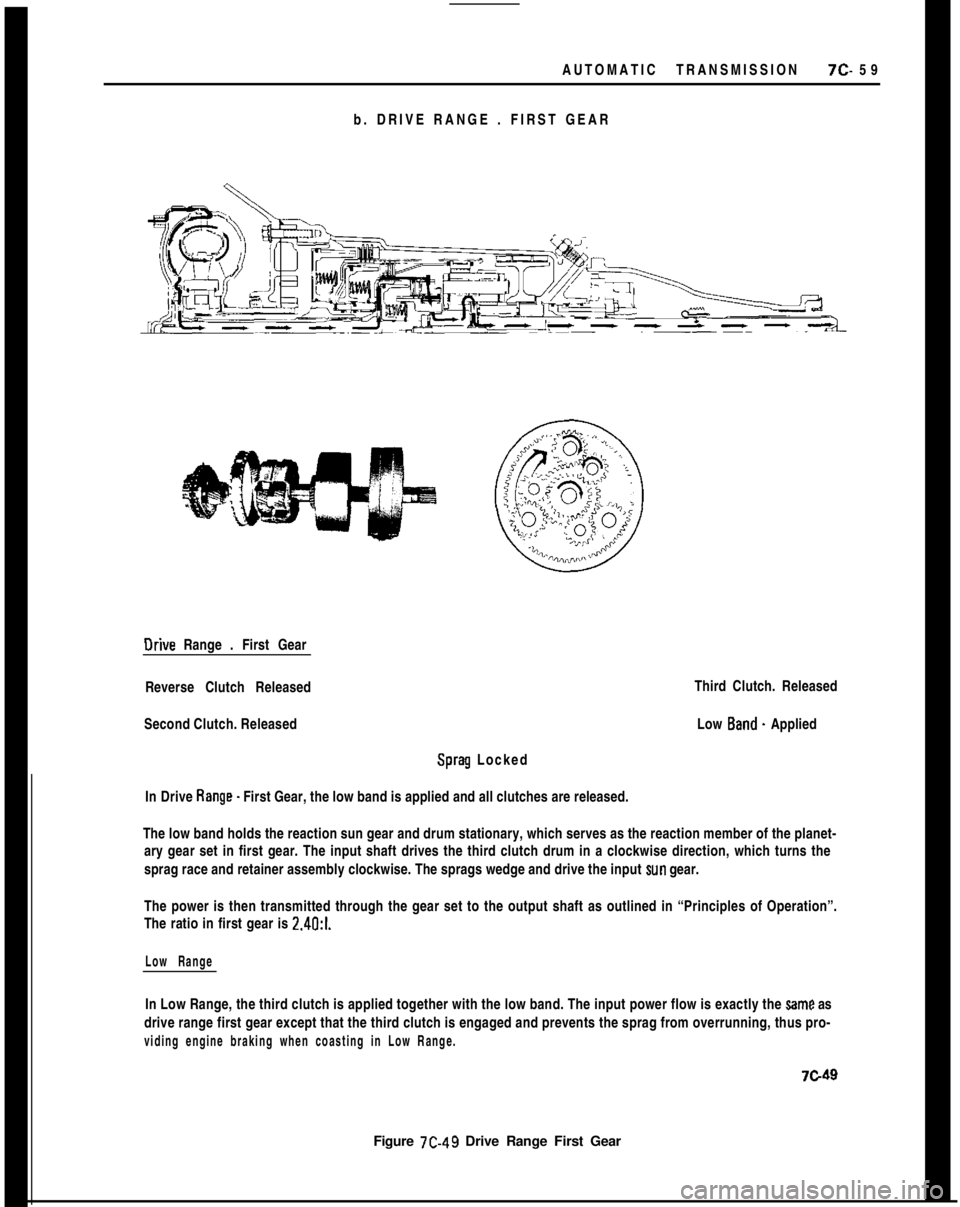

Figure 7C-47 Low Servo

Low ServoThe low servo provides a dual function. See Figure

7C-47. It is the means by which the band is applied

and it provides an accumulator action for the third

clutch during a 2-3 upshift.

In first and second gear, servo apply pressure acting

on the bottom side of the low servo piston moves the

piston against the spring force and applies the band.

During a 2-3 upshift, third clutch pressure is intro-

duced to the top side of the servo piston. When third

clutch pressure, acting on the top side of the piston

and assisted by the servo release spring, is sufficient

to overcome the servo apply force, the servo will

move downward. This removes the apply force from

the band and the band will release while the clutch

is being applied. During the downward movement of

the piston, a time interval occurs which cushions the

apply of the third clutch in the same manner that the

1-2 accumulator cushions the apply of the second

clutch. It is because of this accumulator action that

the band adjustment is so critical. The main function

of the band adjustment is to control the servo release

spring load rather than to control band clearance.

Page 420 of 625

AUTOMATIC TRANSMISSION7c- 59

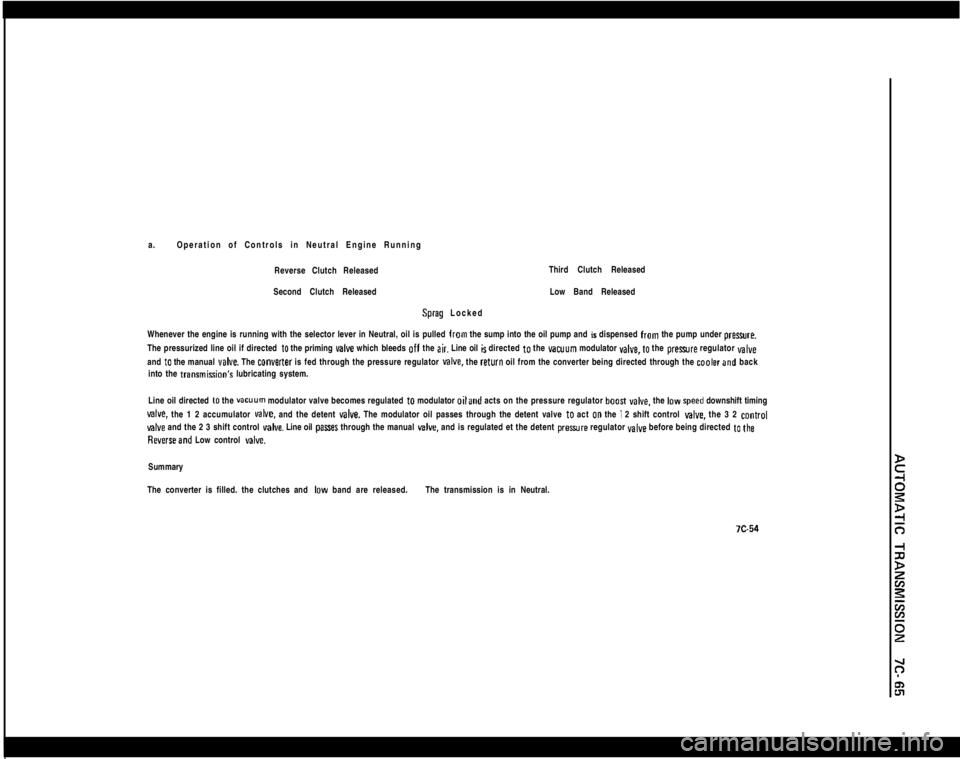

b. DRIVE RANGE . FIRST GEAROrive Range . First Gear

Reverse Clutch Released

Second Clutch. Released

Sprag Locked

In Drive Range. First Gear, the low band is applied and all clutches are released.

Figure 7C-49 Drive Range First GearThird Clutch. Released

Low Band. Applied

The low band holds the reaction sun gear and drum stationary, which serves as the reaction member of the planet-

ary gear set in first gear. The input shaft drives the third clutch drum in a clockwise direction, which turns the

sprag race and retainer assembly clockwise. The sprags wedge and drive the input

sun gear.

The power is then transmitted through the gear set to the output shaft as outlined in “Principles of Operation”.

The ratio in first gear is 2.4O:l.

Low RangeIn Low Range, the third clutch is applied together with the low band. The input power flow is exactly the

Same as

drive range first gear except that the third clutch is engaged and prevents the sprag from overrunning, thus pro-

viding engine braking when coasting in Low Range.

7c49

Page 422 of 625

AUTOMATIC TRANSMISSION 7C- 61

d. DRIVE RANGE - THIRD GEAR

Drive Range

- Third Gear

Reverse Clutch

- Released

Second Clutch. Applied

Sprag . LockedThird Clutch -Applied

Low Band

- Released

In Drive Range

- Third Gear, the low band is released and both the second and third clutches are applied.

In this condition, the ring gear is locked o the input sun gear. With two planetary members connected

inthismanner, the entire planetary system will rotate as a solid unit and provide a direct drive with a ratio of 1 to 1. The

input is split between the ring gear end input sun, and the rarrier is the output member.

Figure 7C-5 1 Drive Range Third Gear

Page 424 of 625

AUTOMATIC TRANSMISSION ?C- 63

Page 426 of 625

a.Operation of Controls in Neutral Engine Running

Reverse Clutch ReleasedThird Clutch Released

Second Clutch ReleasedSprag LockedLow Band Released

Whenever the engine is running with the selector lever in Neutral, oil is pulled from the sump into the oil pump and is dispensed from the pump under preure.

The pressurized line oil if directed

to the priming valve which bleeds off the air. Line oil is directed to the vacuum modulator YBIYB, to the prexwre regulator valveand

to the manual veIve. The converter is fed through the pressure regulator MIYB. the return oil from the converter being directed through the coalerand back

into the transmisGon’s lubricating system.

Line oil directed

to the vacuum modulator valve becomes regulated to modulator oiland acts on the pressure regulator boosI YBCB. the IDW speed downshift timing

valve. the 1 2 accumulator MIYB. and the detent valve. The modulator oil passes through the detent valve to act 00 the I 2 shift control give. the 3 2 control

valve and the 2 3 shift control valve. Line oil pasres through the manual v&e. and is regulated et the detent preaure regulator valve before being directed to the

Reverseand Low control delve.Summary

The converter is filled. the clutches and

IDW band are released.The transmission is in Neutral.

Page 430 of 625

c. Operation of Controls in Drive Range Second Gear

Reverse Clutch

ReleasedThird Clutch Released

Second Clutch AppliedLow Band Applied

Sprag Over Running

As the vehicle increws speed. the govwnor

allow more drive oil 10 pass through, and this increased pressure, acting on the end of the 1 2 shift

vahre. overcomes the I 2 shift valve spring pressure and allovn drive oil 10 pasr through the valve to feed the second clutch oil parsages.Second clutch oil passes through the second clutch orifice control valve, seating the ball and is metered to the second clutch piRon

to begin to apply

the second clutch, whileportion of the oil is directed

10 the accumulator. As the upper portion of the accumulator fills with second clutch oil. itovercomes the leer prewre of 1 2 accumulator oil and spring at the bottom of the accumulator piston. forcing the piston downward. The upper

portion of the accumulator is now filled, allowing full oil preaure

to the second clutch piEton far the final apply. The accumulator, therefore, acts as a

reservoir

10 produce a damping effect for a smooth second clutch apply and the 1 2 shift.

Second clutch oil from the 1 2 shift

valve is simultaneously directed to the 2 3 shift valve to be used as the oil source for the 2 3 shift.

Summary

The second clutch is on. the band is on, the transmission is in drive range

i second gear.

Page 434 of 625

e. Operation of Controls in Second Range Second Gear

Reverse Clutch

Re easedThird Clutch Released

Seconds Clutch AppliedLow Band Applied

Sprag Over Running

The

selector lever is moved to the Intermediate position an the quadrant. the manual valve is positioned to allow drive oil and Intermediate oilto pan through the valve. Intermediate oil is directed

to the pressure regulator boost control cavity, seating the check ball at the reverse passage.Intermediate oil is then directed to the pressure regulator valve downward to

increaSe the oil prepare in the circuit. At the same time. the inter.

mediate oil from the manual valve is directed lo the 2 3 shift valve train closing off the supply of third clutch oil in the circuit, which isexhausted

through the Reverse and Low control

valve.

SummaryWith third clutch oil exhausted. the third clutch is off, the second clutch is an, the low band

servo is applied. The transmission is in second

Range Second Gear.

Page 438 of 625

9. Operation of Controls in Reverse

Reverse Clutch -Applied

Second Clutch Released

Sprag LockedThird Clutch. Applied

Low Band. Released

When the selector leer is moved to the Reverse position on the quadrant, the manual

valve ispositioned to allow Revert oil to pars through the manual

valve into the

Reverse oil passage. The reverse oil applies the reverse clutch. and a portion is directed to the priming valve which acts as a damper until the

line is filled. to effect a smooth and firm apply of the

reverss clutch. At the wne time, reverse oil is directed to the pressure regulator boost control valve

cavity to seat the check ball and prevent reverse oil pasring into the intermediate oil passage. It is then directed to the pressure regulator boast valve forcing

Reverse oil is also directed to act on the end of the

Reverse and Law control valve against the spring to allow detent regulated oil to pass through the valveto the 2 3 shift

valve. The detent regulated oil passes through the 2 3 shift valve and into the third clutch oil passages to apply the third clutch. The third

clutch oil

al= acts on the end of the 3 2 control valve against the spring and modulator oil pressure, clodng off the supply of modulator oil to the 2 3

shift control valve. Third clutch oil at the rwerse and low control valve is closed off from

parring through the valve. and into the servo releal~ parrage.Summary

The

reverse clutch is cm and the third clutch is on. The transmission is in Reverse Range.

Page 442 of 625

DIAGNOSIS

SEQUENCE

1. Check and correct oil level. Refer to Specifications

for checking and refill procedures.

2. Check and correct vacuum line and fittings.

3. Check and correct manual linkage.

4. Road test car using all selective ranges, noting

when discrepancies in operation occur.

5. If engine performances indicates an engine tuneup

is required, this should be performed before road

testing is completed or transmission correction at-

tempted. Poor engine performance can result in

rough shifting or other malfunctions.

CHECKING PROCEDURESBefore diagnosis of any transmission complaint is

attempted, there must be an understanding of oil

checking procedure and what appearance the oil

should have. Many times a transmission malfunction

can be traced to low oil level, improper reading of

dipstick, or oil appearances; therefore, a careful anal-

ysis of the condition of oil and the level may elimi-

nate needless repairs.

When checking oil level in the Opel Three Speed

Automatic Transmission, the procedure outlined in

Specifications should be followed to obtain the most

accurate reading.

Also when the dipstick is removed, it should be noted

whether the oil is devoid of air bubbles or not. Oil

with air bubbles gives an indication of an air leak in

the suction lines, which can cause erractic operation

and slippage. Water in the oil imparts a milky, pink

cast to the oil and can cause spewing.

EXTERNAL OIL LEAKS

Determining source of oil leakBefore attempting to correct an oil leak, the actual

source of the leak must be determined. In many

cases, the source of the leak can be deceiving due to

“wind flow” around the engine and transmission.

The suspected area should be wiped clear of all oil

before inspecting for the source of the leak. Red dyeAUTOMATIC TRANSMISSION 7C- 81

is used in the transmission oil at the assembly plant

and will indicate if the oil leak is from the transmis-

sion.The use of a “Black Light” to locate the point at

which the oil is leaking is helpful. Comparing the oil

from the leak to that on the engine or transmission

dipstick, when viewed by Black Light, will determine

the source of the leak-engine or transmission.

Oil leaks around the engine and transmission are

generally carried toward the rear of the car by air

stream. For example, a transmission oil filler tube to

case leak will sometimes appear as a leak at the rear

of the transmission. In determining the source of a

leak, proceed as follows:

1. Degrease underside of transmission.

2. Road test to get unit at operating temperature.

3. Inspect for leak with engine running.

4. With engine off, check for oil leaks due to the

raised oil level caused by drain back.

Case Porosity RepairOpel Three-Speed Automatic Transmission external

oil leaks caused by case porosity can be successfully

repaired with the transmission in the car by using the

following recommended procedures:

1. Road test and bring the transmission to operating

temperature, approximately 180 degrees F.

2. Raise car on a hoist or jack stand, engine running,

and locate source of oil leak. Check for oil leaks in

low, drive, and reverse.

3. Shut engine off and thoroughly clean area to be

repaired with a suitable cleaning solvent and a

brush- air dry. A clean, dry soldering acid brush can

be used to clean the area and also to apply the epoxy

cement.

4. Using instructions of the manufacturer, mix a suf-

ficient amount of epoxy, BUICK Group 0.423, Part

No. 1360016, or equivalent, to make the repair. Ob-

serve cautions of manufacturer in handling.

5. While the transmission case is still HOT, apply the

epoxy to the area to be repaired. Make certain the

area to be repaired is fully covered.

6. Allow cement to cure for 3 hours before starting

engine.

7. Road test and check for leaks.

Page 443 of 625

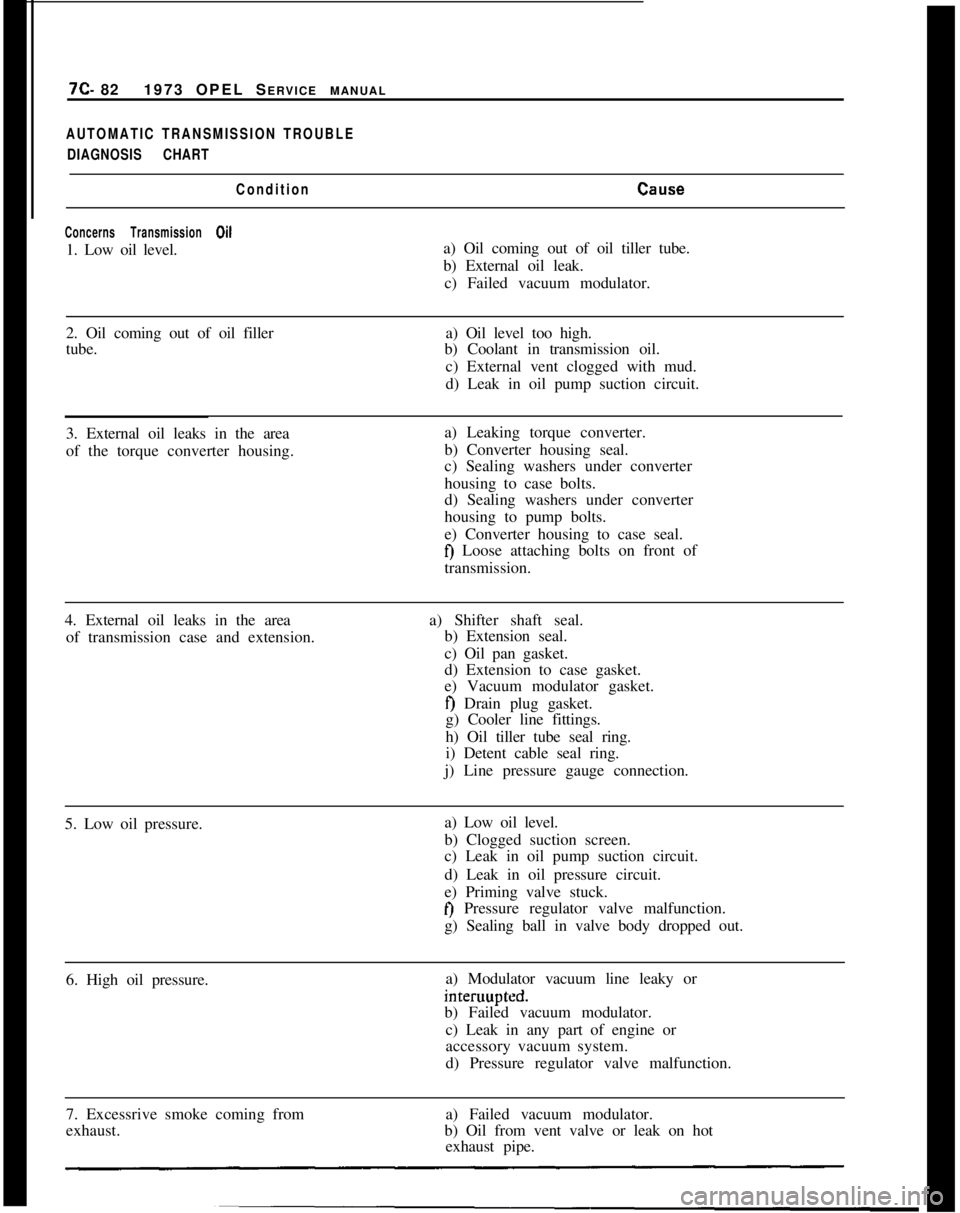

7C- 821973 OPEL SERVICE MANUALAUTOMATIC TRANSMISSION TROUBLE

DIAGNOSIS CHART

Condition

CEllE.e

Concerns Transmission Oil1. Low oil level.a) Oil coming out of oil tiller tube.

b) External oil leak.

c) Failed vacuum modulator.

2. Oil coming out of oil filler

tube.a) Oil level too high.

b) Coolant in transmission oil.

c) External vent clogged with mud.

d) Leak in oil pump suction circuit.

3. External oil leaks in the area

of the torque converter housing.a) Leaking torque converter.

b) Converter housing seal.

c) Sealing washers under converter

housing to case bolts.

d) Sealing washers under converter

housing to pump bolts.

e) Converter housing to case seal.

fj Loose attaching bolts on front of

transmission.

4. External oil leaks in the area

of transmission case and extension.a) Shifter shaft seal.

b) Extension seal.

c) Oil pan gasket.

d) Extension to case gasket.

e) Vacuum modulator gasket.

f) Drain plug gasket.

g) Cooler line fittings.

h) Oil tiller tube seal ring.

i) Detent cable seal ring.

j) Line pressure gauge connection.

5. Low oil pressure.a) Low oil level.

b) Clogged suction screen.

c) Leak in oil pump suction circuit.

d) Leak in oil pressure circuit.

e) Priming valve stuck.

t) Pressure regulator valve malfunction.

g) Sealing ball in valve body dropped out.

6. High oil pressure.a) Modulator vacuum line leaky orinteruupted.

b) Failed vacuum modulator.

c) Leak in any part of engine or

accessory vacuum system.

d) Pressure regulator valve malfunction.

7. Excessrive smoke coming from

exhaust.a) Failed vacuum modulator.

b) Oil from vent valve or leak on hot

exhaust pipe.